The space under a pitched or sloping roof wooden house often used not only for technical purposes, but also as a living space. But to create comfortable conditions, the attic must be carefully insulated from heat loss and external noise, and normal ventilation of all rooms must be ensured.

To understand which insulation is best for an attic, you need to carefully study the parameters of the materials on the market and correlate them with the project requirements for thermal insulation of the room and the degree of preparation of the roofing system.

Depending on the type of roofing materials and common system roof devices in wooden house, the basic requirements for thermal insulation materials are assigned.

During the construction of an object, lathing and counter-lattice for metal or soft types of roofing can be carried out according to different schemes. As a result, there are two types of roofing devices:

- with laying a waterproofing film or diffusion membrane;

- without installing a counter-lattice and a layer of waterproofing.

The second option is considered a gross mistake, but from time to time builders do not leave space for natural ventilation rafter system and do not protect its elements from moisture.

Material requirements

Requirements for insulation materials may differ depending on the type of roofing device, but the basic characteristics must remain unchanged:

- thermal conductivity no more than 0.045 W/mK;

- material density in the range of 30 – 50 kg per cubic meter;

- rigid or semi-rigid structure of the heat insulator.

Thickness

The thickness of the insulation layer directly depends on the purpose attic floor. When installed within this space living rooms and bathroom, it is necessary to protect the structure as much as possible from heat loss and freezing.

That is why experts advise using a layer of insulation of at least 100 - 150 mm. Moreover, the material is laid in 2 layers for more effective protection from heat loss.

Density

It is also worth remembering that the lower the density of the material, the greater its thermal insulation ability and the less impact on the rafter system. We must not forget that making the roof heavier can negatively affect the condition of the entire structure of the house, because the pressure of the rafters on the walls increases, and this can lead to their deformation.

That's why before you choose optimal insulation for an attic, it is necessary to carefully study its properties and calculate the approximate load on the rafter system.

If there is no waterproofing film or diffusion membrane that protects the rafters from moisture accumulation during steam condensation, it is best to choose one of the polymer insulation materials.

Most often, a similar situation arises during the construction of a house in which a residential attic was not intended. That is why materials with extremely low permeability, such as polyurethane foams and expanded polystyrene, become the best option.

Such insulation perfectly protects not only from freezing of the structure or a decrease in room temperature, but also from constant exposure to moisture. They are harmless to humans, but require the creation of ventilation systems, as they interfere with normal air circulation.

An interesting option for roof insulation is a material based on polyurethane foam. This insulation is applied by spraying, which ensures the absolute integrity of its layer without the formation of cold bridges.

In addition, this material does not require additional fastenings or fixation due to good adhesion to the base. To treat a roof of 100 square meters it will take no more than 4 to 8 hours, which significantly reduces the process of arranging the attic floor.

The thickness of such insulation to protect the attic compared to classic mineral wool can be reduced by 1.5 - 2 times and amounts to 80 - 100 mm. It is thanks to the integral structure of the applied layer, as well as the formation of absolutely closed air cavities, that polyurethane foam perfectly protects the room from heat loss.

But it must be remembered that when using such insulation, home owners should install forced ventilation, otherwise accumulated moisture will lead to the development of fungi and pathogens.

IN in this case will cope perfectly with the task of insulation as classic foam, and extruded polystyrene foam.

Both materials have excellent thermal insulation properties, but the extruded version is more reliable and durable. Its thermal conductivity is lower, so the effective layer is reduced to 80 mm.

The cost of polystyrene foam is lower, but taking into account the difference in the required amount of materials, the total costs remain approximately equal. The undeniable advantage of extruded polystyrene foam over polystyrene foam is its non-flammability.

Extruded polystyrene foam, unlike polystyrene foam, is not susceptible to rodents; its structure simply does not allow them to create their nests in the thickness of the material. Nevertheless, polystyrene foam still remains one of the most popular insulation materials.

The density of both types of expanded polystyrene is also selected in the range of 30 – 50 kg/m3 to prevent the weight of the structure. They are fastened using special disc-shaped dowels with large polymer caps.

Fiber and natural insulation

When creating a roof with a counter-lattice and any type of waterproofing device, it is worth choosing semi-rigid materials, such as mineral and stone wool or composites based on natural fibers.

Such materials require additional protection from getting wet, since when exposed to water they lose their properties completely or partially. In addition, their fastening involves the creation of an additional frame, which complicates the work. But such wools have excellent permeability, therefore they support natural air circulation, ensuring a normal level of humidity in the room.

Mineral and stone wools

In fact, such materials are the most budget-friendly option for attic insulation. They are lightweight and dense, so they do not weigh down the structure. Installation of such insulation is simple, but will require several days.

Most often, mineral wool is laid in the space between the rafters. To increase the effectiveness of thermal insulation, complete overlap of beams and rafters is periodically used. The required layer of such materials is 150 - 200 mm.

The main disadvantages of mineral wool are the complete loss of properties when wet, as well as harmfulness to humans when weathered. Exposure to wind can knock out small stone or glass fibers from the bulk of the material.

If they enter residential premises, allergic reactions can occur and respiratory tract diseases can be provoked. That is why mineral wool must be protected on both sides.

Natural fiber materials

Insulation materials are semi-rigid wools formed from plant fibers, natural binding components and antiseptics. The latter help prevent biological corrosion and increase the durability of the insulation. In addition, fire retardants are introduced into ecowool, which reduces their flammability.

Such materials are afraid of waterlogging, but partially retain their properties when wet and completely restore them after drying. Natural wools are suitable for insulating any home, but also require a vapor barrier and diffuse membrane.

Protection of insulation from external and internal moisture

When using semi-rigid wool to insulate the attic of a private house, it is necessary to protect the thermal insulation materials both from condensation that forms under roofing material, and from the internal moisture of the premises.

