The emergence of a popular floor covering is rooted in the distant past. For more than two centuries, production technology has been acquiring new improved characteristics and qualities. With the development of the chemical industry and the advent of artificial materials, there was a change in the structure of the previously patented oil-based canvas - linoleum.

Linoleum is still one of the most popular floor coverings today. Such popularity of the product is due to the fact that linoleum is considered a fairly durable and highly functional material.

The versatility of linoleum is that it allows you to make a choice from a wide range in favor of the option suitable for the solution.

Main product differences

Linoleum is a material with general consumer accessibility. Modern flooring is quite popular. This is facilitated by a wide range of existing coatings, which have the following characteristics:

- Color solutions. The variety of shades and patterns of the material allows you to make a choice, focusing on the taste and style of the selected option for various types of premises. In terms of drawings, this material can imitate any natural materials: stone, wood, or simply have an original ornament.

- Strength. Unlike natural floor coverings such as wood or ceramic tiles, linoleum does not crack over time.

- Softness. The structure has a springy base, which is the reason for the pleasant and comfortable tactile feature.

- Price. Along with budget options, linoleum is also represented by premium options.

- Ease of installation. The technique of laying flooring is simple to perform. To date, laying this material is within the power of both professional craftsmen and a simple layman.

In modern production, commercial linoleum should be distinguished, which is divided into two groups:

- Homogeneous linoleum.

- Heterogeneous linoleum.

Homogeneous and heterogeneous linoleums differ in composition and technological characteristics:

- Homogeneous linoleum, in fact, is a coating consisting of one layer. The structure of this linoleum is homogeneous throughout its thickness. Also, the material has special strength and elasticity. Basically, the texture of a homogeneous coating is a simple marble pattern. This material is used as flooring in rooms with high traffic and industrial load: trading floors, halls of large premises, railway and bus stations, airports.

Consider the composition of the elements of homogeneous linoleum:

- PVC. The polyvinyl chloride used protects the coating from mechanical damage. The disadvantage is a slight smell, which disappears over time.

- Sand is quartz.

- Lime industrial.

- Tint pigment.

The constituent components are mixed in a multi-stage way, and then the mixture is processed in special devices. Then the mixture is passed through the shafts, which give the material the desired width and thickness of the future flooring. The wear resistance of homogeneous linoleum is affected by the thickness of the coating. The greater the thickness of the product, the stronger and more stable the floor covering will be.

Over time, the coating, subject to huge production loads, can be damaged, but this issue is also resolved positively. Restoring linoleum is not difficult, it is polished, thereby removing the upper damaged layer, and a special protective mastic is applied.

Heterogeneous linoleum is a coating consisting of several layers (heterogeneous means heterogeneous in composition). Modern heterogeneous flooring allows it to be laid on any type of surface. The method of its manufacture is much more complicated than the production of homogeneous linoleum.

Heterogeneous linoleum is divided into the following types:

- commercial;

- semi-commercial;

- domestic.

The types of heterogeneous coating differ only in the thickness of the protective layer, which significantly affects the price of the product.

The composition of heterogeneous linoleum includes the following components:

- The base consists of their polyvinyl chloride.

- The next layer of fiberglass, it is this that allows you to maintain the desired surface dimension.

- Next comes the embossed layer. A thin layer of PVC is not limited to color schemes and decorative elements.

- The outer layer of PVC layer is protective. Thanks to the top film, the coating is protected from external damage and wear.

The number of layers applied by each manufacturer is different. It usually ranges from 2 to 6.

Heterogeneous type coatings are absolutely suitable for any kind of premises. Linoleum has proven itself in rooms with a large crowd of people, it can withstand any mechanical stress. The positive characteristics were also influenced by the fact that the material is resistant to fire, and this is an important fact, since the coating is widely used in children's institutions.

The service life exceeds ten years.

Specification difference

Giving preference to such a floor covering as linoleum, you should thoroughly study all the features and technical characteristics of this product. Of the widely used types, each of the presented coatings deserves special attention.

