The most popular method of attaching gypsum boards to the ceiling or walls remains metal carcass. It is reliable, inexpensive, convenient, fast and beautiful. But beginners are frightened by the variety of existing profiles, fasteners, and connection methods.

Let’s try to figure it all out, decide on the types of products, find out what a cutter is and what kind of “fleas” installers have.

A profile for plasterboard is a metal strip with a U-shaped profile, which is the main structural element of the frame. It is made from cold-rolled galvanized steel by profiling.

The zinc coating protects the product from corrosion; to maintain its integrity, you need to try not to scratch the drywall profile, and it is also highly undesirable to use an angle grinder (“grinder”) for cutting, because when heated, the zinc layer is damaged and the steel begins to rust.

The thickness of the steel varies; the thicker it is, the stronger it is, but it is heavier and more expensive, and the screws are more difficult to screw in. You should not take products made of steel less than 0.55 mm; it’s a good idea to have a caliper with you for control. Well, or buy products from trusted brands in reputable stores.

Varieties

These products are produced by many companies, but the sizes and types are more or less standardized for all.

Types of profiles for drywall

Types of profiles for drywall The shapes of the profiles are:

Some experts also distinguish between wall and ceiling views, however, in fact, the whole difference lies only in size - the ceiling one is lighter and more compact, so as not to take away the extra height of the room if necessary. And there is less load on the ceiling frame.

There is also an arched profile for drywall - it has many cuts to easily bend, forming an arc. But most craftsmen do without it, making cuts on a regular profile.

Dimensions of wall profiles

For wall decoration, the types most often used are UD and CD. The manufacturer has taken care of the convenience of the installer and these products are usually compatible in size with each other.

The height of the backrest PN can be 50, 65, 75 or 100 mm. The size of the shelves is the same for all and is 40 mm. This is enough to screw drywall to the UD if necessary.

The height of the backrest PN can be 50, 65, 75 or 100 mm. The size of the shelves is the same for all and is 40 mm. This is enough to screw drywall to the UD if necessary.

Accordingly, the height of the rack backrest will also be 50, 65, 75 or 100 mm. In reality, the manufacturer makes it one to one and a half millimeters smaller so that the rackmount fits into the UD without any problems. The height of the shelf here is different - 50 mm. Thanks to this, you can install the profile for plasterboard on the edge, choosing PN-50-40 as a “ruler”.

The length can be different, most often products with a length of 3, 3.5, 4 meters are used, although the standard allows the production of planks from 2.75 to 4.5 m, and according to individual order the manufacturer can make longer ones.

Ceiling

Since a thinner sheet is used to finish the ceiling, the requirements for the strength of the frame are lower. The most commonly used size here is UD-28-27.

The wall size of 27 mm allows you to assemble the frame with minimal loss of usable space. The corresponding CD-60-27 is used as a carrier.

The wall size of 27 mm allows you to assemble the frame with minimal loss of usable space. The corresponding CD-60-27 is used as a carrier.

If you want to save money or need an even more compact frame, then you can look for products UD-20-17 and CD-47-17.

With their help you can collect very lightweight design, if it does not bear any load at all.

The length of the ceiling profile for plasterboard is similar to the wall profile.

Septal

Reinforced partition profiles for plasterboard types UW and CW is produced with the same dimensions as a regular wall one.

Thanks to this, products can be combined in one design - where there is a load, use a reinforced type, and in other places install a regular one.

The situation is similar with the product for openings; the width is available in a choice of 50, 75 or 100 mm. The length of standard planks is 3-4 meters.

Fastening elements and methods of fastening

In addition to the planks themselves, you will also need to purchase some parts necessary to fasten individual fragments of the frame into a single whole.

The most popular methods are self-tapping screws and a cutter. The industry offers special self-tapping screws for screwing together individual planks and for securing drywall to the frame. The latter were discussed in a separate article (OR-030). Therefore, now let’s talk about self-tapping screws for assembling the frame.

The most popular methods are self-tapping screws and a cutter. The industry offers special self-tapping screws for screwing together individual planks and for securing drywall to the frame. The latter were discussed in a separate article (OR-030). Therefore, now let’s talk about self-tapping screws for assembling the frame.