Pie device

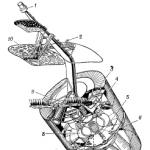

The interior decoration of the attic of the house is a kind of layer cake:

- waterproofing film or diffusion membrane over the rafters;

- insulation layer;

- vapor barrier;

- frame for interior decoration;

- directly finishing material.

It is the presence of two films that allows you to completely protect the selected insulation.

Superdiffusion membranes

When using superdiffusion membranes, the selected material can be attached so that it is pressed tightly against the film. Due to the high throughput of such membranes, water vapor from the premises quickly passes through the insulation without condensation.

Ventilation gap

When using waterproofing with low throughput, it is necessary to leave a ventilation gap of at least 2.5 - 3 cm between the insulation and the film. In this case, the steam will circulate freely in this space, gradually being released outside and not condensing in the body of the heat insulator.

With proper insulation, the attic can become beautiful extra space in any home.

If the roof of a country house forms a spacious attic space, then it can be used to expand the living space. The attic room can serve as a bedroom or office, a sports room, a cinema or a billiard room. To use extra bed all year round, needed good thermal insulation. Insulating the attic will not require large material costs, especially since the work can be done with your own hands. It is only important to choose the appropriate thermal insulation material and carry out the installation correctly.

Requirements for thermal insulation materials

The same technology that is used in the construction of frame houses is suitable for insulating the attic, however, increased demands are placed on the materials and quality of work. How well the thermal insulation will be done attic space, affects both the conditions of comfortable living and the durability of the roof. This is due to the fact that the walls of the attic room form the gables and roof slopes - those surfaces that heat up the most in the summer heat. In winter, on the contrary, blown by cold air currents, they cool down most quickly. If the thermal insulation is of poor quality, the roof will let heat out. One should not think that the danger of such a situation lies in a banal increase in energy costs for heating the attic. Warm slopes will provoke the melting of snow, and this is fraught with many more serious troubles - from mechanical damage to the top covering by the resulting ice to the appearance of fungi and mold that destroy the roofing pie and wooden structures rafter system.

High-quality thermal insulation will make the attic comfortable to live in both the summer heat and winter cold.

When choosing a material for insulating an attic, you should remember that not only the thickness and number of layers of thermal insulation, but also the ease of installation depends on this. Based on the specifics of using insulation, the following requirements are imposed on them:

- Ability to withstand peak temperatures. The material must be frost-resistant and not destroyed when high temperature, maintaining its characteristics even after numerous cycles of freezing-thawing or heating-cooling.

- Durability. The service life of thermal insulation should be no lower, or even higher, than other materials used on the roof. This is due to the fact that replacing a roofing pie is much more difficult than, for example, a top covering made of metal tiles or ondulin.

- The lowest possible thermal conductivity coefficient. It is best to take insulation with a value of no more than 0.05 W/m×K.

- Maximum moisture resistance. Since condensation may appear in the under-roof space, the material should not absorb moisture and lose its properties when wet.

- Fire safety. Thermal insulation must not burn or support combustion.

- Light weight. The insulation should be light so as not to create an increased load on the roof rafter system. The total weight of thermal insulation can be determined by multiplying its density by volume. Experts recommend using materials with a density of up to 50 kg/m3.

- Ability to maintain a given configuration. The insulation is laid in the spaces between the rafters in an inclined position. If you choose a material that can deform under its own weight, then over time it can slide down, forming voids inside the structure. It is necessary to choose thermal insulation that can retain its original size and shape for a long time.

The type of thermal insulation chosen affects the thickness of the roofing pie. Later we will look at how to calculate the amount of material needed.

What materials are suitable for attic insulation?

You can make your attic suitable for living at any time of the year using various insulation materials. Let's look at their features and highlight their strengths and weaknesses.

Mineral wool

For insulation attic space You can use glass wool, mineral wool or slag wool. These materials have the following thermophysical and operational parameters:

- high thermal resistance - up to 1.19 W/(m 2 /K);

- low thermal conductivity - no more than 0.042 W/m×K;

- light weight - from 15 to 38 kg per 1 m2.

Cotton-type thermal insulation is a favorite option for home craftsmen if the roofing pie needs to be installed from the inside of the room. It does not support combustion, has minimal weight, and, importantly, rodents do not grow in its layer. The slab samples retain their shape perfectly, and when laying fiber insulation in the space between the rafters, no precise adjustment is required - the mineral wool is easily distributed without seams or gaps.

Mineral wool is produced in the form of roll and slab materials

The only drawback can be considered increased hygroscopicity. Due to the appearance of moisture between the fibers, the thermal insulation properties of the material drop by more than half, and the material itself begins to collapse. Therefore, mineral wool requires high-quality waterproofing from the roof side and installation of a vapor barrier membrane from inside the attic space.

Polymer thermal insulation

They are often used to insulate roof structures. polymer materials- expanded polystyrene and polyurethane foam. They retain heat well and, due to their hydrophobicity, are not at all afraid of moisture.

Simple polystyrene foam, otherwise called polystyrene foam, is one of the most popular insulation materials on the building materials market. Good performance characteristics- minimal density, low thermal conductivity, moisture resistance and the ability to hold a given shape contribute to the idealization of this material. As a result, it is often used in places where it is strictly not recommended. Firstly, only non-flammable foam plastic of the G1-G2 brand is suitable for insulating residential premises, and not the popular G3-G4, which ignites perfectly and burns out in a matter of minutes. If you choose the latter for insulating the attic, then surviving a fire in it will be unrealistic. Secondly, installing ordinary polystyrene foam is not an easy task, since it is difficult to cut and crumbles easily. Thirdly, this material is subject to aging and begins to quickly deteriorate over time. And in conclusion, it should be noted that polystyrene foam is a favorite material among rats and mice, so it is used only where it will be covered with a layer concrete screed

or hidden behind plaster.

