One of the most popular materials for roof insulation is. It is used for almost any type of roof from flat to three or four pitched. It is also often used to insulate floors.

Popularity of this material It’s easy to explain because it has a lot of advantages:

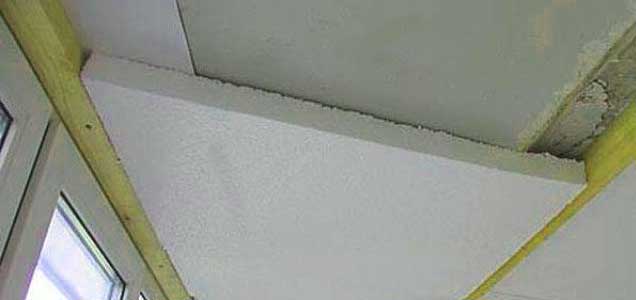

The foam boards are laid between the rafters in the free space. When laying the foam, they try to cut it so that there are as few gaps as possible. The foam is cut using a sharp stationery knife and a metal ruler.

The foam boards are laid between the rafters in the free space. When laying the foam, they try to cut it so that there are as few gaps as possible. The foam is cut using a sharp stationery knife and a metal ruler.

It is very important that there is no temperature difference inside the insulating layers, at which condensation occurs, which can lead to dampness and rotting truss structures.

Polystyrene foam is produced using wooden slats or using glue. All voids and crevices are thoroughly foamed. To avoid the appearance of cold bridges, it is recommended to lay the foam in two layers with overlapping joints, the layers are glued together.

If sound insulation is necessary, soundproofing material is laid on the foam. More often soundproofing materials have a fibrous structure and are prone to moisture accumulation.

If sound insulation is necessary, soundproofing material is laid on the foam. More often soundproofing materials have a fibrous structure and are prone to moisture accumulation.

You can reduce your home heating costs not only by using energy efficient equipment, but also high-quality insulation. We talked about how to properly insulate a roof.

In this case, the installation of insulation should be carried out on absolutely all building structures, including the roof.

An acceptable result can only be achieved correct choosing and following the technology of its application.

Various polymeric raw materials can be used to produce polystyrene foam, incl. polystyrene, from which expanded polystyrene is made.

However, the difference in manufacturing technologies of these materials leads to different physical properties finished product.

So, polystyrene foam is more durable. This is achieved by the fact that, unlike the latter, in polystyrene foam the foam granules of the initial raw materials only sinter with each other during cooling.

In expanded polystyrene, the raw material is foamed not simply by treatment with hot steam, but by extrusion - melting and mixing with foaming reagents. The result is material with much smaller cell size than in foam plastic.

In addition, expanded polystyrene is actually a monolithic material with big amount sealed cells filled with carbon dioxide.

The main differences between polystyrene foam and expanded polystyrene follow from the difference in production technologies:

- foam is less dense;

- unlike foam plastic, expanded polystyrene does not absorb moisture;

- mechanical the strength of polystyrene foam is much higher.

Accordingly, roof insulation with polystyrene foam is practiced in those places where ordinary polystyrene foam is of little use. As an alternative to expanded polystyrene, you can insulate the roof.

Types of expanded polystyrene

The classification of expanded polystyrene foams is based on their manufacturing technology.

Advantages and disadvantages of the material

Among the most significant advantages expanded polystyrene include the following:

- low thermal conductivity;

- light weight, simplifying installation even on roofs of complex configurations;

- hardness;

- frost resistance;

- resistance to moisture;

- durability.

At the same time, the material also has some flaws:

- actively supports combustion, with the exception of fireproof samples;

- It is quite difficult to perfectly join sheets of material, which leads to the appearance of bridges of cold;

easily damaged by rodents; - destroyed by vapors active chemicals;

- ages quickly and crumbles under ultraviolet light.

However, if we exclude the influence of destructive factors, then polystyrene foam is one of the most suitable for roof insulation. suitable materials. If you decide to abandon polystyrene foam, we recommend that you pay attention to.

How to choose high-quality polystyrene foam?

In order not to make a mistake with the choice of insulation, it is advisable to pay attention to the following points before purchasing:

- the material must be non-flammable type;

- You should not rely only on the numbers in the labeling. It gives a rounded value for the weight of a cubic meter of material. It is necessary to clarify specific numbers from the technical specifications;

- extruded polystyrene foam, which is most suitable for roof insulation, has a density of about 40 kg per 1 cubic meter;

- when trying to break off a piece of material, small polyhedra should be visible on the cut, and not large balls;

- you just have to choose famous manufacturers guaranteeing the quality of their products.

