Comfortable working conditions are the basis for employee well-being. To ensure comfortable working conditions for all employees, it is necessary to properly distribute the lighting of the room, as well as equip the building’s air conditioning system.

A galvanized pipe for ventilation is best suited for such purposes. These types of products are produced using the hot rolling method.

Galvanized air ducts for ventilation are characterized by:

- small weight;

- low cost;

- durability;

- ease of maintenance and installation of products.

Galvanized pipe for ventilation is perfect for installing air ducts, chimneys and even for transporting working fluids of any temperature.

Ventilation installation using galvanized steel pipes

Modern air ducts are divided into several types:

- hard;

- semi-rigid;

- flexible.

Today, the most popular are rigid systems, for the arrangement of which galvanized ventilation ducts and pipes are used.

It is worth noting that ventilation made of galvanized steel is the most technologically advanced, does not corrode, and is resistant to sun rays and is capable of moving even aggressive gases.

In addition, galvanized ventilation boxes and pipes are characterized by versatility and durability.

We will help you with the purchase of galvanized pipes for ventilation systems

If you decide to buy galvanized pipes for ventilation, better place You won’t find anything like an online store site! We offer you a wide range of tin products for arranging air duct systems according to the most low prices.

In addition, on our website you can find galvanized ventilation boxes for which the price is affordable. You can place an order in any way convenient for you (by telephone, or by filling out an application on the website). Delivery is carried out to all regions of the Russian Federation.

Air circulation systems in residential or office premises made from various materials. It could be metal different types or plastic. The properties and characteristics are different, but the goal is the same - moving air currents. Ventilation pipes have become particularly important during the rapid growth in comfort and safety.

Metal air ducts

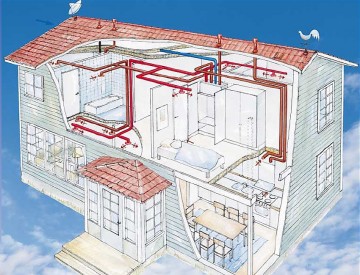

Ventilation systems are present in every modern room

Metal is the most common material used in making pipes ventilation system. It is durable and can withstand high temperatures. A unique advantage is that this material allows the production of elements for highways with any cross-section. That is why metal air ducts are successfully used in the construction of private and industrial buildings.

However, the buyer, and subsequently the user, must be prepared for the fact that metal pipes for ventilation are subject to corrosion during operation. This unpleasant process is accompanied by the appearance of a specific odor in the room. In addition, a system of such pipes will require powerful ventilation unit. Another disadvantage is the high cost, as well as considerable weight, which makes installation difficult.

Plastic systems

Air ducts from of stainless steel able to withstand high temperatures

Residential owners prefer plastic pipes, which have a longer service life. They are excellent for installing both ventilation and exhaust system.

Among the main advantages are the following:

- complete resistance to corrosion;

- light weight;

- simple installation (metal ventilation elements are assembled using various fasteners; when assembling plastic ventilation, there is no need for this, since the pipes are assembled using a sealant or sealant);

- multivariate (you can assemble a branch of any complexity, with any bends and turns);

- no resistance to air flow;

- environmental friendliness ( pvc pipes for ventilation are considered an environmentally friendly construction product, since the material does not cause harm to human health);

- low degree of contamination;

- low cost.

A significant disadvantage of plastic is its low resistance to high temperatures. If the ventilation system is installed at industrial facilities of class I, II fire danger, plastic pipes are not used. But such limitations can also be resolved using an alternative approach: a plastic ventilation system can be mounted on the outer facade of the building. So the high-temperature environment does not cause significant damage to the line.

Corrugated pipes for ventilation

Plastic ventilation easy to use

Special view ventilation ducts- corrugated pipes. Their feature is high flexibility, which means significant maneuverability during installation. They are made of steel, aluminum, plastic.

The following characteristics are considered advantageous:

- high elasticity;

- great strength;

- ability to fit into projects of any complexity;

- easy installation;

- no need for additional connecting elements;

- compactness when compressed.