Polystyrene foam is a type of gas-filled plastic that can be used to insulate attic spaces. Extruded polystyrene foam (EPS) is almost completely devoid of the disadvantages of polystyrene foam, which is well suited for thermal insulation of an attic room from the outside. To do this, insulation boards are laid directly under the roofing material, on top of the elements of the rafter system. Extruded polystyrene foam contains fire retardants, so it burns poorly. Compared to foam plastic, EPS has higher strength and rigidity, which makes it much easier to install. Like other polymer materials, extruded polystyrene foam is waterproof, does not allow steam to pass through, and has good energy-saving properties. This makes it the best option for thermal insulation mansard roof

outside. By the way, very little EPS is required - a 100-mm layer will be enough to insulate an attic space in most regions of our country.

Extruded polystyrene foam is best suited for external roof insulation

Polyurethane foam Polyurethane foam (PPU) is a gas-filled plastic that is applied in liquid form to inner surface

- stingrays When set, the material forms a rigid foam with excellent physical characteristics:

- heat transfer - up to 0.027 W/m×K;

- thermal insulation density - from 30 to 86 kg/m 3 ;

- weight - from 11 to 22 kg.

To apply polyurethane foam, a special installation is used in which the liquid mixture foams when air or CO 2 is supplied.

To insulate the roof with polyurethane foam, you will have to turn to specialists - you cannot do this without special equipment and skills

This method of installation largely determines the advantages of the insulation, since when the under-roof space is blown out, there are no cracks, gaps or cold bridges left in the form of open elements of the rafter system. Polyurethane foam does not support combustion and does not change shape. It does not collapse over time and resists moisture well. By the way, the last factor causes low vapor permeability - the insulation does not allow the roof to “breathe”, which can lead to high humidity in the attic space.

To ensure that the air in the attic space is fresh and light, and the wall surfaces are not covered with mold and mildew, when insulating the roof with polyurethane foam, you should definitely consider a high-quality supply ventilation system.

Ecowool can be considered one of the best materials for thermal insulation work at home. This insulation consists of more than 80% cellulose fibers, so it has low thermal conductivity and is well suited for filling gaps between rafters. Since cellulose in its pure form burns well and is destroyed by fungi, borax is added to its composition as a fire retardant and boric acid to protect against damage by biological organisms, including rodents.

Basic physical properties ecowool:

- thermal conductivity - from 0.037 to 0.042 W/m×K;

- the density depends on the degree of laying and varies from 26–95 kg/m3;

- flammability - group G2 according to GOST 30244;

- vapor permeability - up to 03 mg/mchPa.

In terms of its performance properties, ecowool is close to mineral and polymer thermal insulation, surpassing them in many factors. Yes, unlike mineral wool, it absorbs moisture without significantly reducing thermal conductivity. With an increase in humidity by 1%, a basalt slab will lose a tenth of its thermal insulation properties, while ecowool, when saturated with moisture to 25%, will increase thermal conductivity by no more than 5%.

Ecowool in the form of slabs of various thicknesses is suitable for insulating the attic.

It is also important that when the cellulose insulation dries, it completely restores its original characteristics. At the same time, it can serve as a kind of buffer, capable of maintaining a comfortable level of humidity in the room. Ecowool allows for seamless installation, therefore it forms a monolithic layer without gaps or cold bridges. Its breathability is almost two times lower than that of mineral insulation, and at the same time it remains elastic enough to dampen sound waves. When using ecowool, the attic will be best protected from external noise. And finally, it is impossible to remain silent about the environmental friendliness and safety of this material. It does not contain a single chemical compound that could evaporate and release substances harmful to humans.

How to calculate the thickness of thermal insulation

To calculate what layer of insulation will be needed to insulate the attic, builders use the formula from SNiP II-3–79 δ in = (R - 0.16 - δ 1 /λ 1 - δ 2 /λ 2 - δ i /λ i) × λ ut, in which R is the thermal resistance of the slope, wall or ceiling (m 2 × ° C / W), δ is the calculated thickness of individual structural elements in meters, and λ is the thermal conductivity coefficient of the insulation (W / m × ° C) for structural layers used.

In private housebuilding, the formula is simplified to simple equationδ ut = R × λB, where the last factor characterizes the thermal conductivity of the insulation used in W/m×°C. The minimum thermal resistance of walls, roofs and ceilings depends on the region in which construction is being carried out.

Table: thermal resistance values depending on the region of construction

| City | R (m 2 ×°C/W) | ||

| For floors | For walls | For coatings | |

| Anadyr | 6,39 | 4,89 | 7,19 |

| Biysk | 4,65 | 3,55 | 5,25 |

| Bryansk | 3,92 | 2,97 | 4,45 |

| Velikiy Novgorod | 4,04 | 3,06 | 4,58 |

| Derbent | 2,91 | 2,19 | 3,33 |

| Ekaterinburg | 4,6 | 3,5 | 5,19 |

| Irkutsk | 4,94 | 3,76 | 5,58 |

| Kaliningrad | 3,58 | 2,71 | 2,08 |

| Krasnoyarsk | 4,71 | 3,59 | 5,33 |

| Maykop | 3,1 | 2,8 | 3,5 |

| Moscow | 4,15 | 3,15 | 4,7 |

| Murmansk | 4,82 | 3,68 | 5,45 |

| Nalchik | 3,7 | 2,8 | 4,2 |

| Naryan-Mar | 5,28 | 4,03 | 5,96 |

| Nizhny Tagil | 4,7 | 3,56 | 5,3 |

| Omsk | 4,83 | 3,68 | 5,45 |

| Orenburg | 4,49 | 3,41 | 5,08 |

| Permian | 5,08 | 3,41 | 4,49 |

| Penza | 4,15 | 3,15 | 4,7 |

| Saint Petersburg | 4,04 | 3,06 | 4,58 |

| Saratov | 4,15 | 3,15 | 4,7 |

| Sochi | 2,6 | 1,83 | 2,95 |

| Surgut | 5,28 | 4,03 | 5,95 |

| Tomsk | 4,83 | 3,68 | 5,45 |

| Tyumen | 4,6 | 3,5 | 5,2 |

| Ulan-Ude | 5,05 | 3,85 | 5,7 |

| Chelyabinsk | 4,49 | 3,41 | 5,08 |

| Chita | 5,27 | 4,02 | 5,9 |

The thermal conductivity characteristics of any thermal insulation material can also be found in the tables.

