Ministry of Education of the Russian Federation

Siberian State Industrial University

Department “ Construction production and property management”

Report

on industrial practice

on the topic of:

“Surface painting water-based compositions ”

Novokuznetsk 2002

| Page | |

| 1.1 Basic production functions advertising agency | 4 |

| 1.2 Types of services provided by an advertising agency | 4 |

| 1.2.1 Design services | 4 |

| 4 | |

| 5 | |

| 5 | |

| 1.2.5 Production of advertising and souvenir products | 6 |

| 6 | |

| 6 | |

| 2.1 General information | 7 |

| 9 | |

| 11 | |

| 14 | |

| 19 | |

| 19 | |

| 22 | |

| 2.6 Quality control | 23 |

3.1 The state of water-dispersion paints on the market of paints and varnishes Watercolors used by artists are made in a dry tablet or as a wet paste. In both cases they contain finely ground pigments in gum arabic or dextrin. Glycerin is added to obtain a wet form. Latex paint, which appears in a synthetic binder, is emulsified, that is, suspended in water in the form of tiny droplets. As the paint dries, the water evaporates and the pigment and binder particles combine to form a relatively strong film. This film is porous enough to allow moisture to pass through and thus reduces the formation of bubbles. Most latex paints are used indoors only and have become very popular because they are odorless and easy to apply. 3.2 Water-dispersion paints our life |

24 |

| 3.2.1 Emlak paints | 25 |

| 3.2.2 Lodia paints | 26 |

| 3.2.3 Powdered water-borne paint “AQUAMIX” | 27 |

| 28 | |

| 3.2.5 Paint from Olivesta | 29 |

| 30 | |

| 30 | |

| 36 |

CHAPTER 1. Structure and specific features of the enterprise

In some applications, so-called solid emulsion or powder coated paints are replacing liquid paints. These paints are sprayed onto a metal surface, as in manufacturing. cars or window frames and stick due to electrostatic attraction. The heat causes the powder to flow and form a film.

Qualities that a painting should have.

- Good resistance to weathering and corrosion.

- Be neutral about the support.

Lotus LLC has been present in the advertising services market for more than 8 years. The main activity of this company is outdoor advertising in most of its manifestations (production of various advertising structures, installations, provision of related services). In addition, the organization includes two additional divisions (which have relative independence in making organizational decisions) dealing with construction and finishing works and production of trade and exhibition equipment.

The most important thing is litargyro. Adding oils and boiling the mixture produces a dense liquid that dries quickly. There are other agents, such as oxides of copper, iron, etc. They are used in small proportions. This is water paint. It has cellulose or amyl adhesives and calcium sulfate or calcium carbonate as pigment.

It is porous, permeable, beautiful, matte, not hard, cheap. Do not resist water or washing, and when repainting, remove all previous layers. It is used on internal surfaces plaster or cement, which do not suffer much. Do not expose areas where water condensation occurs because it causes mold stains.

It should be noted that a significant component of the company’s budget is revenue from the rental of places for placing large-format posters (billboards) standard sizes(6x3m).

As mentioned above, Lotus LLC provides a range of services typical of advertising agencies, directly or indirectly related to outdoor advertising, namely:

Technology of repair work in construction

The cut temple is applied with a sponge roller. This is the paint on water based, made of white cement and pigment that resists alkalinity. It is sold in powder, which may or may not be colored. When mixing, the work must be done immediately, since drying and layering are similar to setting cement, that is, they require constant moisture.

It is matte, absorbent and resists atmospheric agents. It should be used on rough, rough and porous surface so that it sticks easily. It is used on outdoors. Apply by brush, roller or spray. This is a water-based paint that has a binder and calcium hydroxide pigment.

1.2.1 Design services

Graphic design (production of original layouts for printing works, large-format printing);

Design projects for premises and building facades;

Design consultations.

1.2.2 Development, production and installation of advertising structures

Flat sign (flat base with an image printed on it)

Finish matte, porous, absorbent, hardens over time, humidity and rain favor carbonation. Resists atmospheric agents. It has good microbicidal properties. It should be handled with care due to its causticity.

It is used indoors and outdoors. Do not use on plaster, wood or metals. It is applied by brush, roller or spray. It is a water-based paint containing an aqueous solution of potassium or sodium silicate, as well as white zinc pigment or other alkali-resistant mineral pigments.

Volumetric sign (complex relief structure assembled from many parts)

Light box (a type of three-dimensional sign - a box equipped with an internal light source, has one or more light-transmitting edges with a printed image)

- “Flag” (a flat sign mounted using special brackets perpendicular to the plane of the wall).

It is hard, weather and alkalinity resistant, so it can be used on concrete and cement, but not on plaster. He has a strong commitment to glass and iron. Pigment transport is transported separately, since mixed life is limited.

It is used outdoors on cement and derivatives, stone, brick and glass. Apply by brush, gun or roller. It is a water based paint with plastic or acrylic resins as the binder and any pigment that resists alkalinity as the pigment.

Roof installation (illuminated sign large sizes mounted on the roof of a building)

1.2.3 Construction and finishing works

As part of this type of activity, the agency carries out construction and major renovation premises of any complexity. The most popular services are:

Internal redevelopment, interior renovation

Explanation of new material

Appearance ranges from matte to high gloss. Resistant to washing and abrasion due to resin content. It dries quickly, although it lingers in humid weather. It is recommended to use acrylic resins on concrete. It is used in interior and exterior applications on plasters, cements and derivatives. If it is being used on wood or metal, you will need to pre-load the primer before doing so.

Smooth: brush, roller and gun. . It has dry as a binder and vegetable oil, such as white alcohol solvent and any pigment. It was previously used for its flexibility and penetration into porous substrates, but some shortcomings have led to it being mixed with rigid enamel-forming resins.

Minor repairs to the building facade

An additional extension to the entrance of the building (the purpose of which is to change the appearance of the building’s façade and add style).

1.2.4 Development, production and installation (assembly) of trade and exhibition equipment

The concept of trade and exhibition equipment includes a variety of furniture and accessories necessary for the equipment trading floors, exhibitions, etc. The greatest demand is:

Drying and hardening are slowed down. . Currently, it practically does not exist on the market. It is used in oil-dominant applications in corrosive primers on metals and wood outdoors due to its penetration properties. It is applied with a brush, leaving a few days between the first coat or implantation and the finishing or second hand.

It consists of dry oils mixed with natural or synthetic solid resins. This is a simple mixture, in synthetic enamels it is a chemical combination. As a solvent, turpentine or white spirit. Good shine that gets lost in the open air. It cannot withstand alkalinity. It dries and hardens slowly, which is delayed by the cold. The white shade is not very pure. They make good clear varnishes.

Showcases

Counters

Shelving, etc.

Advertising and souvenir products imply a wide range of souvenir and gift products on which the customer’s logo or other marking is applied. Thus, the customer receives “branded” mugs, ballpoint pens, keychains, etc., which he can, for example, give to his potential clients for advertising purposes.

Used indoors as a finishing enamel. In appearance, due to the fact that the oil loses its brightness in the sun, the reason for its limited use. Apply with a brush or a special enamel roller. They are obtained by chemically combining solid resins and oils.

Painting walls with water-based paint

The most used resins are alkyl, which has great hardness, good gloss, resists chemicals and weathering and, when combined with oils, has great flexibility. Great brightness, even outdoors. Inside, the brightness decreases and the external resistance decreases.

1.2.6 Panel installations (billboards), size 6x3m, city formats, size 1.2x1.8m

1.3 Problems of construction finishing works

The construction division of the organization we are considering consists of its managers, a team of specialists employed on a permanent basis, as well as a team of temporarily hired workers (in the case of large volumes of work).

They are widely used in finishing and protecting wood and metal surfaces, both outdoors and indoors. In addition to being used as a coating, clear varnishes are obtained. They are also used as anti-corrosion primers, although their use on metal requires careful initial preparation. It is also used on cement surfaces, although it must be neutralized.

It is applied by brush, roller, gun or dip. They are obtained from a chlorinated rubber derivative. Special solvents are usually aromatic. Sometimes they carry cargo, color pigments and suitable additives. They resist atmospheric agents, water and chemicals. They are impenetrable and adhere well to any surface, even alkaline ones. They resist sodas and acids and are softened by oils and fats. They are heat sensitive and decompose at these temperatures.

Initially, the construction department was organized to solve auxiliary problems arising in the production of outdoor advertising. However, it subsequently transformed into a division that independently offers this type of service to third-party customers. But, as before, if necessary, the construction department, as a matter of priority, can be involved by the advertising agency in performing work related to the order for outdoor advertising. For example, when installing a large sign, it is often necessary to repair the facade of the building.

