In order to create proper air circulation in the room, in particular, to create ventilation in the bathroom, a whole complex of structures with different components is created. One of the most important components here are flexible air ducts for ventilation, which serve to move air from one point to another. They can be of several types, depending on the material from which they are made. In this article we will talk about plastic air ducts, the catalog of which is quite extensive.

- 1 Section

- 2 A few words about installation

- 3 View selection

- 4 The key to proper installation

- 5 Negative sides square and rectangular

- 6 Pros

- 7 Cons

Section

An important characteristic of such systems is the cross-section of the air ducts, the selection of which should be selected depending on the location. For example, if the distance between the ceiling and the main ceiling is small, then flat-oval air ducts for home exhaust hood should be installed. In their design, they differ little from round-section systems; air purification occurs with a similar intensity. The manufacture of structures involves the creation of a flat shape on special machines. True, it is worth noting that plastic air ducts with an oval cross-section do not provide significant resistance to air flow, which is not characteristic of other types of systems. As a result, air moves easily and the engine does not receive too much load.

True, the production of systems with a plastic cross-section is overpriced, but the characteristics that ultimately distinguish air ducts for ventilation are justified. The product catalog in this industry offers a large number of options for this product.

Use plastic air ducts in cottages and country houses accepted in air conditioning structures where air purification is necessary, and they are also suitable for heating systems with the supply of heated air masses.

A few words about installation

Installation of systems should only be carried out by people who have received professional training. It is mandatory to calculate the required air exchange during general ventilation, which will allow you to choose the right size structure, and air cleaning will be carried out at the proper level. The production of air ducts involves the additional production of various fittings and accessories, without which installation is difficult. Their main function is to cover certain areas, as well as the ability to connect several air supply sections into one, so that cleaning takes place more intensively and efficiently. Plastic air ducts should be secured using special fasteners. Provided that it is selected correctly, it even improves appearance structural element. Professional sealants are used to seal joints.

Sometimes a design such as a hood without an air duct is used, which will be based on carbon filter. Air cleaning here will be similar, but regular filter replacement will be required, which is not profitable or convenient.

Selecting a view

To determine which plastic air duct will be needed to ensure proper air circulation and through which air purification will be carried out, you should pay attention to the following indicators:

To determine which plastic air duct will be needed to ensure proper air circulation and through which air purification will be carried out, you should pay attention to the following indicators:

- Purpose of ventilation.

- Type of ventilation.

- Ventilation dimensions.

Accordingly, air duct systems are selected for a specific hood. The installation of a structure, the main task of which will be air purification, should be carried out directly from the creation of the project according to which it will subsequently be manufactured. The design of air duct systems for any hoods should be done by an experienced specialist, since air purification will be carried out taking into account all the parameters of the room, including features and area. During the preparation of the project, it is important to take into account the performance of all elements of the hood, so that air purification does not bring any acoustic discomfort.

Unfortunately, most buildings are formed in such a way that the installation spaces plastic systems doesn't stay. As a result, the homeowner has to install narrow pipes for the air supply. This moment has the main disadvantage - the passage of air through a narrow pipeline, even if it plastic version, introduces too much noise into a process such as air cleaning. For calculation optimal area sections use a special formula: . L in in this case– air flow rate, and the result of this formula will be the cross-sectional area in square centimeters.

The key to proper installation

It should be noted that the correct installation of the system, which will be based on air cleaning, can only be carried out by a specialist. You should not skimp on the installer’s work, since plastic air ducts require a certain precision. Any miscalculation can lead to incorrect operation, and air cleaning will not be carried out at the proper level. The result is too poor air conditioning and unpleasant odors. Eg, plastic pipes require the use of sealant when joining; if the tightness is not too clear, this will lead not only to failure of the entire system, but also to a too long process of detecting air leaks.

It should be noted that the correct installation of the system, which will be based on air cleaning, can only be carried out by a specialist. You should not skimp on the installer’s work, since plastic air ducts require a certain precision. Any miscalculation can lead to incorrect operation, and air cleaning will not be carried out at the proper level. The result is too poor air conditioning and unpleasant odors. Eg, plastic pipes require the use of sealant when joining; if the tightness is not too clear, this will lead not only to failure of the entire system, but also to a too long process of detecting air leaks.