Table: thermal conductivity coefficients of materials

To determine the thickness of the insulation, it is not at all necessary to count everything manually. You can use an online calculator, which is easy to find on the Internet. All that is needed in this case is to enter the values of the climate zone, the area of the attic, the type of insulation and its scope. The program will do all other calculations for you.

Insulating the attic from the inside

The simplest and most convenient way to insulate a roof is to insulate it from the attic side. Almost all known thermal insulation materials are used for these purposes. Most often, mineral or glass wool is used - this is due to the low price of these insulation materials. Extruded polystyrene foam is used a little less often, the installation of which causes more difficulties. And unfortunately, ecowool or polystyrene foam blowing is still very rarely used - the relatively high price and complexity of installing thermal insulation play a role here.

When insulating an attic from the inside, not only the walls, but also the floor are insulated

The durability of the materials used and the comfort inside the attic depends on how accurately the technology of thermal insulation measures is followed. The most important role here is played by how correctly the roofing “pie” is laid. If we consider the structure from the inside out, it consists of the following elements:

- finishing with sheets of plasterboard, plywood or OSB, clapboard, etc.;

- vapor barrier;

- thermal insulation material;

- waterproofing;

- counter-lattice and lathing with a ventilation gap;

- roofing material.

It should be noted that a vapor barrier will only be needed when cotton wool materials are used for insulation - in this case it will prevent penetration humid air from the attic room. When using polyurethane foam or expanded polystyrene, there is no need for a diffusion membrane.

As for waterproofing, it is needed in any case, since it will serve as an additional barrier to protect the roofing pie and wooden elements of the rafter system from moisture coming from outside. If fiber insulation is used for thermal insulation, then superdiffusion membranes are used that are capable of transmitting water vapor in one direction. During installation, they are oriented in such a way as to ensure the removal of moisture from the cotton materials. In addition, to improve ventilation between the waterproofing and the roof, they install ventilation gap height from 5 to 10 cm.

When insulating with mineral wool, it is necessary to use a vapor barrier film

The entire process of roof insulation can be divided into several stages:

- preparatory work;

- preparation of thermal insulation material;

- laying insulation in place;

- fastening thermal insulation;

- finishing activities.

You should remember about the insulation of the attic space, starting from the design stage, not forgetting to take into account the features of thermal insulation work at all stages of construction. You should decide from the very beginning what the attic walls will be like. If they serve as sloping surfaces of the roof up to the ceiling, then the roof slopes will be insulated. In the event that vertical wall structures are installed, thermal insulation is installed on the affected areas of the roof, walls and adjacent areas of the floor.

Thermal insulation is installed in used areas

Work order

Before you begin thermal insulation of the attic, the insulation cake should be protected with a layer of waterproofing. This work must be done before laying the roofing material, otherwise it will not be possible to achieve complete tightness of the heat-insulating carpet. They begin to lay the film membrane directly on top of the rafters. The work is carried out from the bottom up, overlapping the previous canvas by 15 cm and gluing the joint with special tape. There is no need to tighten the film; it is better to leave a little slack. A deflection of up to 20 mm per 1 linear meter of material will be enough to prevent the membrane waterproofing from breaking with the onset of winter frosts.

To attach the film to the rafters, it is best to use a construction stapler. If such a tool is not at hand, then the waterproofing can be nailed with galvanized nails with wide heads.

You should think about protecting the thermal insulation pie from moisture at the stage of roof construction.

To ensure normal ventilation of the space between the film membrane and the roofing material, lumber with a thickness of at least 25 mm is used as lathing. They are attached to the rafter legs using corrosion-resistant screws or galvanized nails 50–70 mm long.

To avoid accidental damage to the waterproofing film, holes are made in the sheathing in advance. If the roof is covered with a soft roof, then it is mounted on the sheathing solid base from particle boards

, OSB or moisture-resistant plywood. Metal tiles, slate and other rigid roofing materials are attached directly to the sheathing elements.

- Then installation is carried out from the attic side. To avoid making mistakes, you should follow the order of work:

- The mineral wool panel is cut into pieces, the width of which is 2–3 cm greater than the installation pitch of the rafter legs.

Standard width roll thermal insulation is 1.2 m, therefore, for ease of installation, you should choose the same or halved distance between the rafters. In the latter case, the insulation is cut lengthwise, producing two sheets 0.6 m wide.

- Cut insulation boards are laid in the spaces between the rafters. Initially, the thermal insulation will be retained due to the installation “by surprise”, so each sheet is first pressed in the center, and then its edges are tucked in so that the insulation does not protrude beyond the rafters.

- The mineral wool is covered with a vapor barrier membrane. As in the case of waterproofing, strips of material are laid horizontally, from bottom to top, with an overlap of at least 10 cm. The joints are taped, and the film itself is secured to the rafters with staples.

- The bottom sheathing is made from lumber 2.5 cm thick. In the future, plasterboard structures or other finishing material will be attached to it.

The insulation layer is covered with a vapor barrier membrane, on top of which the sheathing slats are stuffed

Sometimes it is necessary to equip an insulated attic in a house with already installed roof. In order not to dismantle the roofing material, the waterproofing membrane can be installed from the side of the room. To do this, the rafters are wrapped in film, and the material itself is attached to the sheathing. The disadvantage of this solution is that the wooden roof structures remain unprotected if moisture begins to leak inside for some reason.