It is used on concrete surfaces, steel, cement deposits, road markings, swimming pools, etc. they have no problem with repainting. Apply special solvents by brush and airbrush to prevent threading. They are transported in two containers, one in epoxy resin, and the other into a catalyst or hardener. Pigments can come with one of two components.

Limited duration of mixture. Very hard, high chemical resistance, adhesion to cement, fast drying. They can be mixed with resins to create waterproof and water-resistant properties. If it is used on steel, all oxide must be removed. It is used in industrial facilities, in tanks, even if they carry acids or alkalis, in garages, in laundries, on all types of vessels that require frequent cleaning. They have radioactive decontamination property, the reason why they are used in hospitals and laboratories where nuclear medicine exists.

Another example of interaction between departments is the so-called. complex order, which is the most common. Let's say the construction and finishing department is carrying out a set of works on repairs, internal redevelopment, as well as changing the facade (for example, adding a porch, etc.) of the building in which it is planned to open a store. This requires the exterior and interior design of the building in a style that matches the theme of the products being sold. The design project is developed by the designer, and then implemented by the department involved in outdoor advertising. In addition, you need commercial equipment - a set of commercial furniture (various counters, shelves, racks, hangers, stands, etc.). In this case, the trade and exhibition equipment department is involved in the work. For a complex order, the advertising agency provides the customer with a discount on payment for its services.

It is used with a brush, a gun and sometimes a roller. Polyurethane paints. There are two types: those that have one component that is catalyzed by moisture, and others that have two components: polyester resin, mixed with a hardener or catalyst. Special solvents recommended by the manufacturer are used.

Elastic, hard, shiny, resistant to chemicals and weather. Very decorative, not yellow with proper hardener. They are sensitive to alcohols, with which they react and form bubbles. To achieve high quality paint, it is recommended to first give one coat of epoxy paint and then another with polyurethane.

As mentioned above, the construction and finishing work of the advertising agency Lotus LLC also includes interior decoration and redevelopment of apartments, in which I was directly involved, and which (finishing and redevelopment) were carried out in the central area on Tolyatti Street.

CHAPTER 2. Painting work. Surface painting with water-based compositions

Good varnishes for parquet and wooden floors. In furniture, such as varnish or colored enamel. If it is used on metals, it is advisable to give it a coat of mineral beforehand. If multiple levels are specified, do not allow more than 48 hours to pass through them. Used with a spray gun, sometimes with a brush or roller. In taillights with curtains.

Problems of construction and finishing works

Fireproof and intumescent paints. These are paintings that do not burn when exposed to intense flames, and sometimes they isolate the element of fire's action, which is why they delay its destruction. It stops the spread of fire and isolates the support. This is usually done by several thin layers up to 1 mm.

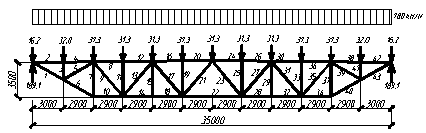

2.1 General information

Depending on the cost of the materials used and the complexity of the work, there are different simple finishing with painting compounds used for utility, secondary premises and temporary buildings; improved - for residential, public and industrial buildings And high quality - for finishing theaters, clubs, shops, etc. Regardless of the type of painting finishing, all of them must be carried out with the same care and precision.

They are sensitive to water because they lose some of their properties. They have a slight fineness in the grain when painted doors are made so that the grain is finer. Apply by spray, brush and roller. They are made from plasticized nitrocellulose to provide you with greater flexibility. There are two types: those that have a direct gloss, with a resin type; and those that, with additives, develop shine when polished. Solvents are special and evaporate quickly.

They resist friction and weathering. They lose some of their shine, which is restored when polished. During evaporation, the solvents are dried. Changes in humidity should be taken into account. They are used as clear varnishes to varnish woods. It has a different range of gloss.

The composition of the process, common to all categories of finishing, is as follows: bringing the room and surfaces into a condition suitable for finishing; preparing surfaces for one or another type of finishing; painting and final finishing.

Painting work begins after checking the installed water supply, gas, sewerage and heating systems, installations hidden electrical wiring and sealing all joints. Laying linoleum, finishing parquet (scraping and rubbing), installing sockets and switches, plumbing fixtures and fittings is carried out after completion painting works.

In the Directory, all paint compositions are divided into 3 main groups:

- Water - adhesive on animals, incl. casein, and vegetable glues, carboxymethylcellulose water-soluble glue CMC, as well as lime, cement, silicate, etc.

- Anhydrous – liquid resins, varnishes – dissolved resins, enamels – pigmented varnishes, cellulose ethers, silicone paints, etc.

- Semi-aquatic – the dispersion medium of which consists of a mixture with anhydrous binders – emulsion paints, which are a suspension of pigments in an emulsion.

Aqueous formulations can form non-waterproof, semi-waterproof and waterproof coatings; anhydrous – waterproof; semi-aqueous - non-waterproof, semi-waterproof and water-resistant.

Any emulsion consists of two liquids that do not dissolve in each other (for example, oil and water), one of which, crushed into very small particles, is distributed into the other. Based on this feature, two phases are distinguished in each emulsion: external and internal. If the oil is in a crushed state and in this form mixed with water, then the outer time is water, and the inner time is oil. If water is crushed into small particles and mixed with oil in this form, then the outer phase is oil and the inner phase is water.

Thus, there are two types of emulsion: WO (water in oil) and OW (oil in water). If the emulsion of VM and MV is left in a calm state for some time, it will begin to separate. The particles of the internal phase will gradually connect with each other and take their place in the composition: the oil will rise up, the water will go down. The smaller the particles of the internal phase, the more stable the emulsion will be. The substance is crushed into chalk particles by intensively mixing the emulsion in ultrasonic emulsifiers and vortex dispersants.

To obtain the most stable emulsion, it is added emulsifiers- substances that promote the formation of an emulsion. Various alkalis (borax, ammonia, caustic potassium) or calcium chloride, lime, solutions of casein, animal and vegetable glues are used as emulsifiers.

Emulsions can, under certain conditions, change from one type to another. Thus, if a substance serving as an internal phase is added to the MV emulsion, in this case oil, then a moment will come when the oil accumulates in such quantities that it becomes an external phase for a given emulsion and the emulsion turns into the opposite, i.e., VM emulsion.

The viscosity of the emulsion depends on the amount of substance taken to form the internal phase: the more of this substance taken, the thicker the emulsion will be. However, an emulsion of one type can transform into another, so it is impossible to pour in an excess amount of substance from the internal phase, since a moment may come when the emulsion suddenly becomes liquid. This indicates that the emulsion has changed into the opposite form to the desired one. To bring it to working viscosity in case of excessive thickness, you should add a substance similar in properties to the external phase. Thus, the BM emulsion can be diluted with drying oil, solvent gasoline, and turpentine. Therefore, the emulsion VM is called oil-soluble. On the contrary, the MV emulsion can be diluted only with water, which serves as the external phase of this emulsion. The MV emulsion is called water-based. The emulsion should be diluted to a working viscosity before use, since a diluted emulsion separates faster.

2.2 Characteristics of water-based compositions

Water-based paints of various colors are divided according to purpose into 2 types: for outdoor And interior work.

Water-based paints different colors for interior work - are a suspension of pigments and fillers in a plasticized polyvinyl acetate dispersion (emulsion) or styrene-butadiene latex, etc. Designed for interior work on wood, turk, cardboard and other porous materials, on metal surfaces primed with drying oil, as well as on old coatings oil paints, enamels, water-based and other durable paints. Water-based paints are not recommended for use in bathrooms, showers and laundry rooms. They are applied with brushes, rollers and paint sprayers.

The following brands of paint are available: E-VA-27, E-VA-27A, E-VA-27APG- based on polyvinyl acetate emulsion; E-KCh-26 and E-KCh-26A- based on styrene-butadiene latex; E-HV-28- based on a mixture of gyrobutadiene and latex SVKh-1(copolymer of vinyl chloride with vinyl chloride).

The paints have following colors: E-VA-27A, E-VA-27, E-KCH-26A and E-KCH-26- white, light grey, sand grey, light beige, pale cream, light yellow, sand, beech, brown-orange, pale pea, Ivory, pea, pale olive, pale pistachio, squash, pale green, blue-gray, pea-gray; E-VA-27APG- white, light pink, light yellow, etc.; E-HV-28- light gray, light beige, sand, etc. Covering capacity from 70 to 220 g/m. Viscosity of paints according to viscometer VZ – 1 (nozzle 5.4 mm) at a temperature of 20 0 C – not less than 20 s; hiding power of paints of different colors in terms of dry film from 70 to 220 g/m2; drying time at a temperature of 20 0 C – no more than 1 hour.

