Considered modern insulation for heating pipes, its types and features. Recommendations are given on the choice of thermal insulation material for hot water supply and heating systems. The properties of all possible insulation materials are listed.

Features of choosing thermal insulation for pipes

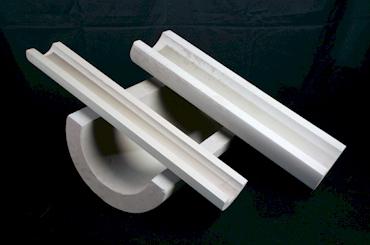

Thermal insulation is used both for centralized heating lines and intra-house heating networks in order to reduce heat loss. When choosing thermal insulation, you need to take into account the diameter of the pipes, the temperature of the coolant and operating conditions. The type of insulator that will be used depends on the diameter of the pipes. These can be hard molded cylinders, half-cylinders, and soft mats in rolls.

Insulation of heating pipes of small diameter can be done using cylinders, half-cylinders (equipped with grooves that create convenient and quick installation on pipes), also using segments made of polymer or mineral wool heat-insulating materials. They have very high thermal resistance. In addition, they have a low degree of water absorption, resistance to mechanical damage and strict geometric size. Let's consider the areas of application of the most popular materials for thermal insulation.

Advice! Mineral wool is well used to protect heating network pipelines and hot water supply pipelines in residential and public buildings, household premises, as well as pipelines whose surface is subject to heating, for example, chimneys.

Types of mineral wool

- Stone wool is made from alloys of basalt rocks. It was described above.

- Glass mineral wool - made from glass staple fiber, based on quartz sand, as well as broken glass. This type of wool cannot withstand high temperatures. It is also called glass wool, fiberglass.

Insulation of heating pipes is possible using polyurethane foam material, which is used for thermal insulation of pipelines for a wide range of applications. However, the disadvantage of polyurethane foam is its relative high cost. TO positive qualities can be attributed:

- resistance to atmospheric factors;

- non-toxic;

- neutral smell;

- strength;

- the coating is not electrified;

- does not rot;

- resistant to plasticizer, solvent, acid and alkali;

- environmentally safe and does not cause harmful effects on the human body.

Products made of polyurethane foam are a rigid structure in the form of walls and ribs, which is produced in production conditions using the “pipe-in-pipe” pouring method, which gives it strength and good thermal insulation properties. These structures are called heat-insulating shells. Reliable protection joints of pipelines from water are carried out with heat-shrinkable polyethylene tape, as well as a coupling various brands production.

Protective cladding

In pipelines with rigid protective lining, pipes made of hot-dip galvanized sheet are used, with seams in the form of a spiral. Steel pipes in tin protective casing contain an insulating layer of polyurethane foam and are installed using the ground laying method. Positive aspects Such insulation can be called quick installation and dismantling, the likelihood of being used several times, and accessibility to damaged sections of the pipeline. If you still haven’t decided how to insulate your heating pipes, then you are presented with the following possible options.

Other foam insulation materials

There are a large number of foamed thermal insulation materials. These include various polymers, such as foam rubber or polyethylene foam. Foam rubber pipe insulation is a flexible, closed cell foam material. Sold in the form of tubes and plates. They have increased fire resistance and are classified as self-extinguishing materials. They do not rot, do not form fungi and mold, and are resistant to water and condensation even at extreme temperatures.

Thermal insulation for pipes made of foamed polyethylene

Thermal insulation for pipes made of foamed polyethylene is presented in the form of a tube with a technological cut with very precise technological diameters and wall thickness. It is resistant to moisture and temperature changes, and is resistant to building materials, such as cement, concrete, lime.

Expanded polystyrene (foam) insulation

It has low thermal conductivity and moisture absorption, does not change its properties for more than 50 years, therefore in some industries it is an indispensable material at a wide range of temperatures. This insulation for heating pipes is made from two halves, connected using the tongue-and-groove method, thus not forming cold bridges. Foam plastic has an unlimited service life. It has good sound insulation and is difficult to ignite.

Penoizol is not inferior in quality to polystyrene foam, being its close relative. It has the same properties as expanded polystyrene. The advantage is that it is applied in liquid form, and as a result, the seams are sealed.