Video: thermal insulation of the attic floor with mineral wool

Features of insulating an attic roof from the outside

If the design of the attic space involves the presence of wooden beams on the walls or its dimensions do not allow using a single centimeter of space, then the roof is insulated from the outside. It is best to do this at the stage of roof construction, since otherwise you will have to remove the roofing material.

Insulation of the roof from the outside can only be done with rigid thermal insulation. The best material in this case extruded polystyrene foam is considered. As noted above, such a coating does not require vapor barrier, so the insulation cake consists of fewer layers:

- slab thermal insulation;

- waterproofing membrane;

- sheathing with ventilation gap;

- roofing material.

The main advantage of roof insulation from the outside is the uniformity of the thermal insulation layer. An undoubted advantage is the absence of cold bridges and the possibility of inspecting and repairing rafters without dismantling the roofing material.

The method by which the attic is insulated from the outside will increase inner space attics and use rafters as decorative elements of the interior

Work order:

All that remains to be done is to lay and secure the roofing material. Rigid types of coverings are attached directly to the sheathing, so the distance between the beams should be taken into account at the stage of its installation. Under soft roof equip a solid base made of OSB or plywood, which is protected with a layer of waterproofing. In this case, there is no need to install a waterproofing membrane on top of the insulation.

Video: everything you need to know about attic insulation

Thermal insulation of an attic room, in addition to actually preserving heat inside, allows you to solve a number of other problems. High-quality insulation will prevent overheating of the roof summer time, which means the room will be as comfortable as in any other room. In winter frosts, the thermal insulation cake will prevent snow from melting and ice from forming, and during rain or hail it will serve as protection from noise. It is only important to take into account the features of various insulation materials and carry out the work competently, taking into account the rules and installation technology.

Share with your friends!Attics, invented back in the 17th century, have been massively popular among people in our country for several years now, turning a dusty attic into a living space. comfortable life. It expands usable area home even at low cost.

Attics can be divided into summer and winter. This means whether the attic is insulated (or poorly insulated) or not. If you follow the advice of experienced builders, it is advisable to equip it a year after the construction of the house in order to avoid deformation and cracking of the material, which is inevitable due to the process of natural shrinkage of the house.

A more preferable option is to arrange the attic space at the stage of developing the house project. But this doesn’t always happen, so the attic is often arranged later. What options exist for this, and how it is technically implemented is the topic of another article, but we will talk about attic insulation, which is subject to more stringent requirements than for insulation of external walls due to large heat losses and a larger area of contact with the external environment.

Before insulating the attic, it is necessary to carefully inspect its internal structures. If necessary, they must be supplemented, strengthened, or somehow adapted to the installation of the selected insulation.

Choosing insulation for the attic

Today on the construction market you can see a wide range of materials that will perfectly cope with the task. But when choosing, the question arises, which insulation is better for the attic. Generally speaking, the insulation must be reliable and of high quality.

“Cotton” insulation is a material that is obtained from mineral or organic fibers - stone wool, glass wool and so on. Cotton insulation fibers do not have closed pores. There is also a special class of foil wadding insulation, which is covered on one or both sides with a layer of aluminum foil.

“Foam” insulation are materials that are produced by foaming polymers, both in the usual way and by extrusion (extrusion). They are conventionally divided into materials with closed and open cells. This also includes the so-called liquid polyurethane foam, which is applied directly to the inner surface and in a few seconds increases in volume several times, filling all the voids.

A well-insulated attic roof usually consists of several layers, where there is not only insulation, but also a vapor barrier and a waterproof and windproof membrane.

Materials for attic insulation such as stone wool and glass wool are very popular in our country due to their resistance to high temperature and deformation, although more modern materials also do not stand aside.

Criteria for choosing a good thermal insulation material

- thermal conductivity indicators;

- volume and weight of insulation;

- maintaining shape stability;

- vapor permeability;

- flammability;

- soundproofing characteristics;

- durability.

A little more detail

THERMAL CONDUCTIVITY. Taking into account the specific location of the attic, this figure should not exceed 0.04 W/m°C. Modern manufacturers often indicate several parameters of thermal conductivity under different operating conditions - at temperatures of 10 ° C and 20 ° C and at two humidity categories - A and B. Taking this into account, the thickness of the insulation for the attic should be calculated as accurately as possible. And to do this, you can either turn to specialists, or you can figure it out yourself by turning to SNiP II-3-79 “Construction Heat Engineering”.

WEIGHT AND VOLUME OF INSULATION. In this parameter, insulation materials can differ significantly from each other. When choosing, do not forget that truss structure The roof must support the weight of the insulation. Unlike light insulation, heavy insulation can bear the weight of both the roof itself and snow in winter.

FORM STABILITY. This parameter is more relevant for pitched roofs with a large angle of inclination, where the insulation can slide and partially collapse under its own weight. This can also be observed during poor-quality installation, when the material slides, also forming bare spaces, and this, as practice has shown, leads to heat losses of up to 40%. Therefore, when choosing insulation, you must pay attention to how long and under what conditions the insulation will retain its properties. geometric shapes. But you won’t find such a parameter as “shape stability” on the packaging, so you need to focus on a special pictogram indicating the specifics - “for pitched roofs.”

VAPTOR PERMEABILITY. Why does this question even arise? Moisture has a negative effect on thermal insulation characteristics materials, so it is necessary to protect it. To do this with inside The insulation must be parasacite. To eliminate moisture that has entered the thermal insulation material, a ventilated air layer must be left between it and the outer (waterproofing) layer of the roof.

Vapor permeability is one of those indicators that can vary greatly from one type of insulation to another.

What are considered good or bad indicators? For example, “cotton” insulation has good vapor permeability, although, when passing through them, steam turns into water, and, despite the fact that the fibers of such insulation are made with the addition of water-repellent additives to reduce wettability, some of the passing condensate may still remain, worsening the thermal insulation properties. To avoid this, an additional vapor barrier layer is installed on the side of the room.