The paint is diluted before use. tap water to viscosity according to the VZ viscometer - 4: 20...25 s - when applied with a paint sprayer, 30...40 s - when applied with a roller and 40...50 s - when applied with a brush. The paints are resistant to freezing (up to 40 0 C) and thawing. The paints are non-toxic, fire and explosion proof. The shelf life of paints is 6 months from the date of issue. For household needs, paints are packaged in containers from 0.5 to 3 liters. The main characteristics of these paints are indicated on the labels.

Water-based paints of different colors for exterior use - They are a suspension of pigments and fillers in aqueous dispersions (emulsions) of synthetic polymers with the addition of various auxiliary substances (emulsifier, stabilizer, etc.). The paints are intended for exterior painting of buildings on brick, concrete, plastered, wooden and other porous surfaces, on primed metal surfaces, as well as on old coatings with oil, enamel and water-based paints.

It is not recommended to paint wooden surfaces with styrene-butadiene paints. The protective properties of these paints remain in temperate climates for at least 5 years, except for VA-17 paints, which retain their protective properties for at least 3 years. The primer is made with drying oil with a tint. Paint is applied with brushes, rollers, or spray guns at a temperature of at least +8°.

Paints are available on different bases. E-AK-111 - based on a copolymer acrylate emulsion of white (100), light fawn (70), light beech (70), beech (70), grayish-pink (80), bluish-gray (80) and red -brown colors (60). Apply over the primer with tinted drying oil. E-VA-17-based on polyvinyl acetate emulsion white (120), light beige (80), sand (100), beech (90), pale pea (110), dark beige (80), grayish pink ( 80), bluish-gray (80), red-brown (60) colors. Apply over a primer filled with drying oil or emulsion with a tint. E-VS-17 is based on a copolymer of vinyl acetate with dibutyl maleniate. E-VS-144-based on a copolymer of vinyl acetate with ethylene, white (120), light yellow (100), light beige (80), beech (90), grayish pink (90), dark beige (70), greenish-gray (60), red-brown (60). Apply over the primer with tinted drying oil. E-KCH-112 - based on styrene-butadiene latex light yellow (180), light fawn (230), beige (150), beech (130), dark pink (120), light brown (100), dark beige (100), gray (110), pistachio (120), red-brown (80) (here and before, the hiding power of the paints in g/m2 is indicated in parentheses).

Before use, the paint is diluted with drinking or distilled water or condensate. Paints are diluted more thinly when working with a spray gun, and more thickly - with a roller or brush. The shelf life of paints is 6 months from the date of manufacture. The paints are non-toxic, fire and explosion proof.

2.3 Painting tools and their characteristics

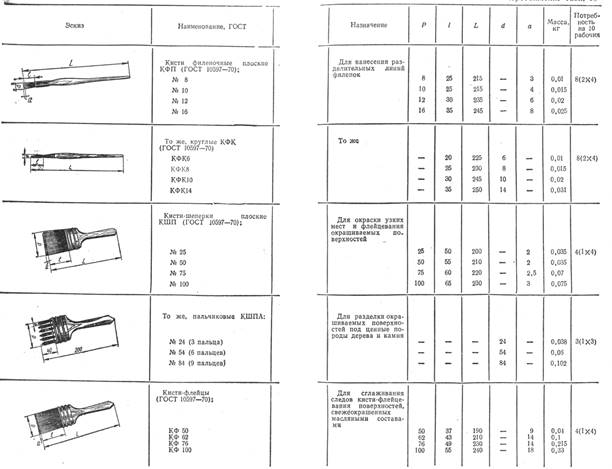

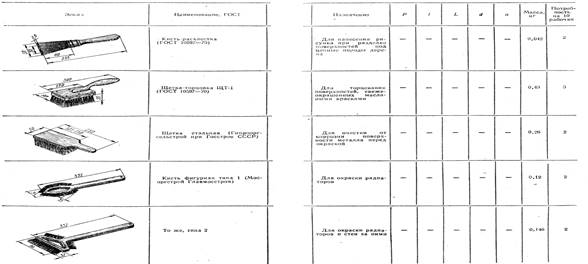

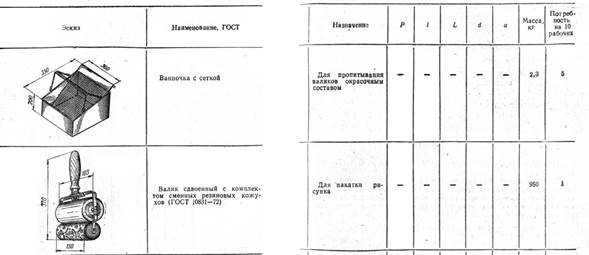

Table 2.3.1

Characteristics of tools for painting and wallpaper work

![]()

2.4 Sequence of painting walls and ceilings with water-based compositions

The surface is prepared as usual. Glue, lime, casein paints are completely removed. Execute proolifka(emulsification) , putty- necessary for correcting defects, sealing, cracks and potholes , oil primer- applied in a thin layer to give the painted surface uniform porosity and better adhesion of subsequent paint layers coloring .

Before painting with a Swedish or Finnish emulsion composition, the surfaces are cleaned of dust and dirt, repaired, dried and painted without primer in one or two times.

Emulsion water-borne paints (Table 2.2) are used for various surfaces; they can also be used to paint metal surfaces that have been previously primed with oil paint. Surfaces for emulsion compositions are prepared depending on the accepted finishing category. Primer and putty compositions prepared using VA or KCh emulsion paints have better adhesion to the base, preparatory and paint layers. It is prohibited to use emulsion compositions to paint surfaces primed with compositions containing metallic salts, over a wet putty layer, plank floors, as well as any substrates at subzero temperatures.

Table 2.4.1

Compatibility of materials for preparatory and cover layers when painting with water-based emulsion compositions

Water-based compositions are applied with a brush, roller or paint sprayer.

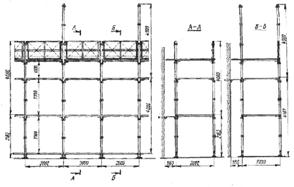

To paint ceilings and walls, use the tools shown in Table 2.4.1, as well as stepladders and folding step or two-step tables. Having accepted the room for painting, the team of painters (usually consisting of two people) begins to prepare the surfaces.

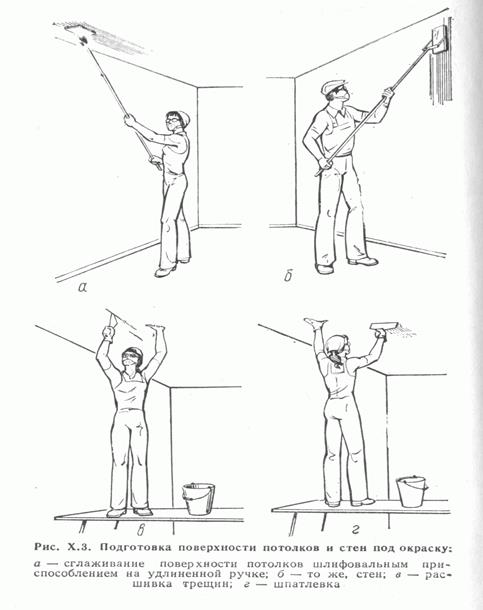

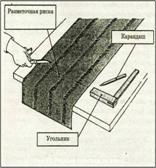

Wearing a respirator and safety glasses, the painter takes the end of the one and a half meter handle of a metal scraper with his right hand, and with his left hand, holding the handle about 60 cm higher, presses the scraper to the ceiling at an angle of 45 0 and with a sliding movement with forward pressure cleans the ceiling. Then use a grass brush on an elongated handle to sweep away the dust. The surfaces of the walls and ceiling (Fig. 2.4.1, a, 6) are cleaned and smoothed with a grinding device, moving it in the upper part of the wall from bottom to top, in the middle - from right to left, in the bottom - from top to bottom, moving around the perimeter of the room, to repair cracks in piece of a Turk, a painter wearing safety glasses stands on a scaffolding table or a stepladder - stilts and, leaning his left hand on the ceiling, with his right hand (with the edge of a metal spatula, moving it along the cracks at an angle of 45°) he opens the crack to a depth of 3 mm, opening it by 90 0 (Fig. 2.4.1, c). Using the same technique, cracks are opened in the upper part of the walls and in the lower part of the floor.

