Purchased furniture for a child’s room, especially made from natural materials, can be quite expensive. In a store or online, you don’t always find exactly the option you like. You can create a children's high chair and table from wood yourself. The work will not be difficult if you prepare all the necessary parts and tools, use your ingenuity and imagination. The reward for the work is a unique product, as comfortable as possible for the baby and practical in home life.

You can create a children's high chair and table from wood yourself.

A DIY chair will cost much less, and one made according to your own sketch will meet the intended parameters and the required degree of comfort for the baby.

The reward for the work is a unique product, as comfortable as possible for the baby and practical in home life.

All natural wood parts can be purchased in specialized departments of construction stores. They will select boards and bars of the required sizes for you.

A DIY chair will cost much less.

A child's highchair, created with one's own hands, is high-quality furniture for a child. In the process of work, you take into account the dimensions of the seat and backrest, which are as comfortable as possible for a growing baby, and check the strength of the structure directly at home.

All natural wood parts can be purchased in specialized departments of construction stores.

Created by yourself wooden high chair you can decorate according to your taste, and not be satisfied ready-made solution purchased furniture.

They will select boards and bars of the required sizes for you.

Required materials and tools

To create a chair you will need various materials. Individual parts will be made from them. First of all, this wooden blocks and boards from which the frame, seat and back are assembled. Instead of natural solid wood, you can use chipboard or plywood, but these materials are not durable. For fastenings, take sufficient self-tapping screws. You will need medium-hard sandpaper.

A child's highchair, created with one's own hands, is high-quality furniture for a child.

Dimensions of bars (length):

- support legs – up to 20 cm;

- seat frame connecting strips – up to 20 cm;

- backrest lintels – up to 20 cm.

A wooden chair made by yourself can be decorated to your liking.

During the manufacturing process, the thickest bars with a cross-section of 5x5 cm are used for the legs. For the planks, parts are taken with a diameter half the size of the supporting ones.

For the planks, take parts with a diameter half the size of the supporting ones.

The parameters of the seat board (height and width) should also not exceed 20 cm. The back part may be slightly higher, but preferably no more than 30 cm.

- they are less durable;

- The environmental friendliness of such products has not been 100% proven.

The parameters of the seat board (height and width) should also not exceed 20 cm.

To make a chair with your own hands, you need the right tools:

- screwdriver;

- screwdriver;

- jigsaw;

- hacksaw for wood.

The dorsal part may be slightly higher, but preferably no more than 30 cm.

The assembled chair will “require” original decor. In addition to the carved option, you can use paint or other materials to apply a design or appliqué. To accurately apply the image you will need a stencil.

The assembled chair will “require” original decor.

Deciding on design and construction

For a wooden product, you can come up with any option. A highchair is usually made with straight supports and the following forms of the back structure:

- solid square or rectangular;

- wide truncated cone;

- straight through (with jumper bar).

To accurately apply the image you will need a stencil.

Creating a product with your own hands requires careful preparation. You must first make a sketch of the project. Visually draw a diagram of the connections of all parts separately with calculations of sections and lengths. Following the sketches, you will recreate the model in reality with exact parameters. A chair that has all the right dimensions will fit the baby and will not create any inconvenience.

For a wooden product, you can come up with any option.

Certain models are created with the expectation that the child will sit at a common table with other family members. In this case, high legs are chosen for the product, which are not attached exactly vertically in relation to the seat and floor, but more widely. The lower part of such a chair will look like a truncated cone, connected for stability by wooden blocks around the perimeter. The top part will be approximately 30-35 cm below the table level.

A children's high chair is usually made with straight supports and the following forms of the back structure

If you have certain skills, you can assemble a folding product. Such items can be easily removed if necessary into storage areas.

For selected design solution parts are processed in accordance with it.

Manufacturing process: step-by-step instructions

After preparing a drawing with exact parameters, we begin to assemble a simple child chair little boy.