A corrugated pipe for ventilation can be connected, if necessary, to rectangular elements. Docking is carried out using simple adapters (from rectangular to circular cross-section). Such an air duct can bend under the right angle. With careful installation and correct calculation of the pipe diameter for ventilation, the integrity is not compromised.

Aluminum

Metal corrugation is more often used at production facilities

A high-quality and economical option for installing a ventilation system is possible thanks to semi-rigid aluminum corrugated pipes.

They are lightweight and at the same time highly durable, fireproof, sealed, easy to install, and always available for inspection.

The corrugated aluminum ventilation pipe is lightweight, does not accumulate static electricity, operates in a wide temperature range (from −30° to +270°), and does not react to aggressiveness external environment, is not subject to pressure changes, does not lose its appearance.

Thanks to the ribs, aluminum air ducts retain their circular cross-section, as well as the ability to stretch (3-4 times) and compress in the longitudinal direction, and bend at the required angle.

Such corrugated pipes have proven their high performance qualities over several decades.

Plastic

Corrugated pipe made of plastic - unique element ventilation system. Its use significantly reduces the cost of purchasing special connecting parts. Saves money and service life (plastic corrugation lasts up to 90 years).

Other advantages include resistance to deformation, heat and shock resistance, the ability in different ways gaskets

Calculation of pipe diameter depends on many factors

The entire ventilation system should be as light as possible. When choosing elements for the highway, it is enough to compare the mass linear meter each material.

The pipe must be thin-walled and at the same time durable. The throughput will depend on this.

In the outlet section, the air duct must have a high degree of annular rigidity, since it will have to withstand atmospheric loads (pressure, temperature changes, precipitation, wind force).

Reliable operation of the entire system will be ensured by adapters for ventilation pipes. They should be selected with special care.

To install exhaust and supply ventilation ducts in private homes, it is better to install plastic air ducts.

The highway should not be too long. A large length will reduce the efficiency of operation (any turn reduces power).

It is advisable to select pipes for installation round shape.

When deciding on the type of construction and type of air ducts, you should take into account the diameter itself. Incorrect selection can lead to an increase in noise level and an excessive load on the motor. exhaust device, during further operation the seal will be broken and the entire system will fail. Before installation, you must seek advice from builders who will tell you how to calculate the diameter of the pipe for ventilation.

Air ducts can be masked. Often used in apartments and houses decorative boxes, which hide all elements, but do not block access to them.

Ventilation elements made of sheet metal practical, durable and easy to install. Due to these and other properties, they are very widely used in industrial ventilation systems. Private homeowners, as a rule, prefer other materials.

Read more about the advantages, disadvantages and operating features of metal ventilation ducts, pipes and shaped elements, read on.

Types of metal ventilation elements

All main and auxiliary components for the ventilation system are made from metal:

- air ducts;

- nipple;

- umbrellas;

- tires;

- plugs;

- bends;

- adapters;

- tees;

- insets,

- metal ventilation meshes and grilles.

Air ducts made of metal

Air ducts form highways for transporting air flows. The air duct outlets are covered with overhead metal ventilation grilles.

According to their cross-sectional shape they can be:

- rectangular;

- round.

According to manufacturing technology:

- straight-seam;

- spiral wound.