Do not forget that air cleaning is a very delicate process, so the customer has every right to control the work of the performers.

Disadvantages of square and rectangular sections

Availability square section air ducts are considered not very convenient to use. This is due to the fact that they are more resistant to air flows, so cleaning occurs with some difficulties. Their installation may also be a little difficult. In addition, plastic pipes of this cross-section are more susceptible to noise than oval or round options. Experts believe that the installation of two round ducts will be much more practical than one square one. However, if there is an indirect air transmission line, it will be much more convenient to use square or rectangular elements.

pros

Speaking about the advantages of plastic air ducts, the following should be noted:

- Plastic equipment makes less noise.

- Light weight of pipes, which greatly facilitates their installation. This is also due to the type of material.

- The smooth surface of the material eliminates the possibility of excess friction.

- Due to the fact that plastic can operate in a wide range of temperatures, installation of such a system is possible for any industry.

Minuses

The disadvantages of such structures include low fire resistance and difficulty of installation under vapor protection conditions.

Thus, plastic air ducts - perfect solution to create a system for cleaning and air circulation. Their use allows you to forget about the need for repairs on long years, and provided correct installation, they will serve at the proper level.

Recently, the development of technology and equipment for your kitchen at home has been making great strides forward...

The desire to live comfortably is a colossal motivation for introducing advanced technologies into our lives.

This process favored the appearance on the market of a system that would contribute to the distribution of air in the kitchen, that is, the birth of air ducts.

Air ducts for ventilation are divided into:

1) depending on the section used:

— a) air ducts are flat, oval, the size range of which ranges from 110×55mm to 204×60mm;

- b) round air duct with a popular cross-section - 100, 125, 150 and 200 mm.

2) depending on the material used:

— a) plastic air duct;

-b) metal air duct

1 Flat and round ducts. Properties, advantages and disadvantages

The use of flat and round plastic air ducts occurs when creating exhaust and supply system ventilation in medium-sized rooms, in addition, they are present in the connection of ventilation and exhaust equipment (in fume hoods, etc.) Regarding installation, working with them is no more difficult than the usual collection of Lego figures.

A number of general properties can also be identified:

- High quality plastic;

- Operation in the temperature range from -30 to +70 ° C;

- Indifference to corrosion, which contributes to long-term operation;

- Virtually no noise during system operation;

- Lack of roughness of materials, which contributes to savings in less frequent cleaning of ventilation;

- Acceptable cost of equipment.

A flat or plastic kitchen air duct has the advantage of being able to lay pipes unnoticed. Having a small height, it is easy to hide in the walls of the kitchen, suspended ceilings, as well as on kitchen cabinets, the size of flat ducts facilitates work in areas with limited space.

For example, if a room was remodeled and there was not enough free space to install round plastic channels. However, if you buy plastic round air ducts and connectors for them, this, in turn, will be more economical.

This is due to the quality of air impermeability, because if air is lost as it moves through the pipes, this affects the quality of ventilation and, accordingly, additional energy costs. This disadvantage This is explained by the fact that the connection in flat air ducts is not so tight in ventilation.

To connect flat air ducts for ventilation systems to each other and also to an elbow, you will need only one, but for a rectangular one you will have to use connectors in the form of sealed flanges. Flat plastic air ducts for the ventilation system are characterized by the appearance of turbulent zones inside, which contributes to the appearance of noise, and their cleaning is more expensive than their analogues.

The production of flat air ducts is also not so standardized and you will have to wait for their production.

If we consider this aspect as cost, it is much more affordable to buy a plastic air duct and their connectors than a metal one. And although it is inferior from the outside, it is still a profitable investment.

Let's delve further and compare the prices of round and flat ducts. We note that the price of a plastic round air duct ø 100 per 1 m is about 100 or 150 hryvnia, a plastic round air duct ø 150 is twice as high and does not differ significantly from the cost of a plastic round air duct ø 200 - approximately 250 hryvnia. As we can see, there are different sizes. The most common are 150 and 200 mm.