Foam glass - consists of cellular glass, has good thermal insulation qualities, and is completely safe. Foam glass has a high strength index, does not shrink, is durable, does not burn at all, and does not react to chemicals and their vapors. It is convenient for installation. Retains its properties for many decades. Not subject to rodent infestation.

Thermal insulation paint

If, after all the options considered, you have not chosen how to insulate your heating pipes, then you should pay attention to one more innovative material - heat insulating paint. It has high thermal insulation properties, protects against corrosion, penetrates hard to reach places, withstands changes in both high and low temperatures. One coat of paint replaces mineral wool or expanded polystyrene, thus reducing the thickness of the coating.

Use of materials is permitted only if there is an indexed link to the page with the material.

High-quality insulation for heating pipes ensures efficient heat supply Houses. For these purposes, there are many special materials, each of which has different properties and technical characteristics. Their wide range is presented in the form of cylinders, polyethylene and rubber tubes, liquid insulation, and also in rolls.

The need to insulate heating pipes

This is done so that the released heat is accumulated in the radiators. Unprotected heating systems in the house give off heat to walls and openings. Pipes hidden in niches without insulation increase the temperature of buildings, which can result in cracks in the plaster and peeling of wallpaper.

Insulation for heating pipes located in basements will not hurt, which will prevent the formation of condensation and protect them from corrosion. Insulation of heating system pipelines is performed to reduce heat losses, save fuel costs, and increase service life.

Types of insulation materials

Heating is produced by products made from mineral wool, rubber, polyurethane foam, as well as combined or filling materials. The materials from which they are made are of the following types:

roll;

combined;

filling;

casing

Insulating coatings with a longitudinal technological cut are easy to install and can withstand high temperatures. Pipe insulation made with mineral wool or casings reduces heat losses. Aluminum foil protects the pipes from condensation and maintains their temperature.

Selection of insulating material

When choosing a material for insulating heating pipes, you should take into account its main characteristics - properties, pipe diameter, operating conditions. When choosing, a factor such as thermal insulation qualities is the most significant. The insulating material must have: ![]()

biostability and chemical resistance to aggressive environments, so that installation can be carried out underground, indoors, as well as outdoors;

water-repellent characteristics that help prevent condensation;

non-flammability, which will ensure the preservation of the structure from exposure to high temperatures;

flexibility, which plays a role when using the material on uneven areas;

durability, which will ensure a long service life of the pipeline.

Modern thermal insulation materials

On modern market you can find a lot of building materials different materials, from which insulation for heating pipes is made. Among the most modern and frequently used are the following:

thermal insulation paint;

foam shell;

energyflex thermal insulation;

polyurethane foam insulation;

basalt cylinders.

Each of them has certain properties and should be selected separately for a specific room.

Thermal insulation paint

Thermal insulation paint is a paste-like composition that has a high index. It consists of foam glass, perlite, and ceramic microspheres. It is applied to pipes of any configuration, has no seams, is fireproof, and provides protection against condensation and corrosion. One applied layer can replace polyethylene insulation, the thickness of which is about 50 mm. Thermal paint is an environmentally friendly product that does not require additional ventilation when used. The main advantage of the material is the ability to carry out insulation in hard-to-reach places.

Foam shell

Foam material is often used in pipe insulation. It consists of two halves, which are connected by a tongue-and-groove lock. Produced in different diameters and thicknesses. The foam shell has low thermal conductivity, does not absorb moisture, is environmentally friendly, durable, and easy to install. The material is flammable, so its use in pipelines with temperatures above 100° C is not recommended.

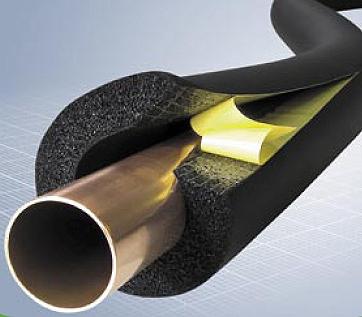

Energoflex

Energyflex heating is the most popular material nowadays. It is used for thermal insulation of pipelines with a small diameter. Energoflex for pipes is produced roll material, as well as in the form of hollow tubes 1-2 m long, shaped like a cylinder of different diameters with a longitudinal technological cut.