Here, very small and short hardware is used, which is popularly called “bugs” or “fleas”. The similarity is not only in size - if you drop such a flea on the floor, it is easily lost, and then can painfully bite into your leg.

The length of such a self-tapping screw is 9-16 mm, diameter is 3.5 mm. They come in two types - sharp tip (LN) and drill tip (LB). The former bite well into steel up to 0.7 mm thick, the latter are capable of screwing into metal up to 2.2 mm thick.

You can also use a metal screw with a press washer.

It has a lower head, so if it is screwed into the plane where the drywall will then be attached, it will interfere less.

But still, in such cases, using self-tapping screws is highly not recommended. If there is a risk that the cap will prevent the drywall from laying down normally, then a special cutter should be used.

But still, in such cases, using self-tapping screws is highly not recommended. If there is a risk that the cap will prevent the drywall from laying down normally, then a special cutter should be used.

A hand tool called a cutter is somewhat similar to a riveter. Only there are no rivets here. The working element of the cutter is a rod sharpened like a nail. When the handle is pressed, it cuts through sheets of metal folded together and deforms the edge of the hole, bending it inward.

Thanks to this, the sheets become fastened, while nothing sticks out from above and you can safely attach the gypsum board.

However, you should not abuse the cutter. The connection turns out to be rigid, but extremely unreliable and weak. Even under moderate load, it can rupture, which in some cases can lead to the collapse of the structure.

In addition to the cutter and screws, you should also mention:

Price

Prices for products greatly depend on the quality of workmanship and the thickness of the steel. However, indicative data is still worth considering.

| Product type | Size, mm | Price, r |

|---|---|---|

| PS | 50x50x3000 | 150-160 |

| Mon | 75x40x3000 | 170-180 |

| PS | 75x50x3000 | 170-180 |

| PP | 60x27x3000 | 120-130 |

| PPN | 27x28x3000 | 80-90 |

The use of drywall in finishing works has many advantages over using other methods of designing rough surfaces. Practicality of the panels, their ideal geometry and ease of installation- these are the main qualities that determined popularity of this material. But, the optimal configuration of such a finish is only possible if a suitable profile for plasterboard is selected, the dimensions and types of which are presented today on construction market in a large assortment.

Rack profile

This profile has a cross-section in the shape of a channel, and its main element is the back, located at a right angle relative to the concave shelves. Regardless of which model is used, the width of the shelves is 5 cm. But the back itself may have different sizes– from 5 to 10 cm. The rack profile for plasterboard is classified according to this indicator, in terms of its standard size. There is, for example, marking PS50-100, according to which you can determine that its shelves have a size of 5 cm and the back is 10 cm. But the actual width of the shelf may differ from the declared width by 1-2 cm. This must be kept in mind, planning installation with high precision.

The shelves of this profile are equipped with three grooves along the entire length of the guide element. The first is intended for the junction plasterboard sheets, and the other two provide alignment of hardware. There are also special recesses in which communication wiring can be laid. For this purpose, the Knauf profile for drywall has two holes measuring 3.3 cm. They can be used just for installation engineering systems inside facing and partition niches.

The advantages of this type of profile include versatility of use. Its shape fits most mounting configurations – including work with double panels. The advantages include expanding the functionality of the rack system by routing cables, pipes and wires. This can be done bypassing the profiles, however, the presence of special devices in the guide itself saves both time and effort when performing this operation. Depending on the model used, the master can achieve high precision during installation. For example, the mentioned Knauf profiles allow for tight joining without deformation or gaps.

If we talk about the disadvantages, they relate to installation configuration limitations– usually in places where more work is required compact installation sheets.

Guide profile

Models of guide type profiles are distinguished by their U-shape and designed for use as the main frame for a rack fixture. In some cases, such devices are used to provide jumpers between other profiles in load-bearing structures for cladding and partitions. As for the dimensions, the guide profile for drywall has approximately the same shelves as in the case of shelf analogues - the width is 4 cm, and the back size is usually 5-10 cm. The element is installed together with an adjacent profile corresponding to the standard size.

The guides also have ready-made holes with a diameter of 0.8 cm in the wall. They are needed to install dowels, which is significant simplifies the process of fixing the frame to load-bearing basis . If the guide profile for drywall does not have special holes for dowels, then you can make them yourself in the profile wall using a drill.

