Various materials are used to decorate the facades of houses, in particular, which is called clinker. Moreover, many are attracted not only by its external characteristics. What is this tile? What is it made of? And why is this façade cladding material so popular among those who want to give their home a unique appearance?

Clinker facade facing tiles for brick and its features

Clinker tiles for facades are made from clay the best varieties. Special substances are added to the main component to improve the properties finished material. After this, firing is carried out at high temperatures. During the process of high-temperature firing, moisture evaporates from the mixture, its molecular structure changes, which makes it possible to give high strength to clinker facing tiles for bricks.History shows that baked clay has been used since ancient times. The fact that it was even used 5 thousand years ago. The inhabitants of Ancient Mesopotamia built luxurious temple complexes. Of course, how modern product, facing tiles appeared much later. But there is evidence that the same Tower of Babel on one side was decorated with burnt brick. Since the 17th and 18th centuries, clinker brick used almost everywhere throughout Europe.

Unique Feature modern material lies in the fact that the façade, finished with clinker, looks like one made of real brick. And often only a specialist is able to distinguish brickwork from tiled design. Moreover, clinker is quite affordable. Clinker decorative brick tiles make it possible to not only reduce the cost of building a new home at an affordable price. It allows you to give an impressive look to an already in use building, the facade of which requires updating.

In addition to affordability, high strength, brick wall tiles, called clinker:

- Serves for an unlimited amount of time, maintaining its original appearance;

- Has low water absorption (no more than 3%);

- Characterized by high resistance to frost;

- Rightfully considered environmentally friendly pure material;

- Helps to save heat resources spent on heating the house;

- Quick and quite easy to install.

An additional advantage of clinker is its variety in terms of color. Its rich colors include more than 100 options, ranging from the shade of traditional red brick to neutral white. The surface of clinker tiles may have roughness, the appearance of untreated material, or be glazed. It goes great with different materials, which allows you to give the facade originality.

Clinker brick tiles: technology for laying them

You can lay clinker yourself. But for this you need to know the rules that allow you to install high-quality tiles. It is suitable for cladding the facades of houses built of concrete, brick, cinder blocks, and other, but most importantly, durable materials. It is necessary to lay clinker only on a surface that has been previously cleaned, and not only from old plaster, but also lime, dirt, rust. Before laying the tile material, it is imperative to eliminate unevenness using a plaster, putty mixture, leveling solution. It is necessary to treat the surface with a primer, which helps to stabilize, strengthen the base, and its adhesion to the mortar for fixing the tiles.It is important to understand that external brick tiles will last a long time if they were fixed to the wall without flaws. Therefore, if the old plaster layer is loose, it should be removed.

Often, before finishing a house, its facade is insulated. What insulating material to choose, how to install it? You can read about this in our other articles. But it is important to know that in this case the clinker will require double lathing. Compared to the same decorative facade plaster, clinker tiles are heavier. Accordingly, you will need to additionally strengthen the surface on which it will be mounted.

Laying facing tiles for a brick façade often starts from the bottom. Experts recommend starting its installation from the second row. During the work, a special spatula is used, the number of which directly depends on the size of the tile material. The larger the tile, the larger the trowel teeth should be. To ensure uniformity of seams, so-called spacer crosses are used. They are inserted into the joints of 4 tiles. They are removed after the glue has set.

For installation you will need an adhesive mixture. It is mixed with water, after which it is allowed to stand for about 10 minutes until its components are completely dissolved. The adhesive mixture is applied to each subsequent square meter. IMPORTANT! If it is immediately applied to a large surface, it will lose its adhesive properties within 20 minutes. As a result, the tile will not stick properly.

As soon as brick cladding tiles glued and time is allowed to fix it (about a day), you can start sealing the joints. Special grouting compounds are used, which are introduced into the seam using a rubber spatula. Places where the tile material meets the door, window openings, should be filled with sealant. To prevent the sealant from sticking to the tile itself, the latter should be moistened by sprinkling it with plain water.

Grouting joints requires special attention. If you neglect this stage of work, moisture will subsequently penetrate into the seams. The latter, once under the façade cladding, will cause it to freeze. The result will not please you at all. The clinker facade facing tiles under the brick will begin to fall off exactly in the place where the seams were poorly sealed.