When using this product, it is necessary to take into account some nuances. Before performing insulation, you should check the surface of the pipes, which must be cleaned and degreased. The water supply is stopped during work and is turned off for another day after work is completed. Installation cannot be carried out when sub-zero temperature. First, the fittings and protrusions are insulated, and then the flat sections of the pipes. When carrying out work with roll material, it is necessary to ensure that upper layer insulation covered the bottom joint. The coating should not stretch during installation.

This type of insulation has hygienic certificates and meets all European and Russian standards. Energoflex for pipes has low thermal conductivity, good sound insulation, resistance to chemical compositions, frost and heat resistance, strength, durability, flexibility, ease of installation.

Polyurethane foam

Polyurethane foam insulation is most often used in everyday life. It is produced in the form of tubes that are connected according to the “pipe-in-pipe” principle.

In addition to reducing heat loss, this design contributes to additional mechanical strength of the pipeline. Polyurethane foam material is resistant to precipitation, does not rot, does not collapse when exposed to chemical compounds.

Basalt cylinders

It is a hollow stone product with a cylindrical shape. They are available coated with aluminum foil or uncoated. There are different diameters and thickness, 1-1.2 m long. You can find basalt cylinders with a tongue-and-groove lock or an even connection that needs insulation. The material is resistant to aggressive environments, bioresistant, and easy to install. Due to hygroscopicity, it requires insulation.

Price

Are you interested in insulation for heating pipes? Its price will depend on the characteristics and properties of the thermal insulation material. Estimated cost of the most commonly used products on construction market is this:

basalt cylinders - from 50 rubles per linear meter;

polyurethane foam - from 10 rubles per linear meter;

heat-insulating paint - from 230 rubles per 1 liter;

energyflex - 10 rubles per linear meter, and more;

foam shell - 30 rubles per linear meter and more.

Remember that you should not save on thermal insulation material. To keep your home always warm and cozy, use quality products from trusted manufacturers.

Radiators in the house

Construction of a private country house is a serious matter. There are no trifles here, there are no important or unimportant processes, which means that it is necessary to treat this with full responsibility. This is fully true for heating in a private home. Moreover, from this utility network comfort and coziness will largely depend, especially in winter, when the temperature outside goes well beyond zero degrees. Therefore, we will consider this particular aspect of building your own home.

Let's make a reservation right away - we will not dwell on the choice of heat source, although we will definitely touch on this. Let's also bypass air system heating, stopping only at the radiator.

Selecting materials

The first question that a developer faces is what influences the choice of materials? Aesthetic preferences are not taken into account here, but the basis for choice is taken technical specifications coolant - its temperature and pressure.

The heating system can be divided into two categories according to the coolant received - centralized heating and autonomous. Accordingly, the parameters of the coolant in different systems ah will differ significantly from each other. For example, in centralized heating mains, the temperature of the coolant in severe frosts is 110-140C at the supply and 65-70C at the return. In this case, the pressure is 6.0-6.5 kg/cm 2 and 4.0-4.5 kg/cm 2, respectively.

Attention! The above coolant parameters refer to routes inside houses, and they are unacceptable directly in the radiator system. To change them, a special unit is installed - an elevator. Mixing takes place there hot water from the supply and return lines. The maximum temperature inside the radiator system of the house is +95C, and the pressure does not exceed 5 atmospheres.

Of course, these parameters are much lower. Here the temperature does not exceed +80C at the supply and +60C at the return (sometimes lower - up to +45C) with a coolant pressure of no more than 1.5 atmospheres. Therefore, the selection of materials for different systems will differ significantly.

Central heating

In this case, you will have to pay maximum attention to radiators and pipes. From their highs technical characteristics the quality of operation of the entire system will depend, as well as long term its operation.

The water heating system in such houses has been in operation for a long time, so considerable experience has been accumulated. If quite recently preference was given cast iron radiators, then today the priorities have changed. After all, the requirements of the modern approach to heating systems have become more stringent in the direction of economy. This means that at low temperatures, radiators must give off heat within the same parameters. Therefore, the installation of bimetallic and steel batteries for today - the best option. Although cast iron has not yet been abandoned either.