The advantages include maintaining the basic functionality of the rack profile. These are the strength of the base, the possibility of laying communication lines, flexibility in the installation process and accuracy in the formation of joints.

By by and large The guide profile for drywall is auxiliary and is rarely used as an independent element, which is its main disadvantage.

If planned a complex system, on which heavy plasterboard panels need to be mounted, this option can be optimal choice for reinforcing the base of the load-bearing frame. The rest depends on the specific execution. The highest quality profiles of this type are made of galvanized steel.

Ceiling profile

This profile, like the rack-mount one, has a C-shape and used in creating frames for facing surfaces and suspended ceilings. Each shelf has three corrugated grooves, which act as stiffening ribs. It has a ceiling profile and corrugations in the walls - one runs in the center, and two along the edges. In turn, the edges of the element are concave into the center, thanks to which it can hang on hangers with clamps.

The wide wall can reach 6 cm in size and act as a convenient basis for fixing plasterboard panels different shapes and standard size.

It is worth highlighting one type of such profile - this guiding system, which is used in the installation of the frame of single-level suspended ceilings. If necessary, this configuration can also be used to install the base under the cladding. IN in this case The size of the profile for plasterboard can also correspond to standard formats - 5 cm in width and from 5 to 10 cm in the back. In this case, holes of 0.8 cm are provided in the wall, which are spaced from each other in increments of 25 cm.

The model is designed specifically for ceiling mounting, so it is equipped with high durability and autonomy in operation. This is evidenced by the presence of corrugations, which give the system additional reliability. Also, the ceiling profile for plasterboard, the sizes and types of which may differ, usually requires a wider range of installation methods. In addition to ordinary dowels, the master can use special clamps connecting elements and hangers.

The disadvantages of this type of profile include its specific shape, which limits the range of applications.

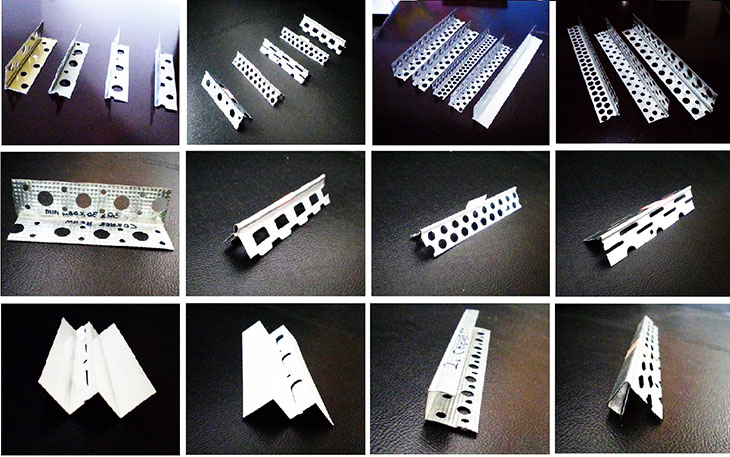

Corner profile

Models corner type used to provide protection external corners sheathing from physical damage. The cross-section of such an element is realized with an acute angle of up to 85°, which allows for tight fixation to the surface of the cladding corner. You can use such a profile for plasterboard partitions, where a protective function will also be performed. The shelves in this case characterized by the presence of perforation with holes with a diameter of 0.5 cm. During the installation process, putty is allowed to penetrate into these holes, which gives additional strength to the fixation of the frame to the cladding surface.

If we consider this profile as a protective element, then among the advantages we can note the reliability of fastening, preventing deformation of the structure, preserving the decorative qualities of plasterboard panels and maintaining the integrity of the cladding or ceiling. Since metal elements are used, the durability of the profile itself is also ensured. Especially if it is made of galvanized steel. This is a practical and simple solution, for which it is valued by experts.

There are few disadvantages to such profiles - quality product It’s not cheap, but unlike its plastic counterparts it performs its tasks more responsibly.

Drywall is a modern finishing product that has gained popularity thanks to its excellent technical specifications. It can be mounted on any surface.

The material is secured in two ways: using glue mixture and on the frame. The last method is the most common. It allows you to quickly and efficiently hide the unevenness of the surface being coated. Special metal profiles are used in the work. They serve as the basis for the installation of the main building block.