A homogeneous single-layer coating, in fact, is the most wear-resistant, since the pattern is practically not erased.

The characteristic features include the following:

- The long operational period of service exceeds twenty-five years.

- PVC is relatively safe for health.

- There are no toxic substances.

- Protected from fire.

The advantages of homogeneous linoleum include, first of all, its high strength, color fastness is dense and evenly distributed throughout the layer. Since industrial lime is present in the composition of the product, it is not recommended to allow excessive contamination, this is fraught with deep contamination of the canvas. It will be possible to remove dirt from the surface only with the help of a grinder, followed by the application of special mastic.

Heterogeneous linoleum in terms of functional and technical characteristics is in great demand among consumers. When purchasing this type of linoleum, carefully study all the letter designations and the classification scale. The correct choice of the purchased canvas depends on these parameters.

For example, if the packaging is labeled as class 21-23, then the product is used only in domestic premises. If there is a class 31-34, then laying is carried out exclusively in public places. Class 41-43 is used in industrial premises, in chemical laboratories, as these types are resistant to chemical reactions. The operational life of a PVC coating is much less than that of a homogeneous material, it is only 10 years.

Household linoleum is probably the easiest to classify characteristics of all PVC coatings. It is used only in domestic premises, as it is not designed for serious loads and high traffic. The coverage of the protective PVC layer varies from 0.15 mm to 0.35 mm.

When giving preference to household flooring, please note that the service life will be short. However, a huge selection of colors and the budget cost of the material will appeal to everyone.

What is the difference between laying linoleums?

As mentioned above, interest in linoleum does not subside to this day. Gone are the days of the Soviet Union, where the flooring was not distinguished by the intricacy of design solutions. Such a coating evoked sadness and dullness. In the modern world, the malls have been replenished with a variety of materials that satisfy any consumer whim.

Since the flooring of this type is quite flexible, laying it will not be difficult, even for beginners. First of all, you need to stock up on all construction equipment: a knife for cutting linoleum, a substrate (if any), an iron ruler, a plinth, glue, a roller for rolling out a surface, a hammer.

Following the exact dimensions of the room, you should correctly cut the flooring sheet.

The main types of laying linoleum should be distinguished:

- Dry laying method.

- With glue.

- Simple styling.

The dry laying method consists in laying the material without the aid of glue or mastic. You will also have to take into account the fact that the canvas shrinks. In expanded form, the coating should lie for several days so that it "acclimatizes". Be sure to leave allowances around the edges.

If the canvas has a pattern, the parts are adjusted accordingly to the elements of the canvas. You will need double sided tape to attach.

Laying on glue is the most reliable of all methods. The method is also quite easy to use. When applying glue to the inside of the canvas, please note that a draft will interfere with the installation process. Applying the canvas to the surface, go through the rolling roller. The next step is to let the surface dry completely.

How to take care of them?

The quality and structure of the material, as well as the methods of care, differ significantly. Polyvinyl chloride has a unique property of protection against premature coating defects. The top layer prevents dirt from entering the linoleum structure, thereby simplifying maintenance. Cleaning is carried out, depending on the operation in a particular room. The material is unpretentious and does not require professional detergents and cleaners, cleaning is carried out with water and a soft cloth.

Compared to homogeneous linoleum, this type of coating does not require the use of special mastic.

According to its characteristics, homogeneous linoleum has a porous structure, which is why the surface is easily contaminated during long-term operation. To do this, you must carefully monitor the condition of the surface. If, nevertheless, heavy contamination cannot be avoided, then cleaning with a grinder with a cleaning agent will come to the rescue. She carefully clean the top, contaminated layer of the surface. Next, a layer of mastic is applied, which will further protect against contamination and increase the period of use of the coating.

How to choose the right product?

Taking care of comfortable living conditions, people carefully choose any building material that will not only save the budget, but also will not harm health.