Having removed dust and waste from the room, proceed to proolifke, wearing safety glasses and standing on a table - scaffolding, the painter, dipping the brush into the primer composition and shaking off the excess from the brush into a bucket, applies the paint from top to bottom with a horizontal movement of the brush, either the right or left hand.

Using the resulting emulsion thinner, you can also prepare compositions for drying and priming.

An emulsion or emulsion diluent is prepared as follows. Pour drying oil into the suspension in a thin stream, mix everything thoroughly with a paddle or stick for 10-15 minutes until a homogeneous mass is obtained in the form of thick sour cream, colored cream or yellow, which depends on the color of the added drying oil. Natural drying oil requires less, oxol - more.

Emulsion thinner 1

Natural drying oil 25% (0.25 l)

Suspensions 75% (0.75l)

Emulsion thinner 2

Drying oils oxol 35-45% (0.35-0.45l)

Suspensions 55 - 65% (0.55-0.65 l)

Emulsion composition for proolifka

Emulsion thinner 820g

Dry pigment 10g

Turpentine 170g

Oil-emulsion primer

Dry pigment 400 g

Turpentine 50-100 g

Thickly grated oil paint 100 g

These compositions are prepared in the following sequence. Add dry pigment or thickly grated oil paint to the emulsion thinner to tint, mix everything thoroughly and only after that add the solvent - turpentine. The resulting composition is stirred to the desired thickness and filtered through a fine sieve.

Proofing with this composition (emulsion) is carried out as usual. First, a light foamy coating appears on the surface, which disappears after 4-5 hours and the surface takes on its normal appearance. After 30 hours, the emulsifying film will dry sufficiently and you can begin to putty or paint the surface with oil paint.

Partial lubrication is also carried out from scaffolding tables (Fig. 2.1, d) or stilt stepladders. Resting his left hand on the ceiling, the painter applies a wide spatula with putty to the ceiling and, moving it at an angle of 30° to the ceiling, applies a thin layer putty composition. Using a narrow spatula, moving it lengthwise and crosswise, the cracks are smeared and the putty surfaces are leveled.

The walls are puttied in the same order.

Prepare the putty like this. Pour the adhesive solution into the emulsion thinner in a thin stream, mix thoroughly and quickly until a homogeneous mass is obtained. Then chalk is added in small portions, everything is thoroughly mixed again and a putty of the required thickness is obtained, which can be used inside buildings for puttying walls, doors and frames.

Oil-emulsion putty

Emulsion thinner 500 g

Glue solution 10% 500 g

Sifted chalk 2000-2500 g

After drying, the putty is sanded manually or using grinding machines, for this, a painter in a respirator and safety glasses, standing on scaffolding tables, lightly presses the machine to the surface and, moving back and forth, polishes a strip of the surface, while another painter, using a brush on an elongated handle, sweeps away dust from the ceiling and walls.

With improved painting, the dried and sanded surface is primed a second time and after complete drying, painting begins.

Paint composition (color) based on emulsion thinner

Emulsion thinner 600 g

Thickly grated oil paint 400 g

Add an emulsion thinner to the thick oil paint and mix thoroughly until the composition is homogeneous. The amount of emulsion thinner may vary depending on the thickness of the paint.

2.5 Technology for painting walls and ceilings

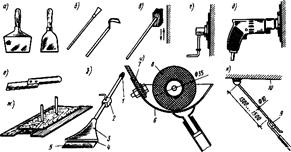

Painting technology is divided into manual and mechanized methods of painting surfaces.

Manually walls and ceilings are painted using hand rollers or brushes, applying strip after strip in a continuous layer.

When dyeing mechanized way 125-180g of turpentine is added to 1 liter of paint. When the color is prepared from dry pigments, take 70% emulsion diluent and 30% drying oils, mix them, and gradually add the pigment there with thorough mixing.

2.5.1 Technique of painting with fly brushes, brushes and rollers

Swing brushes widely used for painting all kinds of large surfaces.

To obtain an even, clean color, you need to know not only the technique of work, but also correctly pick up the paint composition with a brush, which must be systematically shaken out with the same brush, turning it in your hands two or three times. This results in a uniform composition both in thickness and color, and no sediment forms at the bottom of the dish. It is advisable to stir the composition every 5 minutes with a paddle or stick. This is necessary to ensure that there is no sediment in places inaccessible to the brush.

The brush is dipped into the paint composition only with the untied part of the hair, the excess is squeezed out on the edges of the dish. You need to work with the brush so that there are even strokes and the paint lays down in even, thin layers. The brush must be periodically rotated in your hands so that it works evenly on all sides and takes on the shape of a torch rather than a shovel.

If you press lightly on the brush while working, the paint is applied in narrow stripes (strokes or lasses), often in a thick layer. With strong pressure on the brush, the paint flows off, forming drips, but lays down in a thin layer. Therefore, you must first apply little pressure to the brush, and increase the pressure as you use up the paint.

When working with a brush, you need to ensure that, while sliding over the surface, it leaves long, thin strokes of paint, which are shaded as you work.

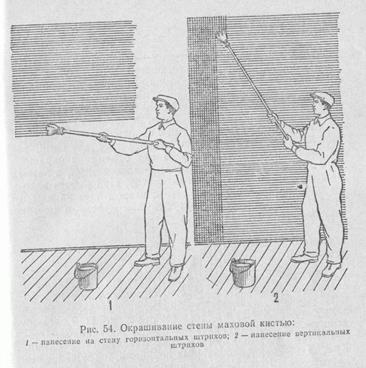

During painting, the brush should be held perpendicular or with a slight inclination to the surface to be painted; the brush, or more correctly the pin, should be held with both hands and moved in full swing, or the pin should be firmly held with the left hand and moved with the right hand. In this case right hand slides along the pin, now approaching the left hand, now moving away from it. When painting with a brush, the paint can be applied both horizontally and vertically, shading them well. It's best to work like this. When painting walls, the paint is first applied with horizontal strokes, and then further shaded with vertical strokes. In this case, it is best to work together: one applies the paint with horizontal strokes, the second follows him and immediately shades it with vertical strokes (Fig. 2.5.1.1).

Of course, you can work alone: first apply horizontal strokes to some part of the wall (grab) and then shade them with vertical ones. Or you can completely cover the entire wall with paint in one direction, then in the other, but here you may have to add paint. With double shading, there are no gaps in unpainted areas.

Paint applied with brushes can be leveled, as if dusting it with a thin layer of paint using a spray gun.

Purpose flute brushes and brushes - maklowitz- flute or trim surfaces painted with brushes. However, they are also used for coloring. You can work with either a short handle or a long one, on which you attach tools; you use flutes and mittens in the same way as with a swing brush, but just don’t rotate them. One or two workers can also work with short-handled brushes. If a person works alone, then he first paints only the top of the wall completely or in parts from a table, stool or stepladder, and then the bottom, carefully shading the paint. When working together, one paints the top of the wall, the second follows him and paints the bottom, carefully shading the paint at the joints.

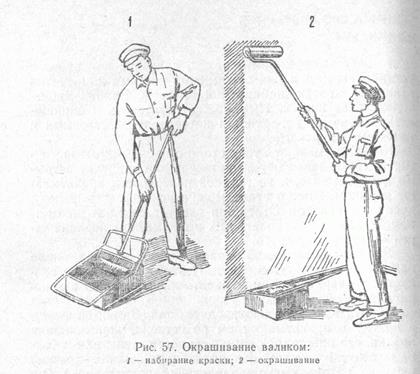

Dyeing technique roller lies in the fact that the work requires a roller, a tray or a bucket with squeezing grids installed in them to remove excess paint picked up by the roller. Rollers are more productive than brushes. They can be primed and painted various surfaces glue, lime and oil paints.

When using a piece of steel with filled holes, it is placed in a baking tray or tray with the sharp ends: down, and along smooth surface roll with a roller. Instead of steel, you can use plywood, boards, and plastic. Holes should be drilled with a diameter of 12-15 mm, placing them in a checkerboard pattern 25 mm apart (Fig. 2.5.1.2).

It is impossible to paint walls in the corners, near trims, baseboards, etc. with a roller. Therefore, such places should first be painted with any brush and the paint should be shaded well.

The work with rollers is done like this. The roller is dipped into the paint and rolled over the mesh. After squeezing out the excess paint, it is applied to the surface of the wall or ceiling and directed in the desired direction: on walls - from top to bottom, on ceilings in the direction of the light rays. When painting the walls from top to bottom, then from bottom to top, apply stripes, or lasses, of paint with a roller one on top of the other so that they overlap by 4-5 cm. First, the roller applies thicker layers of paint, and then you need to roll it over the same place two or more times. As the paint is consumed, the pressure on the roller increases. You can paint the walls in one step using vertical varnishes or in two, when horizontal varnishes are applied first, then vertical ones.