- Calculate the length of the legs exactly according to the diagram, saw off the excess with a hacksaw.

- Cut out the jumper bars to size that will secure the frame in the seat area.

- Connect them with supporting structure. To enhance it, add furniture glue.

- Attach the pre-sized back and seat using self-tapping screws.

- All wood parts must be cleaned sandpaper so that there are no roughnesses and burrs.

A chair that has all the right dimensions will fit the baby and will not create any inconvenience.

If the parts are disproportionate, “adjust” them according to the design diagram using a hacksaw. To make the chair you created with your own hands comfortable, ask your baby to sit on it, ask how comfortable he is.

If all sizes were determined correctly, the child will like it New furniture. To ensure the parts are smooth, sand the surface again.

Certain models are created with the expectation that the child will sit at a common table with other family members.

To varnish the product, use only safe compounds - a special coating for children's furniture, environmentally friendly and having the appropriate certificate.

The top part will be approximately 30-35 cm below the table level.

After exterior finishing varnish, let the chair dry thoroughly for a day or two. Then you can start decorative finishing, if such is intended. If it involves carving, then varnishing is done after completion artistic treatment and sanding parts.

Decorating a chair

Use a jigsaw for carving. You can make a decoration in the form of a flower by cutting it in the center of the back, or any geometric figure. First, mark the area of the future decoration with a pencil so that the carving is even. Parts such as legs and back can be carved. The corners of the seat can be rounded using a jigsaw and sandpaper.

During the manufacturing process, the thickest bars with a cross section of 5x5 cm are used for the legs.

The top can also be made not strictly rectangular, but a truncated cone, rounded, compound. In the latter option, you will need additional bars and cross bars - one or two. They are secured using special holes at the junction with the dorsal frame. This is a rather labor-intensive process, but if you wish, you can choose this option.

For fastenings, take sufficient self-tapping screws.

All steps for processing parts must be performed before the chair is assembled - this way the work process will be faster, more convenient and neater.

If you have certain skills, you can assemble a folding product.

To make a home-made piece of children's furniture look more interesting, you can apply a design to the back and seat. To do this you need to use safe paints. The color scheme should be bright and cheerful. Simple ornaments, floral patterns, and imitation of children's toys, such as cars, look great on wooden furniture.

Instead of natural solid wood, you can use chipboard or plywood, but these materials are not durable.

Due to the fact that the size of the product is small, a large pattern will become a kind of accent that attracts the child’s attention - he will like to sit on such a beautiful chair, play games or have breakfast.

You can use appliqués for decoration – there are plenty of adhesive bright films on sale.

The image will turn out smooth if you use a stencil pre-cut from paper or thick plastic.

You can use appliqués for decoration – there are plenty of adhesive bright films on sale. Whether the image will be monochromatic or multi-colored depends on your imagination.

First of all, these are wooden blocks and boards from which the frame, seat and back are assembled.

It is not recommended to use bulky (protruding) parts, both small and large, in finishing the seat or back of a children's chair. Firstly, it is inconvenient for the child, and secondly, they quickly fall off with frequent use of the product.

To create a chair you will need various materials.

VIDEO: DIY high chair

To make the baby’s life more comfortable, many parents purchase special furniture for everyone life situations. For example, a children's high chair is used to decorate a play area, workplace, and is necessary item children's furniture, which is also used for feeding the baby. The cost of such a device is quite high, and the choice among materials and models is even greater. But there is a solution to this situation - a children's chair made of plywood or boards. The material, tools and fasteners for the manufacture of this product are quite accessible - they can be found in any hardware store or even at home. Special attention It’s worth paying attention to this question: how to make a children’s highchair with your own hands?