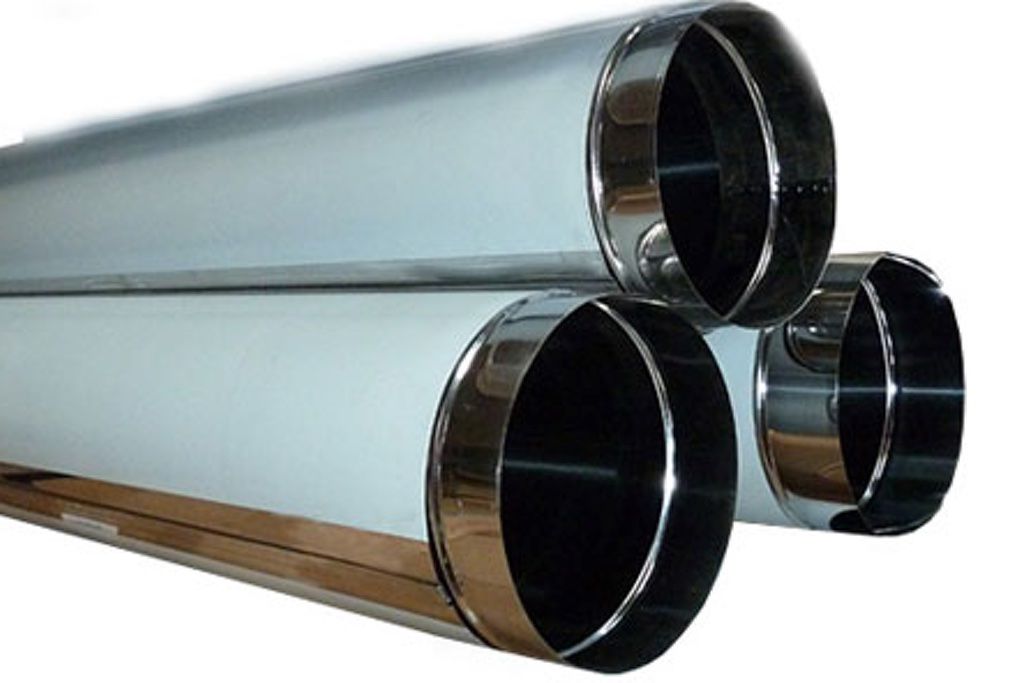

Straight-seam metal ventilation ducts made from thin steel sheet. The edges of a whole sheet are fastened with folds (if the sheet thickness is no more than 1.4 mm) or by welding. Seam joints are not always sufficiently tight and require the use of additional material.

A welded connection is more labor-intensive, but does not have such disadvantages. Straight seam ducts are widely used to create short straight runs.

They are produced in standard lengths and diameters in two tightness classes: “N” and “P”. Class "H" or "normal" indicates the possibility of small air leaks. Pipes of class “P” are additionally sealed.

Spiral-wound air ducts made from metal tape, which is curled into a tube using special equipment. A special rib gives additional rigidity to large-diameter pipes.

More often used in residential areas rectangular air ducts, which are easier to fit into the interior. At the same time, such pipes create greater air resistance. Therefore, in powerful industrial systems preference is given to round air ducts with better aerodynamic characteristics.

Flexible and semi-rigid air ducts are often installed in short sections with many turns. Since the corrugated ribs create the greatest resistance to air movement.

Flexible metal ducts

![]()

Their production technology is completely different from the types described above, and the material is aluminum foil.

Flexible metal ventilation ducts can be:

- isolated;

- non-insulated.

They consist of a spiral frame made of rigid steel wire, on which several layers of laminated Mylar film and aluminum foil are worn. Insulated flexible metal layer wrapped mineral wool 3 cm thick, which is covered with an additional layer of foil on top.

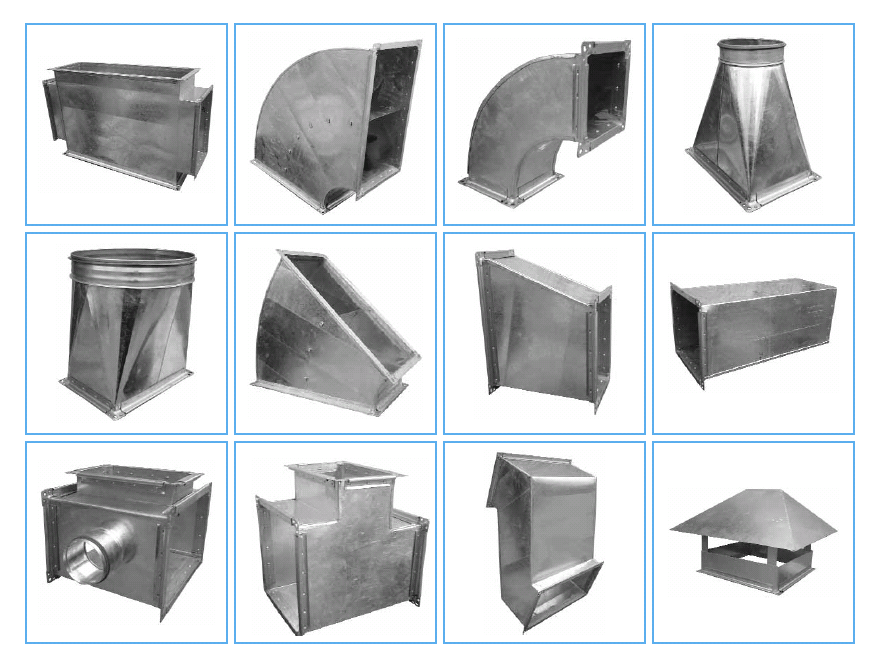

Metal shaped products

Shaped metal products allow you to connect air ducts of different diameters and cross-sections, perform turns and a wide variety of wiring. With the help of umbrellas or metal ventilation grilles, outlets are made to the outside. And metal ventilation meshes protect the air ducts from the penetration of small animals and debris.

Shaped parts are produced in a wide variety of types and shapes. Often the main costs when installing ventilation are not on air ducts, but on fittings. They can be rectangular or round, various diameters and are matched to the air ducts.

To assemble a standard air duct network you will need the following minimum set of fittings:

- bends at 45 and 90 degrees;

- duck;

- nipple;

- tee;

- inset;

- stub.

Metal ventilation grilles are placed on the air duct outlet from the street side. External metal ventilation grilles can be equipped with a blind system. IN winter time or a period of inactivity, the air duct is securely covered from debris and dust. Such devices must be installed at large facilities.

IN residential buildings just cover the exit metal mesh for ventilation. Unpleasant odors and dust are removed from the toilet or kitchen through a metal ventilation mesh.

Sometimes the outlet of ventilation pipes is placed in the floor (for example), in some industries or in saunas and is covered with metal ventilation grille for the floor. Most often, a metal grate is built into the floor to create an area of increased pressure in work areas.

Metals for ventilation elements

Metal air ducts for ventilation are made from corrosion-resistant sheets:

- stainless steel;

- Cink Steel;

- aluminum.

Metal pipes for ventilation made of stainless steel very durable and meet the highest sanitary and hygienic requirements:

- can withstand up to +500 degrees Celsius;

- they are not inhabited by fungus and mold;

- resistant to direct fire;

- resistant to moisture;

- resistant to aggressive environments.

Metal steel is used in hospitals and clinics, schools, as well as in industries with high radiation levels, high temperatures and humidity.

Galvanized metal ventilation pipes are made from cold-rolled steel with a sheet thickness from 0.5 to 1.25 mm, less often hot-rolled sheets no thicker than 0.9 mm. In the second case, the steel is additionally treated with a primer.

- can withstand up to +85 degrees Celsius;

- resistant to air humidity up to 60%;

- biologically stable;

- relatively inexpensive;

- easily assembled into a structure, leaky areas are replaced;

- are light in weight.

Due to these properties, galvanized metal ventilation pipes are often installed in warehouses and dry industries.

Metal ventilation ducts are connected to each other by flanges or nipples.

Aluminum air ducts They are flexible or semi-rigid. They are made from aluminum foil of different thicknesses (from 0.08 to 0.12 mm). The main advantage of metal aluminum air ducts for ventilation is the ability to bend them at any angle:

- can withstand temperatures up to +135 degrees (flexible) and up to +300 degrees (semi-rigid);

- resistant to aggressive environments and ultraviolet radiation (semi-rigid);

- can be installed in catering premises, dryers and ironing rooms;

- do not need grounding.

Semi-rigid ducts can be installed outdoors.

Metal air ducts for ventilation made of aluminum are practical, lightweight and inexpensive. They bend perfectly and are secured to each other with a triple lock. The flexible metal duct for ventilation can be compressed and stretched several times. In a compressed state, flexible and semi-rigid air ducts are convenient to transport and store; their length is 50 cm. When stretched, it reaches 3 meters.

Rules for installing ventilation elements

Before starting installation of the ventilation system, it is necessary to inspect the room and select best method fastenings

To fasten metal air ducts use:

- clamps;

- hairpins;

- corners;

- bolts and nuts.

Sometimes you have to resort to welding.

Installation of flexible metal pipes has its own rules:

- To reduce pressure losses inside the pipe, install them only in an extended state;

- It is more convenient to cut off the excess pieces immediately;

- It is more advisable to use wide brackets that do not pinch the pipe;

- To pass through walls, solid adapters or metal sleeves must be used.

Distribute the suspension points using the following rules:

- on turns, the bending radius should be less than the diameter of the duct;

- sagging is allowed no more than 5 centimeters per linear meter;

- at vertical installation pipes between the fasteners there should be a distance of 1 - 1.8 meters.

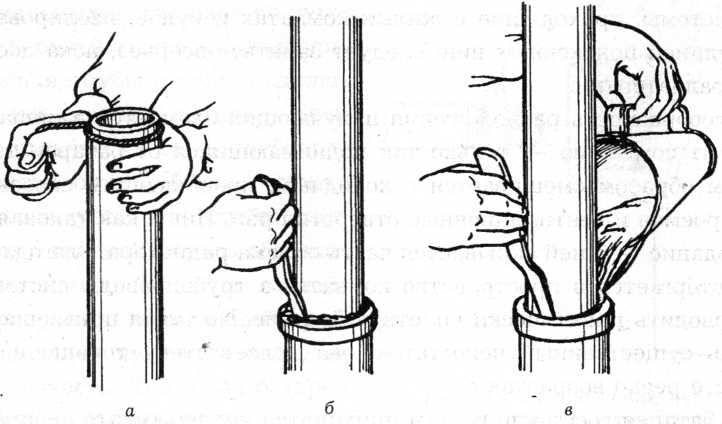

Connecting air ducts and ventilation fittings to each other

To connect circular elements, the following are used:

- Flange mounting. To ensure a tight seam, the flanges are attached with a flange. The flange openings must remain free;

- Bandage mount rarely used, mainly in hazardous industries. It provides complete sealing. First, the ends of the air ducts are flanged, then a bandage is put on. It is filled with a chemically neutral substance or conventional sealant. The technology is simple and inexpensive, but the production of bandages is quite expensive. Therefore, it is not widely used;

- Coupling or nipple. Manufactured with rubber seal or without it. If there is no rubber band, sealant treatment is required during installation. Its composition and quality should be taken into account Special attention when placing the system outside the building or in aggressive environments;

- Trumpet- the simplest and most widely used connection. A pipe of a smaller diameter is inserted into a pipe of a larger one.

It is provided like this:

- the air duct is made in the shape of a cone;

- one end of the air duct is slightly narrowed, the other is widened.

To connect rectangular elements the following are used:

- Flanges that are fastened with rivets or spot welding. The second option is simpler and more common, although it leads to rapid burning of the pipe at the welding points;

- Tires are the most common type of fastening in general exchange systems. The sides are connected to each other by corner inserts. On air ducts of large diameters (200 mm and more), a tightening element must be installed.

When connecting rectangular ventilation pipes, the corners must be sealed. Connections are made using tapes from:

- monolithic rubber;

- foam rubber;

- polymer mastic rope.

Disadvantages of metal ventilation elements

- More expensive than plastic ones;

- When manufactured at internal surfaces roughness may appear, increasing air resistance;

- Relatively large weight of the structure, due to which it is necessary to use special fasteners;

- Susceptibility to corrosion of air ducts made of “black” steel;

- Aerodynamic noise.

Metal ventilation from external grille and before air ducts, it was slightly replaced on the market by products made of polymers that do not have the listed disadvantages. Nevertheless, best material for powerful air exchange systems than metal does not exist today.

This is how straight-seam air ducts are made on the most modern machines:

During construction public buildings, residential buildings or industrial premises it is necessary to provide ventilation systems. This is due to sanitary and hygienic standards, safety standards and vital necessity. To put it simply, during installation high-quality ventilation will not unpleasant odors in the apartment, dampness and mold on the walls, and in industrial premises harmful impurities in the air. Ventilation pipes and fittings are complex system smoke removal and air purification in buildings where there is no natural ventilation, for underground structures and high-rise buildings. Design specialists are engaged in the development and implementation of such systems.

Types of ventilation ducts

Plastic ventilation ducts are widely used in all types of premises. Pipes and connecting parts made of plastic provide the necessary level of tightness of the ventilation system and are not susceptible to moisture and corrosion. Smooth surface air duct reduces noise levels and creates best conditions for free passage of the flow of the calculated volume at the required speed. In addition, they do not require regular cleaning, therefore, the service life of the ventilation system increases. However, with all their advantages, they can be used in systems with ambient temperatures up to +50°C. During installation plastic pipes It is worth remembering that passage nodes in concrete or brick floors require the use of a steel sleeve, but the use of roofing felt or roofing felt is also allowed.

Plastic ventilation ducts

Flexible air ducts are made of plastic or metal. Mainly used for exhaust ventilation with ambient temperatures from -30°C to +120°C. Ideal for installation in gypsum plasterboard boxes, fitting into any interior. The advantages include the possibility of using corrugated air ducts for complex room layouts, as well as ease of installation. Passage units for flexible ventilation air ducts also require compliance with installation standards and the use of sleeves, and when installed in walls, additional insulation with a layer of concrete to avoid damage to the seal. Exhaust pipes for ventilation are led through a shaft to the roof or roof.

IN industrial enterprises metal rectangular or square ventilation ducts with numerous connecting elements. The connection node or joint is selected according to the design data.

Installation of ventilation ducts made of steel has a number of difficulties; the tightness of the system, the quality of sound insulation and its service life depend on the quality of welding or assembly of products. Ventilation ducts of rectangular or square cross-section make more efficient use of room space. However, often internal corners boxes create air resistance and, in order to cover the loss of air pressure, it is necessary to install additional electrical equipment.

Example of installation of metal air ducts

For exhaust air duct systems, sandwich pipes are increasingly being used, which are made of connected two galvanized pipes filled with insulation.

The double-walled design of the chimneys ensures that there is no condensation in the pipe and fully complies with fire safety standards, since the insulation is made of fire-resistant material. Double-walled galvanized pipes for ventilation are often installed outside the building, but can also be used for exhaust shafts.

Single-wall chimney pipes are used indoors as self-constructed, which is connected in the main chimney, and as a sleeve in existing brick ventilation shafts. Metal air duct chimneys are made from corrosion-resistant stainless or galvanized steel. If pipes are laid in shaft channels, it is necessary to additionally insulate the pipes from a refractory material, securing it with galvanization.

Calculated data

To maintain human health, GOSTs and SANPiNs were developed, which regulate the performance of the ventilation system. Ventilation performance begins with the calculation of air exchange and air distribution network, and the selection of air distributors (grills). To do this, you need to know the purpose and area of the premises, as well as draw up a diagram of the laying of air ducts. Air distributors are selected from catalogs based on air flow and noise level. Taking into account all the characteristics of the above calculations, a heater and supply unit are selected.

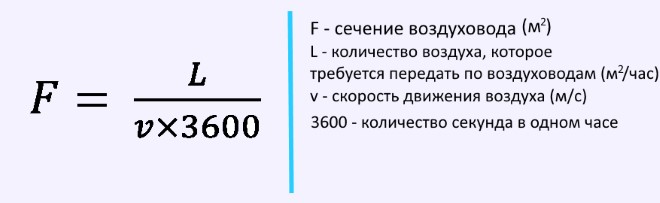

Focusing on regulatory data and the dimensions of the premises, in order to create the necessary air exchange at a given speed, specialists calculate the area or diameters of the air ducts. It is necessary to understand that the cross-sectional area of the pipe directly affects the flow and speed of air in the duct. Reaching required parameters air speed, we must not forget about sound insulation of flat or flexible metal ventilation ducts. Additional noise in corrugated pipes or rigid ducts can be reduced by using sound-absorbing sandwich board insulation, reducing the number of right angles, sharp turns and transitions from one pipe diameter to another.