In any case, the paint must be thoroughly shaded. If defects are found, repainting is performed.

Sometimes the paint is applied to the surface with brushes, shading well, and then rolled with rollers, leveling it, thereby obtaining an even color.

The roller not only paints, but also primes surfaces. It is advisable to use a tinted primer, i.e. the same color as the paint.

Using a roller is more productive than using brushes. In one working day you can paint up to 300 m2 of wall surfaces. The service life of the rollers is very long. A roller made of high-quality fur is capable of painting more than 3 thousand m of various surfaces.

After finishing work, the rollers must be washed in warm water with soap, removing all paint. From lime compounds the rollers quickly become unusable.

2.5.2 Technique for painting a surface with a spray gun

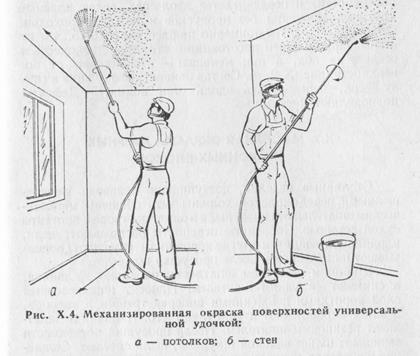

Mechanized painting of walls and ceilings with adhesives is carried out using a fishing rod. The painter works in safety glasses and a respirator.

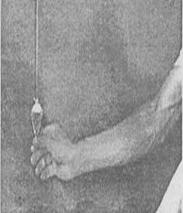

When painting the ceiling the painter directs the jet perpendicular to the ceiling surface and rotates the elongated fishing rod tube in spiral circles with a diameter of 0.8...0.9 m in a horizontal plane, ensuring uniform saturation of the surface (Fig. 2.5.2.1, a). Painting is carried out along the wall in parallel strips, overlapping by 5... 10 cm. Having painted the strip, the painter moves the fishing rod by 0.9 m and, moving in the opposite direction, paints the next strip.

When painting walls With one hand he holds the handle of the fishing rod and the control valve, resting it on himself (Fig. 2.5.2.1, b), with the other he holds the elongated tube, standing half-turned towards the wall. Then he brings the nozzle to the upper part, standing, presses the valve handle, directing a cone-shaped stream of sprayed paint perpendicular to the surface, and moves along it, making smooth circular movements without skipping or double passes. The nozzle is located approximately 0.75... 1 m from the wall. At a greater distance, the composition loses speed and settles on the floor, and at a smaller distance, it bounces off the surface. The composition is applied from top to bottom and bottom to top, moving along the walls of the room, defects are corrected with brushes.

2.6. Quality control

The quality of finishing depends on the thorough preparation of painting compounds and adherence to the technology for performing the work. All painting compounds must have a specified viscosity. They must be strained or otherwise cleared of foreign matter and used within the expiration date.

Painted surfaces must be uniform in color, without stains, stripes, splashes or brush hairs. The texture of the surface painted with oil or enamel paints should be glossy or matte, without unevenness due to poor sanding. Local curvature of lines and shading in mates are unacceptable.

CHAPTER 3. New materials. New technologies

3.1 The state of water-dispersion paints on the market of paints and varnishes

Based on ongoing research, water-dispersible and water-borne acrylic materials are among the environmentally friendly, high-quality and economical paints widely used in industrialized countries, where their share in the total consumption of paints and varnishes exceeds 60%, and in construction reaches 80-85%.

Competition with importers forces large enterprises to reconsider their views on the range and quality of produced materials (Table 3.1.1). Domestic enterprises began to actively introduce acrylic materials for construction into production (putties, primers, facade paints, paints for interior decoration and wood processing). The output of products in small packaging is gradually increasing, improving appearance and printing design of packaging, the range of materials is expanding.

Table 3.1.1

3.2 Water-dispersed paints of our lives

3.2.1 Paints "Emlak"

Having its own experimental base and highly qualified specialists, working in contact with foreign partners, the Emlak company produces materials that meet European standards. Currently, two directions are successfully developing: traditional organic-soluble and modern environmentally friendly water-soluble compositions.

The Emlak company has been focusing on the production of environmentally friendly water-borne acrylic materials for several years. Compositions with silicones, epoxies, and alkyds give these materials a wide variety of protective, decorative and technological properties.

For interior decoration For residential and industrial premises, a system of materials is produced, including the impregnating transparent primer "Polykrem-V", the white latex putty "Shpakrem-V" and the high-white paint "Blik". The material system meets the requirements of European standards and allows for high-quality finishing of premises.

Primer "Policrem-V" is intended for preparing chalky, porous absorbent surfaces for subsequent painting with water-dispersion or oil paints, or wallpapering. The primer ensures equalization of the absorbency of the surface being painted, adhesion of finishing materials, and reduction of paint consumption.

To correct defects on plastered, concrete and wooden surfaces, single-dispersion putty “Shpakrem-V” is used, which is usually applied to a surface treated with primer.

Water-dispersion paint “Blik” has a high degree of whiteness (92%) and is intended for indoor use.

Arem-Comfort paint provides a more durable cleaning coating for interior finishing. It is available in two modifications (matte and semi-gloss) and is recommended for painting children's and medical institutions.

Akrem-Facade paint is perfect for use in wet areas and places of intensive use with frequent washing: gyms, stairs, halls and various institutions. Almost complete absence of odor, pleasant velvet texture, drying within 1 hour make this material indispensable for repair work Oh.

3.2.2 Lodia paints

Paints and varnishes with the trade name "Lodiya" appeared on construction market in 1997. These materials belong to the group of water-dispersed ones and are produced on an acrylic or latex base.

Water-dispersed acrylic paint is not toxic, belongs to hazard class 4, is fire and explosion-proof, however, when airless spraying, workers must protect their respiratory tract with a respirator.

Paints for interior work are distinguished by high hygienic characteristics and reliable performance, and can be used in medical and children's institutions.

The material does not contain organic solvents and forms a matte, water-repellent, non-flammable coating that is resistant to climatic factors. Weather resistance of the coating is at least 6-8 years.

Application of paint and preparation of the surface for painting is carried out in the same way as for Lodiya-N paint.

The company is currently expanding its dispersion production program finishing materials: putty, decorative plasters and etc.

3.2.3 Powdered water-borne paint “AQUAMIX” »

Powdered paints and varnishes have appeared on the market of paints and varnishes, which are multicomponent solid finely dispersed systems consisting of pigments, filler, film former and necessary additives. Like to liquid paints, they are subject to certain requirements: the ability to apply thin layers and form coatings that have a set of necessary properties.

In powder paints, the separating medium is not liquid, but air, which makes them advantageous and convenient to transport, store and use. They can be stored and transported at sub-zero temperatures, and prepared in the quantity required for a given job. Immunity to temperature fluctuations increases the feasibility of using paint in the Russian climate.

A solution of white powder paint is easily tinted with the same paints of other colors or aqueous pigment concentrates.

Before use, powdered water-borne paint is diluted in water, mixed thoroughly and painted on any porous surface (wood, brick, concrete, etc.). After the paint has dried (after 40-50 minutes), you can pour water onto the painted surface without fear of changing the original appearance and losing the protective and decorative properties of the coating.

The production technology is waste-free, environmentally friendly, fire- and explosion-proof. All processes included in the technology are carried out in the solid phase; there are no drains or discharges.

Currently, a wide range of colors of AQUAMIX powder paints are produced using this method, and white paint can be easily tinted with any color paints from the same series. At the same time, AQUAMIX colored paints can be used for tinting any other water-based paints.

The main area of application of AQUAMIX paint is facade finishing work. Paint is produced specifically for painting walls and ceilings white.

3.2.4 Water-dispersion paints for the protection of steel and reinforced concrete structures from corrosion

One of the most widely used methods of protection in practice various materials, products and structures against corrosion under the influence of the atmosphere and industrial gas-air environments is the creation of a protective paint coating on their surface.

Paints VD-KCH-1F Available in two brands:

VD-KCH-1FA - for protection against corrosion of metal (carbon steel, cast iron, aluminum and its alloys), and grades VD-KCH-1FO - for painting facades (external surfaces) of buildings and structures for various purposes, as well as for finishing interior interiors public and industrial premises.

Dye VD-KCH-1FA can be used as a primer in combination with traditional ones for final finishing.