The types of profiles for drywall and their purpose are different. It all depends on the type of finishing performed.

Scope of application

The types of profiles for drywall are varied. Each of them has its own purpose. Products are used for the construction of such structures:

- suspended ceilings;

- interior partitions;

- walls with insulation.

Metal profiles are used in the manufacture of decorative structures: arches, columns, etc. It will also become indispensable in leveling any surface.

Technical characteristics of metal profiles

The material is made of galvanized steel. The sheet thickness is 0.6 mm. Production technology - cold rolling. The product is endowed with excellent technical characteristics:

- strength;

- durability;

- wear resistance;

- moisture resistance;

- resistance to aggressive environments.

Profiles for drywall (types may be different) are additionally coated with zinc. This helps protect products from corrosion.

Types of products

To make the gypsum plasterboard structure durable, plasterboard profiles are used. Types of elements:

- guides;

- rack-mounted;

- corner;

- arched

Guide profiles for drywall (types and characteristics differ depending on the type of product) can be ceiling or flat. Rack guides are called wall guides.

Characteristics of guide profiles

The elements are created for the construction of ceiling and wall structures. Manufacturers label them with PN. They help to evenly distribute the load of HA sheets over the surface.

Guide profiles for drywall (types: ceiling and flat) are responsible for the rigidity of the metal frame. Auxiliary elements are attached to them.

The wall thickness of the flat profile is 7.5-10 cm. The width reaches 5 cm, and the thickness of the strip is 4 cm. There are special holes in the structure of the product. With their help, the frame is attached to the base.

Note. Additional holes required diameter You can drill in the profile with a drill.

The ceiling guide profile for plasterboard (various sizes and types of products) is mounted either on the surface of the ceiling or on the top of the wall. The choice of fastening type depends on the complexity of the design.

Advice. If the suspended ceiling has several levels, it is better to fix the frame on a horizontal and vertical plane.

The wall thickness of the product is 0.4-0.6 mm. The profile length reaches 3-4 m. The height of the ribs is 2.7 cm, the width of the wall is 2.8 cm. The products can withstand the maximum permissible physical loads.

Rack profiles

The elements are intended for the construction of walls and partitions. The wall profile for plasterboard (dimensions and types are presented below) is the basis of the lathing. It can be guiding and auxiliary.

Product dimensions:

- length - 3m,

- width - 17.6 cm,

- thickness - 0.5-1.2 mm,

- stack width - 5 cm.

The profile has special holes. With their help, the element is fixed to the surface. There are also grooves for mounting communication connections. Which also simplifies the process of building walls.

A plasterboard partition (types of profiles for fastening: wall, ceiling and corner) is constructed on a load-bearing floor base. One side of the structure is attached to the wall, the upper part to the ceiling.

Arched profile

The main advantage of such a product is plasticity. The profile can be bent to different sides, cut and trim to the right size. It can easily withstand significant physical activity.

Important! In the construction of the arch it is better to use thin wall gypsum board. It is endowed with small mass.

The element has also found wide application in the construction of such structures as columns and non-standard projections on walls. Adding a radius to such a product is not difficult.

The length of the profile can be from 2 to 6 m. The radius can be concave or convex. The product is mounted on load-bearing bases: ceiling, wall or floor.

Corner profile

The product is intended to create correct angles designs from HA. Particularly popular are Knauf profiles for drywall (types differ in cross-sectional parameters). In their structure they have special holes for self-tapping screws. With their help, the product is quickly and easily attached to the corner.

Since the profile is processed after installation plaster solutions, its surface is coated with zinc. It prevents a humid environment from negatively affecting the structure of the element.

Metal profiles from the company "Knauf"

The products are distinguished by their quality and affordable price. The Knauf profile for drywall (the sizes and types of elements are different) is used in repair work for a long time. It is endowed with practicality and durability, wear resistance and reliability.

Types of products:

- rack-mounted;

- guide;

- arched;

- septal

The selection of elements is carried out depending on the type of work being carried out.

Rack element "Knauf"

The profile is used to create false walls, partitions and suspended ceilings. The guides are attached to the floor and ceiling bases. They are connected to each other by grippers. GK sheets are mounted on such a structure.

The product parameters are as follows:

- length - 2.5, 3, 4, 6 m;

- height 2.7 cm;

- width - 0.6 cm.

