Wood carving is an amazingly beautiful and very popular type of hand-made wood processing these days. The carved interior details captivate with their magnificent appearance and reflect rich national traditions.

Creative people who are simply itching to do something very interesting and useful should pay attention to wood carving. Girls and women may think that this is only a man's activity. And they will be wrong, because there are no fewer women woodcarvers than men.

About wood carving for beginners

Can be used to decorate indoor and outdoor spaces different kinds carvings and techniques for implementing the plan. If you are interested in this type of needlework, then you must understand that you need to master the methods and techniques of wood processing, acquire the necessary tools and improve carving skills.

IN modern world smartphones and tablets wooden stand, decorated with wood carvings, looks very original.

Skillfully executed carvings in the form of simple and ornate patterns and ornaments seem to enliven the world and endow it with sophistication, charm, emphasizing the taste of the owner of luxury items and the talent of the craftsman.

The works of the best carvers decorate the temples. Pay attention to the photo of the iconostasis of the upper Church of the Savior of the Image Not Made by Hands, which is located in Moscow, in the Church of the Intercession Holy Mother of God in Fili.

Modern masters with delicate taste create real masterpieces.

And thanks to finishing technologies and protection of the finished product from the destructive effects of mold and insects, these wood carvings have served people for hundreds of years.

Pay attention to the magnificent carved pieces of furniture:

Stylish doors:

Delightful figurines self made:

Very often, connoisseurs collect handmade carved items. Wonderful chess that is worthy of any collection.

Perhaps, over time, your wood carving masterpieces will be carefully preserved by collectors or decorate temples.

Types of wood carving

Of all types of wood carving, it is very interesting openwork or through thread on wood, which is characterized by some transparency, in which only the image remains, without a background. An example is an applied carving - this is an ornament that is attached to a finished background after production by a craftsman.

Geometric carving woodworking – This is a type of carving in which the pattern is formed using many simple geometric shapes(a diamond is often used).

Oriental carving on wood it is distinguished by its whimsical shapes. Egypt is the cradle of the oriental type of wood carving.

Relief carving on wood. In this technique, the image is located above the background or at the same level with it. This carved panels various shapes with three-dimensional images.

- This is a flat-relief carving, but distinguished by an abundance of carved and stucco decorations, various colors, curls, leaves, figures of people in unnatural poses, fabulous fantastic animals.

Originated in the village of Kudrino. Well-known products in this type of carving are boxes, vases, dishes, ladles, and home decor items. The main element is a floral ornament: rosettes, curls and twigs.

Volumetric (sculptural) carving Great for making sculptures, animal and human figures, toys. - a subtype of volumetric thread. This is the main industry of the village of Bogorodskoye in the Moscow region. The famous Bogorodsk toys are figurines of animals and people made of linden and alder.

Most often used to decorate wooden Scandinavian churches. Wood carvers decorated the inside and outside of church buildings with images of Gods and various animals.

- the simplest and most unique type of carving. On a flat background, the master cuts out grooves - grooves, forming a pattern. Carved landscapes - images of landscapes on wood.

All these types of carvings are quite conventional. Each master chooses the most suitable one, taking into account work experience, quality of wood and creative inspiration.

What can be decorated with carvings?

The most simple staircase transformed, decorated with carved balusters. Balusters- these are figured columns in the form of columns, a stylish and noble decoration of the staircase. Wooden balusters look organic with a spiral wooden staircase.

Bas-relief. Another name is "low relief". This is a sculptural image on a plane. Most often these are figures of people and animals .

Choosing tools for wood carving

As in every business, wood carving has its own secrets and nuances, which allow one to reveal the beauty of wood in a wonderful ornament. It is necessary to select special tools for wood carving and stock up necessary supplies and sketches for wood carving, which will be embodied in the form of drawings, borders, lace or genre scenes.

Basic tools

Very high demands are placed on the quality of carving tools. Of course, skill plays an important role, but well-selected and sharpened tools will help bring your idea to life. Experienced carvers will tell about its quality at first glance at a tool, but beginners are lost in the store because of the huge selection.

The basic set for wood carving includes:

- several knives and chisels;

- needle files;

- hacksaws for metal;

- vice;

- sandpaper;

- drill with several types of drills;

- bars.