For metal structures operated in highly aggressive environments, combined coatings are used: as a primer - VD-KCh-1FA paints, coated with chemical-resistant enamels or varnishes. They are used for protective and decorative painting of metal structures for various purposes (mechanical engineering products, building construction, bridges, sea and river vessels, railway and metro cars, bus bodies, etc.

Dye VD-KCH-1FO designed to work against atmospheric influences of structures made of reinforced concrete/concrete, slate, brick, cinder blocks, etc. Recommended for painting facades and interiors of residential, civil, industrial and agricultural purposes, as well as asbestos-cement materials, wood-based board materials (chipboard, CBPB), hardboard. Painting of aluminum and alloys is allowed.

Paints VD-KCH-1F applied by pneumatic and airless spraying (using equipment various types), as well as by dipping, brush, roller. The surface to be painted must be cleaned of dirt, including old peeling paint, and dried. It is recommended to carry out painting work at an ambient temperature of no lower than 15°C and a relative humidity of no higher than 80%.

For practical application Good compatibility of VD-KCh-1F paints with other paints and varnishes is very important, both as a primer and as a top layer for final finishing. Even old, non-flaking paint and traces of corrosion on a steel surface when using VD-KCh-1FA paint do not reduce the quality of the resulting coating.

3.2.5 Paint from Olivesta

AOZT "Olivesta" (formerly Moscow plant "Lakokraska") was founded in 1929 and is modern enterprise, equipped with high-performance domestic and foreign equipment capable of producing the entire range of paints and varnishes.

The company produces a wide range of paints and varnishes for construction and repair work on concrete, plaster, brick, wood, metal, as well as old coatings.

Water-dispersed compositions of Olivesta JSC are represented by paints VD-AK-101, VD-AK-201, VD-AK-201p(TU 2316-002-17201234-94). They are a suspension of pigments and fillers in an aqueous copolymer acrylic dispersion with the addition of various auxiliary substances.

Depending on the brand, the materials are used to obtain matte coatings on concrete, plaster, wood, primed metal, used in atmospheric conditions and indoors (VD-AK-101), for interior finishing of walls and ceilings (VD-AK-201), only for finishing ceilings (VD-AK-201 p).

The color range is from white to ocher-yellow, etc., according to the color chart adopted for this material. It is possible to produce any color and shade to order according to NCS.

When painting over old coatings, the surface must be cleaned, sanded and washed with soap and water or washing powder, ammonia solution or 3% solution, and then clean water. Surfaces previously coated with chalk or lime paints must be thoroughly cleaned until the previous layer is completely removed.

At optimal conditions(18-20°C) drying of one layer is carried out within 1 hour. Paint consumption per layer is 110-150 g/m2.

3.2.6 Water-dispersion fire-retardant acrylic paint AK-151 “KROZ”

Water-dispersion fire-retardant acrylic paint AK-151 “KROZ” was developed by JSC “Ekzemplyar” (Moscow) and is produced at the enterprise 000 “Zelenopol” (Zelenograd) according to TU 2316-001-18585923-99. agreed with the Main Directorate for State Traffic Safety of the Ministry of Internal Affairs of the Russian Federation and the State Sanitary and Epidemiological Supervision authorities.

The paint is intended for use in industrial and civil construction, fire retardant finishing material for interior and exterior work. It is made from high quality water-based components and does not contain toxic organic solvents. Under the influence of high temperatures, a protective coke layer is formed, which prevents further spread of flame through the wood.

The paint is applied directly to the wood in several layers. The drying time of one coating is about 1.5 hours. Unlike existing domestic and foreign analogues, it has high adhesion and, due to its thixotropic structure, is easily applied with a brush or roller, as well as by air spraying. The surface to be painted requires special preliminary preparation(stripping, etc.).

The shelf life of AK-151 “KROZ” is 6 months. The finished product is packaged in polyethylene buckets of any volume. The main color is white, tinting is possible by adding pigments at the request of the customer.

3.3 Methodology for selecting professional painting equipment

Department industrial equipment was created in the diversified holding "EKONIKA" in 1989. Since 1994, "EKONIKA-Techno" has been operating as an independent enterprise. Over the years of operation, the range of equipment offered has been expanded, warranty and post-warranty service schemes for equipment, and the supply of spare parts have been developed. Dealer companies "EKONIKA-Techno" operate today in 21 regions of the country and sell more than two thousand types of industrial equipment. For the convenience of customers, the company publishes an illustrated catalog of equipment, in which each piece of equipment is described in detail - specifications, recommendations for use, etc. Nevertheless, buyers of equipment, in particular painting equipment, have many questions regarding the criteria for selecting equipment for certain types of work.

The development of finishing technologies has changed the nature of painting. Traditionally, a painter's main tool was a brush. Currently, the technical equipment of painting works has changed significantly - painting units various systems, air-sandblasting systems, high-pressure water-sandblasting units and a variety of accessories allow you to work effectively on any surface of buildings and structures.

New technologies require high qualifications, deep knowledge of building physics, coating application methods, as well as appropriate mechanization means.

Air Spray Method the most common and is one of the highest quality methods of applying paint compositions. This method is used for painting small surfaces in industry, construction and at home.

The principle of air atomization is based on the fact that compressed air passing through special nozzles different designs, breaks the paint into fine particles, forming a spray torch.

Due to the fact that spray guns can be equipped with nozzles of various diameters, it is possible to spray paint compositions of any type and almost any viscosity.

There are four main types of air spray equipment. In them, the paint supply is adjusted by positioning the needle, which locks the nozzle. The spray torch is formed by an air nozzle.

IN manual pneumatic paint sprayers with an overhead container(Fig. 3.3.1, a) paint is fed by gravity, due to gravity, from the container to the nozzle. The paint supply is adjusted by a needle that locks the nozzle, by changing the compressed air pressure and, in some more expensive models of paint sprayers, by an additional valve, which is located immediately after the paint container.

IN manual pneumatic paint sprayers with a bottom location of the paint container(Fig. 3.3.1, b) the paint composition is sucked (ejected) into the paint nozzle due to the vacuum created by compressed air. There are systems where the paint container is a small paint pump into which part of the compressed air is supplied to impart excess pressure.

When choosing the type of spray gun, you must first of all be guided by the operating conditions (positioning of the spray gun during operation, compressed air pressure, the possibility of using paint injection tanks).

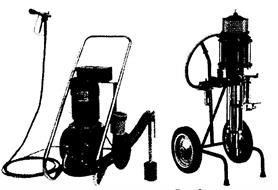

Principle of operation air spray units With pneumatic diaphragm motor(Fig. 3.3.2, a) is based on the use of a pump with two diaphragms. Compressed air, entering the installation, is divided into two streams. The first flow is directed through a special hose through a pressure reducer into the gun to fix the torch. The other flow enters through the second pressure reducer to the pump. The pump sucks the paint directly from the container and delivers it to the spray gun. Such units are widely used in industrial enterprises.

IN air spray units with low pressure and high air supply ( HVLP)(Fig. 3.3.2, b) the source of compressed air is not compressors, but electric turbines (blowers) of different power. Turbines produce dry compressed air in large volumes without oil or moisture. Overpressure is no more than one atmosphere, but due to high performance turbine and ideal design of spray guns is achieved high quality surface to be painted.

When selecting air atomization systems, it is necessary take into account the technical characteristics of paints, who are selected for work. This is viscosity, density, dry residue, recommended nozzle diameter for this paint.

An important aspect correct selection air spray systems are compressor selection. It should be taken into account that more viscous paint compositions require the installation of a larger diameter nozzle, and as a result, the consumption of compressed air by the spray gun or air spray unit increases.

EKONIKA-Techno specialists can accurately select a spray gun whose characteristics take into account the client’s production tasks as much as possible.

Method airless spray is based on creating high hydraulic pressure on the paint composition and displacing it at high speed through a special elliptical nozzle. This method, unlike the air spray method, is usually used for large volumes of work. The use of airless spraying units can reduce losses of paint composition due to fogging, significantly increase productivity by applying thicker layers of paint and reducing the number of passes.

The disadvantages of the airless spraying method include relatively high paint consumption, reduced quality of the painted surface, limitations when painting products of complex configurations (paint losses increase significantly), difficulties when applying paint compositions with coarse inclusions or fillers.

Principle of operation airless spray units with membrane pump (Fig. 3.3.3, a) is based on the fact that the rotation of the motor shaft using a flywheel disk or eccentric is converted into a reciprocating movement of the spring-loaded pump diaphragm. In this case, with the help of suction and discharge valves, the paint composition is sucked in and pumped through a high-pressure hose to the paint gun. The pressure is changed using a pressure regulator.