“Foam” insulation (especially with a closed cellular structure) allows virtually little vapor to pass through, but only foil insulation and glass are completely vapor-tight.

To avoid the greenhouse effect, you need to properly arrange internal air exchange, even if you decide to use insulation made of mineral wool with good “vapor permeability” abilities, you need to design vents or efficient ventilation system. But the best option would be not to rely on the vapor permeability of the insulation, but to organize a separate vapor barrier layer.

THE INDICATOR OF FLAMMABILITY OF A MATERIAL is important for ensuring a safe human life, because no one is immune from unfortunate accidents. Therefore modern construction material should be as close as possible to “NG” - non-combustible materials.

In fairness, it must be said that at the epicenter of the fire and brickwork, both metal and reinforced concrete significantly lose their load-bearing capacity.

SOUND INSULATION CHARACTERISTICS are also important for a comfortable life. Even if no one lives in the attic above you, rain, hail and even strong winds can make you uncomfortable. As for insulation, cotton insulation takes the lead here. Thanks to their fibrous structure, they perfectly absorb noise. But if you want to achieve the maximum noise-insulating effect, then it is best to use foam insulation together with cotton insulation.

DURABILITY usually depends on stability and water absorption.

As already mentioned, the arrangement of thermal insulation requires accurate calculations taking into account the climate in the region and the purpose of the building. But a person does not always bother himself with any calculations, doing everything according to the principle “whatever there is enough money for.”

Information for those who like to do things by eye

In this case, perhaps, it would be best to be guided by the principle, the more, the better (if, of course, the design can withstand). The most popular insulation in Russia today is made of basalt wool. In temperate climates, it will be sufficient if the thickness of the attic insulation is 18 cm. Although in regions with a warm climate, a layer of 10 cm will be more than sufficient.

But if you live in a colder region, then a 25 cm layer of thermal insulation will guarantee you warmth even according to preliminary calculations. And to eliminate cold bridges, the wool is laid in three layers, ensuring overlap at the seams. If the height of the rafter board is not enough, then counter battens are stuffed from the inside and the rafters are sheathed. From the inside, everything is lined with a board, under which a vapor barrier must be attached.

To retain heat inside, foil materials are often additionally installed. With all this, special attention should be paid to the vapor barrier, because to insulate the attic, you should not allow moisture to reach the heat insulator, and unwanted condensation under the roof will not give you pleasure.

Today, polyurethane foam is also popular, which makes it possible to obtain a monolithic layer of insulation without cold bridges, and the effect is achieved even with a smaller thickness of its layer. Polyurethane foam has the lowest thermal conductivity coefficient. In hot weather it prevents air heating, and in winter it prevents heat loss and the formation of icicles.

In terms of density, it is necessary to choose a material with indicators from 15 to 35 kg/m³.

When insulating an attic roof, do not forget about insulating its ends!

Even when insulating the attic, there are simple rules:

- the higher the requirements for thermal insulation material, the more expensive it is;

- when choosing a method for insulating an attic, you can use not one type of insulation, but two, so that the advantage of one material compensates for the disadvantage of the other;

- The choice will largely depend on the roof design.

But, according to experts, there are no exclusively “bad” or exclusively “good” thermal insulators, there is only their incorrect use.

It should immediately be noted that windproof film in this case, it is fixed in exactly the same way as when insulating materials in mats.

- Wet application of the material is carried out using special equipment that sprays material mixed with water and a special glue.

Ecowool is sprayed under pressure, so the material fills all the gaps and cracks, thus creating good heat and sound insulation.

After spraying, excess material is removed using a special roller and at the same time leveled.

Another installation option could be to fill closed wall or floor cavities with wet ecowool.

A vapor barrier film is first fixed and stretched on the walls from the inside, a hole is made in it through which the space is filled thermal insulation material — ecowool.

- The dry insulation method is excellent for laying ecowool on the attic floor. This method can be done manually or using the same equipment.

If insulation is done manually, the insulation is simply removed from the packaging and loosened. Then it is distributed between the floor beams and compacted. The thickness of the layer should be equal to the height of the floor beams.

However, it is better to install the insulation under pressure using special equipment.

Ecowool is covered with a vapor barrier film on top, and slats 20 ÷ 25 mm thick are placed on top of it on the beams - this lathing will create the necessary ventilation gap. After this, the floor covering is laid.

Video: “dry” method of application ecowool

Sputtering polyurethane foam

It is increasingly used for thermal insulation of buildings both inside and outside. It is especially popular for frame buildings and attics.

The only hitch in carrying out the work yourself may be complex equipment for spraying polyurethane foam, without which it will simply be impossible to do. There is an option to rent a device from a specialized company, but this will also be expensive, not to mention buying it. In addition, you need to learn how to configure it correctly and have at least basic skills in working with it.

Perhaps it will be easier and cheaper to invite a specialist who will do this work quickly and accurately. For small volumes, the process can be started and completed in one day.

Spraying can be carried out on any surface - smooth and rough, plywood, metal or even a dense vapor barrier film reinforced with rope weaving.

Sprayed polyurethane foam forms a seamless surface, while penetrating into all small and large gaps and sealing them hermetically.

PPU can be sprayed directly onto the inner surface of the roof and sewn on top decorative material- this insulating layer will be sufficient if the building is located in a climate zone with mild or moderate winters.

Video: insulating the attic with sprayed polyurethane foam

So, each material has its own advantages and disadvantages. Of course, the price of insulation, the complexity or availability of its installation play a big role, but still the issues of thermal insulation efficiency and safety should come to the fore, so you need to focus on the material that will create the most comfortable atmosphere in the attic room and, at the same time, bring minimum damage to the health of the residents of the house.

find out detailed information, from our new article.