When installing a ventilation system pipeline, taking into account the characteristics of the room environment and operating conditions, round, square or flexible ventilation ducts made of plastic or steel structures. The cost of a ventilation system depends on the quality of the material used, the thickness of the metal and the number of fittings. Welded air ducts made of black steel will cost less than galvanized pipes. Shaped parts of plastic or metal pipelines allow you to assemble a ventilation and smoke removal route with numerous turns and intersections with other communications.

Briefly about the important

To summarize, let us highlight the main requirements for the design and installation of ventilation systems:

- Air ducts for ventilation can be made of plastic or metal, depending on the environment in which they are laid. The quality of the material does not affect air circulation.

- When laying pipes in floors and walls, it is important to remember that the passage points must be protected with a steel sleeve or other wrapping material.

- The formula for calculating the cross-sectional area of ventilation pipelines is used from design reference books or SNiPs.

- Ventilation ducts (material and number of fittings) are used based on the type of building and the tasks set by the designers.

- Do not forget about soundproofing materials, and also comply with the requirements for fastening air ducts to reduce additional noise in the room.

- Ventilation ducts can be laid not only indoors, but also in the channels of existing shafts, as well as outside the building.

- A flexible air duct is used when installing a complex ventilation line and to solve any design solutions, and flat ones are used mainly for industrial premises.

The process of installing a ventilation system is a basic and mandatory standard of sanitary and hygienic rules. The arrangement of such structures, as a rule, begins already at the design stage construction work. It is possible to install pipes for ventilation of a house not only at the construction stage, but also during repairs.

Basics functional purpose such systems - supply of fresh air to the room, removal of waste masses. They are especially important when gas heating equipment is installed in the house. The absence of pipes for the ventilation system in the house poses a potential threat to the health of all residents.

Air ducts, chimneys: installation features

Quantity necessary pipes and fittings for ventilation is determined by the following factors:

- area and volume of the room;

- power gas equipment, its purpose;

- features of the completed construction project.

High-quality ventilation pipes ensure reliable, safe, uninterrupted operation of the entire system. Hoods and pipes are installed in the kitchen, bathroom, saunas, and rooms where the fireplace is located.

It is simply necessary to buy ventilation pipes to ensure the possibility of high-quality supply of premises fresh air. Today, the most common type of these products are PVC products. The main advantage of the material is durability, it is not susceptible to corrosion, and is resistant to temperature changes and deformation.

Depending on where the system will be installed, products may be used different diameters in combination with a variety of connectors and corrugated elements. The efficiency and uninterrupted operation of the system will depend on the correctness of their choice.

The Elits trading house recommends using stainless steel pipes for ventilation. This option is more reliable and durable. We offer all kinds of shapes, sizes, diameters of products that can be used both for furnishing residential premises and in industrial construction.

Pipes for ventilation: price, shapes and sizes

A modern manufacturer offers the consumer a huge variety of components for installing a ventilation system. Among this entire range, the following main forms are distinguished:

- round section;

- rectangular section;

- Components non-standard shape(combined, trimmed, etc.).

Pipes for ventilation, you can buy in Moscow at the lowest prices from our company, with round have the following advantages:

- they are not equipped with protruding parts, which makes it possible to install the system in a smaller area;

- make it possible to use a smaller insulating layer, which reduces the cost of installing the system;

- low level of pollution.

Products with square section used when greater throughput is needed. Such products have a more attractive appearance. External ventilation pipes are most often of this type.

We offer pipes for ventilation in Moscow of all listed types and shapes. As for materials, our catalog includes products made of galvanized and stainless steel.

Galvanized steel is used when it is necessary to move air with a temperature of no higher than 80 degrees. Otherwise, we recommend using heat-resistant stainless steel pipes. They can easily cope with more difficult conditions, differ increased level resistance in environments with elevated temperatures.