Units of this design are usually driven by electric, gasoline or diesel engines.

Main node airless spray units with plunger pumps(Fig. 3.2.3, b) is a high-pressure plunger pump with a piston-type pneumatic drive or an electric drive.

When compressed air is supplied through a gearbox to a pneumatic drive using a distribution mechanism, air is alternately supplied to the upper and lower cavity of the pneumatic cylinder. In this case, the piston and the pump plunger associated with it perform reciprocating movements. The pump's suction and bypass valves open and close respectively, allowing paint to flow into the pump cavity and force it into the high-pressure hose to the paint gun.

The useful area of the pneumatic drive piston is usually set to be 15-80 times larger than the useful area of the pump plunger, which makes it possible to correspondingly increase the pressure on the paint composition compared to the pressure of the supplied compressed air.

Plunger pumps are simple in design and maintenance, differ from diaphragm pumps in their higher reliability, and the ability to apply paint compositions of both regular and high viscosity to the surface.

Combined spray method, known abroad as the airmix (aircoat) method, is a combination of two spray methods - airless and air.

The fact is that the torch during airless spraying is uneven in length, especially at the edges. In order to achieve uniform distribution of paint over the entire cross-section of the torch, a special design of the nozzle and paint gun is used.

The spraying of the paint composition occurs through an airless spray nozzle, but the torch is adjusted by an air nozzle installed around it. Compressed air enters the torch through special holes in the air nozzle and, acting on it, evenly distributes the paint over the cross section of the torch.

The spray gun has two inputs, one for feeding paint under high pressure, the other for supplying air from the compressor. The quality of the torch is regulated by a special valve directly in the gun.

Using any airless spray unit, it is possible to implement the combined spray method by replacing regular pistol for airless spraying on a special combination spray gun.

The combined spraying method allows you to obtain higher quality coatings.

Today, when requirements for quality and speed of work increase, the user understands that to achieve good result impossible using inappropriate technology. It is important to find a company that provides a wide range of services - professional consultations, custom assembly of complex technological equipment, its commissioning, warranty and post-warranty service.

EKONIKA-Techno specialists will provide technical advice, help you navigate the variety of modern equipment and tools, and offer the most profitable terms cooperation.

List of used literature

1. Construction works: For student teams / O.O. Litvinov, V.A. Lyashchenko – 2nd ed., revised. and additional – K.: Vishcha school. Head Publishing House, 1986. – 263 p.

2. Finishing work in construction. Ed. G.R. Thiladze. M., Stroyizdat, 1976. 512 p. (Builder's Handbook). Author: G.R. Thiladze, M.S. Stesin, A.E. Surzhanenko, B.L. Kheifits.

3. Chmyr V.D. Materials Science for Painters: A Textbook for Environments. Prof.-techn. School – 3rd ed., revised. and additional - M.: Higher. school, 1982.-128 pp., ill. – (Vocational education).

4. Shepelev A.M. Apartment renovation on your own. – 7th ed., trans. and additional - M.: Mosk. Worker, 1987. – 416 p., ill.

5. //Building materials. – 2000. No. 10.

Technology of high-quality surface painting with water-based compositions

Introduction

1. Tools and accessories

2. Materials

3. Execution technology

4. Quality requirements

5. Organization of labor and workplace

6. Safety precautions

List of used literature

Introduction

Painting surfaces with water-based compositions is the most popular type of surface finishing. Its advantage is such factors as this type of finishing is inexpensive and does not require very significant skills in its implementation. The materials used to carry out this work are environmentally friendly and fireproof. Doesn't call unpleasant odor, dries quickly. Quite durable.

High-quality painting surface finishing on modern stage development of finishing works is the most commonly used finishing. Although there are three types of surface painting according to the quality of execution, in addition to high-quality painting, there is also simple and improved painting. High quality is the most common. Since the scope of its application is growing. Water-based compositions are used in almost all types of buildings: residential, industrial, shops, offices. which require high quality finishing. At present, it is possible to use simple improved surface painting only in the utility room. Water-based compositions are used to paint plastered, concrete surfaces. As well as surfaces finished with sheets of dry plaster. Structural wallpaper intended for painting.

It is impossible to improve the technology of painting work without mechanizing all technological processes, therefore, in the textbook, much attention is paid to the mechanisms used in the production of painting work for the preparation and application of various painting compositions, for heating and drying premises. The paint composition applied to building structures during the finishing work in accordance with the requirements of the project forms a paint coating. Painters carry out the coating according to the samples provided.

Paint and varnish coatings are classified according to a number of characteristics.

Purpose: technical - protection of painted structures from corrosion, decay, moisture absorption, fire, action chemical substances and so on.; sanitary - creating proper sanitary conditions in the premises, maintaining cleanliness; decorative - architectural and artistic decoration of a building, structure or its separate rooms.

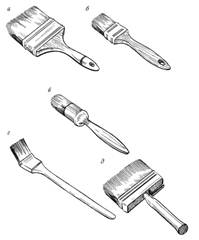

1. Tools, materials, devices

The greasing spatula is intended for greasing small cracks. And also as an auxiliary spatula for large volumes of surface filling. This spatula can be used as a scraper when cleaning the surface.

Flute paint brushes

Widths of fluted paint brushes: 25, 60, 62, 76 and 100 mm. Flutes are made from badger hair or high-quality bristles. The fastening is a metal frame, the handle is wooden, short. Flutes are used mainly to smooth out marks from a hand brush or handbrake on freshly applied paint composition. However, flutes can also be used for applying paint composition.

Macks (1) are round or rectangular. The bristles are made from half-back bristles with the addition of up to 50% horsehair. Used for painting primer surfaces.

Hand brushes are small paint brushes with a wooden handle. Hand brushes are designed for painting with adhesive and oil paints on small surfaces. Handbrake sizes Ø - 26, 30, 35, 40, 45, 50 and 54 mm.

Swing paint brushes

Dimensions of the fly brushes: Ø - 60-65 mm, hair length - 100 mm. Used for surface priming.

Paint rollers

Working with paint rollers significantly increases the productivity of painting work. The paint roller absorbs more paint and covers a larger area in one pass. Paint rollers can be used for both painting and priming

Radiator brushes are equipped with an elongated handle, curved at the base. Used in painting work on hard-to-reach surfaces such as heating radiators They also produce special paint brushes - radiator brushes.

A rubber spatula is used for filling and filling small cracks and holes. These types of spatulas are also made of plastic.

Applying putty to large areas

Metal spatula is designed for applying putty over large areas

The plastic roller is intended for rolling out the roller during painting or priming the surface.

The paint block is intended for sanding the surface.

The paint spray gun is designed for applying water-based paint compositions to the surface.

The finisher's table is used for painting work at height.

2. Materials

Properties of building materials.

Painters or paint and varnish materials are called compositions that are applied to the surface to be finished in liquid form, in thin layers, and which form a thin protective film. Firmly adhering to the base. Painting materials have a number of properties characteristic of all building materials in general. But they are the ones who allow us to give building materials protective resistance of the surface being finished.

This physical properties(density. Porosity, water absorption, humidity, moisture release, frost resistance, thermal conductivity, color, shine, light fastness, weather resistance).

Mechanical properties(strength, elasticity, ductility, fragility, hardness, abrasion, elasticity). Chemical properties(acid resistance, alkali resistance, water resistance, oil resistance, corrosion resistance, toxicity)

Paint compositions include water-based and non-aqueous pigments and binders. In aqueous paint compositions, lime, cement, liquid glass, etc. are used as binders. various adhesives, in non-aqueous - natural and artificial drying oils, synthetic resins, bitumens, etc. Binders determine the type of painting (adhesive, oil, synthetic) and the scope of its application.

Adhesive compositions usually paint walls and ceilings indoors with normal humidity. Synthetic, silicate, water-based paints are more versatile. They are used for finishing any type of surface except metal. They reliably protect structures and products in alternating conditions. temperature regime and exposure to aggressive environments.

The applied paint compositions, after drying and hardening, form a strong adhesion to the surface being painted. protective film.

Classification of painting compounds

Painting compositions are classified according to the type of film-forming substance and the operating conditions of the coatings.

According to the purpose of the coating, the following types of painting compositions are distinguished: primers, which ensure adhesion of the coating to the surface; putties and lining pastes that level the surface to be painted; painting compositions that impart decorative, protective and technical properties to surfaces.

The alphanumeric designation system for basic painting compositions consists of five groups of symbols for paints, enamels, primers, putties and four groups of symbols for varnishes.

The first sign is full word- denotes a group of composition (paint, varnish, enamel, primer, putty).