The easiest way is to build a wooden chair. This option has many advantages that relate specifically to the type of material:

- The material is easy to process

- The cost of wood is not that high

- Aesthetic appearance of the product of this material initially acceptable and without additional coloring or decoration

- Wood product is completely environmentally friendly

Let's consider what components and consumables you need to make a children's wooden highchair with your own hands. In addition to the main material you will need additional elements, without the use of which quality product It just won't work:

- Fastening of parts can be done using furniture glue, carpentry nails or small self-tapping screws

- Sometimes metal corners are used to strengthen the structure

- Often the seat and back are upholstered with foam rubber, which is covered with fabric

- To hide the places where parts are fastened using self-tapping screws, you need to buy special plastic covers

- There are also rubber and plastic pads for the legs so that they do not scratch the flooring

For processing, you may need wood stain or varnish. Sometimes a wooden chair is painted with eco-friendly paint. Such measures are not necessary, the main thing is that the baby does not get hurt due to a poorly treated surface of the product.

What parts need to be made

First, sketches and drawings are prepared, regardless of whether the chair for the child will be made of plywood, chipboard or wooden boards. Only then, using a jigsaw, are the parts cut out from which the product itself will be created. There are not so many of them, but without one of them, the made chair will not be so strong:

- Required to have top, bottom, front and side bars

- Four legs

- Middle crossbar

- Seating surface

If one of the parts is missing, the product will not be reliable and will not last long or will be completely unusable. You can think over your own option for arranging the chair. The same presence of parts is required to construct a high chair. Distinctive feature This product is that the high chair can be combined with a table, that is, it turns out to be transformable furniture.

Plywood construction

A children's high chair made of plywood is the most affordable material. In addition, it is much easier to make a plywood chair with your own hands, even if the master is new to this business. The main thing is to clearly formulate a sequence of actions and carry out preparatory measures:

- At the very beginning, it is important to prepare drawings and connection diagrams. With their help, the type of future product, as well as the dimensions, are determined.

- It is also important for a highchair to ensure comfort of use, so you need to determine the possibilities for its further use.

- First, the base is made, that is, the stool, and then all other parts are attached to it.

- You should cut plywood very carefully, as it tends to tear or break. At the same time, it is not enough to simply cut out the parts - their edges need to be properly processed.

- Any small chair requires specific handling measures so that the child does not get hurt during use.

A constructed chair can be considered ready only when all stages are fully completed. The finished product is processed according to all requirements, strength and reliability are tested. Additional finishing may be present, especially if it is a high chair.

In any case, a self-made chair made of wood, as well as its derivative materials, can be further modernized and remodeled. The cost of such a product will be much lower than in the store. You can choose the design yourself, using all kinds of materials for decoration. This product will last long years, while parents will not worry about the health of the baby’s posture, and the child himself will have his own place to study.

For large quantities modern materials, wood still does not lose its relevance. This is especially true for furniture for children. Of course, you can buy a children's wooden chair in a store, but they are often made of plywood and do not differ high quality. And children's wooden adjustable chairs made from good hardwood are very expensive. To give your child a durable, beautiful and comfortable high chair without spending a lot of money, you should make it yourself. There is a wide variety of models, but the article will discuss three main ones: a regular high chair, a transformer and a high chair for feeding.

DIY wooden children's chair

Before you start manufacturing, you must remember that children's furniture must be safe for health. It should not have sharp corners, it should have perfect smooth surface, without gaps, cracks and gaps, and must also be strong and reliable.

The optimal height of the back of a children's high chair is 55 cm, the seat is 32 cm. You can attach the parts different ways: for self-tapping screws, nails, dowels (at least 2 pieces for each joint) or wooden tenons. Let's consider the last option.

