Sandwich panels are a modern version of roofing material. Installation of roofing in the form of multilayer panels is not difficult, as the material weighs a little. Light weight is both an advantage and a disadvantage, as strong gusts of wind can tear off the coating.

In three-layer roofing panels, the outer layers are profiled metal (thickness 0.5-0.7 mm), inside there is a heat insulator (fiberglass, mineral wool, polystyrene foam or polyurethane foam). All layers of a sandwich panel are a single product, the layers are connected using glue or by pressing.

Advantages of roofing sandwich panels:

- Good noise and heat insulation;

- original appearance;

- fire resistance;

- Service life of more than twenty-five years;

- Versatility - there are elements of different sizes.

Mounting Features

The roof, which is planned to be covered with sandwich panels, must have the correct slope. The slope of the roof is prescribed in SNiPs, the wrong design of the roof almost halves the life of this roofing.

- If there are windows or skylights on the roof, then the slope should be greater. In this case, the calculations are carried out on an individual basis.

Problems when choosing the wrong slope of roof slopes:

- Rapid wear of the material, deterioration of operational parameters;

- The occurrence of stagnant water;

- Poor waterproofing, roof leaks;

- Loss of aesthetic appeal.

Today, many traditional roof coverings are being replaced by new technologies, which are significantly different in essence from the old ones. For example, quite reliable insulated roofs are obtained from elements such as roofing sandwich panels. Their capabilities are very wide, and therefore in Russia warehouse and retail buildings, residential complexes and special facilities are being actively built from them.

At the same time, modern roofs made of sandwich panels look quite stylish and from afar resemble classic roofing materials. But at the same time, they are much more functional, because they combine three components at once: the roof, the insulation, and even the finishing coating from below. In general, and in economic terms, such sandwich panels are more profitable.

If you are interested in this technology, let's take a closer look at it and draw some interesting ideas for ourselves.

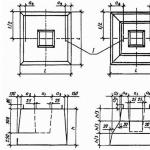

A modern sandwich panel is a three-layer construction, where the insulation is located between two profiled metal sheets:

Let's take a closer look at the profile itself:

- on the one hand, the panel has stiffening ribs, presented in the form of special protrusions in the form of a trapezoid, usually 40 mm high.

- on the other hand, the panel has a microprofile 1.5 mm deep.

We turn to the technical characteristics of sandwich panels. So, today the dimensions of roofing sandwich panels vary from 1000 to 1120 mm, length - from 2 to 14 meters, much depends on the equipment.

The sandwich panels themselves differ as follows:

- at the place of installation: for roofing and wall, ceiling and universal;

- if possible load: on self-supporting or facing;

- at the assembly site: for those that can be assembled directly at the construction site, element-by-element assembly products and for those that are manufactured in the factory and brought to the construction site ready-made.

By the way, the very first designs of roofing panels had two types of connection along the edges of the sheets: a standing seam or a seam with internal elements. Of course, such systems had many disadvantages.

For example, the outer metal sheet was flat, with a slight profiling, and therefore, under the weight of the snow cap, it sagged, and deformed under the hot sunbeams. Because of this, microcracks appeared in the corners of the bends.

Officially, this is called "low-cycle fatigue" of the metal. It was impossible to move in such places, so as not to damage the outer sheet and the insulation itself. In addition, the very quality of the seam seam often left much to be desired, because such manipulations with metal require high professionalism.

Modern panels differ significantly from them:

- Firstly, the fastening of roofing sandwich panels is now different.

- Secondly, today the minimum slope of a roof made of sandwich panels is 5-7 degrees, while more than 12 is recommended.

- Thirdly, today all the same requirements are imposed on such roofing sandwich panels as on ordinary roofing.

Namely, to ensure the sealing of all joints, drainage and protection from the weather. For such panels, all this is realized with the help of a special lock.