The second character (two capital letters) shows the film-forming substance (a type of resin, copolymer, drying oil, etc.). If the composition includes a mixture of film-forming substances, then the second group of signs is designated by the type of film-forming substance that determines the main properties of this composition. Between the second and third groups, an index is placed that determines the type of painting composition (for water-based, water-borne, powder, organosilicate, etc.): B - without active solvent, B - water-borne, OD - organodispersed, P - powder, E - emulsion.

The index is separated from the second group of characters by a hyphen.

Composition of paints

Pigments are one of the components paints and enamels. The color of the paint coating, its hiding power, as well as resistance to atmospheric factors, chemical reagents and high temperatures depend on the type of pigment. Pigments have a certain color, since they are able to selectively reflect daylight rays. When a light ray falls on a pigment, part of the radiant energy is absorbed, while the other is reflected, coloring the pigment in the color of the reflected rays.

Characteristics of water-based compositions

Water-based paints of various colors are divided into 2 types according to purpose: for external and internal work.

Water-based paints of different colors for interior work

They are a suspension of pigments and fillers in a plasticized polyvinyl acetate dispersion (emulsion) or styrene-butadiene latex. Designed for interior work on wood, plaster, cardboard, polyvinyl acetate dispersion (emulsion) or styrene-butadiene latex.

And also on old coatings with oil paints, enamels, and water-based paints.

Before use, the paint is diluted with tap water to a viscosity according to the VZ viscometer - 4: 20...25 s - when applied with a paint sprayer, 30...40 s - when applied with a roller and 40...50 s - when applied with a brush. - when applied with a roller and 40...50 s - when applied with a brush. The paints are stable when applied with a roller and 40...50 s when applied with a brush. to freezing (up to 400C) and thawing. The paints are non-toxic and explosion-proof. The shelf life of paints is 6 months from the date of issue. For household needs, paints are packaged in containers from 0.5 to 3 liters. The main characteristics of these paints are indicated on the labels.

Water-based paints of different colors for exterior use are a suspension of pigments and fillers in aqueous dispersions (emulsions) of synthetic polymers with the addition of various auxiliary substances for primed surfaces, as well as for old coatings.

Primer for interior work is designed to prepare highly absorbent substrates for subsequent coatings. A primer for interior work is used before applying paint (The presence of small particles in the primer that can penetrate into narrow pores allows for good adhesion to the surface.

A primer for interior work allows you to achieve high strength and durability of the final coating and reduce the cost of subsequent work by reducing material consumption.

The primer for interior work is used for pre-treatment of concrete, brick, plastered and other types of mineral surfaces;

facilitates the application of paints;

reduces paint consumption;

after drying, it forms a smooth matte translucent milky surface;

subsequent application of paint is carried out only after the primer has completely dried;

Oil-adhesive putty is intended for finishing the interiors of buildings.

Oil-adhesive putty is used in construction and repair for finishing and leveling various concrete, brick, plastered, wooden and other surfaces, sealing joints and cracks, filling cracks and then painting them with water-based paints.

The quality and durability of the final finish is determined not only and not so much by the quality and durability of the finishing materials themselves. This is much more influenced by the quality of the base on which it is laid. finishing coat.

It is well known that finishing layers (paint, wallpaper, etc.) decorative materials) are not applied directly to construction materials: concrete, plaster, blocks, gypsum boards (gypsum plasterboard, gypsum board). The immediate basis for finishing materials is a certain intermediate layer - putty.

The main purpose of putty is to eliminate surface defects, repair and level it, and correct planimetry. With the help of putty, a number of other problems are solved - the creation of complex curved surfaces (domes, columns, arches, rounded corners, etc.), as well as various architectural details(rods, cornices, moldings, etc.)

First of all, putties are divided into “dry” and ready-to-use.

High quality dry putty mixture- this is a complex multi-component composition containing all the necessary components (binder, filler and various additives), it is the components that determine the properties of the putty.

Immediately before use, the mixture is mixed (diluted) with a strictly defined amount of clean, cool water.

Ready-made putties are an excellent material for finishing works. The solvents that are initially in the material evaporate after it is applied to the surface, which leads to some shrinkage. This unpleasant property limits the use of ready-made putties in thin finishing layers and practically does not allow them to be used for pre-leveling and repairing the base in thick (more than 5 mm layers). To be fair, it is worth noting that today there are already ready-to-use putties that can be applied in a layer of up to 15 mm, but, as a rule, these are expensive specialized compounds used only for special cases.

Based on the type of main binding component, putties are divided into gypsum, cement, and polymer.

The most important thing is the classification of putties by purpose. How to choose leveling putty (or putty of the first layer), finishing (or putty of the second layer) and universal.

Leveling putties (or first layer putties) are the most common type of putties. They are intended for preliminary leveling of the surface of the base. Their choice depends on the type of base, its basic properties and characteristic features, operating conditions. The properties (characteristics) of the leveling putty are the determining factor in the strength and durability of the entire system, because It is she who bears all operational and temperature-humidity loads.

The leveling putty of the first layer must meet the following three basic requirements:

have good adhesion to the existing base and be fully compatible with it;

easily and reliably fill all defects in the base, correct the planimetry (geometry) of the surface;

have the necessary strength and durability of the base surface.

For leveling putties, especially in the real conditions of our construction sites, important parameter is the possibility of applying them in a layer of variable thickness (usually from 0 mm to 15 and even up to 25 mm). In cases where the use of plaster is not yet effective. In this case, the appearance of visible shrinkage, shrinkage cracks, peeling and other defects is unacceptable.

It is important to note that manufacturers of the highest quality modern leveling putties do not require the additional use of reinforcing materials. The characteristics of the product itself must guarantee the absence of cracks under standard conditions and exclude the occurrence of shrinkage. The use of reinforcing materials is necessary only in places of increased structural deformations or in particularly difficult working conditions. These locations are determined at the design stage or preparation of the Work Project.

It is quite convenient and useful to use materials that have a long or precisely standardized lifetime (the time of use of the prepared composition). For stable operation throughout the working day, for large volumes of work, materials with a lifetime from 8 hours to 24 hours are used. If it is necessary to carry out urgent work or work in small volumes, you can use special materials with a lifetime of 30 minutes to 3 hours.

Great prospects The use of special leveling putties for mechanized application helps reduce costs and speed up finishing work. This ensures production of up to 400 m2 per shift. The technology of mechanized application of putties has not yet found widespread use in modern construction, but this is a matter for the very near future.

Finishing putties (or second-layer putties) are putties designed to obtain a surface completely ready for application of the final finishing coating. The choice of finishing putty mainly depends on the set of requirements that apply to it finishing coating.

Base for painting

The main requirement when preparing for painting is the evenness and smoothness of the surface. The main attention should be paid to the grain size of the putty filler and its composition. The finer the aggregate grain, the smoother the surface. The best samples finishing putty, having a filler fraction of up to 100 microns, give a perfectly smooth (no sanding required), silky, non-chalking white surface and allow you to eliminate the smallest defects grounds. In addition, such putties are very plastic and easy to apply, they have a fairly long lifetime, during which the plasticity of the material does not change during application. All this provides an excellent basis for high-quality painting.

It is also very important that the finishing putty be fully compatible with both the underlying layer of leveling putty and the paint. Different paints are quite different from each other. They have H, different penetrating and even dissolving abilities. Because of all this, spots may appear on the painted surface due to uneven absorption or even the dissolution of the paint putty layer. Significant differences in the vapor permeability of the putty and the paint layer can lead to detachment of the finishing layer from the base (the “stocking” effect). In addition, individual paints can have significant shrinkage deformations during the drying process, and if the underlying layer is insufficiently strong, they can even peel off along with it.

Base for wallpaper or similar adhesive coverings

Universal putties are putties that are both leveling and finishing, and even special. It is convenient for non-professionals when the same material can be used to perform minor surface repairs, carry out preliminary leveling of various types of bases and perform fine finishing preparation, as well as special types works (structural decorative finishing, laying gypsum blocks).

In construction. The section provides for the main decisions and organizational and technical measures for the installation of the roofing tent structures of the building of the 2nd stage of construction of the Ice Palace sports complex in Kolomna, Moscow region. During the period of work, it is planned to use temporary and permanent roads, electricity and water supply networks for the construction needs. ...

Location. In addition, there must be a minimum allowable supply of special fire extinguishing agents (powder, gas, foam, combined). 2. Technological process painting metal surfaces with modern oil compositions. 2.1 Introduction As is known, ferrous metals (which include iron and some of its alloys) are thermodynamically unstable and quite easily...