To do this, it is necessary to be based on the characteristics of the products offered:

- The presence of an unpleasant odor. If there is the presence of irritating odors, which indicates harmful chemical components, then it is better to abandon this material.

- The weight. Well-known manufacturers do not violate the technological process of manufactured products. Therefore, a high-quality coating has a heavy weight, because all layers are observed and correctly applied.

- Products should be purchased only in specialized stores. After all, only there you can get reliable information about the availability of certificates.

- The surface pattern must be clear and evenly applied.

- The thickness of the linoleum must be within the limits of GOST. For a homogeneous floor covering it is 1.5-2 mm, for a heterogeneous floor covering it varies from 0.4 mm to 0.6 mm.

Linoleum is a practical, beautiful material that is used for laying flooring. You can install the product yourself. In addition, homogeneous linoleum has many other advantages.

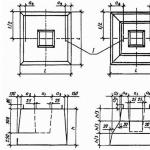

Coating structure

Coating structure

Its basis is a layer of polyvinyl chloride, which consists of various fillers. Among them are:

- plasticizers,

- lime,

- dolomite,

- quartz sand.

In order for the product to have the desired shade, pigment is added during production.

It should be noted that there is not only homogeneous, but also. These two types of material differ in the way they are produced. Homogeneous linoleum is made from a homogeneous mass. That is, its structure remains the same, no matter how thick the material has. Heterogeneous is made from several layers, most often - 4.

A feature of the coating is that the color penetrates its entire thickness. That is, the shade remains bright and does not fade for a long time. As for the pattern, it can be applied along or randomly.

Advantages and disadvantages

The material has the following advantages:

- Elasticity.

- Good flexibility.

- Wear resistance.

- Low level of abrasion.

- Antistatic properties.

- Ease of installation and maintenance.

However, heterogeneous linoleum has many advantages, for example: you have a large selection of colors. In addition, a homogeneous material is inconvenient in that white spots can be seen on it periodically, which are removed with great difficulty. Also, this product is very expensive.

During the purchase of this material, you should pay attention to the technical specifications, as well as to the marking icons on the packaging. For example, if you see the sun on a pack, this means that the flooring is resistant to ultraviolet rays. If there is no lightning icon, then this linoleum does not have antistatic protection.

Pictograms on linoleum packaging

Pictograms on linoleum packaging Material technical parameters

Homogeneous linoleum has the following characteristics:

Thickness:

- thin layer - 1.5-2 mm;

- thick layer - 2-3 mm.

Wear resistance classes:

- 33-34 - material for office rooms, which are characterized by a high level of load;

- 41 - commercial linoleum, which has poor resistance to mechanical stress. Therefore, it can be used only in those rooms in which there is little traffic;

- 42 is a more durable material that can be laid in rooms with an average load;

- 43 - this material is the most durable, therefore it can be used in rooms with a high level of mechanical load on the floor.

Abrasion level:

- T is the highest value. It means high quality of the material, and a low amount of impurities in it;

- P is the average strength indicator. The amount of impurities is 40%;

- M - this material has low strength. The level of additives in this case is 40-60%;

- F is the lowest grade material that has the lowest strength. In this case, more than 60% of additives are present in the composition of the floor covering.

These are the main technical specifications that you need to know when purchasing the material.

Mounting Features

If you want to purchase homogeneous linoleum, and its characteristics suit you, then you can proceed with its installation. The installation of the presented product is no different from the installation of heterogeneous linoleum. It provides for the following actions:

How to join canvases correctly?

Commercial homogeneous linoleum is often used for laying in residential premises, as well as heterogeneous. In order for it to serve for a long time and with high quality, it is important not only to choose and glue the canvases correctly, but also to connect them well together. This can be done in several ways:

- Hot welding. It uses a hair dryer and a special welding cord, which is laid between the sheets of linoleum, melted with hot air and connects them. The gap between the canvases should be commensurate with the cord.

Hot welding of linoleum in stages

Hot welding of linoleum in stages - Cold welding. In this case, the specialist uses a special liquid glue, which must be poured into the gaps. After drying, the residue must be carefully removed.