External facing tiles to look like brick or finishing with facing bricks: which is better?

Experts have long compared facing bricks and clinker according to their characteristics in order to find out what is best to use for facade finishing. As their research in this direction has shown, clinker tiles are superior to their competitors in strength. It can withstand even large mechanical loads.In addition, do not forget that decorative brick tiles come in a wide variety. Facing brick is significantly inferior to it in this regard. Accordingly, he will not allow you to fantasize about façade design. Undoubtedly, brick for cladding makes it possible to give the house a presentable, solid appearance. But a luxurious finish can be achieved if clinker is used, especially if you prefer finishing options using different materials.

So, a fairly popular option for such finishing is “clinker + decorative plaster”. Even very bold compositions can be made from these materials. By the way, it's very simple. Anyone who has set themselves the goal of not only adding beauty to the façade of their home, but also protecting its walls from the effects of negative environmental phenomena can master the technology of working with it.

A house is not only a fortress where its owners can feel safe. An important necessity from an aesthetic point of view is that wall surfaces serve as decoration for the building and attract admiring glances from others. It is also imperative that the walls reliably protect from bad weather and guarantee energy savings.

To meet such requirements, building materials manufacturers produce different kinds facing materials. At the same time, according to reviews from home owners, brick-like tiles are the most popular. It imitates natural construction material so precise that you may not notice the difference between brick walls and tiled wall surfaces.

Porcelain tiles for facade

Two types are produced from clay ceramic tiles, differing from each other in the method of production. The first option is porcelain stoneware. The material has increased strength due to production technology. The raw mass is pressed under high pressure and is fired at a temperature of 1300 0 C. This is a non-porous material, comparable in structure to a monolith. Porcelain tiles practically do not wear out under the influence of wind, frost, moisture and temperature changes.

The standard dimensions of porcelain stoneware tiles are 36.5×12 cm. The naturalness of the cladding is given by corner elements made using the same technology. The front side is stylized to resemble the structure of a brick, and is given a certain roughness and uneven color.

Very often tiles are made from porcelain stoneware large sizes simulating natural stone, for example, granite, travertine or sandstone, as well as brick with a torn front surface. The price of imported porcelain stoneware brick tiles starts from 1900 rubles per 1 m2. Cost of products domestic production from 800 rubles.

The tiles are attached to the wall surface using a wet method. That is, on a pre-leveled solid base, the products are fixed using special adhesive mixtures. It is not advisable to use small-sized tiles for arranging ventilated facades. For this purpose, products with large dimensions are used that imitate a natural stone with a polished or textured surface.

Clinker facade tiles

Clinker tiles are formed from a raw mass and fired at high temperature within 36 hours. Clinker was originally intended for use on outdoors and resists well almost all destructive weather influences: rain, frost, wind and sun.

The use of clinker tiles significantly reduces the cost of building a new house. Its advantage is that it can be used to decorate walls made of gas and foam blocks. It is also easy to use clinker to renovate the façade of an old building. There is only one important condition To use clinker tiles, namely, the walls of the building must be pre-leveled, there should not be any looseness or crumbling plaster on them.

The variety of colors of clinker tiles provides ample opportunities in creating designs and making decorative dressings and combining colors. Laying is done on thin layer glue mixture directly on the wall or on the insulation high density, reinforced with mesh.

Price facade tiles under the brick German manufacturer Stroeher ranges from 1900 to 2660 rubles per 1 m2, depending on the type of treatment and surface texture. Cheap tiles Russian production costs 2-3 times cheaper. Products measuring 240x60x6 cm can be purchased at a price of 650 rubles per 1 m2.

You can learn more about the features of laying tiles under brick in the following video:

,

Thermal panels for facade cladding

Thermal panels combine three types of building materials:

- Insulation;

- Insulating film;

- Decorative coating.

In most cases, extruded polystyrene foam is used as insulation. The front side of the panels can be lined with plastic, metal or ceramics. Finishing with porcelain stoneware or clinker imitates wild stone or brick standard sizes, different shades and textures.