Regarding flat air ducts, the pricing policy, for example, length 0.5 mm, section 55 * 100 costs about 50 hryvnia, and 1 meter is already about 100. However, do not forget that round plastic air ducts for the ventilation system are smaller in size than flat ones and fewer of them are needed .

2 Artificial ventilation or choosing a kitchen hood.

The kitchen, a room where there is always an abundance of various odors and the settling of fats, requires the installation of a good hood. However, let's not confuse the hood with ventilation.

Ventilation is a natural process that ensures air circulation in a room, and an exhaust hood is only in a certain area and it will not replace general ventilation kitchen, but to complement it with the main advantage. Flat air ducts for kitchen hoods will be economical and invisible.

Plastic duct parts (connectors 100 150 and 200)

Before buying a flat air duct for a kitchen hood, pay attention to the performance of the hood; the cross-sectional diameter will depend on this. According to the pricing policy, the smaller the diameter, the more acceptable the price. However, do not forget about the disadvantage of this type. Moving with the times, many choose air movement for the kitchen. At the same time, connectors and turns of ducts also need to be considered and taken into account.

The principle of operation of such hoods is based on the fact that air is sucked into the tank using a powerful motor, and then, purified using filters, it is returned to the kitchen area.

They can be classic, suspended (air exhaust from the front panel for mounting kitchen cabinets directly above it), built-in (allow you to hide the knee and device in kitchen furniture) and telescopic (which, if necessary, extends to a certain distance from the wall).

Flat kitchen hood for kitchens without an air duct has proven itself for kitchens with small area. There are disagreements about the recirculation method of exhaust hood, considering that preference should be given to flowing air circulation, where unfavorable odors are completely removed from the apartment and are not filtered.

However, if you think about the fact that when the flow hood is turned off, the exchange of air flows does not occur and the operation of the ventilation system deteriorates significantly, recirculation takes its due first place. In the “ON” state, the movement and filtration of harmful vapors are simply carried out, and in the “OFF” state there is natural air exchange.

But here you should pay attention to the fact that you will be faced with the fact that the data needs to be changed regularly, which will bring additional material costs, and also from the design side the choice is small.

2.1 Ideal solution. Using connections.

There are connectors on the market for shaped parts for flat and round air ducts, which come in a variety of elbow sizes. This greatly simplifies the installation of a ventilation system, and moreover, achieving the desired result. The range of connections fully corresponds to the size range of flat air ducts on the side, and is designed for round ducts with a diameter of 100, 150 and 200 mm.

2.2 Round plastic air ducts - video

To create turns, there is a round plastic elbow for air duct elements. The connectors here are also plastic. The rotation can be carried out at different degrees (45, 90). If it is necessary to connect to round channels with a diameter of 100, 150 and 200 mm, the presence of a gearbox will be required. This gearbox is not included in the kit.

Plastic reducers for round air ducts can be universal, but allow connections with diameters of 80, 100, 150 and 200 mm. The gearbox is attached using clamps and has similar properties. In addition, we can say that the gearbox should be connected strictly according to the rules and instructions.

Thus, flat - oval air ducts optimal solution for creating ventilation systems. This choice contributes to the satisfaction of the main aspect that we always strive for - obtaining quality at an affordable price.

2.3 Review of rectangular plastic air ducts - video

Plastic air ducts for ventilation have gained great popularity today. Compared to metal analogues, they are increasingly preferred. This is due to the fact that the costs plastic structures are relatively low, and in addition to this, they have a number of advantages that are increasingly tilting the choice of buyers in their favor.

Types and sizes

Plastic ventilation ducts There are rectangular, round and flexible.

Rectangular

Dimensions: 110x55 mm, 120x60 mm, 204x60 mm. Their peculiarity is that the box has a width 2 times greater than its height. Perfect for compact ventilation systems in residential premises, because... they can be hidden, for example, using a hanging or multi-level ceiling. Also, they are easier to install and install yourself. Therefore rectangular plastic boxes are the most popular and best-selling.

Despite the fact that the surface inside the air duct has no roughness, rectangular shape the structure itself creates resistance to passing air. This should be taken into account when calculating the construction of the ventilation structure. It is also not recommended to use plastic channels for mounting the hood, where the material may be damaged or deformed due to exposure high temperatures. Plastic air ducts do not provide such ventilation.

Round

There are 100, 120 and 140 mm in diameter. Unlike rectangular ones, the air resistance in round air ducts is much less, which also needs to be taken into account when calculating the operation of the ventilation system. In addition, due to its aerodynamic nature, such a design will be almost silent in operation. When installing a system of round air ducts, the material consumption will be less than when installing a structure with a rectangular cross-section, but it will be much more difficult to hide such a system.

Flexible

They have both rectangular and round section. Their advantage is that they are easy to install, repair, cut and adjust to fit required parameters. They can be turned in any direction, folded and bent many times without damaging the material. However, it is better to install them unfolded, this will extend the life of the air duct.

Important! Flexible air ducts can be used in conjunction with other types and shapes of air ducts; for this you need to purchase special plastic ventilation connecting elements. A serious disadvantage is that the air resistance in an air duct of this type is quite high, so the structure will be quite noisy during operation.

What is plastic for air ducts

- HDPE (polyethylene low pressure). Used both in domestic construction and in industrial premises. Withstands temperatures from -40˚ to +80˚. Resistant to sudden temperature changes, as well as aggressive chemical environments;

- PVC (polyvinyl chloride). Durable and reliable material, its service life is over 40 years. Does not emit foreign odors. Environmentally safe for humans and the environment;

- PVDF (polyvinylidene fluoride). Refers to fluoroplastics. Able to withstand temperature range from -40˚ to +140˚. It has high resistance to chemical, physical and mechanical influences. Widely used in the chemical and pharmaceutical industries for piping and ventilation systems;

- PP (polypropylene). Frost-resistant, UV-resistant, durable and reliable. The most common in domestic construction and repair work in residential premises and offices.

Pros and cons of plastic ventilation ducts

The undoubted advantages include:

- long service life;

- smooth inner surface;

- corrosion resistance;

- affordable price;

- environmental friendliness;

- easy to install.

Important! Indeed, unlike metal air ducts, plastic ones do not rust, create fewer obstacles to passing air, have a light weight and low price. However, there is also a drawback: PVC air ducts for ventilation cannot withstand temperatures above 80-85˚C, unlike metal ones, which work effectively when heated to 1000˚C.

The ventilation channel is calculated before purchase

Thanks to what exists today big choice various air ducts and fittings for them, such a system can be installed independently. Shaped parts allow you to lay the air line in any direction, connect flat air ducts for ventilation with round ones different sizes, rotate at an angle of up to 90˚.

The main thing is to produce correct calculations ventilation work can be done using a special one. After all, errors in calculations will lead to the fact that you install ventilation that will not cope with its task. The result of such errors will be impaired indoor air circulation and excessive humidity, which can ruin both the fresh renovation and the health of the people living in the house. When drawing up a plan, keep in mind that the more turns the air line makes, the lower the speed of the air moving in it will be. You can try to calculate it yourself, but it will be better if a specialist does it.

But what won’t be so difficult to deal with is installing the structure according to ready-made calculations. IN construction stores you can purchase the necessary shaped parts, standard-sized channels and divide them into sections of suitable length. Or order the entire system with transitions and corners from the manufacturer according to your finished plan.

After carrying out the necessary calculations and purchases, we proceed directly to installation. Recommended procedure for installing the ventilation structure as quickly and efficiently as possible:

- cut the channels into pieces the right size(plastic is easily cut with a hacksaw);

- collect large and complex ventilation units using fittings. Make holes in the parts, attach shaped fasteners with bolts;

- use a special tape or sealant to treat the joints;

- make marks on the walls and ceiling in places where the shaped parts will be fixed;

- lift large units to the installation site and secure them using clamps and brackets attached in advance;

- install the remaining small parts;

- Treat each seam and joint with sealant.

You can also fasten parts of the air ducts using welding, but then, if necessary, you will not be able to disassemble the structure. When passing the box through a wall, it is recommended to use a sleeve - a special adapter that will provide strength and prevent breakage and damage. The distance between fastenings should not exceed 1 m when horizontal installation, and 1.8 m when vertical.

The permissible sagging of a meter segment is no more than 5 cm, otherwise an additional clamp must be fixed in the middle. Corrugated air ducts must not be bent at an angle of more than 90˚ during installation.

Despite the fact that flat plastic ventilation is installed quite compactly, its appearance may differ from general interior. In this case, the ventilation structure can be covered with plastic desired color or “hide” in plasterboard box, and finish it according to your wishes. A simpler option is to cover the channels self-adhesive film suitable color.

Plastic rectangular air ducts for ventilation today it is not without reason that they have become in demand and popular when installing a ventilation system. Overall, they are superior to their metal counterparts in all respects except heat resistance. At correct drafting ventilation plan and selection of the required size of channels, this design will last a long time and will delight you with quality.

Plastic air ducts for ventilation are necessary for housewives who are familiar with the situation when you prepare food in the kitchen, and the smell and smoke spread throughout the apartment. This creates a lot of inconvenience at home - in such an atmosphere you feel uncomfortable, and the things around are saturated with the smell of cooking food. Fortunately, humanity has invented hoods. This is homemade ventilation system, which picks up smoke, fumes and odors and throws them out into the street. You can buy modern exhaust equipment in the store, but the effectiveness of its operation largely depends on correct selection and installation of air ducts.

What types of plastic air ducts for ventilation are there?

Depending on the section:

- The air ducts are round with a diameter of 100-200 mm.

- Air ducts flat size 110x55 mm or 204x60 mm.

Depending on the material used:

- Air ducts are metal.

- Air ducts are plastic.

Advantages of plastic air ducts for ventilation

Although the fire resistance of plastic air ducts is much lower compared to metal ones, the number of advantages of products made from this material clearly outweighs this single disadvantage.

- Plastic is ideal for use at home.

- Wide operating temperature range: -30 - +70°C.

- Durability - unlike metal, plastic is not subject to corrosion.

- In operating mode they do not create noise.

- Plastic air ducts do not become clogged because they have a perfectly smooth surface.

- Affordable price.

Which duct should you choose?

Both round and flat plastic air ducts are used to create supply or exhaust ventilation in a medium sized room. At home, it is appropriate to use plastic structures - it is easy to connect hoods, cabinets, umbrellas and other ventilation equipment to them. Installing air ducts is no more difficult than a children's construction set.

Flat air ducts are appropriate in small rooms - unlike round ones, they use the ceiling space more efficiently. However, due to their geometry, flat air channels have less tightness: round pipes are connected by one fitting, and flat ones - by connectors in the form of sealing flanges.

Round channels are ideal for air movement, but flat ones create dead zones in which turbulent phenomena occur. The latter cause clogging of channels and noise. Cleaning flat ventilation pipe will cost more. Round air ducts are produced in standard sizes, but flat ones are made mainly to the dimensions of a specific customer.

Choosing a plastic hood

Plastic ventilation and exhaust hood are two different things. If the first provides ventilation of the entire room, then the hood acts locally. It is impossible to ventilate the kitchen using such equipment. Before designing an exhaust system, pay attention to its power. High-performance systems are needed for dining rooms and kitchens with large work area, low-performance - for small premises. The diameter of the selected air ducts will directly depend on the exhaust power.

The price of air ducts also depends on the diameter. The ventilation system must be designed in such a way that the ducts have as few turns and bends as possible - they will reduce the performance of the system. For kitchens, choose one of two types of systems - classic or recirculating. The latter is that the air from the kitchen is taken by the equipment and filtered, and then returned to the kitchen.

Many manufacturers promote such hood systems, but they have disadvantages. Filters must be changed regularly - if this is not done, the effect will be the opposite. In addition, a recirculating hood does not provide an influx of fresh air, but only circulates what is in the room. No matter how high-quality filters are, they will not be able to provide adequate physical and chemical composition kitchen air.

Recirculation models are compact and do not require the construction of air ducts. This is very important for small rooms. Such equipment can be classic, built-in, suspended, telescopic. In addition, among them there are combined models: when turned on, they filter the air, and when turned off, they provide a supply of fresh air from the street or work on the principle of a classic hood.

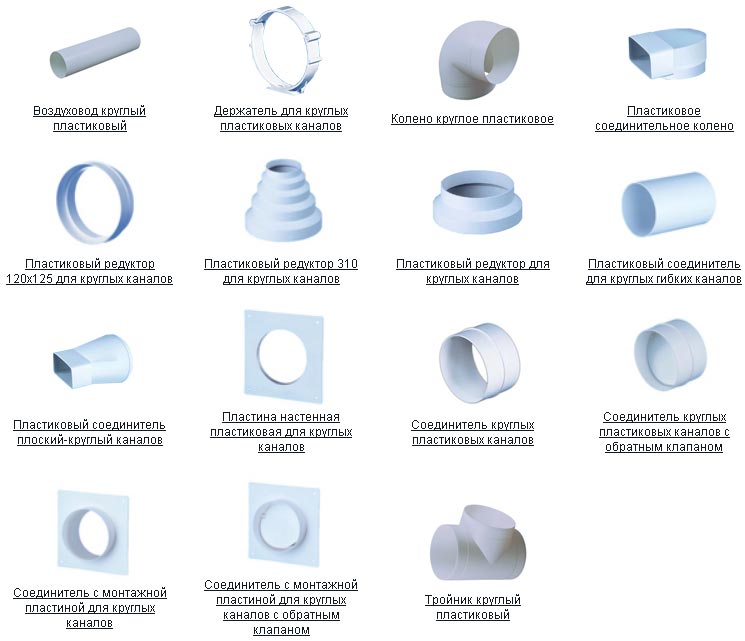

Air duct connectors

Plastic elbows are provided to rotate the air ducts. The pipe and elbow are connected to each other with plastic connectors. The ventilation channel can be rotated by 45 or 90°. A reducer is provided to connect round air ducts with a diameter of 100, 150 and 200 mm. The latter can be both universal and standard sizes. The reducer is fixed to the pipe using clamps.

Air duct fittings

- Grilles - for air distribution in supply and exhaust systems air ducts

- Transitions for flat (round) ducts - for connecting air ducts with different cross-sectional areas.

- Valve connectors - have a valve that prevents the formation of reverse thrust with the fan turned off.

- Wall plates - for connecting ducts to ventilation shafts.

- Holders - for mounting air ducts to a wall, ceiling or other plane.

- Universal connectors - for connecting air ducts at any angle.

- Transitions for flat and round channels.

- Tee for round and flat channels.

- Knees horizontal and vertical.

Why choose plastic air duct

When purchasing a plastic air duct for ventilation, it does not require additional decoration - it will fit perfectly into the interior of a kitchen, office, cafe or other room. Installation of plastic air ducts is extremely simple - it does not require special knowledge, skills or equipment. All you need for installation is to buy a plastic air duct, a stepladder, a hammer drill and a screwdriver.

The plastic air duct for ventilation is very light, so it is easy to transport. It is not subject to corrosion and is easy to clean if clogged. The noise level from plastic air ducts is much lower than from galvanized metal ones. Modern models made of plastic do not burn, do not emit flammable substances and are not exposed to aggressive chemicals.

A plastic air duct can also be used in small industries where it is inappropriate to install an industrial-type system. High-performance systems are very relevant for office centers where there are a large number of computers. Air duct fails Fresh air directly to the workplace and creates an optimal microclimate. In addition, systems supply and exhaust ventilation have proven themselves for catering establishments - they create a favorable atmosphere, remove odors and excess moisture.

Buying round and flat ventilation ducts made of plastic is the optimal solution for organizing ventilation in domestic conditions. A plastic air duct, unlike a metal one, is easy to install, provides optimal air flow quality and is inexpensive. The range includes options with different shapes section and diameter. This allows you to select a model for a specific exhaust system project.

Buy a plastic air duct at the most best prices from the manufacturer, just leave a return request and our specialists will contact you and advise on all issues.