- Iron connection. In this case, a plastic film lubricated with PVA glue is taken. Further, it is placed under the joints, covered with material and ironed with a not very hot iron.

Remember, if the material is correctly selected and laid, all the necessary characteristics are taken into account, then the floor covering will last a very long time. However, it will not lose its appearance.

Leave your opinion and comments on the article in the form below!

In the modern world, there are a huge number of different materials for home improvement. Linoleum is a comfortable and practical floor covering. Many have already appreciated its excellent performance. However, homogeneous linoleum is especially popular today. This flooring is very easy to install. It is important not only to choose the right product, but also to perform the installation qualitatively. Experienced specialists recommend that you familiarize yourself with all the features and nuances before buying.

Advantages

Linoleum commercial homogeneous has a number of advantages.

Here are just a few of them:

- high wear resistance;

- elasticity;

- ease of operation;

- antistatic.

Composition and characteristics

Homogeneous linoleum is produced from high-quality raw materials using the latest technology. For the manufacture of this finishing material, dolomite, lime and quartz sand are used. As for the physical characteristics of homogeneous linoleum, they exceed all expectations. This material is extremely resistant to aggressive environments and chemicals. The value of residual deformation in any situation does not exceed 0.1 mm. The service life of such a coating can reach a quarter of a century.

Main criteria

How to choose the right commercial homogeneous linoleum? The price in this case is by no means the main thing. You can check the coverage for quality right in the store. It is enough just to bend the corner of the linoleum. If it turns white at the fold, it means that it contains additional components that are used to reduce the cost of the finished product. If a crack forms during bending, then it would be better to refuse the purchase altogether. Many impurities can significantly reduce the quality of homogeneous linoleum. To choose a good coating that is highly resistant to wear, you need to carefully study the markings on the price tag. If necessary, you can ask the sales assistant to decipher the entries you do not understand.

wear resistance

There are several grades of wear resistance that Tarkett commercial homogeneous linoleum can be characterized by.

- 33, 34 - linoleum, characterized by high wear resistance. It can be used for laying in domestic premises and offices.

- 41 - used in rooms with low traffic. Possesses poor resistance to mechanical influences.

- 42 - can be used in designed for medium loads.

- 43 - the most durable type of coating. Designed for high patency and able to withstand significant physical exertion.

When studying product specifications, it is essential to understand the difference between abrasion resistance and wear resistance. In the first case, we are talking about patency, and in the second - about the mechanical effect on the surface.

What size coverage is needed?

If you need to cover a large room with linoleum, then most likely you will have to use two or more canvases. The main thing to consider is the presence of a drawing. If it is necessary to join the canvases, it is important to choose the right pieces of material. To fit a large fragment, it may take from 30 to 70 centimeters of linoleum. It is important to buy material from the same batch. Otherwise, the segments may have a different shade. At the same time, you can hardly find a defect in a hardware store. But after laying on the floor, everything will immediately become clear.

Mounting Features

When laying homogeneous Tarkett linoleum on the floor, it is worth remembering a number of features.

- The base for laying must first be prepared. To do this, level the surface with a special mixture or screed. You can also try using wood boards for this purpose.

- Before laying on the floor, homogeneous linoleum should be left for some time in the room. So he can adapt to the microclimate in the room.

- Allowances for cutting material should be 2-3 cm.

- To improve the adhesive characteristics of the adhesive composition, the surface is pre-treated with a primer.

- The adhesive is applied evenly to the surface using a notched trowel. Do not immediately press the coating laid on top of the base. The glue should cure within 20 minutes. After that, you can fix the canvas with a rubber roller. It is necessary to roll out linoleum from the center to the edge, and then across.

- To connect two segments, it is necessary to use the hot welding method. In domestic conditions, you can use an ordinary iron. With it, you can not only process the seams, but also repair the damaged fragment of the product. To do this, it is necessary to put a film lubricated with a simple PVA glue on the joint. After laying the coating, the surface is covered with a thin cloth, and then processed with a hot iron. The filler, when melted, will fix the place of the cut, and the connection will not be visible.

The final stage

Laying work usually ends with the installation of skirting boards and thresholds. There should be a small gap of a couple of centimeters between the coating and the wall. This is necessary because the natural expansion of the material occurs during installation. If the edge is made close to the wall, the surface of the linoleum may swell. It is impossible to restore the deformation on such a coating.

Color options

One of the drawbacks that homogeneous linoleum (2 mm thick) has is a poor choice of colors. Such material will hardly fit into rooms of non-standard design.

For the most part, such coverage is available in the following versions:

- under marble;

- stone chips;

- abstract drawings.

Often homogeneous linoleum is used in office space. Due to its high antistatic properties, a large number of electrical appliances can be installed on such a coating.

Fire qualities

Homogeneous linoleum, depending on its class, may have different technical characteristics. However, one of the important qualities of this material can be called the ability to self-extinguish. The flame spreads poorly on such a surface. Commercial homogeneous linoleum, the thickness of which reaches 2 mm, belongs to the KM-2 class. This group of materials is characterized by low flammability, moderate flammability and the ability to smoke. If the coating belongs to the category RP-1, this means that the flame does not spread over its surface.

Term of use

Long service life is another important characteristic that those who buy homogeneous linoleum rely on. The price of this coating is not too high, but at the same time, the time of its use is comparable to that of a tile. It is worth noting that today in stores the cost of this material is from 400 rubles per square meter. Price depends on color and quality. The manufacturer gives a ten-year warranty for each square meter of linoleum. Practice shows that the coating of this type retains its original appearance for 15 years.

As for the dimensions, all rolls of this material are characterized by a single length - 2 meters. has a wide variety of possible options. As for the thickness, everything here is determined by the EN-428 standard. This means that the density of the protective coating according to the standard is 2 mm. This is more than that of a heterogeneous type material.

Other characteristics

What other important qualities does homogeneous linoleum have? Thickness, fire properties, service life - we have already considered all this. The mass of a square meter of such material is on average 3 kg. Many are also interested in the noise-absorbing characteristics of the material - they range from 6 to 10 dB. With regard to electrical properties, the resistance of linoleum reaches 109 ohms, and the maximum value of the power withstanding voltage is 2 kW.

Due to its excellent performance characteristics, the flooring can be used in high traffic areas such as educational buildings and public corridors. Very often, homogeneous linoleum is used in the repair of schools, kindergartens, catering establishments, shops, hospitals and sports facilities. During production, the coating is carefully checked for compliance with various environmental standards. It is completely harmless to the human body. During operation, this material does not emit any toxic substances, so it can even be used for installation in medical institutions. However, before purchasing this type of coverage, you need to make sure that it has all the necessary certificates. Unfortunately, counterfeit products that are manufactured in violation of environmental requirements are often found on store shelves today.

Conclusion

Can homogeneous linoleum be used for finishing private houses and apartments? Professionals answer this question in the affirmative. This material has a number of undeniable advantages. This is wear resistance, and the absence of toxic fumes, and fire resistance. Such a floor will not be afraid of any loads and blows. At the same time, it perfectly withstands the influence of chemicals and is undemanding to care for. Of course, homogeneous linoleum has its drawbacks. Firstly, the palette of shades of this material is rather poor. Therefore, it can usually be found in public and government institutions. Secondly, high requirements for installation. To achieve the desired result, you will have to properly prepare the base for laying, which sometimes requires additional financial and labor costs.

In the construction industry, there are materials and coatings called "eternal", and one of these is a homogeneous linoleum made of PVC. In addition to polyvinyl chloride, it includes sand, dolomite, lime and a number of other materials. Due to the presence of a 4-layer structure, the warranty period of the material exceeds 4 decades. In order to fully appreciate its benefits, a homogeneous coating must be properly selected.

As mentioned earlier, PVC, manufactured in accordance with the requirements of GOST, acts as the basis. Further production cycle may vary depending on the specified parameters.

For example, we can talk about adding plasticizers and various fillers. As the latter, sand mixtures are used, the task of which is to increase the strength of the material.

Layering has a positive effect on the aesthetic characteristics of linoleum. Regardless of the complexity of the pattern, it can be applied to a sufficiently large depth. As a result, the coating retains its original strength and appearance for many years.

In addition to the characteristics already mentioned, this linoleum has several other strengths:

- Elasticity;

- Elasticity;

- The material does not collect static electricity;

- The coating can be laid in workshops where there is always a risk of spilling aggressive chemicals;

- Low maintenance cost.

Properly selected homogeneous linoleum is a long-term investment in your own future. Environmentally friendly, durable, pattern-preserving material allows you not to think about re-repair for decades. Its installation is allowed in apartment buildings, private buildings and enterprises.

If there is an increased likelihood of static electricity in the workshop or living quarters, then the choice is made in favor of homogeneous linoleum.

Homogeneous and heterogeneous linoleum: what is the difference

Attention to detail is the key to choosing a durable coating for an office, apartment or industrial enterprise. Quite often, beginners confuse 2 common types of linoleum - homogeneous and heterogeneous. If the first variety includes about 2-4 layers, then heterogeneous linoleum consists of 6-8 layers. Due to this, the average thickness of the flooring is about 6-7 mm.

It is based on reinforced fiberglass, which is first processed with PVC paste.

In addition, the material includes a number of other constituent elements:

- Protective canvas layer;

- Layer with a decorative pattern;

- pigment layer;

- Polyurethane protective film - used to maximize the extension of the service life;

- A coating that smooths out existing irregularities.

The use of heterogeneous flooring is justified when there is no time for the necessary primary and final processing, but it is necessary to ensure maximum strength of linoleum. Due to the presence of a 6-layer structure, the coating does not require additional maintenance for 25-30 years.

Choosing homogeneous and heterogeneous linoleum: what you need to remember

Builders with and without experience often fail to make the right choice between the two common types of linoleum. When it comes to living quarters, everything is simple.

The technical characteristics of the room are studied, on the basis of which the optimal type of coating is determined. The situation is more complicated in industrial facilities.

In this case, it is necessary to analyze the situation in context.

- Maximum and minimum level of dynamic and static loads;

- Estimated operating temperature range;

- Activity use much coverage;

- The number of people who are in the same room during the day is planned;

- The presence of static voltage;

- Humidity level;

- The need to strengthen individual elements.

In order for the laying of hetero-/homogeneous linoleum to be successful, it is necessary to develop a project. The document takes into account significant characteristics that affect the degree of activity of the floor covering. For example, in the chemical industry, where it is necessary to exclude even the slightest probability of a concentration of static stress, a homogeneous type is used.

The choice in favor of heterogeneous linoleum is justified, for example, within warehouses. Here there is always a danger of falling weights on the floor, which requires increased wear resistance.

At the same time, it must be remembered that the floor covering will cope with the task only if the technology of its installation is observed.

Proper laying of homogeneous linoleum

Having figured out what homogeneous and heterogeneous linoleum is, you can proceed to the stage of determining the required amount. The calculation is made in two ways. The first implies that the flooring is laid for commercial use. This means that the focus is on durability and attractive appearance. The second calculation method is used for residential and industrial premises.

For example, a room with a total area of 20 square meters allows the use of a single canvas. This means that you do not need to spend a lot of time on matching segments. In addition, glue is consumed more economically.