Material thickness - 0.5 and 0.8 mm.

Sometimes the length of the product is not enough to create a finished design. For this purpose, the elements are provided with special holes for connecting fasteners.

Guide profile from Knauf

Product marking: UD. With the help of such elements, the correct direction for attaching the plasterboard is set. The material is mounted using self-tapping screws and dowels. If a wall or partition is being built, the profile is attached to the wall, floor and ceiling.

The height of the product is 27 mm, width - 28 mm. The length varies between 2.5 and 6 m. The guides ensure the strength of the frame.

Arched profiles "Knauf"

The products are used to create curved decorative elements. They are mounted to walls and ceilings. If you need to make an arched opening, use special profiles (guides).

Arched metal profiles can be like this:

- smooth;

- concave;

- convex.

The radius of the product is 0.5-3 m in increments of 50 cm.

The first type is a flat metal strip. It is given a certain bend by making cuts in the right places.

Partition profile from "Knauf"

Element marking is UW. The width of the strips is 5, 7.5, 10, 12.5, 15 cm. The height of the shelves is 0.5 cm. The length of the strips can reach 6 m.

The partition profile is endowed with the following characteristics:

- strength;

- reliability;

- resistance to aggressive environments;

- resistance to fire.

The height of the walls of the product makes it possible to efficiently insulate the structure. Sheet insulating material is inserted into the cells of the metal profile lathing. GCR is attached to the frame on top of it.

Manufacturing technology for drywall profiles

The production of products requires the presence of special equipment - profile bending machines with removable attachments. Raw materials for the manufacture of elements - metal sheets of various thicknesses.

Note. Large manufacturing enterprises who produce profile sheets, produce profiles from leftover material.

Work process:

- setting up the machine to the parameters of the metal sheet used;

- filling the strip or blank into the device;

- rental of the product depending on the installed type.

Finished items must match regulatory documents- GOST.

Installation of profiles for drywall

Even a non-specialist can cope with such a task. Initially, it is necessary to determine for what purpose the sheathing is being constructed: creating a wall, partition, arch, or leveling the surface. Depending on the task at hand, the type of metal profile is chosen.

For work you will need the following tools:

- construction tape;

- level;

- grinder or metal scissors;

- screwdriver;

- drill.

All structural elements are fastened together with self-tapping screws and additional fastening connections. Experts recommend making small frame cells. This will give strength to the sheathing.

Stages of work:

- marks are made on the surface of places for attaching profiles;

- install horizontal guide elements at a distance of 40-60 cm from each other;

- vertical auxiliary profiles are fixed between them (the width between them should be no more than 50 cm);

All elements are connected with metal screws.

Installation of drywall on profile sheathing

The following is used in the work:

- stationery knife;

- self-tapping screws for drywall;

- construction tape;

- screwdriver

Drywall sheets have various sizes. In some cases, they do not need to be trimmed.

It is better to start installation from a corner. The HA is leaned against the sheathing and begins to be secured from the top of the sheet. The distance between the screws should not exceed 30 cm. Subsequent sheets are fastened using a similar method. After this, the joints of the material are treated with putty and sandpaper.

Sheathing the surfaces of walls, ceilings or constructing partitions from plasterboard sheets (GKL) or GVL - gypsum fiber sheets begins with the construction of a frame base. Certain types of profiles are used to assemble the structure.

Kinds

- Guide (PN)– international designation UW. As the name suggests, it is used as guides to which racks or guides are attached to construct a ceiling frame. The profile shape is U-shaped.

- Ceiling guide (CNP)– in the international classification it is designated UD. Has the same purpose as the UW profile. It is a fundamental and indispensable part when constructing a ceiling structure for gypsum fiber board cladding.

- Ceiling (PP)– international designation CD. Ceiling frame bases for finishing gypsum boards are assembled directly from these parts.

- Rack-mount (PS)– according to the European classification CW. It is from this type of metal profile that partitions and wall structures are built under sheets of plasterboard.

- Arched. This type has a curvilinear shape (a combination of concave and curved sections or arched). Used to create arched openings and complex curved structures.

- Beacon profile (PM). Used as a base during plastering and a guide for rules. Leveled profiles allow you to achieve a smooth surface of walls and ceilings when leveling them.

- Corner (PU - protective and PSh - corner plaster). To protect outside corners plasterboard structures PU are used. The holes made along the entire length of the part facilitate the penetration of putty, thus it is securely fixed. Corner PSh are used for plastering internal, external and corners doorways. Through special holes in the profile, the plaster penetrates freely and is evenly distributed over the entire surface, firmly fixing the product.

Fasteners

In the design of residential and office premises Complex and multi-level structures can be assembled for finishing with gypsum plasterboard and gypsum fiber board. To implement these plans, you cannot do without connecting and fastening elements:

- Crab connector. Single level connecting element for PP (CD). Designed for joining profiles at the same level at an angle of 90º. When the load is less than 20 kg/m. sq. the structural parts are fixed with special latches. Otherwise, additional fastening is required with two self-tapping screws on each side.

- Two-level connector. Performs the same functions as the previous docking product, but on different levels frame. This part is sold unwrapped. Therefore, before installation, its edges must be bent and given a U-shape.

- Straight hanger for PP profile. Used for ceiling bases under plasterboard and attached directly to the ceiling. With its help, profile beams are mounted exactly level. It is sold unfolded and during work it is necessary to give it the shape of the letter “P” to the required height (maximum 15 cm). Attached with self-tapping screws to the side shelf and dowels to the ceiling surface. Maximum load 40 kg.

- Anchor suspension. Has the same purpose as the previous mount. Due to the presence of draft, the suspended ceiling can be lowered 100 cm from the ceiling plane. Maximum load 25 kg.

- Extension. Used for joining two profiled (CD) elements at an angle of 180º, i.e. extend load-bearing beams designs. It has a concave base and is inserted inside the profile. Additionally secured with self-tapping screws.

- Corner connector. Used to connect ceiling profiles at corner or T-shaped joints.

Profile sizes

The range of sizes is standardized and each type of profile has its own maximum and minimum dimensional characteristics.

- Mon– length: 3000 mm, height (shelf): 40 mm, width (base): 50, 60, 65, 75 and 100 mm.

- PS- standard lengths: 3000, 3500, 4000 and 6000 mm, height: 50 mm, width: 50, 65, 75, and 100 mm.

- PP– length: 3000 mm, height: 27 mm, width: 60 mm.

- PNP– length: 3000 mm, height: 27 mm, width: 28 mm.

- PU– length: 3000 mm, shelf dimensions: 25x25 mm and 31x31 mm, profile thickness: 0.4 and 0.5 mm.

- Corner PS– length: 3000 mm, shelf size: 35x35 mm.

- PM– length 3000 mm, section dimensions: 22x6 mm, 23x10 mm, 62x6.6 mm.

- Arched. Concave - standard lengths: 2600 mm, 3100 mm, 4000 mm, bending radius: from 500 to 5000 mm and more. Convex - standard lengths: 2600 mm, 3100 mm, 4000 mm, bending radius: from 1001 to 5000 mm and more.

- The suspension is straight. The standard length is 12.5 cm. But lengths from 7.5 to 30 cm are available for sale.

- Anchor suspension. Standard pull lengths: 25, 50 and 100 cm.

Prices for profiles

Approximate prices for all types of profiles and fasteners:

- Mon– from 50 to 150 rubles/piece.

- PNP– from 47 to 100 rubles/piece.

- PP– from 65 to 170 rubles/piece.

- PS– from 90 to 275 rubles/piece.

- Arched– from 30 to 400 rubles/piece.

- PM– from 20 to 90 rubles/piece.

- PU and PS– from 20 to 130 rubles/piece.

- "Crab"– from 10 to 50 rubles/piece.

- Two-level connector– from 7 to 30 rubles/piece.

- Straight suspension– from 5 to 25 rubles/piece.

- Anchor suspension— from 15 to 40 rubles/piece.

The price of the profile depends on the cross-section and length of the product itself, and on the manufacturer. Therefore, the cost of profiled parts and fasteners on the market can vary widely.

Rules for choosing a quality profile

When choosing profiled parts Special attention pay attention to product quality:

- Any type of profile must be smooth along the entire length of the beam. Curvature negatively affects the quality and shape of the structure.

- The galvanized coating must not be damaged. This type of defect leads to moisture penetration under the zinc layer, which leads to the destruction of the part.

- The thickness should not be less than 0.55 mm. Otherwise, the threads quickly work out, the screws turn and the entire frame begins to come loose.

- The cross-sectional dimensions and length of parts must comply with established standards. A discrepancy between the dimensional characteristics will lead to the impossibility of joining the structural elements.

- The profile should not have burrs or nicks. This indicates its low quality. You may injure your hands when handling it.

- If the notch is weak or sparse, difficulties will arise when screwing in the screws - they will “dance.”

- Excessive perforation ( special knurling) may be a trick of the manufacturer, due to which it is impossible to check the thickness of the profile.

- Do not buy a painted profile or one that is too shiny. This is how unscrupulous sellers try to hide obvious defects and defective products.

- At the same time, a “cloudy” or matte surface indicates that the coating was applied electrolytically or from recycled zinc. This greatly reduces the quality.

- The product must have sufficient rigidity. Squeeze one sample of the product with your hand, and then the same one from another manufacturer. This deficiency will lead to fragility of all bases under drywall.

- High-quality products have pronounced stiffening ribs along their entire length.

- Corner connectors can be used instead of crabs.

- Carry out installation work wearing protective gloves.

- When assembling the frame, use a magnetic bracelet on which you can attach screws for convenience and speed up the work.

- Traces of rust on the surface of the profile indicate a damaged and low-quality zinc coating.

- Excessive savings on profiled parts can negatively affect the quality of the design.

- Before the purchase necessary details you should make a drawing of the future foundation with all structural elements, make quantitative calculations.

- Check the thickness with a caliper; if you don’t have one at hand, compare two profiles of the same type from different brands.

Modern ceiling structures and the walls are easy to assemble. Profiles for plasterboard systems are installed at the base of the frame. They are securely attached to the wall with dowels. GK sheets are mounted to the created metal frame using self-tapping screws. Such rational way allows you to reduce time and effort to create suspended ceilings, soundproofing partitions, decorative walls and other figured elements of the premises. In addition, the price of profiles for plasterboard and plasterboard sheets is currently available to every client.

The easiest and most convenient way to buy drywall profiles and other related products is in our online store.

Types of goods and their applications

In order to firmly secure a system of plasterboard sheets in a structure, you need to form a reliable metal frame. Depending on what kind of base you need - ceiling or wall-mounted, you need to select and buy such building profiles as:

- Rack-mounted

- Wall.

- Ceiling.

- Ceiling-mounted.

- Ceiling-wall.

- Guide.

Every metal element participates in the process of frame formation. Post and guide building materials form the basis of the structure. Dropped ceilings are mounted on a frame made of ceiling-rack products; partitions and partitions are formed from wall, rack and guide elements. Thus, for the device multi-level ceiling or decorative wall you will need a set of metal elements.

Parameters and cost of products

The online store offers a wide range of building materials for quality repairs premises. Before making a choice in favor of this or that product, you should know the sizes and prices of the profile for gypsum boards. In accordance with established standards of building materials, manufacturers produce standard sizes profile under gypsum board. The length of the products is 3 and 4 m, and the size of the sections differs by model (mm):

- Rack: 50x50, 75x50, 100x50.

- Guides: 50x40, 75x40, 100x40.

- Ceiling: 60x27.

- Ceiling guides: 28x27.

The products are suitable for gypsum board sizes. Standard sheet parameters are: 1.2x2.0; 1.2x2.5; 1.2x3.0 m. The thickness of the plasterboard depends on its purpose: wall - 12.5 mm, ceiling - 9.5 mm, arched - 6.5 mm. Due to the thickness of the products, prices for wall plasterboard will be higher than for ceiling plasterboard. You can learn more about the characteristics and cost of products by tearing off the product card.

We sell products trademark Knauf, whose building materials serve as a reliable basis for high-quality construction of structures and finishing of premises. In the online store you can easily buy a wall profile - one of the main elements for creating plasterboard systems, as well as a set of metal guide elements.

The cost of installing plasterboard systems will depend on the design parameters. You can easily calculate required amount building materials and scope of work. If you need help, contact the company's managers.

Easily and quickly purchase products online. All you need to do is select the product names, add them to your cart and fill out the form. The manager will contact you shortly to clarify the order and arrange fast delivery building materials directly to your address.