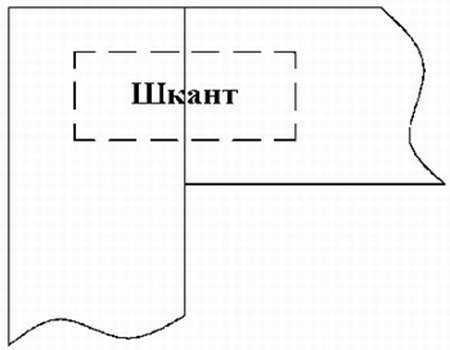

To fasten the structure, strong hidden rectangular tenons are used, which are placed in the grooves with glue. For maximum reliability, the tenons, in addition to glue, are fixed in the grooves with through dowels with a diameter of 6 to 35 mm.

List of parts and materials

- Top crossbar(1) 1.9x4.1x16.5 cm - 1 pc.

- Back leg(2) 3x3x55 cm - 2 pcs.

- Carved crossbar(3) 1.4x4.1x16.5 cm - 1 pc.

- Middle crossbar (4) 1.4x2.9x16.5 cm - 1 pc.

- Boards for the seat (5) 1.4x10.5x26.3 cm - 2 pcs.

- Bottom crossbar(6) 1.4x2.9x16.5 cm - 1 pc.

- Side crossbar and drawer (7) 1.4x2.9x17.7 cm - 4 pcs.

- Front leg (8) 3x3x30.5 cm - 2 pcs.

- Front crossbar and drawer (9) 1.4x2.9x19.5 cm - 2 pcs.

For the rear and front legs, straight-layered pine bars with a cross-section of 3x3 cm are used. Starting from the seat upward, the rear legs should narrow to 1.9 cm. And the front legs - from the seat to the bottom to 2.4x2.4 cm.

Important! Only the outer edges can be planed. This is necessary so that the inner edges of all legs remain parallel to each other, which will ensure easy installation of the drawers and crossbars.

The front edge of the top crossbar should be rounded, and the carved edge can have any pattern, but it is advisable to avoid sharp corners.

The middle crossbar is installed so that its lower edge is flush with the seat.

First of all, the back pair of legs is glued together, as well as all the crossbars. Next, a pair of front legs and a crossbar are connected, after which they are connected to each other with drawers and crossbars.

All gluing points are compressed with clamps, but with obligatory control of right angles. To do this, you can use a carpenter's square. The seat planks are attached last. Their reliability is especially important, therefore, after the glue has completely dried, they are additionally strengthened with wooden dowels, for which holes must be drilled. The protruding ends are removed with a chisel.

Children's wooden transforming chair

It is a set of children's table and chair that can be transformed into different positions. This is a single desk for studying and a comfortable chair for feeding. It folds up quite compactly, which is especially important for small apartments.

Necessary parts for the high chair:

- legs 39 cm - 4 pcs.;

- rounded corners - 4 pcs.;

- upper crossbars 22 cm - 2 pcs.;

- crossbars 34 cm - 2 pcs.;

- diameter 30 cm - 3 pcs.;

- seat base 20x30 cm - 1 pc.

Details for the table:

- legs 50 cm - 4 pcs.;

- strips 41 cm - 4 pcs.;

- diameter 34 cm - 4 pcs.;

- table top 45x38 cm - 1 piece.

For legs, slats, crossbars and crossbars, it is best to use timber with a section of 2x4 cm, and for the tabletop and seat, plywood 1.8 cm thick is suitable. Rounded corners are cut from boards 2 cm thick. As mentioned above, the wood must be well dried and have no knots or cracks.

Making a chair frame

All parts will be attached to each other with glue, but to ensure higher strength, wooden dowels measuring 2x5 cm should also be used. They can be easily made with your own hands from plywood 8 mm thick.

For each dowel, a special groove is made at the connection points. First, using a drill (6 mm drill), the ends are drilled in the place where the dowel will be laid, and then the groove is directly selected with a chisel 8 mm thick. But before installing it, all connections must be coated with glue.

Thus, the side parts of the future chair are assembled, tightened with clamps (making sure that the angle is exactly 90 degrees) and left until the glue dries completely. Below is a drawing of a children's wooden chair.

After this, they must be sanded well until the surface is smooth.