It is a known fact that in Russia, at least 5 months a year (in the northern regions - all 8) a heating system operates in any living space of the house. And under open air at this time there is a noticeable cold. And, if we are talking about the attic, which has the largest area of contact with the open atmosphere, then you should take this seriously. After all, in winter there is a serious temperature difference on both sides of the roof and the gables of the attic, which is why the heat flow always moves towards the source of the cold - out. And the task of insulating the attic is to stop this flow and minimize heat loss, for which purpose materials with low thermal conductivity are used, in simple terms - insulation.

But it's not that simple! Therefore, first of all, it is important to decide which insulation is best for the attic - based on the materials of its manufacture, planned operation and expected internal temperature. With us you will easily understand everything!

Requirements for attic insulation

So, what insulation can be called the best for an attic roof? It all depends on what exactly you expect from it, because for thermal insulation of the attic of baths and saunas, where fire-hazardous chimneys, it's hard to think of something better basalt insulation, which can withstand up to 1000°C, but for insulating an ordinary attic summer house This is a losing option: mice will eat everything. But what do you need?

Each material has its own valuable properties, and its disadvantages. When choosing a material for attic insulation, most people are interested in such aspects as:

- Thermal insulation qualities.

- Economical.

- Durability.

- Ease of installation.

- Water-repellent properties.

- Noise insulation

- Versatility

But let's approach this issue from a professional perspective. Of course, the most valuable quality is still the ability of the insulation to retain heat:

The second important point: is it possible to insulate both the pitched walls of the attic and the floors with the same insulation? Therefore, pay attention: if the name of any insulation contains the word “station wagon”, then it can be used both for roof insulation and for walls, floors and ceilings. For finishing the attic, this is the best option: we buy the material we like and immediately finish the walls, gables, and floor. Fast, and less problematic - now all insulation will have the same properties and will last the same long time.

And now about sound absorption. But why does the roof need soundproofing, since there are no neighbors behind it, no trampling feet? Let's put it this way: those in whose house roofing made of metal (profiles, metal tiles), and even if it rained once, such questions do not arise. It is clear that a non-residential attic can still be left without sound insulation, but when arranging a residential attic, it is important to understand that comfort is, first of all, silence.

The choice of insulation for the attic directly depends on what it is made of Basic structure: made of reinforced concrete, metal or wood. And the more flammable the material of the same rafters, the less flammable the insulation should be, so that later the “bohemian” space does not burst into flames like a match.

And finally, for attic insulation, due to the presence of constant water vapor in the room, the most valuable quality is still hydrophobicity:

Now let’s talk about which insulation material is most suitable for the attic roof of your particular home.

How do you insulate an attic today?

The most popular materials for attic insulation are insulation based on mineral wool and fiberglass, and newer and still little studied in everyday life are ecowool, foil boards and natural materials.

Glass wool: you want it and it hurts

Fiberglass wool is one of the most inexpensive options. Its installation is simple, there is no toxicity to humans when closed, and the lack of organic matter makes such insulation unattractive to small rodents. And the most important thing is that glass wool has a second degree of fire safety, which is quite a lot.

The only significant drawback is fine glass dust, which gets on the mucous membranes of the eyes and causes damage, and the skin begins to itch very much. Those. For such work, you cannot do without special closed clothing, gloves, a respirator and glasses with rubber elements. Clothes after installation work will have to be destroyed - no amount of washing will save it. Let us note that those who have ever, through carelessness or stupidity, worked with glass wool with their bare hands, then avoid it throughout their lives.

Mineral wool: priority is warmth

Mineral wool is much more flexible in this regard. It consists of synthetic fibers and small crumbs of stone, clay and much more. Fiberglass may also be present in it, but not much. Thanks to its light weight, excellent vapor permeability and low hygroscopicity, this material can hardly be overestimated. On sale you will find it both in the form of rolls and in the form of slabs, the most different sizes and thickness - from 50 to 100 mm.

Heat is retained in mineral wool due to its multilayer structure, in the layers of which air is retained. Moreover, this insulation is also vapor-proof, i.e. "breathes". And unlike foam plastic, small rodents do not grow in mineral wool.

Among the disadvantages, it can be noted that mineral wool quickly collects dust and is not resistant to moisture, and therefore its waterproofing must be thought out especially carefully. As for the fire safety of mineral wool, quartz sand can even retard fire if such a nuisance happens.

The most popular brands of mineral wool for attic insulation are Izover and Ursa.

Isover as an insulation material is valuable not only for its thermal insulation qualities - it has high noise absorption. That's why, if you are planning to equip the attic of your house as a nursery or home cinema, then opt for this insulation. Then your evenings will be relaxing!

Where does this property come from? It's all about the specially created air lenses of this insulation. And, as you remember from the school physics course, materials of different densities together significantly impede the passage of sound vibration. For example, after insulating a roof with metal tiles with Izover, the sound of rain will no longer be heard.

But Ursa insulation is supplied for sale in a convenient soft roll. As the manufacturer promises, Ursa insulation is made from a natural composition - fiberglass and quartz sand. There is nothing harmful or dangerous for humans or the environment here. And at the same time, it retains heat remarkably well, absorbs noise, and is not liked by insects and rodents due to its inorganic origin.

And mineral wool lasts for 50 years, without any signs of rot, bloom or decay.

Basalt wool: an environmentally friendly option for mineral wool

The safest and most known species mineral wool is basalt. Let us remind you that basalt is a natural material, a stone that is melted in a factory and turned into thin fibers. Yes, this insulation really does not burn up to 1000°C - after all, this is the melting point of the stone. But mice really adore him, although at such a height as the attic, it’s easier to deal with them, don’t you agree?

Among the popular brands of basalt wool is Rocklight: excellent heat and sound insulation, non-flammability, ease of installation. In addition, the price of this insulation is pleasantly surprising, because... the quality is quite high. The fire safety of this insulation is excellent: it can withstand even temperatures of +1000C for some time.

Rocklight is also quite durable, does not cake, and its vapor-permeable properties are maintained throughout its entire service life. Fungus never grows in this insulation; the walls “breathe,” which is important for an attic.

Extruded polystyrene foam: an easy solution

Extruded polystyrene foam is attractive to many due to its simplicity and ease of installation, as well as the absence of itching on the skin. None discomfort! The insulation process itself looks like you are putting together a puzzle. But the price of this insulation, of course, will surprise you a little - the cost is low.

But the attic is rarely insulated independently, with polystyrene foam alone: this material is more valuable in combined insulation. Like in this example:

Polystyrene foam: cheap, cheerful and risky

One of the most inexpensive roof insulation materials. First of all, polystyrene foam is good because it can be easily installed with your own hands, without calling any specialists, and it is especially convenient for sloping walls of an attic or roof.

Polystyrene foam has several density levels. That is why this material has good sound insulation, and therefore about the loud noise of knocking on metal roofing the drops can be forgotten for a long time. Polystyrene foam is also good because it does not shrink over time.

The rigidity of the foam used determines how strong the material will be under compression and bending. But the denser the material, the greater its flammability will be, so to insulate the roof, do not try to choose the hardest insulation materials - after all, you will not walk on them.

PPU: we reach the most inaccessible places

When the attic is insulated from the inside with sprayed polyurethane foam - polyurethane foam - the housing under the roof will be completely residential. And, I must say, this is really excellent thermal insulation, and many other qualities:

- PU foam has excellent thermal protection properties: only 2.5 cm will protect the attic from cold sweat in the same way as 8 cm of mineral wool. Only polystyrene foam can be called fairly close in thermal conductivity to this material, which copes with its task almost twice as bad.

- Here is another valuable advantage: when insulating with polyurethane foam, you will not need either a frame or special fasteners. And the most valuable thing is that PU foam has no seams, whereas seams are always cold bridges.

- Also, if hoods and chimneys pass through the attic, around which it is especially difficult to create a seal, give preference to this insulation. The same applies to any complex shapes and surfaces.

- And finally, what do you think is the biggest problem with attic insulation? Of course, moisture! And to protect yourself from it right under roofing pie not so easy. Unless, of course, we are talking specifically about polyurethane foam, which does not dampen at all and easily contacts any roofing material. And at the same time it is also vapor permeable!

- Polyurethane foam also has excellent adhesion to any surface.

- Unlike expanded polystyrene, which is close to polyurethane foam in its thermal insulation properties, this material is also vapor permeable, i.e. "breathes". What a valuable quality for an attic!

- PUF is not eaten by mice, is not worn down by insects, it does not rot or mold.

The only disadvantage of such insulation is that it is impossible to spray polyurethane foam on your own, without equipment. You will have to either hire an entire construction team or get a competent contractor.

Natural wool: environmentally friendly, but problematic

Yes, in some areas, especially in the Caucasus, it is actively used as roofing insulation. natural wool and felt. And these are completely acceptable materials: wool felt is listed in SNiP as a vapor-permeable building material. And its insulation coefficient is the same as that of basalt insulation - 0.045 W/mS.

Most often, such wool is placed in bags, and in dense rows they are placed on the roof. But sometimes they are used in roofing pie as a full-fledged insulation, pre-treated to prevent unpleasant odors.

Wool in the Caucasus is very cheap due to the large number of sheep. Therefore, it is easier to insulate with this material, which can be found in excess, than to purchase ready-made and expensive ones. And the disadvantages are quite significant: these are insects and rodents who simply adore everything natural.

Ecowool: simple and environmentally friendly

Another very interesting new product became the so-called ecowool. It is made from newspaper waste, finely cut and processed so that it does not burn or rot. As for the fears of many citizens that newspapers contain dangerous lead, this technology has long been a thing of the past.

True, it is unlikely that you will be able to insulate an attic with eco-wool yourself - construction companies are engaged in this new product.

Now we come to practice. And the last question that you ask yourself when purchasing the selected insulation for the attic is whether to buy it in mats or rolls?

What is more convenient: rolls or mats?

In fact, the form in which this or that insulation is sold plays a big role for many ordinary people. Some people prefer to work only with slabs as they are more convenient, but for the majority, rolls seem rational: rolled out and secured, what could be simpler?

Let's put it this way: with roll material really convenient to work with. They rolled it out to the required length, cut it, and rolled the cut piece. They brought a new skein to right place, rolled out again, straightened and secured. Roll insulation is also convenient because, with a standard distance between rafters of 61 cm, the roll can be easily cut in half with a regular knife, and its halves will fit perfectly into their niches - just roll them out:

But in practice, for many, packing rectangular slabs turns out to be less convenient, which leaves the most waste. But it is easier to transport, and the insulation in it does not bend, like in a roll, which is a critical issue for many materials:

And finally: when buying insulation, be sure to pay close attention to the integrity of the packaging, otherwise you won’t end up with problems later. The insulation packaging must be completely sealed, slightly compressed, without a single scratch or torn film. This is the only way to prevent moisture from getting to the insulation before installation begins.

Now imagine what happens to insulation in poor-quality packaging: moisture and water vapor penetrate the material through holes and slits (and this stuff is everywhere), the insulation gets wet in places and changes its geometry. On site, you unpack the roll or slabs and begin installation, and then it turns out that the insulation, swollen and heavy in places, does not fit together in any way, the cracks are visible even to the naked eye. Having somehow suffered, you cover all this stuff with clapboard or drywall - and that’s it! We don’t leave finished insulated walls unfinished, even for several hours - why? And as a result, the not dried insulation ends up in a closed and dark space - perfect place for mold development. The consequences are usually not pleasing to the eye, but you will know about their presence by unpleasant smell from under in just a few weeks.