The further course of action is as follows:

- Measure the actual width and length of the room;

- Take into account in the measurements the protrusions existing under the plinths;

- A single piece is bought in the store, otherwise different suppliers may offer linoleum with a non-identical pattern or shade;

- Make sure that there are no even minor defects on the concrete base;

- If necessary, future euro-floors are leveled by milling;

- If the budget allows, then you can use mixtures to level the base;

- Carry out dedusting and priming;

- Dry the base - even slight traces of moisture will lead to a decrease in the degree of resistance of the material to the surface;

- If you plan to lay linoleum on a wooden base, then you need to make sure that it does not fasten and does not have cracks;

- A certain difficulty is represented by floors that differ significantly in height;

- If something like this takes place, then they need to be brought to a common denominator using plywood;

- Laying technology provides for the "rest" of linoleum in the expanded state before installation for 2-3 hours;

- Fit Tarkett linoleum or another selected brand to the size of the room;

- Remove excess pieces at the joints and apply glue to the base;

- The minimum required time for the technical maturation of the adhesive is 30 minutes;

- Roll out the linoleum and "weld" the seams.

It must be remembered that cold welding is better for a homogeneous coating, and hot welding is better for a heterogeneous one.

Characteristics of homogeneous linoleum (video)

Durable, environmentally friendly and versatile - all of the above epithets refer to a homogeneous and heterogeneous coating. The differences between them are in the degree of strength of the material. In this regard, before buying it is worth developing a construction project. His task is to determine the parameters of the room and the requirements that the coating must meet.

Linoleum is a fairly popular type of flooring. It can be used both in the apartment and in industrial premises. The material was so widely used due to its high technical characteristics. One of the popular types of linoleum is homogeneous. What is it and what are its features? For answers to these and many other questions, see our today's article.

Homogeneous linoleum - what is it?

This type of flooring contains polyvinyl chloride. Homogeneous linoleum (including class 43) belongs to the category of PVC coatings and has a number of advantages. Sand, dolomite and lime are used here as a filler.

The material has a uniform structure. However, his pattern penetrates through the entire thickness. Homogeneous linoleum, along with high strength, has one drawback. It's the lack of color variety. Therefore, such material hardly fits into non-standard room designs. Basically homogeneous linoleum is available in the following colors:

- Imitation of marble surface.

- Stone crumb.

- Abstraction.

Often such material is used in offices. This linoleum is highly antistatic, which allows you to easily place various electrical equipment.

Classes

The technical characteristics of the material are largely determined by its class.

There are the following types of homogeneous floor coverings:

- Class from 21 to 23. Such products are suitable for residential premises with a small number of people.

- Class 31-34. This material is used for public premises. The coating has good durability.

- Class 34-43. Linoleum homogeneous of this class is commercial. Differs in high wear resistance and is calculated on operation in production and factory rooms.

If we consider the technical characteristics of commercial homogeneous class "43" linoleum, we can find that it contains fillers that give more weight and a smooth appearance after laying. However, these additives significantly reduce strength.

Such a material, of course, surpasses the characteristics of a heterogeneous analogue. However, the latter will be more elastic and easier to style.

Fire characteristics

Regardless of the type and class, homogeneous linoleum (what it is, we already know) withstands the effects of chemically active substances and endures high temperatures. Also, the material has the ability to self-extinguish. Flames on this floor covering are difficult to spread. If we consider commercial homogeneous linoleum 2 mm, it belongs to the fire hazard class KM-2. This means that the material has the following properties:

- Moderate flammability.

- Low flammability (category G-1).

- Moderate smoke generating ability.

Also, commercial linoleum meets the RP-1 category (which means that it does not spread flames).

Service life

This is another important characteristic that many take into account when buying flooring. Linoleum is highly durable. And the homogeneous type was no exception. The service life of this linoleum can be compared with ceramic tiles. The manufacturer's warranty is 10 years for each square meter of coverage. But, as practice shows, such linoleums do not lose their appearance for 15 or more years under conditions of intensive use.

Dimensions, thickness

All homogeneous type linoleum rolls have the same width. This parameter is two meters. But its analogue (heterogeneous) is produced with a wide variety of sizes (from two to four meters wide).

With regard to thickness, commercial homogeneous linoleum complies with the EN-428 standard. What does it mean? According to this standard, the thickness of the protective coating is exactly 2 mm. Homogeneous linoleum has a greater thickness than heterogeneous (in the latter, this parameter does not exceed one millimeter).