Making the back and seat

The back and seat are made of 25x30 cm in size from 2-3 sheets of plywood glued together. It is advisable to round all corners. Foam rubber is glued to them and everything is covered with a fabric cover. Before installing them on the chair frame, they are fastened together with metal brackets.

Now let's start assembling the chair. First, two finished sidewalls are connected using planks. Fastening is carried out using the technology already described. The seat itself rests on slats, and to secure it you will need cylindrical dowels or screws. Then the lower strips and the back strip are installed on which the backrest will be mounted. After all work has been completed, the chair should be left to dry.

In addition to the main table, you can also make a small tabletop. It is especially convenient for feeding or playing with small children. To make it you will need plywood sheet, from which the tabletop is cut required size. It is attached to the armrests using glue and dowels. But it makes more sense to attach it with self-tapping screws; this will allow you to easily dismantle it if desired.

Making a table

The technology for assembling the table is absolutely identical to assembling the chair. Therefore, there is no need to describe it in detail; you just need to focus on the main stages. First, the side parts of the table are assembled and sanded, then they are connected cross bars and sand again.

When the children's wooden transformable chair is ready, it is coated with several layers of varnish.

High children's wooden feeding chair

Making furniture with your own hands is a labor-intensive process. Nowadays it’s easier to buy ready-made or order it than to make it yourself. But there are times when an item is needed for a short time or there is no way to pay a lot of money for it. One option is a high chair for feeding your baby. The tip below will tell you how to make one from an old chair with your own hands.

Children's wooden chair assembly diagram

To make it you need the simplest chair with a backrest. It is very good if it has. It is important that it has crossbars between the legs and is strong and reliable. In the future, turning it over, the back will serve as the front legs of the future chair. Next, you will need strong wooden slats the size of the height of the chair; we fix them as shown in the figure. So, we get a back pair of legs, which are fastened together with a strap. To achieve maximum stability, the rear legs must be attached at an angle that is selected individually. Then all the legs are fastened together with horizontal strips.

The frame of the future chair is ready. You can make it more convenient to use by attaching smoothly sanded boards or a sheet of plywood as a seat. A soft seat is placed on top of it. Small smooth boards are used for the back and table top.

That's all, the chair is ready.

It doesn’t matter how the children’s wooden highchair is assembled, the main thing is that it should be comfortable and safe for the child. So that the finished chair and table have an aesthetic appearance and last as long as possible, they are coated with a protective paint and varnish composition in several layers. Besides this, everything wooden parts can be decorated with bright designs, which are applied with a simple brush or sponge through a stencil.

It is optimal to use artificial leather for seat upholstery, because it is easy to clean. This is especially true for young children. It is desirable that the back of the chair also has soft upholstery made of waterproof fabric.

Before assembly, all wooden parts must be carefully sanded with sandpaper, first coarse-grained, then fine-grained, until a perfectly smooth surface is obtained.

If the chair is assembled with self-tapping screws, their caps are recessed and closed with plastic plugs matched to the color.

In addition, you can get creative and make the chair colorful and interesting for a child, choosing a bright one upholstery fabric, and painting all wooden parts oil paint bright colors.

Or you can entrust the design to the future owner of the chair itself.

Children's wooden chairs photo

The baby is growing by leaps and bounds, and all the time he really wants to be like adults. A table and a chair are one of those things that are not only “like an adult’s,” but are also highly functional. Most of these products in stores are either sold at a very high price, or are made of low-quality plastic with a specific odor and short-lived chipboard. But there is a good way out for parents - these pieces of furniture are easy to make yourself.

Required materials and tools

There are not so few materials for making a children's table and chair from wood yourself; they are available and can be bought at any construction supermarket. As a base material, you can use not only natural wood, but also plywood or chipboard. But, of course, a much more durable and durable material is wood. It is environmentally safe and does not emit toxic fumes and does not cause various allergic reactions.