Now, as for the pipes. There are three options:

Boiler room in the house

- Galvanized steel pipe. Many may be skeptical about this type of material, but these pipes are still standing and working for about 50 years. The only thing that experts recommend is to carry out installation not by welding, which violates the protective galvanized layer, but by a threaded connection.

- Metal-plastic pipes. Not everyone agrees with this decision, because it is believed that this type of pipe will not be able to withstand high temperatures. There are no objections, but again we note that everything will depend on the parameters of the coolant. The temperature in the radiator heating system does not exceed +95C, and such indicators metal-plastic pipe will bear it calmly.

- Corrugated stainless pipe. This is a new product that has already proven itself excellent:

- Firstly, it is not afraid of high temperatures, corrosion, or pressure. It's stainless steel.

- Secondly, this is a bendable product.

- Thirdly, the parts of the pipe are connected to each other using threaded adapters, and the tightness of the joint is ensured by a silicone seal.

True, such a pipe is not cheap. But the simplicity and speed of assembling the pipe circuit must be given due credit. This process can only be handled by a non-specialist in the singular.

Heating system

Central heating in country houses- rare case. Typically, this is an autonomous system that uses special equipment responsible for heating the coolant.

Choice necessary materials in such cases, it always begins with the selection of a heating boiler, or rather, with the calculation of its power. Do this if necessary high accuracy, not so easy. After all, you will have to take into account a large number of different indicators and coefficients. For example, the number of windows, the thickness of the walls, the presence of thermal insulation of house elements, the type of used finishing materials, features of the region where the house is being built, and so on.

Modern boilers

An ordinary person cannot cope with such calculations. And even if it does work, it will take a lot of time. Therefore, there is a simpler option - take into account 1 kilowatt of thermal energy, which will provide heat for 10 square meters area of the house. But keep in mind that this arrangement is possible if the ceiling height does not exceed 3 meters. If this indicator increases or decreases, coefficients must be used. But this proportion is taken as a basis.

The water heating boiler can operate at different types fuel. The choice in each case will be based on the most common energy carrier in your region. But listen to our advice - choose those boilers that can operate on different types of fuel, that is, combined options. With their help, you can avoid many problems associated with a shortage of, say, gas or electricity, diesel fuel or coal. By switching from one type of fuel to another, you instantly solve your heating problem.

Now let's return to the pipes. Experts recommend pipes made of reinforced polypropylene as the best option. Reinforcement is used specifically - this way the issue of reducing the linear expansion of the material when it is heated is resolved. If radial piping is used in the heating system, then optimal choice– pipes made of cross-linked polyethylene. Such material comes to retail trade in the form of bays 200 meters long, which means it is possible to carry out installation with a minimum number of butt joints.

And lastly - radiators. IN autonomous system You can use any type of home heating heating batteries. But, as often happens, the optimal price-quality ratio is taken as the main indicator of choice. Therefore, aluminum radiators would be most appropriate here. The price of such devices is not very high, but the heat transfer is really high level. One section aluminum radiators has a heat output of up to 210 watts - this is a very high figure.

Heating system piping

So, the materials have been selected, now you need to decide on the pipe layout. This question is not simple, because the efficiency of the entire system will largely depend on it. What schemes can be offered today?

Single pipe system

Single-pipe connection principle heating system

This simple circuit, cheap, does not require complex configurations. It is usually used in low-rise construction, when it is necessary to use only one highway.

The circuit is a ring with a heating boiler in the center. A pipe circuit extends from it, which connects the heating radiators to each other in a sequential order.

Although this is a simple and cheap scheme, it has a couple of disadvantages. And the most important thing is a sharp decrease in the temperature of the coolant when it reaches the last heating devices. This means that the last rooms in this network will always be cool.

Is there a way out of this situation? There is always a way out, and here there are even two of them:

- The first is to increase the number of sections in the latest radiators.

- The second is to install into the system circulation pump, which will evenly distribute the coolant throughout the batteries.

Two-pipe scheme

It can be of two types - two-pipe system heating with natural circulation and forced. This wiring diagram is considered optimal. True, its creation requires a large amount of materials - pipes, fittings, shut-off valves and other things. But its efficiency and fuel economy are beyond praise. Especially when it comes to natural coolant circulation.

Throttle for balancing is required

It should be noted that this type of wiring has several types of supply line assembly. ABOUT beam wiring It was already mentioned a little above when we were talking about. It is this scheme, which is also called a collector, that is the most effective regardless of what kind of house you are going to build - one-story or multi-story.

In this case, the supply line rises upward from the heating boiler, which is led above the heating devices by several meters. After that, a pipe is led from this point to each radiator, let us emphasize - to each one. That is, a free-standing radiator has its own supply line. This is a guarantee that all batteries, without exception, will have the same temperature, which is important for organizing comfort inside the house.

Without a doubt, the number of pipes with such wiring increases sharply, which means that costs also increase. In addition, such a system will have to install an expansion tank, which will also require financial costs.

Is it possible to reduce the cost of a two-pipe heating system? It is possible if you select the circuit in which the circulation pump is mounted. It is called two-pipe with bottom feed. In this case, it is possible to distribute heating along the floor, which not only reduces the cost of purchasing materials, but also allows you to hide pipe lines under the floor covering.

By the way, to reduce the volume installation work, many experts use this type of scheme as a passing two-pipe system. In it, the coolant supply and return lines run in one groove, in one installation channel. This is not always possible to do, because much will depend on the configuration of the house and the arrangement of the rooms in it. But if such an opportunity arises, then it will definitely be used.

Circulation pump

Modern pump

A circulation pump is not always used and not in all cases. But with its advent, serious shortcomings of heating systems disappeared. This small device can be installed in any type of heating system. We especially note the one-pipe circuit and the two-pipe circuit with bottom wiring. It is the pump that helps create a small but stable coolant pressure in the pipe network. Thanks to this, it will move at a low speed, which is enough to transfer heat to the radiators and heat up in the heating unit during this period of time.

Many may notice that this pump is powered electric current, which means you will have to pay extra for electricity consumption. That's right. But the circulation pump has a small power, so the electrical current consumption is negligible and will not greatly affect your wallet. But the efficiency of the entire heating system will significantly increase.

What if the power supply is cut off, what should you do? This happens, so you need to provide a special unit where the circulation pump will go. In the return line, closer to the boiler, an insertion of this unit is made, in which the pump is installed on the bypass and is cut off from the main circuit by a shut-off valve. But you will also have to install a valve on the main circuit. If the power is turned off, you need to open the valve on the main circuit and close the valve on the bypass. And when the current supply has resumed, everything should be done in reverse order and turn on the pump itself.

Conclusion on the topic

Today they are considered the best option organizing heating in private homes. Basically, the criterion of safety, efficiency and optimal use of all equipment as a whole is taken into account. Of course, this is not the only way to heat your homes - there are many other options. But life shows that this one is the most common.

1.

2.

3.

4.

5.

Heating pipe insulation is used to minimize the percentage of heat loss. The material used for this must not only ensure heat preservation, but also perform protective functions for the pipeline system. For example, thermal insulation for heating pipes must prevent the appearance of condensation, must eliminate the possibility of freezing of water in the system and protect the pipeline from the harmful effects of corrosion.

Selection of insulating material for heating pipes

The cold climate characteristic of our country necessitates insulation of not only centralized main pipelines, but also heating circuits installed in houses. When choosing insulation, you must rely on the following factors:Cylindrical and semi-cylindrical rigid insulation is mainly used to protect small diameter pipes (read also: ""). The design of such insulation includes grooves that greatly simplify installation on the pipeline.

In addition, for better quality and reliable insulation You can use mineral wool or plastic. Rigid insulation can not only withstand high temperatures and prevent condensation, but also protect pipes well from mechanical damage.

To determine suitable material To insulate heating pipes, you need to know how they are classified and how they differ.

Types of heating pipe insulation

Mineral wool

Mineral wool is a fairly popular insulation material because its efficiency is quite high.In addition, mineral wool has a number of advantages:

- high heat resistance without loss of original properties;

- good resistance to damaging chemicals;

- minimum level of water absorption (especially after treatment with special substances);

- no toxic emissions when heated.

The advantages of using mineral wool as insulation are obvious: it is quite reliable, is not afraid of almost any impact and is safe. Such insulation for heating pipes is often used to improve the performance of the heating system and water supply in many homes. In addition, this material is ideal for insulating pipes that constantly operate at high temperatures. The use of mineral wool ensures good sound insulation of heating pipes.

In addition, other heat insulators are made based on mineral wool. It was described above stone wool, for the production of which rocks are used, but there is also glass wool, the main raw material for the production of which is crushed glass or processed quartz sand. This type of heat insulator is not as versatile as mineral wool, but still finds application in some branches of construction.

Glass wool

Glass wool is mineral insulation 3-4 microns thick, produced in rolls from 1.5 m to 2 m long. This thermal insulation material has a rather low density, so it can only be used in systems whose temperature does not exceed 180 degrees Celsius.This insulation allows you to create thermally insulated pipes for heating. centralized system. Among the positive qualities of the material are high vibration resistance, good resistance to biological and chemical influences and high reliability.

Polyurethane foam

Polyurethane foam heat insulators are a rigid type of insulation. The basis of this design are ribs and walls. One of the popular names for polyurethane foam insulation is insulating shell.This insulation has big amount positive qualities, among which the most notable are:

- no toxic emissions and unpleasant odors;

- high resistance to rotting;

- no negative impact on the human body;

- high strength, preventing mechanical damage;

- excellent dielectric properties;

- good resistance to chemicals;

- Excellent performance in harsh weather conditions.

The only drawback of polyurethane foam insulation is the very high cost due to the difficulty of manufacturing the material.

Foamed polyethylene

This material is very often used to create thermal insulation. Foamed polyethylene is environmentally friendly, absolutely harmless to human body, resistant to humidity and temperature changes. This insulation is produced in the form of a tube having a certain diameter and equipped with a notch for ease of installation. Foamed polyethylene is excellent for insulation heating pipes and main water supply pipelines. This polyethylene can be used in combination with other types of building materials.

Other types of thermal insulation for heating pipes

In addition to the described insulation materials, which fall into the category of the most common, there are others that are also very often used in construction. Each of these types is suitable for solving certain problems, and they all answer the question of how to insulate heating pipes.Expanded polystyrene

This insulation material made in the form of two parts that are securely connected to each other, as a result of which the possibility of cold penetration through the thermal insulation layer is completely neutralized.Styrofoam

The positive qualities of polystyrene foam include good moisture absorption and thermal conductivity, as well as resistance to high temperatures. In addition, polystyrene foam belongs to non-flammable materials and can last for several decades. With help of this material is created high-quality sound insulation heating pipes.Penoizol

Its characteristics are very similar to polystyrene foam, but it is produced in liquid form. The advantage of penoizol is that it leaves absolutely no gaps when applied. This makes it possible to use it not only as insulation, but also as a sealant.Foam glass

This material has a very high mechanical strength. Foam glass does not pose any danger to humans, and its good performance makes it very profitable to create durable insulation. In addition, creating thermal insulation using foam glass is not difficult, so it is recommended for those who do not have experience in construction work.

Thermal insulating paint

Thermal insulating paint was invented in Russia. The material contains foam glass, ceramic microspheres and some other heat-insulating substances. Paint applied in a 2 mm layer can replace several layers of mineral wool. The paint has high performance and does not cause any harm environment. The material is produced in the form of an aerosol, which greatly simplifies the process of creating thermal insulation.Installation of thermal insulation on pipes

Thermal insulation for heating pipes is installed step by step, in accordance with the following algorithm:- Before installing the insulation, the pipes must first be covered with tape, which should spirally cover the entire surface of the pipeline.

- Now you can install the insulation directly. At this stage, you need to carefully ensure that all seams are carefully secured - otherwise, so-called “cold bridges” may appear, and their appearance will negate the entire effect of installing the insulation.

- The last step is to secure the thermal insulation. For this a good one will do tape that will hold the insulation on the pipeline as securely as possible. Poor-quality thermal insulation of heating pipes on the street in the future will certainly allow unwanted substances to pass through to the pipes, which will negatively affect the performance of the system.