Knives should be made only from high quality steel. It is better to purchase them in specialized stores for creativity. Although on initial stage Just sharply sharpened knives will do. An excellent start would be knives from Tatyanka, Narex, Kogatana, etc.

It is not necessary to choose an expensive foreign-made instrument, because domestic instruments can be the same good quality but much cheaper

As your skill grows, you may need a set of tools, a milling machine, a drill, etc.

Chisels for carving

Sometimes, instead of a chisel, a sharpened screwdriver or file is used for wood carving.

Flat chisel- This long rod, at the end of which there is a flat cutting edge. Very often it is used for primary wood processing.

Semicircular chisel- this is one of the most important tools for work. They differ somewhat in the degree of roundness, that is, they are medium, round and sloping.

It still happens V-shaped version of chisels. It can be useful for geometric wood carving, which we will introduce you to below.

Beginners need only a small wood carving set of good quality to immediately get used to the correct movements and pressure.

In this video there is a wonderful master A. Yuryev shared with us which tools to choose for carving.

How to protect yourself from injury when carving wood

Any tool of a master carver can be compared to a straight razor, therefore, when working with it, you must strictly follow safety precautions. The material must be positioned so that you can work freely with a knife or chisel, eliminating the possibility of the sharp edge hitting your hands.

The work place should be comfortable and clean. All unnecessary tools at the moment should be carefully folded, because they are very sharp and can cause injury.

Materials for work

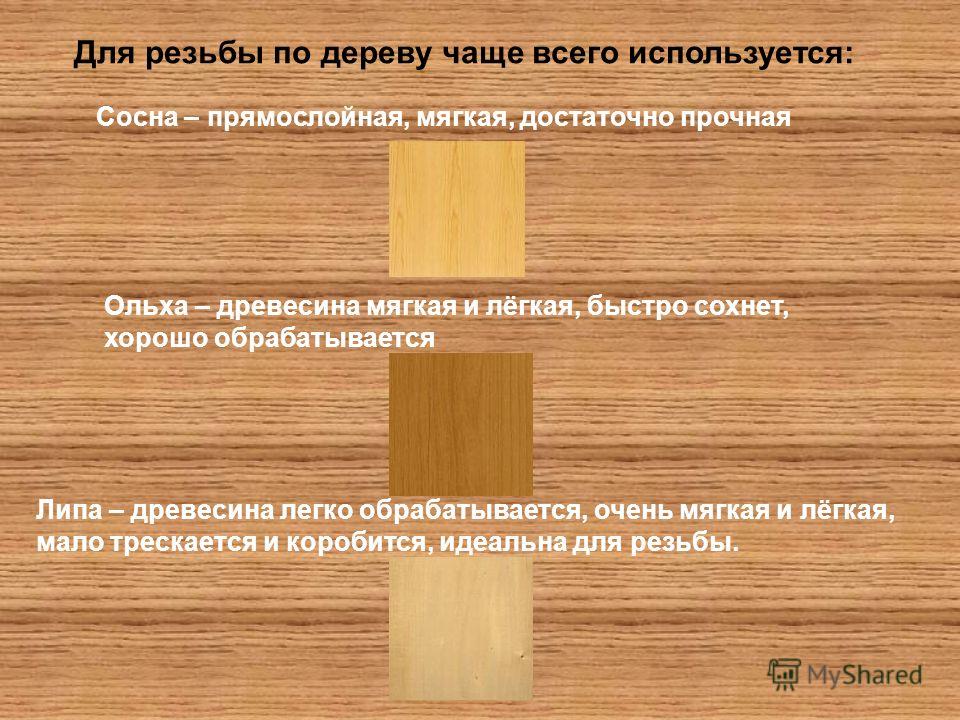

Each type of wood for carving has its pros and cons. Soft wood is easy to work with, but there can also be a lot of defects. These are aspen, linden, birch. For beginners this wood fits better Total.

Oak, boxwood, mahogany are more expensive and complex wood. It is hard and durable, so it is difficult to carve from such wood. Very often there are troubles when working with such types of wood. Either the instrument or the craftsman may be harmed.