List necessary materials for the table includes a quite affordable assortment.

- Tabletop. You can work out its dimensions yourself. The tabletop, like some other parts, is best made to order. Classic square or rectangular shapes are welcome. Round children's table is not a common practice.

- Four wooden legs. It is also recommended to buy them to order. Now such products can be ordered in carpentry workshops and even in some construction stores.

- Boards for the power body. They must be purchased in quantities of 4 pieces.

- Screws, nails or tenons with glue of your choice.

You also need to purchase material for a hand-assembled chair.

- Boards for back and seat.

- Bars for handles. They are purchased optionally, depending on whether you plan to make armrest handles or not.

- Four legs. They should be small, but carefully sanded.

- Screws or nails of suitable sizes.

In addition to these things, you will need tools that will be needed for both the high chair and the table:

- electric drill;

- wood glue;

- sandpaper;

- roulette;

- ruler;

- pencil;

- hammer.

Construction schemes

When purchasing wood materials, you must check their quality. The bars and boards must be free of nicks, cracks or small protruding burrs. The wood should not be damp, rotten or infested with pests. Table. The design of the table itself is not complicated, so the absence of drawings is allowed; the main thing is to carefully connect and “fit” the parts of the future product to each other. Initially, you need to count on the fact that the height of the table will be no more than 50 cm. This height will be the most optimal for a child. It is important to consider that the dimensions of the table and chair must be comparable.

The design of the table itself may be different, but we will focus on the classic square version with 4 legs. A special feature of the table design are its legs. They should be quite thick and stable. The cross-section of each leg should be within 5x5 cm. Chair. As a rule, the design of all chairs with a back (this is what we are considering in this article) is identical; differences can only be in the shape and size of the back. You can also experiment with the shape of the seat. It can be classic square, polygonal, round, carved or upholstered.

Not so popular self-production, but quite real tables and chairs, assembled without the use of screws, nails or other fastening materials. The parts are fastened using a special technique for fastening wooden blocks at the joints. Such work requires experience and skills, so it is not entirely suitable for non-professionals. There are a large number of options when it comes to fastening the structure - various screws, nails, types of glue and even spikes.

Upon completion of the process of constructing the table and chair, it is imperative, as in the beginning, to check them for the presence of protruding pieces of wood and cracks. All sharp corners should be smoothed out as much as possible and uneven surfaces. But more about this below.

How to do it yourself?

Let's take a closer look at the furniture manufacturing process.

Chair

- Preparing the legs. Since a children's high chair is furniture with small dimensions, then, accordingly, its parts should be small. In particular, the length of the legs should not be more than 30 cm for a 70 cm high chair. All legs need to be cut down and adjusted with sandpaper to the same length. Of course, the planks must also be sanded.

- Prepare strips for the legs and jumpers for the seat. This is done for the subsequent stable and strong construction of the chair.

- Connect the entire structure. At this stage, you need to carefully check all the connections of the parts.

- Glue the structure. It's best to use furniture glue for this, but superglue from the hardware store will work just as well.

- Securing the seat and legs. This can be done using self-tapping screws or with a simple hammer and nails. Lately, spikes have gained relative popularity. The part is “slung” onto the spikes and the whole thing is held together with glue. It turns out to be a fairly reliable mount.

- Processing with sandpaper. This process is necessary in order to remove all potentially dangerous nicks on the wood and give the high chair a pleasant appearance.

Table

- First of all, you need to use a tape measure to measure the length of all the legs. If there is a difference in their length, then they need to be adjusted. A child's wobbly table can cause a lot of inconvenience, especially when feeding the child. This is done using a hacksaw.

- Drill slots in each of the legs with an electric drill. You need to make a groove at the end of the part, and then make it rectangular.

- Measuring the depth of the grooves. Next, you need to measure a distance on each of the bars equal to the depth of the grooves.

- Correction. To do this, you need to saw each of the wooden blocks on all sides, and remove the excess with a knife or sandpaper.