NOTE!

Use material with a density less than 17 kg per 1 cubic meter. as roofing material extremely undesirable. It has excessively high porosity and will accumulate moisture.

How to choose the optimal insulation thickness?

The choice of the thickness of polystyrene foam for roof insulation is influenced by several factors.

The choice of the thickness of polystyrene foam for roof insulation is influenced by several factors.

Firstly, roof type: flat or sloped.

Secondly, the presence insulated attic.

Third, climatic conditions.

Practice shows that for middle zone the most optimal is thickness of expanded polystyrene 100 mm. This thickness can be achieved several layers of material, laying them with overlapping and waterproofing the seams.

Roof insulation with polystyrene foam: technology and practical advice

Sequence of actions for insulating flat pitched roofs varies significantly. If flat roofs insulated With outside , That pitched sheathed from the attic. If you are planning to insulate mansard roof, then be sure to read it.

External insulation of a flat roof:

- on a cleaned reinforced concrete base flat roof apply a layer bitumen-polymer waterproofing. These can be either various mastics or weld-on rolled materials;

- if necessary, a slope-forming layer of fine gravel, slag, expanded clay, etc. is poured;

- fits vapor barrier fabric. The joints of the overlapping sheets are sealed with tape. Vapor barrier is necessary here for the reason that there may be microcracks in the floor slabs of a flat roof, and there may be leaky seams between them. Without a vapor barrier from the inside, moisture from warm rooms will penetrate under the insulation and accumulate there;

- as possible closer to each other sheets of expanded polystyrene are laid out;

- layer is laid fiberglass for mechanical protection of insulation. Can be used instead of canvas sheets flat slate or other materials capable of bearing significant loads;

- sheets are laid overlapping waterproofing material;

- mounted roof covering.

Scheme roofing pie flat roof

When using polystyrene foam for insulation of pitched roofs from the inside, the installation technology will be slightly different:

- all inner part roofs are laid along with rafters and sheathing. The canvases are placed with overlap, the joints are sealed with sealing tape;

- Insulation sheets cut to size are attached. To fix them, you can use either glue or specialized fasteners (nails with very large heads);

- all joints between sheets and rafters are treated with foam adhesive for polystyrene foam;

- If necessary, further layers of insulation are applied. Each layer is sealed separately;

- . Vapor barrier film prevents the penetration of moisture from warm air attic space inside the insulating pie. To ensure waterproofing, the joints of the canvases are glued with construction tape.

- the resulting structure is sewn up with sheet finishing materials ( moisture resistant drywall, multilayer plywood, fiberboard, etc.);

- finishing is installed.

Finishing roof insulation work

The insulation is laid in several layers to create the required thickness

For interior decoration it makes sense to use materials with low thermal conductivity (wooden lining, imitation timber, etc.). This will help improve the quality of the insulation performed. If you are planning, we recommend that you familiarize yourself with the nuances of insulation.

Not allowed to use sealants, chemically incompatible with this insulating material.

As you can see, roof insulation with polystyrene foam is not the same difficult process as it seems at first glance. With proper preparation, even a beginner in construction can install insulation.

Useful video

We bring to your attention video instructions for self-insulation polystyrene roofs:

Conclusion

Roof insulation with polystyrene foam profitable both in terms of the achieved effect and in terms of the cost-effectiveness of the entire event. Consumables They're not too expensive, but self-execution of all work provides even greater savings.

In contact with

Installation of roof insulation is one of the important stages construction of a country house.

Measurements and calculations show that, on average, through a roof laid without thermal insulation, up to 30% of heat is lost.

You can block the path to these losses with the help of various thermal insulation materials. However more often than others modifications of it are now used.

Insulation with polystyrene foam pitched and flat roofs and ceilings.

Insulation with polystyrene foam pitched and flat roofs and ceilings.

The popularity of this material is quite understandable: it is light and easily processed, has very low thermal conductivity, is not spoiled by microorganisms and not afraid of water.