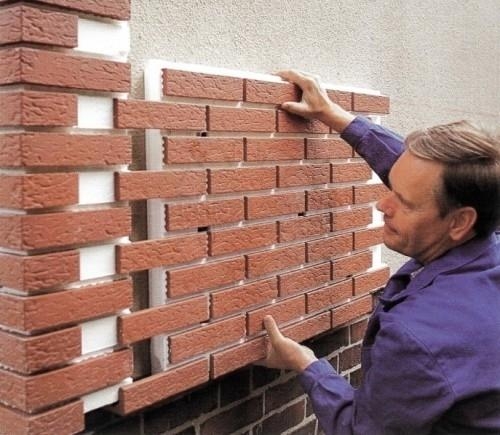

The panels are made in such a way that individual bricks protrude from the sides. Subsequently, during installation, they are joined according to the principle of the designer, thereby ensuring the reliability of laying the material. In the photo below you can see how the assembly process occurs.

Advantages of using thermal panels in facade finishing:

- Can be used on any type of wall;

- High speed of installation due to the dimensions of the panels;

- Fewer seams than when tiling standard sizes;

- Possibility of carrying out installation work in any season;

- Ensuring simultaneous insulation of the house and finishing of the facade.

To cover the facade with panels, the walls are leveled with mortar or sheathing is mounted on them. Thermal panels are attached to brick and concrete surfaces with dowel nails with a length of 120 mm, on wooden sheathing fastening is carried out using anodized screws with a length of 100 mm. Installation begins with the corner elements from the base, leaving a distance between the panels equal to the width of the seam between the individual bricks.

The main share of the cost of thermal panels is determined by the finishing material on the front side and the brand of the manufacturer. Products from Dutch, German and Finnish manufacturers predominantly use clinker coating. Their cost is from 2500 rubles per 1 m2. Thermal panels from Poland are a little cheaper, their price varies from 1200 to 1700 rubles per 1 m2. Russian facing material you can buy inexpensively even with high quality ceramic coating, price range - from 800 to 1000 rubles per 1 m 2.

Most cheap option thermal panels up to 600 rubles per 1 m 2 with plastic coating. They are used for insulation and improvement of old buildings and apartments in multi-storey buildings. Panels are produced in the form of rectangular or square blocks of various colors with brick-like seams. This type of material is perceived as brickwork only when looking at the building from a distance.

Brick-like facade tiles allow you to realize the most original ideas when facing facades. At the same time, its diversity allows it to satisfy the price requirements of buyers of various categories.

- This stylish solution for any interior. Recently, design using such material has become increasingly popular (it has even been called “loft”).

However, the brick itself still makes the surface heavier, requires certain knowledge in masonry and “steals” some of the space in the room. A much more convenient analogue in this regard is a tile that imitates it.

What are the bonuses here?

First of all, such a presentation is interesting because it allows you to get away from standard templates. The use of such tiles will help create a unique and inimitable interior.

Besides this, there are other advantages:

- affordable price (compared to natural stone);

- durability in use:

- resistance to mechanical stress:

- warranty for use for up to 15 years (or more);

- high level of fire resistance;

- heat and sound insulation of the room;

- no unpleasant odor.

- variety in color presentation;

- texture of the coating;

- small sizes.

For every style and taste

The material is truly harmoniously suitable for any interior. It will allow you to realize any designer’s fantasy. Most often, such tiles are used to stylize a variety of historical styles. Big choice The area of use also represents - it starts from the hallway and will look completely complete even in bedrooms.

Types of tiles

The modern market offers several options for such cladding solutions. Among them, the most relevant will be the following:

- gypsum brick-like tiles;

- ceramic analogues;

- clinker options.

The choice of each of them will be determined by the goals set. Depending on the characteristics of the chosen type.

Decorative gypsum tiles for brick look is a true leader in interior cladding. It meets all the stated requirements, and even a beginner can handle the installation of such a coating. Its perfection is outweighed by only two disadvantages - fragility and water permeability. However, here you can find a way out: the blocks reinforce and cover special composition, having hydrophobic properties. (more details about the surface here)

Definitely, this option is only a facing tile underneath (it will look great, for example, on fireplace structures).

In contrast to the considered ceramic- this is already a brick-like facing tile for exterior decoration (although it is also successfully used indoors). It also has environmentally friendly origin and high tensile strength. There is an additional advantage here - the material does not conduct current.

Clinker facing tiles for brick facades more often relevant when working with the foundation. This type does not require any special care, but despite this, it is very durable. The whole secret is in the production technology: production is carried out by firing clay (special varieties are taken). Thanks to this method, the material will not contain any voids or inclusions.

They look quite nice, made to look like brick. Or option. Video link.

Features of installation work

The installation of such tiles is somewhat similar to the work of laying tiles. But there are some peculiarities here that must be taken into account. In general, the work algorithm will be as follows:

- The surface is prepared and leveled. It is important to remove dust beforehand.

- If necessary, you can apply a primer.

- For the work, tile adhesive with special fillers is used - they will provide elasticity to the solution.

- The drawing and future location are pre-selected.

- The tiles are laid imitating traditional brick laying.

- When applying the adhesive solution to the wall, it is necessary to use only 1 m2 of the total area. Such requirements are due to the fact that the solution dries out very quickly.

- At the final stage, the joints are grouted (after the glue has completely hardened) - usually a day after the work is completed. Grouting can be done using the “joint” technology, which will give the entire masonry a similarity to real brick. The depth of the seam should not exceed 1 mm.

- Finally, the surfaces can be coated with paint.

There is another styling method - “dry”. It is customary to use facing blocks that have protrusions. In this case, slats are attached to the wall, with a step that is equal to the tile width. In the future, gypsum block protrusions will be placed between them and the wall. The work occurs in a vertical order and starts from the corner. The slats themselves will perfectly hide the seams.

More on the topic:

Often decorative rock appears under the name brick facing tiles due to its size and small thickness. This kind finishing material used in cases where the use of conventional facing bricks does not seem possible. In addition, this type of material is used to stylize buildings as brick: such tiles completely imitate masonry, while being much cheaper and lighter than its natural counterpart. Leonardo Stone offers its customers various series of brick-like facing tiles, which you can find in the “Products” section.

The ultimate illusion of brickwork

A brick facade is very beautiful, but not always the owner of a building can afford to cover his house with brick. Sometimes this requires building an additional foundation or strengthening existing structures. And sometimes there is not enough money to buy ceramic bricks. In all these cases, brick-like facing tiles can come to the rescue.

Types of “brick” tiles

This type of tile comes in the following types:

- Ceramic - made in the same way as ceramic brick;

- Clinker - produced from high-quality clays by extrusion;

- Hand molded - made by cutting bricks hand molding, therefore fully consistent with it appearance and characteristics and partly by size;

- Gypsum – this type of facing tile is recommended for use indoors, in the interior.

Advantages of brick-like tiles

This material, laid out on the walls of a building, looks like real brick. However, compared to brick, tiles have many advantages:

- It is lightweight - such a facing material does not require reinforcement of structures;

- It is cheap - the cost of tiles is much lower than the cost of full bricks. And if you decide to purchase “brick-like” tiles through our website, you will generally be able to save a significant part of the budget allocated for cladding. In addition, laying such tiles requires less mortar than laying brick, which also saves money;

- It is attractive in appearance - you are guaranteed the complete illusion of walls lined with real brick;

- It is easy to use - laying tiles “under a brick” is much easier to do than the brick itself. Do you think calling a tow truck is expensive? Don't believe it! Call the SKOROKHOD evacuation service, they have car evacuation in Minsk from only 270 thousand rubles! Such work takes less time, which means you will need to pay less for the services of a mason;

- It is durable and protects the walls from atmospheric influences - this advantage is also typical for brick, we present it here so that you understand that brick-like facing tiles have the same advantages as real brick.

In our product catalog in Moscow you will find several collections of brick-like facing tiles that will help create the complete illusion brickwork. You can choose the tile color that best suits your design ideas. If you have any difficulties making a choice, our consultants will help you decide. If necessary, you can order from us not only the material itself, but also installation services. Our professionals will do your cladding quickly, efficiently and inexpensively.