- Connecting parts. At this stage it is important to check the accuracy of the angles; they should all be straight.

- Bonding the structure. The final stage, in which all the parts, if they are tightly connected to each other, are glued together with wood glue. For greater structural stability, you can use a hammer and nails.

Furniture decoration

The main thing when decorating children's furniture is the safety of the coatings. Paints and varnish should be purchased from a reliable manufacturer and tested on a piece of wood in advance. Relatively recently, domestic and Western manufacturers released a special varnish for children's furniture. According to the manufacturers, it is safe to apply and does not emit harmful fumes after drying. The most common design option for a chair after painting is stencil designs. They can be applied with a regular small brush from an art supply store. The same applies to a wide variety of stickers on furniture.

Paint colors should be bright, but not toxic. Primary colors are welcome - blue, red and yellow. As drawings, you can choose various folk ornaments, simplified drawings of animals, symbolic symbols such as stars, hearts (for girls), cars (for boys), and even letters and inscriptions. Your child may be delighted and inspired by the opportunity to decorate their future furniture themselves. A good option in this case, the prints of his palms are. Special craftsmen with golden hands can experiment with carving. You can decorate the back of a chair with it. To do this, you first need to draw a drawing with a pencil, and then begin the work itself with a jigsaw. If you initially plan to do the carving, it is best to do it before you assemble the chair.

Children's things are very often exposed to various mechanical and other influences, so it would be better to protect the surface and apply several layers of varnish. In extreme cases and when there is an urgent need to protect the table surface, you can use epoxy resin, which, when hardened, forms a thick film similar to a glass surface. But this should only be done if the table will be used for drawing or will be frequently exposed to wet cleaning with chemicals.

If we're talking about about furniture intended for children, First of all, you need to take care of her convenience, reliability, strength and security, including environmental ones.

The best option - wooden chair. Of course, modern wooden chairs available for sale are different high cost if they are made from really valuable and high quality breeds wood

Why not do DIY chair for a child? With the help of this article you can choose the best materials for a children's high chair, get detailed instructions and recommendations for its production and decoration

Types of children's high chairs

What are there chairs for children? Modern manufacturers offer a wide range of chairs designed for children of different ages.

They may differ in purpose, design used material and other criteria.

Many models can be manufacture on one's own.

The most common and practical Highchairs for children include the following: kinds:

- Simple chair - an ordinary children's highchair with a backrest, instructions for making which are available in this article.

- Folding chair - A universal chair with rich functionality. It is assumed that you can change the angle of the backrest, adjust the footrests, attach a table top, etc.

- Swing chair – The name of the chair speaks for itself. All children, without exception, enjoy swinging on such a chair. IN modern models The seat can be used as a rocking chair.

- Transformer – This is a chair and table set that can be installed and used in different ways. When assembled, the transformer is convenient when disassembled - it functions as a simple chair and table, standing separately.

Some models provide regulation leg heights and backrest position, and high chair "grows up" together with the baby.

If you have small experience in the field of carpentry, it is better to limit ourselves to manufacturing ordinary high chair without additional functions. Main - understand the basics and the principle of operation, and in the future you can start creating more complex models chairs.

What material is it made from?

- natural tree;

- plywood;

- Chipboard.

Very widespread is the creation of children's furniture (chairs, cribs, tables, etc.) from plastic pipes After assembly and decoration you get enough attractive and unusual designs, but their reliability and durability is highly doubtful.

It is recommended to choose wood as the main material for the children's chair, plywood or chipboard, since these materials are absolutely safe for a child, are characterized long lasting operational life and others positive properties. With the help of this article you can make a high chair from tree.

Important! Before you begin assembling the chair, the ends of all chipboard parts should be covered with furniture edge. She not only performs decorative function, but also prevents the release of formaldehyde.