Other characteristics

The average weight of one square meter of material is about three kilograms. Noise absorption level - from six to ten decibels. The electrical resistance of the material is 109 ohms. The coating withstands voltages up to two kilowatts. Abrasion - 30 grams per square meter.

Application area

Where can this flooring be used? Due to the high technical characteristics, homogeneous linoleum can be used in:

- Corridors of residential and public buildings.

- Educational audiences.

- hotel rooms.

- Living rooms (nursery, living room, bedroom).

- Halls of libraries and meetings.

- Retail stores.

- Catering premises.

- Sports fields and registrations.

- Pharmacies and medical offices.

- Operating rooms.

- Large office premises.

- Exhibition halls.

- Movie theaters and even train stations.

Environmental standards

In the manufacture of homogeneous linoleum is subjected to rigorous safety checks. According to international standards, it complies with the ISO-14001 standard. What it is? Homogeneous linoleum that meets this standard is absolutely harmless to the human body. It does not emit toxic fumes, therefore it is recommended for use in medical institutions.

Note! Before buying, you should check the availability of these certificates. There may be many counterfeit products on the market that do not comply with these environmental standards.

Main advantages

Should I use this cover for personal purposes? Experts give a positive answer. Homogeneous linoleum has undoubted advantages. This is high wear resistance, fire safety, no toxic odor, as well as a long service life. As for the last characteristic, the manufacturer Tarkett gives a 20-year warranty on its products. Such a floor can withstand any shocks and loads. It does not deform and does not absorb moisture. Homogeneous linoleum is undemanding to care. It resists chemicals and has an antistatic effect.

Flaws

The main disadvantage of this flooring is the lack of a wide range of colors.

Therefore, the material is used mainly in public institutions and in industry. Also, homogeneous linoleum is subject to high laying requirements. The surface for such a coating must be perfectly flat. This is the only way to achieve the desired result.

Laying technology

Let's look at how homogeneous linoleum flooring is made. Before laying, this material should lie in the room for at least a day. The recommended air temperature is 20 degrees Celsius.

Flooring is made on a perfectly flat surface. First, the homogeneous linoleum is adjusted to the size of the room or room. The overlaps at the joints of the product are two centimeters, and near the walls - three. Next, cut off the linoleum strictly along the angle between the wall and the floor. In the area of \u200b\u200bthe joints, a ruler is applied and excess material is cut off.

If homogeneous linoleum is laid from several pieces, specialized glue is used. Along with this, the base and the reverse side of the material are primed. How is the adhesive applied? A roll of linoleum is rolled up to half.

At the next stage, the surface of the linoleum is rolled with rollers. This eliminates air bubbles that can remain in the adhesive. Rollers process the coating from the center to the edge. Next, the tool rolls the material across the strip. Then the second half of the roll is rolled up and similar work is done.

Docking seams

In order for homogeneous linoleum to meet its technical characteristics, it is necessary to correctly dock its seams. It is needed in the case of laying several panels. There are several ways to connect:

- Cold welding. This method is usually used for commercial homogeneous linoleum. What is the essence of cold welding? Liquid glue is poured into a narrow slot between the panels. After a day, the composition takes on a solid form. In this case, the glue does not leave any traces.

- Hot welding. In this case, a slot for the cord is left between the linoleum. The latter is purchased to match the color of the PVC coating. The cord is refueled in a building hair dryer with a special nozzle. Then it is carried out through the slot. Excess cord is cut off immediately, while the product has not cooled down. After a few hours, such a cord forms a strong and reliable connection.

There is another, more budgetary way. To do this, the joined parts of the linoleum are bent and a film (cellophane) is placed under the seam. From above it is treated with PVA glue. The parts to be joined are pressed against the cellophane, a newspaper is placed and this “sandwich” is treated with an iron.

So, we found out what homogeneous linoleum is and what are its features.