However he has some features, which affect the installation and installation sequence, as well as the operation of the house:

- Vapor tightness. Polystyrene foam and other modifications of polystyrene foam allow only a few milligrams of water vapor per hour to pass through 1 square meter surfaces. They also do not allow water to penetrate deep into the material, but due to their porous structure they can collect some moisture on the surface. At the point of contact with wooden structures, this leads to rotting of the wood, and the foam itself turns black on the surface. For this reason, all modifications of polystyrene foam must be protected with vapor and waterproofing film, and the room must be ventilated. Subject to such conditions, this material lasts up to 80 years or more.

- Flammability. Modern foam plastic grade PSB-S – self-extinguishing material. This means that it lights up, but after the flame is removed it goes out. However, it is a flammable material, so it should not be installed around the chimney. In this place, mineral wool and expanded clay are used for thermal insulation.

- Low elasticity. Unlike mineral wool, polystyrene foam has almost no elasticity. For this reason, slabs are cut out of it, which are only 1 cm wider in width than the distance between the rafters. Such slabs fit tightly into the opening. If you increase the width of the slab, it will warp during installation. This leads to the formation of gaps between the plates and the formation of cold bridges. The edges of the slabs do not fit tightly to the wood everywhere, so the gaps have to be filled polyurethane foam.

- Sensitivity to sunlight. Expanded polystyrene of all modifications is destroyed by ultraviolet rays sunlight. This means that when laying it, it is carefully protected from light rays. External side covered with roofing material, and the interior with a vapor barrier membrane and finishing. Leave the foam even with inside You can't do it without finishing. Light coming through dormer windows, causes yellowing and destruction of this material.

Choosing tools and materials

Polystyrene foam is available in various modifications, the properties of which will have to be taken into account when choosing materials (according to GOST 15588-86 and SP-50.13330.2012).

The best thermal insulation properties have polystyrene foam brand PSB-S-35 and extruded polystyrene foam (penoplex). They also withstand significant compressive loads.

All of the above brands are suitable for roof insulation, but usually used PSB-S-15, because it creates minimal load on attic floor. PSB-S-35 and (), as a rule, are used for insulating flat roofs, since resistance to compression is required there.

For work you will also need:

- . It will protect the insulation and rafters from steam penetration from the room. It is recommended to choose a two-layer water vapor barrier membrane Megaspan B. Its rough side holds drops of condensation on its fibers, preventing it from draining. After the air humidity decreases, the condensate evaporates.

- Windproof, moisture-proofing membrane. This membrane protects the insulation from drops from above when the roof leaks, but allows steam to pass through when it dries. wooden structures. It is advisable to choose a membrane type Megaspan A or other superpermeable membranes.

- Wooden blocks with a cross section of 50×50 or 40×50 mm, treated with antiseptic preparations. They are needed to construct the sheathing.

- Nails and hammer for attaching film and finishing material.

- A sharp knife for cutting foam.

- Polyurethane foam without toluene for sealing joints.

- Stapler and staples for attaching film.

- Construction tape.

Technology for insulating a gable roof with foam plastic from the inside

It is advisable to install thermal insulation under the roof immediately when installing the roofing material. However, the developer does not always manage to do this. In such cases, insulate the roof comes from within.

It is advisable to install thermal insulation under the roof immediately when installing the roofing material. However, the developer does not always manage to do this. In such cases, insulate the roof comes from within.

Modern installation technology roofs require the installation of a wind and moisture protective membrane. If it has been laid in compliance with all the rules, you can immediately begin installing the insulation.

Polystyrene foam is cut into slabs of width 1 cm larger than the distance between the rafters so that they fit tightly into the opening.

The slabs are laid in several layers, overlapping the joints of the previous layer with the slabs of the next one. It is recommended to glue polyurethane foam one layer to another and fill all the resulting gaps between them and the rafters so that cold bridges do not form.

After filling the openings Between the rafters, a vapor barrier membrane is stapled to their lower surface. Instead of fastening with brackets, the film can be fixed with wooden strips, through which the film is nailed to the rafters. It is unfolded and laid from bottom to top, overlapping the edges of the bottom layer by 15 cm.

The joints of the canvases are taped with tape. A double-sided membrane of the Megaspan B type is always laid with the smooth side facing the foam. After installing the vapor barrier a sheathing is constructed on the rafters, to which it is attached finishing material. After this stage is completed, an air ventilation layer is formed between the film and the finish.

If the roof has been laid without waterproofing membrane , work will have to begin with its installation. In this case, the membrane is laid around the rafters with the pile facing the insulation. They attach it to the rafters and external sheathing. Only after the membrane is secured, do you begin laying the insulation.

Features of flat roof insulation

This can be done immediately after installation of the ceiling. Usually such an overlap is used reinforced concrete slabs

, which need to be cleaned and a vapor barrier membrane attached to them.

This can be done immediately after installation of the ceiling. Usually such an overlap is used reinforced concrete slabs

, which need to be cleaned and a vapor barrier membrane attached to them.

For thermal insulation of flat roofs, foam plastic that can withstand pressure well is chosen (see above). Sheets of this insulation are glued onto film and secured to reinforced concrete with dowels. Laying rule the same: each subsequent layer must overlap the joints of the previous slabs.

The foam is covered with fiberglass on top, and then with a waterproofing membrane, on top of which lay geotextiles. Geotextiles can be covered with expanded clay, onto which reinforced cement-sand screed, and then paving slabs are laid.

If you lay it down external thermal insulation for some reason it is difficult, a flat roof can be insulated with foam plastic from below. If the roofing covering is reliable, then the shift of the dew point towards the room does not matter. First, a sheathing of wooden blocks is mounted on the floor slab, securing them in the slab with dowels.

Expanded polystyrene boards glue directly to a clean and dry floor slab between the bars, and then additionally secure with dowels. The joints are also sealed with polyurethane foam.

Expanded polystyrene boards glue directly to a clean and dry floor slab between the bars, and then additionally secure with dowels. The joints are also sealed with polyurethane foam.

The insulation is insulated from the steam from below with a vapor barrier membrane with the pile down. It is nailed to the bars through wooden planks. Next, the insulation is hidden behind a suspended or suspended ceiling.

Thermal insulation of a roof with foam plastic is simple and does not require high qualifications. After studying the properties of materials and mastering the skills of working with them, any House master can handle this kind of work.

Foam insulation requires thorough hydro- and vapor barrier, as well as protecting this material from sunlight.

Watch the video for a master class on roof insulation with foam plastic:

The question: is it possible to insulate a roof with foam plastic, perhaps, is as pressing as the phrase “Execution cannot be pardoned.” In fact, they meet diametrically on the Internet different opinions on this topic. Let's devote one more material to the burning issue that arises when it is necessary to insulate a roof. Should I use polystyrene foam for the roof, or maybe choose a proven option that no one disputes?

Well, firstly, when a user enters the query: roof insulation with polystyrene foam, it is not at all clear what kind of roof he has. Attic or cold attic, or maybe even we're talking about about flat roof insulation? The type of roof is the first question that needs to be clarified.

In order not to languish with long expectations, it is worth saying that we have already discussed the issue separately. Question about flat roof will be discussed later, in a nutshell: they insulate it, most often with penoplex or expanded polystyrene. That is, it is quite possible. Although in most cases such roofs are part industrial buildings and insulation is carried out by contractor teams.

What can we say about cold roof- the most popular option in domestic conditions?

Features of foam plastic in connection with roofing

It is worth noting that there are different types expanded polystyrene, each of which is applicable for its own purposes.

- Ordinary polystyrene foam (marking PSB 15) is the most common, white foam plastic;

- EPPS - extruded polystyrene foam. A denser, tougher material that can withstand heavy loads. In addition, the latter has lower hydrophobic properties.

And if there are no loads on the roof (if we are talking about insulation between the rafters), then the extra hydrophobicity definitely won’t hurt. You can often find polystyrene foam with a quarter. (Protrusion or groove on the edge).

This material is intended for laying joint-to-joint on a flat surface. For example, penoplex is one of these. For use between the rafters, you need even sheets in the form of rectangles.

Why do disputes arise?

There are 5 main questions that arise when it comes to roof insulation with foam plastic. Namely:

- The need for ventilation of wooden roof structures;

- Changing the geometry of rafter structures, depending on humidity;

- Question about vapor permeability of expanded polystyrene;

- Fire safety;

- Harmful substances when heated under the roof.

Before considering whether these objections are really justified and whether it is possible to overcome them, let us generally compare, and Are there any special reasons that encourage the use of this particular material for the roof from the inside?

To know means to compare

It seems that the most important competitors, by the way, ahead of foam plastic in the field of roof insulation, are mineral wool. Specific solutions, such as ecowool or polyurethane foam, are also used, but their share is lower. In addition, both require special equipment, so it is fairer to compare polystyrene foam with mineral wool in terms of roof insulation.

So, the first indicator for insulation is . How are our friends doing with this indicator?

Thermal conductivity

As you can see in the diagram below, mineral wool is slightly inferior in this regard to its “white” comrade.

For example, to replace a 20 mm thick layer of polystyrene foam, a 40 mm layer of mineral wool is needed. This means that a smaller layer of foam is sufficient to achieve the same effect. What can we say about the cost?

Price

So, for example, 7 sheets of EPS, URSA, 50 mm thick (size 1250 by 600 mm) cost 1,300 rubles (22 dollars). Polystyrene foam, for example, Knauf 50 mm (1000 by 600 mm) will cost 860 rubles ($15).

As we found out, for the same purpose we need 100 mm of wool. For example, let's take the famous Rockwool Light Butts. 5 slabs 100 mm thick cost 580 rubles. The size of one slab is 1000 by 600 mm. Now we need to compare the cost of 1 square meter of such thermal insulation.

The EPS packaging, which costs 1,300 rubles, contained 5.25 m2. The package of polystyrene foam at the price of 860 rubles contained 6 m2. The pack contains 3 m2 of cotton wool. You can take a calculator and calculate or look at the table below.

So, we can conclude that only foam plastic wins in terms of cost. EPS will be much more expensive. Some will appeal to the longer lifespan of polystyrene over mineral wool, but in conditions of use on the roof, it seems that none of the materials will last 50 years.

By the way, specific figures for the thermal conductivity of the materials compared.

As you can see, although there is a gain, it is small.

So, according to two main indicators for materials:

- Thermal conductivity;

- price,

The leadership of polystyrene is very doubtful. Are there any questions that definitely need to be taken into account?

Things to think about

Let's return to the 5 points-questions at the beginning of the article:

In general, as you can see, there is something to think about. If, of course, everything is done correctly, namely:

- Provide sufficient ventilation for the cold roof;

- Select polystyrene foam of flammable group No. 1;

- Use chamber-dried timber for rafters,

roof insulation with foam plastic from the inside is possible, provided that the attic will not be residential. However, there are more questions than answers here. But, if for some objective reasons you decided to use this particular heat insulator, below are the installation recommendations.

Let’s make a reservation, if by roof insulation you mean ceiling insulation (from the cold roof), we discussed this issue in a separate article.

Installation of polystyrene foam between rafters

Sheets of foam plastic are inserted between the rafters into a spacer. To achieve the result, you should adhere to the following sequence:

- Measure the distance between the rafters;

- Cut a sheet of polystyrene foam to the desired width;

- Insert the sheet into the sheathing.

Sometimes the width of the rafters does not allow it to accommodate required thickness insulation materials. Considering that there should be a distance of 50-100 mm between the thermal insulation and the hydraulic barrier on top, for example, the thickness of the rafters is 180 mm, only enough to attach 80 mm of foam. The remaining thickness is filled on top, securing the second layer of insulation with self-tapping screws.

The joints between the rafters, if any, are sealed with foam or sealant.

So, today we have such a scandalous topic: how to insulate a roof with polystyrene foam. What do you think about this method of roof insulation?

Finally, 2 videos with polarity of opinions.

In a person’s mind, a house is, first of all, a “roof over one’s head” that protects its inhabitants from snow, rain and wind. However, it is important not only to keep out the cold and bad weather outside, but also to retain the heat inside, which is produced by heat-generating devices. According to thermal imaging studies, 20-30% of total heat loss occurs through the roof surface. Therefore, when building a house in northern and temperate latitudes, thermal insulation of slopes is mandatory. Last time professional builders They insulate the roof with polystyrene foam, the effectiveness of which we will discuss in this article.

Foam plastic is a foamed mass of polystyrene foam, in the smallest bubbles of which air is “preserved.” Due to the fact that the gas content in this material reaches 97-98%, it has low thermal conductivity, light weight and practically does not burn.

Polystyrene foam used for roof insulation is produced in the form of slabs different sizes and thickness. The density of expanded polystyrene is only 15-25 grams per 1 square meter; denser grades are used for installation on floors and ceilings, where they are subject to significant load. This type of insulation has the following advantages:

- A light weight. Perhaps the most important advantage of polystyrene foam is lightweight this material. One square meter of insulation based on polystyrene foam is only 15-25 grams, which makes it possible to insulate the roof with foam plastic without reinforcing the rafter frame and sheathing.

- Low thermal conductivity. A 10 cm layer of polystyrene foam has the same thermal insulation properties as double brickwork or a 20 cm wooden wall.

- Easy to install. Working with expanded polystyrene; the installation technology of this insulation involves the use of the most simple tools, available in the arsenal of any master.

- Vapor and waterproof. When using polystyrene foam for roof insulation, you do not have to worry that the thermal insulation properties of the material will decrease upon contact with water. Almost zero hygroscopicity and vapor permeability make this insulation the best option for thermal insulation of slopes.

- Fire resistance. Foam production technology High Quality involves the addition of fire retardants, substances that lead to self-extinguishing of the material. Therefore, such insulation is considered safe and non-flammable.

- Durability. The service life of polystyrene foam is more than 50 years. This material is not susceptible to decomposition, rotting and the action of fungal or mold microorganisms.

Note! based on polystyrene foam have low resistance to mechanical damage. In addition, they are destroyed when some varnishes or paints come into contact with the surface of the material. Rodents are not averse to profiting from polystyrene foam, so it requires special protection.

Varieties

Expanded polystyrene is a type of synthetic polymer or plastic that is widely used in manufacturing. Several types of roof insulation are produced from it. Depending on the production method, there are 2 main types thermal insulation materials based on it:

- Regular foam.

Conventional polystyrene foam is produced by foaming polystyrene foam under the influence of air or carbon dioxide. This is a lightweight, inexpensive, non-flammable insulation with excellent thermal insulation qualities.

The weakness of conventional foam plastic is the fragility of the boards; this material is extremely susceptible to pinpoint impacts that can damage the sheet. It has low strength, higher thermal conductivity and permeability, and is also cheaper. To insulate the roof, foamed polystyrene foam with a sheet thickness of 100-200 mm is used.

To produce this insulation, the extrusion method is used. First, polystyrene foam granules are mixed with a foaming agent under the influence of high pressure and temperature, and then extruded through an extruder.

The result of these actions is a denser, solid insulation with a closed fine-cell structure. He has a higher mechanical strength, does not allow water and steam to pass through, and also has improved thermal insulation characteristics.

Extruded polystyrene foam for roofing is more expensive than usual, however, thinner sheets are used for insulation. Experienced roofers believe that it is better suited for thermal insulation work.

Important! Although polystyrene foam is a non-hygroscopic and vapor-proof material, roof insulation is carried out using a waterproofing and vapor barrier membrane. The membrane that protects the insulation from steam penetration is fixed on the inside of the roof, and the membrane that protects from moisture is fixed on the street side. This measure, in conjunction with exhaust ventilation will help extend the life of the roof rafter frame.

Installation technology

Despite the high performance characteristics insulation, the main component of effective thermal insulation is high-quality installation in compliance with all technological nuances working with expanded polystyrene.

Installation errors can even create big problems than lack of insulation, for example, to rotting rafters, dampness or mold. Roof insulation with foam plastic is performed before laying the roofing material on the rafters in the following order:

- From the underside of the rafters to the brackets construction stapler secure strips of vapor barrier membrane. The membrane is cut into sheets required size and fix it across the rafters so that it sags a little, and there is an overlap of 10-15 cm between the strips. The joints are glued with adhesive tape or construction tape.

- From the attic side, perpendicular to the rafters, guide bars made of wood or metal are attached on top of the vapor barrier, which will support the insulation. The thickness of the guides should ensure ventilation gap between thermal insulation and wall cladding.

- Foam boards are inserted between the rafter legs and glued using special glue. The material is cut so that there are fewer joining seams.

- Joints between slabs and joints between insulation and rafter legs sealed using polyurethane foam.

- Strips of waterproofing membrane are fixed over the rafters, overlapping one sheet over the other to avoid leakage at the joints.

- The waterproofing is secured with counter battens, the sheathing is installed and the roofing material is laid.

Professional roofers advise: if you are insulating a residential attic roof with polystyrene foam, consider installing fibrous sound-proofing material, especially if roofing metal tiles or corrugated sheets are used. Expanded polystyrene has low noise-reducing ability, so the roof increases sounds during rain.

Video instruction