Dimensions and drawing

For manufacturing chair according to this drawing, it is necessary to prepare the following elements designs:

- 1 – top crossbar(1.9 x 4.1 x 16.5 cm);

- 2 – two rear legs (3 x 3 x 55 cm);

- 3 – crossbar carved type (1.4 x 4.1 x 16.5 cm);

- 4, 6 – planks, located in the middle and bottom (1.4 x 2.9 x 16.5 cm);

- 5 – seat from two boards (1.4 x 10.5 x 26.3 cm);

- 7 – two kings and two strips located On the sides(1.4 x 2.9 x 17.7 cm);

- 8 – two front legs (3 x 3 x 30.5 cm);

- 9 – two kings and two planks, located at the front (1.4 x 2.9 x 19.5 cm).

The legs of the chair should gradually become narrower: rear – up to 1.9 cm, starting from the middle of the chair to the top, anterior – up to 2.4 cm, starting from the middle of the chair to the bottom.

Advice: To make it as easy as possible to mount the strips and drawers, only the outer edges of the parts should be reduced. Thus, the internal edges will be parallel to each other.

Description of work stages

At manufacturing child's highchair, it is important to pay attention to it security: avoid the formation of sharp corners, cracks, cracks cracks, gaps between structural elements, as well as roughness and other defects.

At manufacturing child's highchair, it is important to pay attention to it security: avoid the formation of sharp corners, cracks, cracks cracks, gaps between structural elements, as well as roughness and other defects.

To give attractive appearance of the top crossbar, it can be rounded. carved the crossbar can be designed in any way with all sorts of patterns, but without sharp corners.

Fastening details in in this case will be performed using wooden thorns and glue, but you can use other methods using nails, furniture dowels or self-tapping screws.

In the case of spikes, the most durable ones are used secret elements rectangular shape, which is inserted into holes pre-treated with glue.

To further secure the studs, you can use through pins (6–35 mm in diameter).

Chair assembly:

Step 1. First of all, you need to fasten the rear legs chairs and adjacent crossbars.

Step 2. Attach the remaining front legs to the structure crossbars and kings.

Step 3. Attach the upper one to the rear legs, carved and the middle crossbar (attached at the same level as the seat).

Step 4. So that all places where parts are connected are glued together as much as possible durable, use a special tool - carpentry clamp. It is designed to press the parts tightly against each other.

Step 5. When all bottom slats and legs are firmly connected together, attach to the base of the chair seat, consisting of two planks. For added security and strength, secure the boards after the glue has dried. dowels, pre-drilling holes for them. If the seat boards partially protrude beyond the base, the excess ends must be removed using chisels.

Important! Using a clamp, be careful to ensure that the parts are connected at right angles. You can control this moment using a carpenter's square.

How to decorate a chair

New furniture, even the highest quality, made by your own hands, is unlikely to attract the attention of a child without interesting registration There are tons of options decorate children's chair made of wood.

New furniture, even the highest quality, made by your own hands, is unlikely to attract the attention of a child without interesting registration There are tons of options decorate children's chair made of wood.

To do some methods decoration you can even attract the future owner of the chair. For example, you can paint a chair together with the child at his discretion.

Most common ideas staining:

- Using multiple bright shades;

- Imitation rainbows;

- Application patterns;

- Picture of loved ones characters from fairy tales, cartoons, etc.

The second option for decorating a chair is special case, which you can purchase or also make yourself. There are no restrictions in this regard either. The cover can be the most ordinary - from fabric plain or with drawings and other decorative elements. You can also imagine in the form of a bird, animal, flowers, cars, and also make original ones.

Another idea - gluing on the sides of the seat there are bright strips of fabric, decoration backrests with all kinds of elements ( ribbons, artificial flowers, beads, etc.). Show fantasy, and most importantly, don’t forget to ask for opinions child.

And for inspiration - a few examples design children's chairs:

For more information on how to make a children's chair out of wood with your own hands, see video: