List of dishwasher faults. Ways to eliminate, do-it-yourself repairs. How to repair a dishwashing machine? We repair automatic dishwashers. (10+)

Dishwasher malfunctions and repairs

A dishwasher (DM) is a fairly simple unit. Many of its faults can be diagnosed and fixed independently. Let's look at them in more detail.

Water does not heat up

Heating in the PM is carried out by a heating element installed at the bottom of the chamber for dishes. Complex models are equipped with a temperature sensor that allows the machine to heat water to a certain temperature in accordance with the selected mode. Simple models turn on this heating element for a certain time without any feedback. During this time, the water heats up as much as it can.

In machines with a temperature sensor, if the element burns out, the work stops altogether, since the water cannot heat up to desired temperature, the temperature sensor does not work, the washing process cannot be continued. This malfunction can be determined by the behavior of the machine. It fills with water (a characteristic sound is heard), then it begins to heat the water, and then the machine dies, nothing happens. Some machines have a thermocouple burnout indicator.

In machines without a temperature sensor, burnout heating element does not cause the machine to stop. The machine continues to wash dishes cold water. The quality of washing, of course, drops sharply. You can determine the malfunction by opening the machine after the dishwashing cycle. The cookware and the inside of the machine should be quite warm. You can also feel the drain pipe of the machine when draining the water for the first time. It should be warm. If the dishes and the outlet pipe are cold, it means that the heating element has failed or the automation that controls it is faulty.

You will not be able to repair the automation yourself. But the heating element can be replaced. Let's check it first. We turn the car over. Remove the bottom, if there is one. Looking into the dish compartment, we will find the heating element. It stands at the bottom of the chamber (now, in the new position of the machine, it is at the very top), and its contacts and the mounting block are brought out through the bottom. The contacts are connected to the wiring. Some elements are connected with a clip, while some wires are screwed with nuts. In any case, disconnect the wires and use a tester to measure the resistance of the element. The tester should show the presence of conductivity.

If there is no conductivity, the heating element (thermal element) is definitely faulty. It is easy to remove. It is secured with several bolts or screws. We unscrew them from the bottom and remove the heating element from the side of the chamber for dishes.

Electric shock from the car

With a 99% probability, the heating element is also to blame. It hit him. We remove the thermal element and inspect it. Usually cracks and defects are visible when visual inspection. You can place an element in salt water and measure the resistance between one of its electrodes and the salt solution. The presence of conductivity indicates breakdown. However, this measurement method does not always give the correct result. In some rare cases, a broken heating element does not show conductivity.

The cause of burnout or breakdown of the heating element is usually too hard water and neglect of use table salt for softener regeneration.

The water is overheating

Some time after filling the water, steam begins to pour out of the machine. The wash does not start. The water temperature sensor or the brains that control the heating element have failed. Such a brain malfunction occurs theoretically, but in practice I have never seen it. Usually the sensor is faulty.

Water does not pour

There may be several reasons. Firstly, the water supply valve is faulty. This valve is installed immediately behind the water supply pipe from the water supply. Together with this pipe, it usually forms a monolithic, non-separable structure. Secondly, the mesh that is installed between the water supply hose and the inlet pipe is clogged. Third, the water level sensor is faulty. The car always thinks that the water has already filled.

Let's check and clean the mesh first, as this is the easiest. If this does not help, then remove the valve and check it with a tester. Conductivity must be present. If there is continuity, you need to read what is written on this valve. If it is designed for 220V, then you can very carefully (so as not to get under voltage yourself), plug it into the network and make sure that it opens, for example, by blowing into it. If it is designed for a different voltage, then this voltage must be supplied. In some cars, this valve operates from a 12-volt power supply to the brain. But such valves - very rare. Usually 220V is supplied. It is clear that if 220 is applied to a 12-volt valve, it will immediately burn out.

If the problem is not in the mesh or in the valve, then the level sensor is faulty. Here I want to upset you; if the level sensor malfunctions, the heating element usually burns out immediately.

Water does not drain

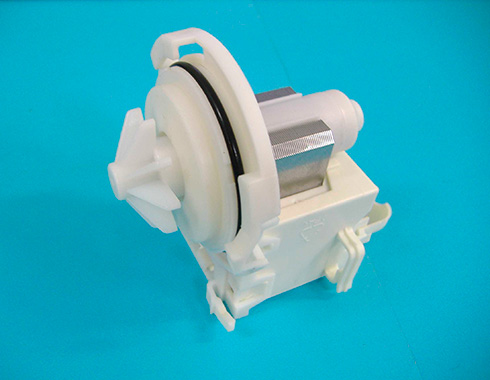

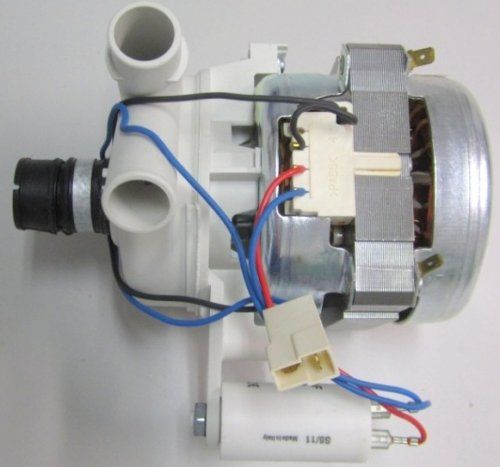

The water drain unit (valve and pump) is faulty. They should be replaced. Usually this is a single block.

The water is overflowing

Some time after turning on the machine, water begins to flow from all the cracks. The level sensor is faulty. But, unlike the previous option, it now shows a constant lack of water. This malfunction is unpleasant from the point of view of flooding the neighbors below, but is not dangerous for the heating element. This sensor is usually installed at the bottom of the machine. Let's turn the dishwasher over, remove the bottom cover and replace the sensor.

Dishwasher doesn't wash dishes

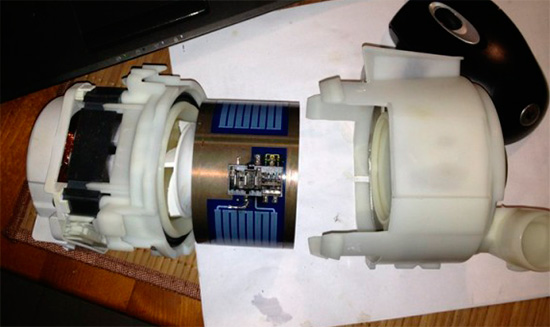

The machine turns on, fills with water, heats the water. But then the characteristic sound of washing is no longer heard. There are no streams of water. There may be three reasons. Firstly, the filter is clogged. The filter is located at the very bottom of the dish compartment. It needs to be opened and washed. Secondly, the nozzles in the combs are clogged. The injectors can be cleaned with a toothpick. Third, broken circulation pump, which drives water from the bottom of the dishwasher chamber into the nozzles and ensures washing of dishes. This pump makes a characteristic sound when washing dishes. If there is no sound, the pump is probably broken. You can replace the pump yourself. It is installed under the bottom of the cooking chamber. Power is supplied to it by a clip, water is supplied and discharged through tubes that are put on the inlet and outlet pipes of the pump and secured with clamps. The clamps must be removed and the tubes disconnected. The pump is secured with one or more self-tapping screws. Unscrew them and remove the pump. Installation is carried out in reverse order.

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared. Subscribe to the news to stay informed.

If something is unclear, be sure to ask!

Ask a Question. Discussion of the article. messages.

Dishwasher problem. Stopped working halfway through the program. I removed the water from the filter and cleaned the injectors. I turned it on and got some water, but the pump doesn’t work (the machine doesn’t supply water to the blades). I disconnected it from the network, drained the water and connected it - it ignores the lack of water, the heating element heats dry.

Dishwashing machine maintenance...

Installation, connection and operation dishwasher. What are the disadvantages...

Knitting. Autumn foliage. Drawings. Pattern schemes...

How to knit the following patterns: Autumn foliage. detailed instructions with explanations...

Knitting. Waffles. Striped shadows. Strings on the wrong side. Drawings...

How to knit the following patterns: Waffles. Striped shadows. Strings on the wrong side...

Knitting. Zigzag arrows. Bows. Drawings. Pattern schemes...

How to knit the following patterns: Zigzag arrows. Bows. Detailed inst...

Knitting. Diagonality. Flower fantasy. Tightened stripes. Drawings....

How to knit the following patterns: Diagonal. Flower fantasy. Tight stripes...

Knitting. We knit three loops from one loop. Drawings. Pattern schemes, oh...

How to knit three loops from one loop. Examples of drawings with such loops...

At one time, a British magazine conducted a survey of readers about the quality of household appliances. There was only one definite conclusion - problem-free household appliances do not exist. Moreover, the models of the elite class begin to fail after 5-6 years. Their conclusion about the degree of reliability of dishwashers of leading brands. Thus, the British named Ariston, Bosch and Electrolux as leaders in durability among brands.

But, as was said, even the most reliable home assistant begins to fail. And when this happens, there are two options: roll up your sleeves and take on the repairs yourself, or call a specialist from the service center for help. Statistics speak in favor of the first option, namely, most dishwasher malfunctions are corrected at home. And in the statistics of service centers, the leading place is occupied by “no drainage”.

Therefore, it is quite possible to fix minor and not very complex faults yourself, but to do this you need to get acquainted with the structure of the dishwasher and consider possible options dishwasher repair. Which is the purpose of this article.

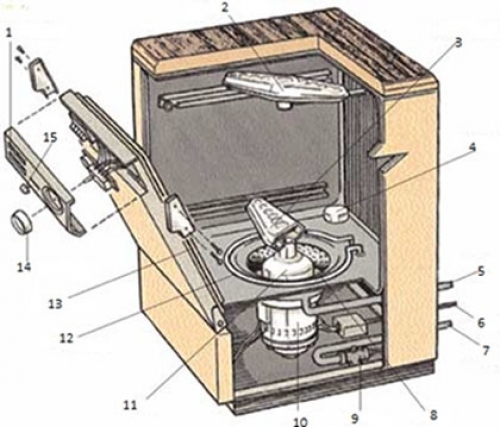

Dishwasher design

The case, as in any household appliances, performs the function of a base on which all the main components and assemblies of the machine are located. The main elements of a dishwasher include the following:

- The control panel, which is always located on the front side of the machine. It consists of a digital microcontroller (timer), control buttons and an indicator display (an indicator beam that is projected onto the floor surface can be used as this).

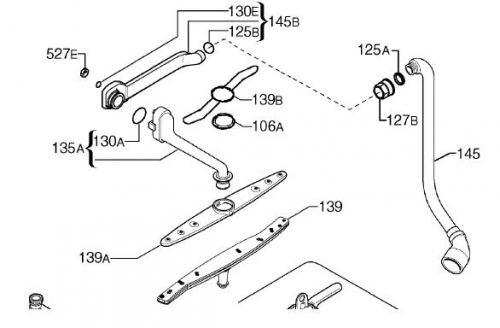

- Spray blocks or impeller. This is a water supply system for washing dishes. It consists of a system of tubes and nozzles (there are two of them: upper and lower). Thanks to the special design, water from detergent supplied under greater pressure than provided high quality washing dishes.

- Float switch - a means of protection against water leakage. A hollow plastic cylinder floats up at a certain volume of water and thereby closes the contacts. Depending on the constructive solutions these contacts close the pump activation circuit to pump out water or carry out emergency closure of the water supply valve to the machine.

- The drainage unit consists of a drainage pipe, which is connected to the general sewerage network and a sump pump. The operating principle is identical to draining into washing machines, who is familiar.

- Water inlet with built-in inlet valve, which is controlled by a digital microcontroller.

- The water pump is used to supply water to the sprayers and, on some models, to drain the water. As a rule, it is located together with an electric motor, which starts the pump.

- Filters are designed to “catch” leftover food and other items.

These are actually all the most important and most frequently encountered malfunctioning elements of dishwashers. Of course, different manufacturers may add other blocks that expand the functionality of the unit. But all of the above is a base; once you understand it, you can easily understand the individual design elements of your car.

The most common malfunctions and how to fix them

To repair a dishwasher with your own hands, you need to have a minimum set of tools, namely:

- screwdrivers: Phillips, flat and hex (as shown in the image);

- multimeter with resistance measurement scale (Ohm);

- pliers and wire cutters.

There is no indication, the machine does not respond to pressing buttons

If there is no indication at all, check the presence of voltage in the outlet using a multimeter. If there is voltage in the outlet, the machine will need to be opened.

If there is an indication of the buttons and display, but the program does not start, check that the door is closed tightly. It didn’t help - repairing Zanussi dishwashers requires disassembling the machine.

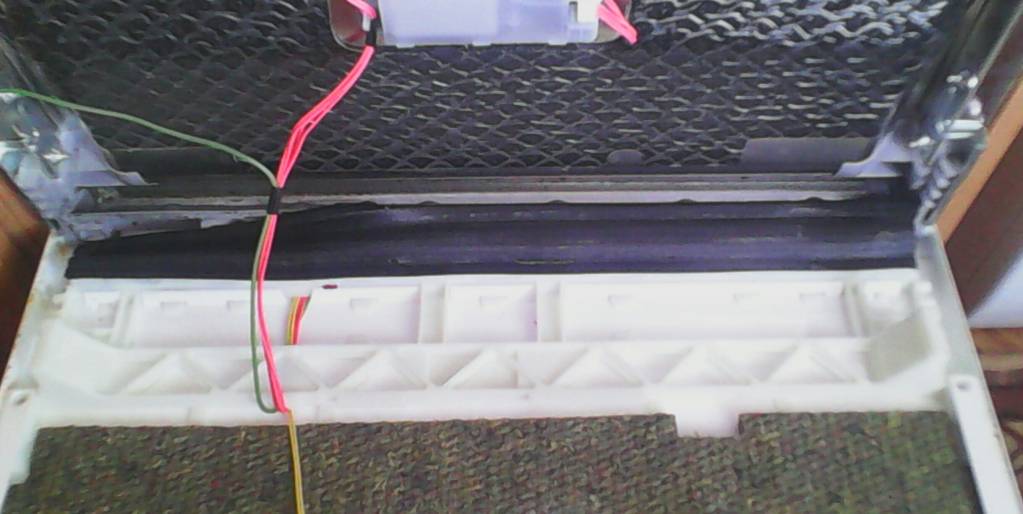

At the bottom of the machine, under the front panel, there should be junction box with terminals. The voltage enters this box through the cable, and then diverges further through the control contacts. Therefore, it is necessary to remove the panel and check the condition of the terminals. This place is exposed to moisture and therefore the contacts may well oxidize. If so, clean the joints with sandpaper.

After you get to the box and if you visually do not find any damage to the wires and connections, you need to ring the power circuit and determine the location of the damage. Disconnect the voltage input wires to the box and test them with a multimeter (while the machine is disconnected from the network and water supply, and all water is drained). Both wires must be interconnected with a device with an established resistance measurement scale, i.e. if the conductor is intact, it should be short, as if you connect two probes together. You can easily replace a faulty cable from the socket to the box yourself, and if after that the machine comes to life, great. If not, then for dishwasher repair Siemens machines or other brands, there are two options: call a specialist or, at your own peril and risk, look for a fault in the circuit further.\

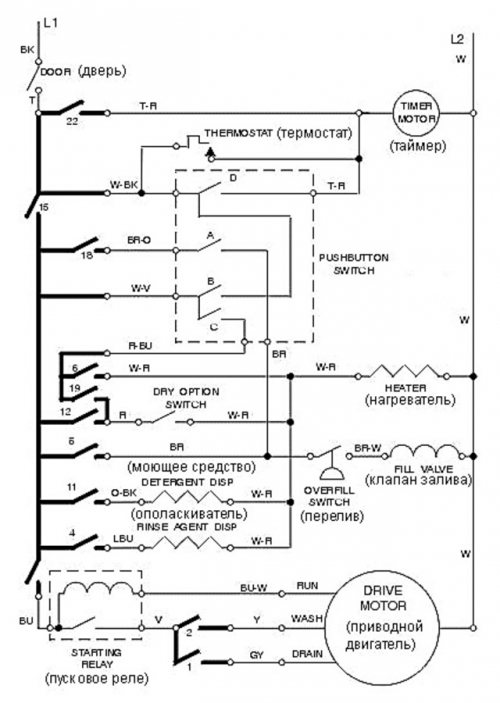

To select the second option, i.e. search yourself, first of all, you will need to find an electrical schematic diagram Your dishwasher model. And then check the entire chain step by step. To do this, break the chain at the connection points and use a tester to check the functionality of all links in the chain.

For easier understanding of the circuit and troubleshooting, here is some information:

- in the diagram, all the colors of the wires are abbreviated in English letters, they all have different colour, thus making it easier to find the required section of the electrical circuit. So be careful and you won't go wrong. An example of such designations: BK - black, T-R - yellow-brown with a red stripe, W-BK - white with a black stripe, BR-O - brown with an orange stripe, etc.

- small circles on the diagram indicate the places of terminal connections; it is in these places that it is necessary to break the circuit and take measurements;

- a dash-dot line means that these groups of contacts and circuit elements are located inside some block, for example a starting relay or a button panel (on the diagram next to the circled area the name of the block and the connection location are indicated with the designation and name of the contacts).

Note. For any chain there must be a beginning and an end, i.e. In order for the voltage to trigger some element of the circuit, it is always necessary that the “+” can get to the minus. Carefully trace the path of switching on the element of the electrical circuit you are interested in (whether it is a bimetallic plate or a heating element). It’s like a route from point A to point B, if there’s a break somewhere, it means a dead end, the voltage won’t pass, all the elements won’t be able to work.

No water supply

If the water supply tap is open and the machine does not draw water into the system, it means either the filter mesh is clogged or the water supply valve is faulty. The valve and screen are located at the bottom of the machine where water enters the machine. It is necessary to disconnect the machine from the pipe, remove the panel and check these elements. If the mesh is clogged, it must be washed with a stream of water. The performance of the valve, or rather its coils, can be checked with a tester. To do this, disconnect the coil leads and measure the resistance. If the device shows a short (as when connecting the probes together) - the coil has an interturn short circuit. If there is zero resistance, then there is a winding break. If there is a certain amount of resistance, the winding is intact, but the problem is inside the valve. In all cases, you will have to buy a new intake valve, similar and with the same capacity.

The machine turns on, water is drawn in, but the washer does not start

Determine by sound whether the electric motor is “humming”. The answer is positive, which means that most likely something has jammed, either the engine or the pump. How to check and unlock the pump is shown in the video below.

The cause of the malfunction may also be damage to the motor windings. To check it, you need to disconnect its terminals and check with a multimeter for open windings or an interturn short circuit. In case of the mentioned malfunctions, it is necessary to replace it with a similar motor or rewind it, which will be carried out by a specialist.

If there is no sound of starting and running the engine, repairing Indesit dishwashers and searching for damage must be carried out in the same way as described in the first malfunction, i.e. It is necessary, guided by the diagram, to follow the circuit and look for the cause of the break.

No water drain

Need to check sewer pipe- Is the drain clogged? The cause may be a clogged or damaged drain pump. To determine the cause of the malfunction, it must be removed and checked for clogging. You can also check the serviceability of the windings using a multimeter.

The cause may also be dirty filters; how to service them is shown in the video below.

No reverse

The causes of this malfunction can be either damage to the motor windings or a malfunction of the timer. With the latter, everything is not very simple, so if you suspect a timer, contact a specialist in the repair of Bosch dishwashers or other manufacturers.

Car leak

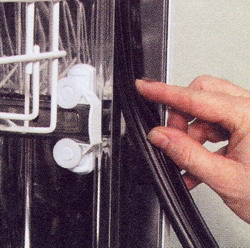

A car leak may be related to the condition of the door seal; this can be checked visually. If its condition is unsatisfactory, then you can buy a new one and replace it with a new one without any problems.

If there is a leak from under the car, it is necessary to determine the location of the leak. To do this, you need to remove the panel in order to get to the bottom. This will allow you to visually identify the location of the leak, usually a damaged pump seal, water supply hose or drain system.

The car makes unusual sounds

Check for metal or glass fragments. Possible bearing wear. If at the same time the quality of dishwashing has decreased, this may indicate damage to the pump impeller. Therefore, if there are no fragments, it will be necessary to disassemble the engine and pump in order to determine the degree of wear of the bearings. The motor shaft must run smoothly and smoothly without obstacles.

No water heating

This malfunction may be caused by the following reasons:

- heating element is faulty;

- temperature sensor is faulty;

- timer malfunction.

You can figure out the first malfunction yourself; disconnect the heating element and check for resistance. If there is a break, we buy a new one and replace it. With the other two it will be quite difficult, for example, to check the timer you need to know the entire sequence or algorithm for turning on the contacts for heating the heating element. That's why optimal solution for most users there will be a call to service center.

No dish drying

If the machine is equipped with a turbo dish drying system, then this malfunction indicates damage to the windings of the fan motor or damage to the fan motor circuit. It’s easy to check the windings; you need to get to the fan motor switching terminals and check their serviceability with a multimeter. If the fan is operational, it is necessary to check the entire electrical circuit for turning on the fan.

We looked at the most common dishwasher malfunctions. Of course, it’s impossible to describe everything, but we hope that we have covered the troubleshooting algorithm sufficiently so that you can start repairing dishwashers yourself. It is worth mentioning that DIY repairs of Electrolux dishwashers, or any other dishwashers, should be done after the warranty period has expired. Otherwise, you will lose the manufacturer's warranty, but it is, of course, up to you to decide.

Dishwashers from Indesit are affordable household appliances. The price of dishwashers of this brand is significantly lower than that of other brands. Therefore, they are in demand among consumers.

Malfunctions may appear a year or two after purchasing an Indesit dishwasher. Electronics are very sensitive to voltage surges, which leads to burnout of contacts and the control board. Let's look at the main causes of breakdowns and options for eliminating them.

The time of failure cannot be predicted, but the cause must be found out. After years of use in the dishwasher, any of the components may fail. How to identify the problem? See recommendations:

- Pay attention to the symptoms of failure. Is the machine malfunctioning or won't turn on? All this points to the cause of the malfunction.

- Look at the display. Often the self-diagnosis system generates an error in the form of a code. Deciphering the code will indicate a breakdown.

What malfunctions are typical for Indesit dishwashers:

- Failure of the heating element leads to a decrease in the quality of dishwashing. The machine does not heat the water. It is necessary to check the heater and its wiring. The electronic module and triacs for controlling the heating element are also inspected.

- Extraneous noises during operation may indicate wear on the motor bearing. This happens when the oil seal becomes unusable, the lubricant is washed out and the bearing begins to creak. It is necessary to completely disassemble the pump and replace the bearings. Noise also occurs when glass gets into the pump impeller.

- A typical malfunction is that the machine does not take in water. The problem lies in the filling system. Everything needs to be checked, cleaned, replaced.

- When your dishwasher leaks, it may be due to the door seal. It could be worn out or damaged, then a replacement is needed. The Indesit dishwasher tank itself often leaks. Here you will need knowledge on how to disassemble the equipment and replace the tank.

- Why does the Indesit dishwasher squeak when working? The problem may be in the control module. Diagnosis and replacement of the part will be required.

- If the water drainage does not work, the drain pump, filter and hose must be checked.

Let's move on to the search faulty parts and their repair.

How to repair a dishwasher with your own hands

You can repair the Indesit dishwasher yourself. To ensure everything goes well, follow our recommendations.

The heater often suffers from scale and voltage surges. Because of poor quality water with a high salt content, plaque settles on the heating element. Over time, the scale layer becomes larger, which leads to overheating and combustion of the heating element. In addition, more energy is spent heating water.

Instructions for replacing the heater:

- Unplug the dishwasher. Turn off the water supply.

- Place the car on its side.

- Open the bottom cover. In the Indesit dishwasher, the heating element is connected to the pump.

- Before removing the heater, check it for serviceability. Disconnect the heating element wiring, attach the multimeter probes to the contacts. If the part is faulty, it must be replaced.

- Unclench the heater clamps and disconnect it.

- Disconnect the clamp and remove the hose from the pump to the water container.

- Disconnect the pump wiring.

- Remove the pump and heater from the housing.

- By turning clockwise, disconnect the heating element.

to install new element, remove the seal from the pump and replace it. To make the heater easy to put on, lubricate its edges and seal.

The heating element is installed in the reverse order, the removed clamps are replaced with new ones.

If waste water is not washed away after washing, check the drainage system. How to do it:

- Open the machine door and remove the trays and racks.

- Pull out the filter at the bottom and metal mesh(if there is). Wash the parts under running water.

- If water has accumulated where the filter is installed, remove it with a sponge.

- Push and pull the pump cover.

- Inspect the impeller for blockage and clean it.

To check the pump's functionality, approach it through the bottom of the car.

Disconnect the pump wiring and check the contacts with a multimeter. If damaged, replace it. To remove the pump from the circulation pump, turn it clockwise.

A leak in an Indesit dishwasher occurs due to a worn seal on the door. You can easily replace it with your own hands:

- open the hopper door;

- disconnect the seal around the perimeter of the machine;

- take a new gasket, insert it in place of the old one, spreading it around the perimeter;

- remove excess sealant with a knife.

Carry out a test run to check the seal in action.

To replace the lower door seal, proceed as follows:

- open the hopper door;

- Unscrew the screws around the perimeter of the inner door panel;

- lift the door up external panel Pull the doors down and remove them;

- open the door again and remove the basket from the hopper;

- below you will see part of the seal;

- pull out the seal by pulling the edges with tweezers;

- On the new product you will see a mark with right side– this means that the right part of the seal should be installed from the right inward;

- fill the seal and assemble the door.

The control module is a complex and expensive part. Each triac on the module is responsible for the operation of certain parts of the dishwasher. It is better to entrust module repair to a specialist.

But if you want to inspect it and find the problem, here is a guide:

- remove façade panel doors, as described above;

- Unscrew the bolts that hold the control panel;

- place the panel on top of the case;

- to disconnect the module, disconnect the black wire;

- unscrew the screws holding the module to the panel;

- disconnect the wiring; Before repairing, it is better to photograph the location of the connectors.

You can inspect the part. Installing a new module is done in the reverse order.

Taking a long time to fill the machine with water indicates a blockage in the system. How to troubleshoot:

- Turn off the water supply.

- Unscrew the inlet hose from the PMM body.

- Disconnect the second end of the hose from the communications.

- Inspect it and rinse under running water.

- Pull out the strainer. It is installed at the inlet to the intake valve.

- Clear it of any blockage.

The intake valve is also checked.

If there is no blockage, test the electronic parts with a multimeter. If the valve breaks, it must be completely replaced.

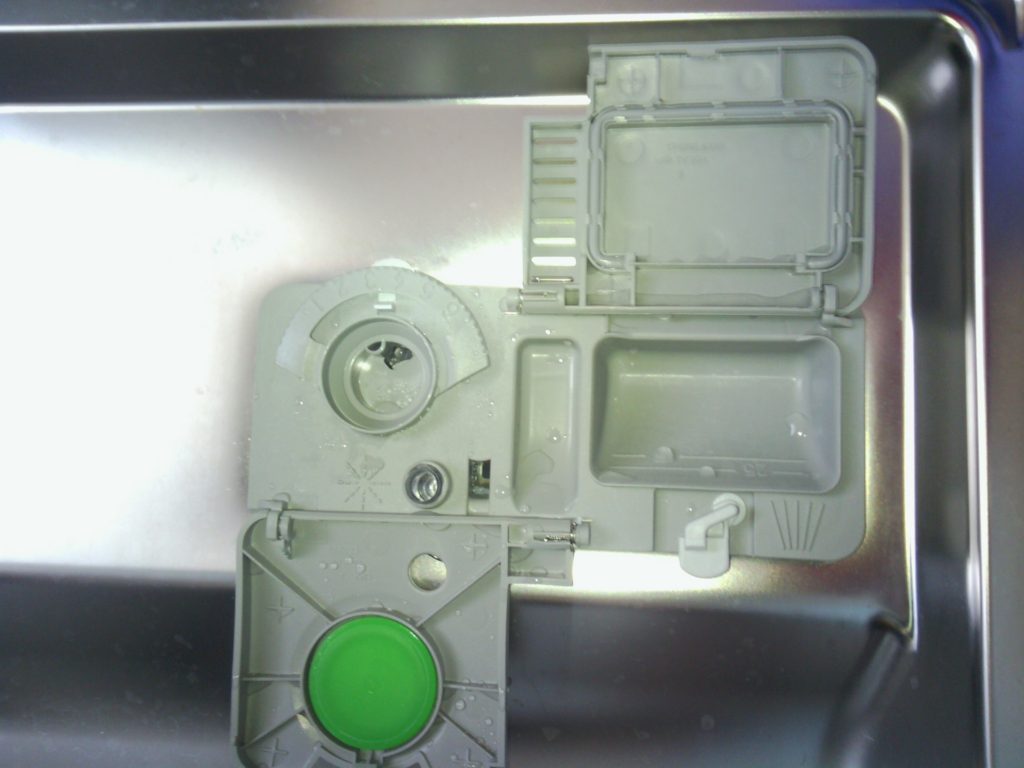

A common reason why the quality of dishwashing decreases is a clogged dispenser tray. If you don't clean the compartments of detergent and powder, the walls will become tarnished. It is difficult to remove it later, so after each wash, wipe the tray with a cloth.

Also check the rocker arm injectors for blockages:

- Remove the upper blade by unscrewing the fastening element;

- pull the lower one towards you;

- Clean the small holes with a toothpick and rinse under running water.

Now you can start the Indesit dishwasher and check the serviceability of all elements.

Monitor the condition of your equipment and do not neglect the first symptoms of a breakdown. It is much easier to fix a problem right away than to carry out a full repair later.

If you bought a dishwasher, and it suddenly decided to break down, don’t get upset and call the service center - you can do the repair yourself, without outside help. Dishwashers are not as complicated as it seems at first glance. Many people do their own repairs to Bosch dishwashers. The main thing is to learn to understand the basic faults, which we will talk about in this review-instructions.

Dishwasher won't turn on

Repairing Bosch dishwashers is carried out in the same way as repairing any other dishwashers - they are designed in approximately the same way. And the simplicity of the design allows you to count on success during repair procedures. Let's figure out why the dishwasher may not turn on and show absolutely no signs of life.

First of all, you should suspect a mechanical on/off button. It is not designed to last a million cycles, so it can easily fail. The contact groups here are weak, therefore, breakdowns occur frequently. The repair is preceded by testing the button - you can measure the presence of voltage at the output or test the functionality of the contact group with a multimeter operating in ohmmeter mode.

We may also suspect other components of the dishwasher to be faulty. Bosch machines– this is a power cable and a control module. We check the integrity of the cable with the same ohmmeter, but testing the control module at home is difficult. But if food does come to it, then we have no choice but to sin against it.

In addition to the above modules and components, it would not hurt to verify the integrity of the fuses and the functionality of the socket and electrical wiring - the repair consists of replacing the indicated items.

Dishwasher won't start washing dishes

Malfunctions of a Bosch dishwasher can be very different - after all, there are a huge number of parts on board that can break. If the dishwasher stops running programs, then repair is preceded by a thorough check of the equipment. First you need to open and close the loading door - it is quite possible that the cycle does not start precisely because of it. At the next stage, we check the filter of the device.

Failure to start may be caused by other faults. If the dishwasher is modern, it will show an error code. By looking at the table with codes, you will understand what exactly went wrong. This diagnostic scheme is particularly convenient, as it allows you to quickly identify the faulty unit. All you have to do is carry out repairs based on the data obtained during diagnostics.

Also, the normal start of a Bosch dishwasher can be prevented by faulty sensors (thermostats, pressure switches), a motor (also known as a circulation pump) and a control board. Repair of all these parts and assemblies most often comes down to their complete replacement.

Water does not flow into the car

We are trying to figure out the malfunctions of Bosch dishwashers in the absence of normal water filling. First of all, you should inspect the inlet hose - it could have been accidentally pressed under the body of the device. We also try to open and close ball valve, installed after the tee or on the final section of the incoming pipe. At the same time, we make sure that there is water in the water supply - to do this, you need to open the tap above the sink or in the bathroom.

If there is water, we try to check the mesh filter installed in the inlet hose or in the Bosch dishwasher itself. If there are blockages, the mesh should be washed or blown out. If the water supply system has additional coarse filters, we check them too - they could become clogged or simply break.

If water still does not want to flow into the dishwasher, check the operation solenoid valve installed at the entrance to the device. To do this, use a multimeter in voltmeter mode - when starting the program, supply voltage must be supplied to the valve (for it to open). If there is no current, then the repair will be reduced to replacing the valve.

Repairing a Bosch dishwasher when there is no water filling involves checking the integrity of the wires supplying the valve. If there is no power even at the output of the control board, then the board itself needs repair.

The machine does not drain water

Bosch dishwashers are reliable and resistant to breakdowns. However, no one is immune from repairs. If the device stops draining waste water into the sewer, you need to take action. This is usually where the drain pump breaks down.– it is not particularly durable, and if additional loads are applied to it, it easily fails. Repair technology – complete replacement faulty node.

At the same time, we check the integrity of the connecting wires that supply power to the pump. The repair technology in case of a break is a complete replacement of the wires, observing the cross-section. If the noise of the pump is still heard, you need to check its patency and evaluate the patency drain hose– perhaps he was caught by something.

The dishwasher is leaking

Do-it-yourself dishwasher repair often involves dealing with leaks. They form in a variety of places, causing a lot of trouble. It's most pleasant when the dishwasher is equipped Aquastop - this module automatically shuts off the water supply when a leak is detected. After that, all that remains is to find the leak and eliminate it. However, in some situations even Aquastop does not help.

Here is a list of possible culprits for leaks:

- The working chamber - its metal walls may become leaky, and water begins to drip into the pan. Repair consists of sealing the chamber with soldering or special sealants;

- Connection points - in dishwashers Bosch machines leaks can form at any connecting joints;

- Inlet hose - if it breaks, repairs will be required not only to the dishwasher, but also to the floors (and, God forbid, to the neighbor’s apartment). In this situation, devices with Aquastop come to the rescue - they monitor the integrity of the hoses and the presence of water in the pan.

Water cannot flow from some other places.

If a leak is detected, immediately disconnect the dishwasher from the water supply and take all measures to promptly remove water from the floors.

Noise in the dishwasher

Repairing a Bosch dishwasher often comes down to finding the source of suspicious noises. The most alarming situation should be when there was almost no noise, and suddenly it appeared. In this case, you need to urgently find the fault and have the equipment repaired. Here's what you need to pay attention to:

- To the electric motor (aka circulation pump) - here bearings may begin to make noise, spoiled by water leaking from under the seals. The repair method depends on specific situation– sometimes the entire engine changes;

- The drain pump is the main source of noise. If it begins to rumble louder than usual, it means that it is about to end;

- On the rocker arms and their mechanism - sometimes the noise arises here.

There are usually no other sources of noise in Bosch dishwashers.

Dishwasher does not heat water

When repairing a Bosch dishwasher at home, specialists are often faced with a lack of water heating. But in this case it is not necessary to call a specialist, since you can handle the repairs yourself. For this we check the integrity of the heating element using a multimeter in ohmmeter mode– the resistance of the heating element should be several tens of ohms. If it is significantly larger or amounts to several megohms, then we can state a break - the repair comes down to replacing the heating element.

You also need to test the thermostat by applying something hot to it - it should change the ohmmeter reading. Be sure to test the integrity of the wiring through which the supply voltage is supplied to the heater. If there is no current, we check its presence at the output of the control board - if there is silence here, then the problem lies in the board.

Dishwasher does not dry dishes

Repair of Bosch dishwashers may be due to lack of proper drying. If your Bosch dishwasher is equipped with condensation drying, you should make sure that you have rinse aid - it directly affects the quality of drying, causing the water to flow down under its own weight. Condensation drying dries dishes through natural drying, so there is nothing to break.

In addition, in some modes condensation drying does not work, so the kitchen utensils will come out slightly damp.

Turbo drying in Bosch dishwashers is more complicated - it consists of a fan and an air heating element. Repair may be required for both the first unit and the second, depending on what is broken. It also doesn’t hurt to make sure that the supply voltage is supplied to prevent damage to the wiring or control module of the Bosch dishwasher.

Dishwasher electrocutes

A Bosch dishwasher may also require repair if it is electrocuted. This usually indicates a malfunction of the heating element. that heats the water. Testing its integrity comes down to measuring the resistance between its contacts and the body. If the resistance is infinitely high, then the heating element is intact - the fault should be looked for elsewhere. If the resistance is too low, the heating element needs to be changed - an internal breakdown has occurred in it, and it cannot be repaired.

In addition to the heating element, all internal connecting wires and various electronic components must be checked - they should not cause short circuits to the housing.

By repairing your Bosch dishwasher yourself, you can save a lot of money. Judge for yourself - just calling a specialist will cost from 500 to 1,500 rubles. Here you also need to add payment for the amount of work and the cost of spare parts for the Bosch dishwasher. As a result, such repairs cost a lot of money. By using our instructions, you can save on self-repair Bosch dishwasher and spend that money on something nicer.

It’s hard to be surprised by the presence of a dishwasher in the house today. Due to high work commitments and the opportunity to free up personal time, many residents of megacities prefer to install additional equipment in the kitchen. But over time, even the best high-quality luxury dishwashers break down. Most often, the breakdowns are insignificant; they can be fixed independently, without resorting to the services of technicians from the service center.

How the mechanisms of dishwashers work

Principle of operation technical device simple enough:

- The built-in microprocessor reacts to the tightness of the closed door and activates the drain pump;

- When the water level in the pump is sufficient to wash a certain amount of dishes, which is confirmed by a special sensor, the circulation pump comes into operation. It is this detail that creates required pressure inside the housing, causing the impeller to rotate;

- At the same time, the dispenser with soap solution opens, the heating element heats the water and the dishes are cleaned of dirt and food debris;

- The dirty water is drained and a new portion is poured in for rinsing. After this procedure, the water is drained, the contents are dried, and the sensor signals the end of the machine’s operation.

Finding out the reasons for equipment failure

How can I check what happened? It’s very simple, if after drawing water the machine does not function, then the following has happened:

- The filter is clogged and needs to be replaced;

- Residues of food got into the nozzle holes and clogged them. To fix this, you need to clean the injectors;

- The circulation pump has failed. This breakdown does not happen often, and it can be identified by the characteristic silence after filling with water. A normally operating pump emits a quiet hum.

Replacing a part in the device is easy. You can do this yourself without calling a specialist. The only thing you will need to do is purchase a new circulation pump that is suitable for your machine model. The most common brands on the market are Bosch, Ariston, Indesit, Beko, Electrolux and Hansa.

Ariston dishwashing equipment

If the circulation pump for an Ariston dishwasher is broken, then to disconnect it you will need to lay the equipment on its side, remove the lower part of the bottom, disconnecting the latches. The next step is to disconnect the power cable and remove the broken part along with the fastener. After removal, you need to press your toes with your toes, with which the pump is held in the volute, and turn the part counterclockwise. Ready.

In order to install a working central unit in place, you need to do all the previous operations in reverse order:

- Insert the device into the cochlea, turning it clockwise until it clicks;

- Install the finished structure in the old place and connect the power wire. The control wire also needs to be connected;

- The bottom with the pallet must be installed in its original position and the machine must be placed vertically.

Thus, replacing the circulation pump of a dishwasher is a simple procedure. To correctly replace a failed part, desire and concentration are all it takes. To check whether the replacement was completed correctly, plug in the equipment and check how successfully water begins to circulate through the system. If a characteristic quiet humming sound is heard and the machine operates in standard mode, then all operations have been performed correctly.

Bosch dishwashing appliances

In some cases, it is easier to disassemble the circulation pump for a Bosch dishwasher than to buy a new one.

To perform this operation, you will need to remove the part according to the standard scheme:

- lay the equipment on its side;

- remove the lower tray by unscrewing the latches;

- disconnect two cables: power and control;

- remove the snail and turn the mechanism in the opposite direction, removing the central pump itself from the structure.

Now let's start disassembling the circulation pump itself:

- The upper part of the pump is easily removed when turning to the right and will need to be separated;

- The lower part of the part is non-separable and must be put aside;

- On the collapsible part you can see broken plastic bushings;

- One bushing is located at the “foot of the mushroom”, and the second is located inside the “cap”. Finding similar bushings can be quite difficult, so it is better to order ceramic replacements from a mechanic. It is advisable to make a few extra parts from plastic;

- When disassembling the upper part of the pump, remove any remaining grease and dirt from its surface. You need to act carefully so as not to damage the element;

- On final stage You will need to install new bushings and attach the top of the pump to the set aside one. At this point the repair can be considered complete.

Repair of the circulation pump of the Indesit dishwasher

Typically, Indesit guarantees the quality of its products, so the cause of failure of the central heating unit may be clogged components of the element. In some cases, it is enough to simply wash the circulation pump for the Indesit dishwasher with detergent under warm running water and remove any remaining food and dirt from the holes. If this does not help, then try replacing the seals (rings and washers) with new ones.

It is extremely rare that parts of an element wear out. In this case, you will have to purchase a new part to replace the old one. You can replace the damaged part of the machine according to the previous schemes. The process is practically no different from the options discussed above. The same goes for Electrolux, Hansa and Beko dishwashers. The only important difference concerns the cost of the pump. Spare parts for this type of parts are much cheaper than for Bosch, Ariston and Indesit. The most expensive spare parts are for Bosch equipment.

Therefore, before replacing, it is worth checking the compatibility of parts. In some cases, you can use elements from other companies if they are completely the same in size.