An experienced carver can easily work with various woods, including with juniper. Well, for beginners it is better to use inexpensive materials - spruce, pine, pear or birch.

Whatever tools are chosen for wood carving, safety precautions must be strictly observed!

Geometric carving technology

Geometric wood carving is considered the simplest and is perfect for beginners. To create the intended design, you need to have a small set of wood carving tools and clearly follow the design. In geometric wood carving, symmetry and repetition are of utmost importance. This achieves a wonderful play of light and shadow.

Cutting boards using this technique and wooden panels look wonderful in the kitchen.

Geometric carving consists of sequential cutting out of simple geometric shapes: rectangles, triangles, squares, rhombuses. But the result is a wonderful ornament, which, when different lighting looks different.

Execution Sequence any wood carving is like this:

- First, a wooden blank is made (board, deck, blank).

- Next is rough leveling of the surface of the workpiece, during which all defects and roughness are removed.

- Then a decorative relief is formed using special cutters.

- After the main carving is completed, the finishing process is grinding, impregnation, painting, varnishing.

You cannot work with a workpiece on your knees! The master must have a table to work on.

Master class “Geometric wood carving on a cutting board”

Tools. You will need 2 knives for wood carving: a triangular jamb knife and a feather knife, a ruler, a compass, a pencil.

A triangle jamb knife is necessary for cutting triangular shapes of various configurations, as well as for cutting long straight lines. A pen knife is used to cut long lines such as a petal or groove. Carving knives should be sharp and comfortable.

First stage. We make a sketch of the pattern on the board. It can be applied using a compass and ruler. Or you can print out carving patterns taken from the Internet and use carbon paper to transfer them to a prepared cutting board.

Second phase. Cut out the petals. We use a pen knife.

During work thumb presses firmly to the board, and the index finger lightly touches the wood. This will help regulate the depth of the knife into the surface and the angle of inclination. And your thumb will help you move the blade smoothly. First, we cut in one direction at an angle, then we turn the board over and cut on the other side.

If the shavings curl like a rope, the knife is good and sharp. It must be periodically sharpened with a piece of leather with GOI paste.

Third stage. We cut out the triangles with a blunt knife. Using the heel, at an angle of 45 degrees, we cut the knife into the wood, not reaching the edges of the pattern on three sides. The slots should meet on all sides in the shape of a pyramid. The sliver falls out and forms a beautiful triangle.

Fourth stage. What we couldn’t cut, carefully clean it so that the edges are frequent and even. Using the same principle, we cut out grooves and triangles around the perimeter of the board.

Fifth stage. We polish everything sandpaper, treated with natural impregnation. All! The work is done. We decorate the kitchen useful and beautiful cutting board with wood carvings.

Wood carving designs

To perform wood carving, photographs, drawings and sketches are simply necessary. Large patterns for wood carving are used for large items: for house facades, interior decoration carvings of churches, windows.

For interior items and furniture, carvers use small patterns, which are carefully worked out by the master.

YOU WILL NEED IT

We offer you an archive from . Choose, print, create.

Video master classes on wood carving for beginners

Of course, the wood carving looks especially impressive in the video. Channel "HAND WOOD CARVING" shows the features of geometric carving for beginners.

A woman's view of wood carving. Channel tatianacarving shows us how to make flower petals and leaves.

Konstantin Belyaev on his channel he talks in detail about wood carving cutters.

And in this video Ivan the Builder shows how to make relief-planar carving:

We will be very glad if this article inspired you to take up wood carving!

The Englishman E. Harris, when making the original 13-meter spoon from red cedar, spent a week working with a chainsaw, chisels and a mallet. Ordinary craftsmen, for whom carved patterns are a hobby, use a wider range of woodworking tools. Exist hand knives, chisels, cutters, electric, laser engravers, devices for drills, sharpening machines (flexible shaft). When making large structural elements of dwellings (columns, beams) with decorative carvings, a chainsaw, multifunctional power tool, jigsaw, and reciprocating saw are usually used.

The default wood is sufficient soft material, therefore, the service life of the tool, taking into account reusable sharpening, is much higher than analogues used in metal processing. When choosing a beginner who is mastering this technology, it should be noted that high-quality hand tools for wood carving can cost no less electric engraver. A standard set of knives costs 1,500 – 700 rubles, an extended set has a price of 3 thousand rubles.

Exist different technologies(ornament, animals, relief, applied carving), styles of carvings. For beginners, since 1990, the most popular style is Tatyanka, which has several nuances:

- work without a stop - the workpiece is not fixed during the cutting process

- material without defects - with the exception of knots specially played out by the master

- texture is not taken into account - soft linden is preferable

- storage - boards with unfinished patterns are stored in a wet rag or PVC bag on the balcony (in any unheated room)

- tools – radius chisels (number 6, 17), jamb knife (blade 1.5 mm, blade width 20 mm, heel angle 45 degrees)

This technology is optimal for beginners, since the tool and material are inexpensive.

In addition to this technique, there are methods:

- volumetric carving – small 3D image

- openwork decor - the background of the picture is drilled out, sawed out with gaps

- geometric pattern – embedded in a smooth background

- relief – the background is recessed, the picture protrudes above it

- flat carving - not a deep designation of a silhouette in the same plane as the background

After some practice, the master chooses a tool that is convenient for himself for each technology. For example, a bas-relief can be cut out with a chisel, a knife, or a drill; to make an openwork composition, you will have to use a jigsaw, drills, and modify the ornament with cutters.

Knives

All woodworking tools of this type have standard numbering, which is quite difficult to understand. You should start by purchasing standard kits, which are completed by specialists. After gaining some experience, the master will be able to independently expand the range depending on the chosen technique and individual genre preferences. The most popular knives are the following types:

- Tatyanka – long handle, blade bevel position 2 cm from the master’s hand with a standard overhand grip

- Bogorodsky – 9 – 7 cm blade for rough contouring, 6 – 3 cm for fine work, semicircular shape, partial sharpening similar to a penknife

- A jamb is an analogue of a shoe knife with a blade beveled at 45 degrees and sharpened on one side

In addition to these options, there are hundreds of knives different forms, dimensions. The leading manufacturers of this tool are the following companies:

- Flexcut – sets of knives, chisels, mixed types

- Frost – in addition to cutters, produces spoon cutters

- Dem-Bart is a manufacturer specializing in tools for decorating stocks

- Narex – sets from 4.5 thousand rubles

- Petrov and Son - straight knives of five types

- Pfeil – Swiss quality, violin, marking modifications, left-handed jambs, netsuke quills

Knives for wood carving require sharpening using the following technology:

- block - rough, then fine-grained plane (circular, then cutting movements)

- fabric skin - sequentially at 320, 400, 600 using the same method

- leather belt – with abrasive paste-compound

The technology is used after purchase; with daily editing in the future, the last two points are sufficient, depending on the strength of the wood.

Chisels

Woodworking tools of this type are straight, angle (V-profile), reverse (convex shape), curved (radius edge), and cranberries. Unlike a chisel, a chisel immediately selects a groove in the wood the desired profile. Power chisels are tapped with a mallet, manual chisels are designed for manual pressure without shock loads.

The best wood carving chisels are those from Kirschen and Stubai. Any modification (without a handle) from these companies costs from 800 rubles and has a high service life correct sharpening, which a novice carver will have to learn.

It is better to carry out detailing and sampling of soft wood using budget chisels from Japanese manufacturers, Transnistria, and Korneev companies. A tool with a short blade is designed for manual work; it is easier to position and control in solid wood. Long bladed chisels are designed for percussion carving.

Power sculptural instruments can be distinguished by the thickness of the blade (from 2.5 mm); for non-impact modifications it does not exceed 1.5 - 1 mm. Stickers are equipped with mushroom-shaped handles - you cannot hit them with a mallet, they are uncomfortable to hold with both hands. Working with a chisel requires practice; this type of chisel is used in carving miniatures.

Chisels (like chisels) are never superfluous; they can significantly expand the craftsman’s capabilities. Thus, if the budget is sufficient, expanded sets are purchased, and if the budget is limited, sets of 5–3 items are purchased.

There are battery-powered and mains-powered electric chisels, in which the equipment is driven by a vibration motor. The tools have a high price (from 15,000 rubles), a set of equipment of 3 chisels costs 5 – 3 thousand rubles.

Tool sets

A set of woodworking tools facilitates the practice of making patterns; professionals include several cutters and chisels in the set. The assortment allows you to decorate crafts, power structures buildings, make applied carvings in almost any style. With certain successes and a firm decision to choose this hobby, the master usually buys several additional chisels and knives.

At the initial stage, it is enough to decide on the type of thread:

- during production garden sculptures percussion chisels and jigsaws are relevant

- For decoration wooden poles gazebos, it is better to choose a router, a manual disk or a reciprocating hacksaw

- a hand engraver will allow you to decorate platbands, windshields, and cornice strips with high-quality ornaments

- The same power tool can be used to decorate furniture facades

- carving on small-format piece products is often carried out using hand chisels, knives, and cutters

In any store, instructions for hand and electric tools can provide information on the area of application.

Power tools for wood carving

Unlike chisels, knives, and chisels, which allow you to devote every free moment to your favorite work, power tools for wood are energy-dependent equipment. The technology for decorating blanks differs from manual cutting, however, it also requires attention, perseverance, and accuracy.

Engravers

Tools for woodworking in the mid-price segment – hand engravers with a set of attachments for roughing and finishing. Most of them are equipped with a flexible shaft (analogous to a dental drill), which, if equipped with a drive (drill, screwdriver, sharpening machine) can be a full-fledged power tool for openwork, applied, figured, ornamental carving.

Working with an engraver is much easier than using cutters; productivity increases by an order of magnitude. Budget modifications cost from 1.5 thousand rubles, tools from leading brands have more complete set equipment costs 10–7 thousand rubles.

Flexible shaft for wood carving

This type of woodworking hand tool is available for any budget. For example, Bosch produces a 1.25 m shaft 3500 rpm with a 6 - 1 mm chuck for drills from any manufacturer. The equipment weighs 850 g, costs 2.5 thousand rubles, and makes it possible to produce carvings of any complexity on wooden blanks and structures.

Wood carving is carried out using special tools. High machinability, which is characteristic of wood, allows you to obtain products of various shapes and sizes. It is necessary to choose the right tool for carving, since the features of operation and the complexity of the work performed depend on their specific qualities.

Main types of tools

The most popular ones are on sale various options execution of carving tools. All of them are divided into two main groups:

- Manual ones are characterized by low cost and ease of use. However, we must not forget about the low productivity of manual labor.

- Electric ones have recently become widespread, since their use can significantly speed up and simplify wood processing. As a rule, electric tools are purchased during serial production of products; they are characterized by a higher cost, but allow obtaining more accurate dimensions and high quality treated surface.

Despite the widespread electric tools, you still can’t do without manual ones. They are often used to treat hard-to-reach places.

When producing such instruments, a certain numbering is used, which is quite difficult to understand. Many experts recommend purchasing wood carving knives included in standard sets. They are produced by specialists in the field in question and can be used to perform work of varying complexity. Only after gaining experience will the master be able to expand his range of knives depending on genre preferences and needs. The most widely used types of the instrument in question are:

- Bogorodsky is a design option that can be used to obtain a black outline. With a blade of 6-3 cm, the knife is suitable for obtaining thin work or semicircular shapes. The handle can be made using a variety of materials.

- Tatyanka is a knife with a long handle, the bevel of the blade is located at a distance of 2 cm from the hand. This simplifies the wood processing process.

- The jamb is a design option similar to a shoe knife; the blade is beveled at an angle of 45 degrees. Sharpening is one-sided, used when obtaining a wide variety of shapes.

A chisel for wood carving of low density can be made from inexpensive materials. If desired, you can purchase budget options Japanese manufacturers. It is worth considering that models with a short working part are intended for manual work and are not easier to operate. Options with a longer working part are intended for impact work.

Saws

Saws can be used to work with solid wood. There are a variety of options for this instrument; when choosing, attention is paid to the following points:

- Tooth size.

- Length of the working part.

- Handle type and comfort.

- What metal is the working part made of?

When considering a similar tool for cutting wood, it is worth considering that most are designed to change the length of the workpiece.

Too large a tooth allows you to speed up the work process, but the quality of the cut is poor.

To improve the quality of the resulting end surface, you can use saws with a fine and frequent tooth arrangement.

Special tools

There are quite a lot of them on sale specialized tools, which only apply serial production various wood products. An example would be:

- Flexible shaft. This design option is suitable for producing threads of almost any complexity. Even a novice master can afford it.

- Laser engraver. A household model of such a device costs 7 thousand rubles. Execution options that are capable of working on 3D projects cost at least 30 thousand rubles.

A laser engraver is a multifunctional piece of equipment that can be used for a variety of jobs. To do this, it is possible to change working attachments and change processing parameters. Similar thread cutting tools can be purchased at a specialty store.

How to choose a knife?

The most widespread are carving knives. They allow you to get almost any shape using manual processing. When choosing, pay attention to:

- Comfortable handle.

- The type of metal used in the manufacture of the working part.

- Shape, thickness and length cutting edge.

It is best to give preference to tools that are made from hardened tool steel. Such an alloy can withstand long-term use without sharpening.

How to choose a chisel?

Wood carving chisel can be characterized by various shapes cutting edge. When choosing it, attention is paid to the following points:

- Power tools are selected according to the thickness of the blade. Impactless modifications have a thickness of about 1.5 mm. It cannot withstand high impact loads.

- The choice is made depending on what type of work will be carried out. There are several dozen varieties of chisels, each suitable for obtaining a specific carving.

- On sale there are electric chisels with a battery or a wire for mains power.

- Attention is also paid to the popularity of the brand. More famous manufacturers They produce high-quality products that can be used for a long period.

In specialized stores you can find sets of chisels. They may include several instruments of different types.

Instrument care

Hand tools can be served at home. As a rule, after long-term use it is necessary to sharpen the cutting edge. To do this, you can use special equipment or a regular sharpening stone.

If the working part is made using ordinary steel, then the surface must be cleaned of liquid and contaminants.

From time to time, the rust that forms is removed.

Tools for wood carving must be carefully selected. Wood carving as a type of decorative and applied art has a long history and has provided humanity with real masterpieces. At home, you can also create works of art, and simply diversify the interior. Although some appeared modern models With electric drive(for example, a drill for wood carving), in general the instrument preserves traditions and is intended mainly for painstaking manual labor.

Different types of chisels for wood carving

Wood carving is the processing of wood to give it a special shape or create a relief on it. The following main types of such operations can be distinguished:

How to use the tool

When performing wood carvings, following works: drilling, sawing, cutting and gouging. For creating quality product It is impossible to do without measuring tools.

During the work process there is a need for auxiliary tool or devices that help fix the workpiece and limit the degree of impact.

The nature of the work determines the choice the necessary tool. Historically, the most best samples are performed using hand tools, however modern trend to mechanization and automation of labor did not bypass this area of activity.

Set of various cutters for wood carving

Set of various cutters for wood carving There is a whole range of machines, mini-drills (drills), jigsaws, grinding machines etc. Certain products can be made in automatic mode using copy-milling devices (pantograph).

What types of knives are used?

One of the most important cutting tools used for are wood carving knives different designs and appointments. The following types of knives are distinguished:

What chisels are needed when working?

Of course, the main handmade tools are wood carving chisels. The most common types of chisels include the following tool:

What other tool can you use?

In addition to the main devices discussed, additional tools are used when carrying out work to carry out specific work.

This is usually used additional tool for wood carving:

- Spoon knives or spoon knives: usually a sharpened ring welded to a steel bar that is inserted into the handle - are used for removing accumulated sawdust in recesses, as well as for grinding the inside walls of large recesses, for example, when cutting utensils.

- Hammers and punches: durable metal rods with a specific pattern on the end. Most common when creating the main background.

When carving wood over large areas, various auxiliary tools are also used:

- For drilling work: gimlets, rotators, hand drills.

- When sawing: hacksaw, hacksaw, jigsaw, two-handed saw.

- Auxiliary equipment: mallet, staple, miter box, clamps, vice, various clamps, hammer.

To carry out measurements and markings, the following tools are used: ruler, square, protractor, leveler, measuring rod, plumb line, leveler, level, calipers, vernier calipers, bore gauge, surface thicknesser, compass, tape measure.