By the way, the panels themselves are produced in a whole series, with a variety of properties:

Piece-by-piece assembly panels: simplicity and reliability

Roofing sandwich panels of element-by-element assembly are easily assembled multilayer structures that consist of a cassette, a metal base for insulation, special hydro-wind protection and external cladding. We can say that this is such a semi-finished product, because these panels are finally assembled directly at the construction site.

This design is based on cold-rolled or hot-rolled steel with a thickness of 0.71 millimeters. An additional polymer coating is often applied to it. In appearance, this again resembles a box, the bottom of which will serve as the ceiling of the roof space.

Inside such a box is mineral wool or basalt fiber, located with a slight tension. On top of the insulation - hydro-wind protection in a special vapor-permeable membrane.

Monopanels: thoughtful design

You will be interested to know what is already producing sandwich panels today, which form a soft roof, and only their inner side is metal. This design is called "monopanel".

It is from such panels that the roofs of commercial buildings, sports facilities and industrial buildings are often built. In such a panel, the inner side is the carrier, and at the same time it also serves as a ceiling lining.

It is made on the basis of a steel profiled sheet coated with zinc (if possible, with a polymer too). As a heater, penoizol is used here - a special filling foam with a flammability group G1. Such a group speaks of low flammability, when the panel does not burn, but only chars.

Let's list the main advantages of monopanels. So, they can be:

- install on roofs with absolutely any slope, and quickly enough;

- transport by any means of transport;

- apply in buildings of the second degree of fire resistance;

- carry out all installation work in a fairly wide range of humidity and temperature.

At the same time, panels can be cheaper than other types of sandwich panels.

Today, two main types of monopanels are produced - with a soft coating and metal. So, with polymeric rolled material, sandwich panels have a perfectly smooth surface, on which snow does not accumulate on the roof at all. It is reliable and durable, and all external joints and junctions are sealed with modern compounds.

The metal coating for monopanels is made on a machine with special longitudinal flanging, in order to then bring them into a double standing seam using a seaming machine.

Sip panels: proven material

In Russia, until recently, there was experience in using only roofing sip panels, which are also classified as sandwich panels, although sometimes experts call them different materials. But here, just like in a classic sandwich panel, there is a heater between two rigid sheets.

It is a structural thermal insulation panel that is used for the construction of prefabricated housing. It is a monolithic structure in which two OSB-3 oriented strand boards and expanded polystyrene are glued together under pressure.

At the same time, such panels are very durable and light at the same time. So, the mass of one square meter is not more than 15 kg, but this square meter is able to withstand a vertical longitudinal pressure of more than 11 tons!

In Russia, such construction is also still a little new, although it is gaining popularity day by day. But there is one more difference from the usual sandwich panel - the sip-panel does not use a vapor barrier or windproof membrane. Here, the OSB-3 board is glued to the insulation itself, and does not warp over time.

Interestingly, abroad quite often there are options for sip panels with OSB sheathing on only one side, and on the other side there is a metal sheet.

Moreover, in Russia they are still trying to find an analogue to such panels, replacing OSB with cement-bonded particle boards, fiberboard or glass-magnesium sheets. But there are some moments here: self-tapping screws in panels based on a mineral binder do not hold well and are often subject to corrosion, which does not happen with OSB-3.

Internal content and characteristics

So, what are these panels made of? Let's take a look at their structure!

Outer Coating: Weatherproof

Quite often, metal sheets formed by repeated bending are used for internal and external cladding of such roofing sandwich panels. Much less often, such a lining is made of sheets of corrugated board.

The profile of the top sheet itself is usually flat, almost flat, and with rather high trapezoidal projections to ensure proper drainage. The higher the protrusions, the more they reduce the thermal deformation of the panels, but they also cost more:

Here are the main types of profiling of such panels:

Roofing sandwich panels differ more significantly from each other in terms of coating. Moreover, high requirements are imposed on the facing of sandwich panels, because the finishing coating takes on all the operational loads. This is both climatic and dynamic, when workers go to the roof to repair it or clean it from snow.

In the Russian market, almost all three-layer sandwich panels have a steel outer cladding, made of cold-rolled steel sheet from 0.4 to 0.7 mm. Here, the zinc coating is hot-applied and has a thickness of 25 to 50 microns. Further, several layers of polymer coatings are applied to the zinc surface at once, with a total thickness of 25 to 200 microns. There can be up to eight such layers in total.

So, when high color retention and resistance to pollution are needed, a polymer coating is used. For example, the popular cover Hiarc. Its subspecies Hiarc Matt pleases the eye with a beautiful color with a matte surface, which gives the roof a special expressiveness. They also produce sandwich panels in metallic colors.

The next type of coverage is high build- This is a thicker primer layer with a special pigment that is resistant to mechanical damage.

Another coating is polyester enamel, or polyester. It is suitable for almost all climatic zones, resistant to atmospheric mechanical influences. But it cannot be called too reliably.

Such a coating is used in cases where there are no increased requirements for corrosion resistance to sandwich panels. But, if we talk about the roof, this option is not acceptable, this material is more for interior than for exterior.

Pural - This coating is based on polyurethane resin. It looks like a fairly thick layer with high wear resistance.

Polyvinyl– polymer coating with particularly high corrosion and UV resistance. It retains its color and luster longer than all types of coating, remarkably withstands molding.

The choice of insulation: bubbles or cotton wool?

As a heater for sandwich panels, basalt mineral wool, glass wool, expanded polystyrene, polyurethane foam and their varieties are used:

Also, for monopanels, it still uses such a type of insulation as penorezol. In this case, the insulation can be of various densities, depending on what heat-insulating properties it should have. The thickness of such products is selected according to the exact heat engineering calculation, usually from 40 to 300 mm.

In the context of all these panels look like this:

If you want to delve deeper into this subject, check out this video review:

Let's note the advantage of basal mineral wool. And stack the sandwich panels so that the fibers are oriented vertically. This design is the most stable and does not threaten shrinkage of the insulation.

Due to this, the density of sandwich panels is in the range of 90-140 kg per square meter, and the thermal conductivity coefficient is 0.043 W/m2. But at the same time, which mineral water is still the heaviest of all types of heaters used.

Another option is glass wool. Such panels are slightly lighter than those with mineral wool, and their thermal conductivity is 10% lower. They are allowed to be used in operation at temperatures over 400 degrees Celsius.

But the lightest sandwich is polystyrene foam panels. Its thermal conductivity coefficient is only 0.0022 W / m2, which is very small.

But no less qualitative is its analogue - polyisocyanurate foam. Polyisocyanurate foam differs from ordinary polyurethane foam in its higher fire resistance. In fact, this is its modified analogue:

If we talk about the main difference between the types of insulation, then the main one here is fire safety. Since mineral wool sandwich panels are more heat resistant, they are assigned the EI240 class. But polyisocyanurate foam panels have a fire resistance rating of EI60.

Also an important point: piece-by-piece assembly roof panels come with additional insulation or without it at all. So, if the thickness of the standard insulation is considered insufficient, then it changes with the help of another heat insulator.

Here, on top of the main insulation inside the base, Z-shaped runs from 50 to 200 mm high are installed and UPTP strips are glued to avoid cold bridges.

In this case, the runs are mounted across the rafters. Inside such runs, the required number of layers of thermal insulation is put in, then a hydro-wind protection and shelves of Z-shaped runs are mounted on top of the additional insulation. And already sheets of the selected roofing are attached to the shelves themselves.

The internal filling of the panels affects their fragility:

Reliability of adhesive connection

All three main elements of the sandwich panels are interconnected with a special elastic adhesive. Moreover, the choice of glue is approached with all responsibility, because, for example, the same basalt-based insulation is a rather porous material with a fragile surface. Therefore, it is important that the adhesive can penetrate deep into the roughness of the insulation and fill the voids between the fibers and the metal.

As you understand, the glue itself is used quite a lot here, and in a foamed form, after which it hardens. At the same time, it is important that the glue is moisture resistant, not afraid of weathering and tolerates temperature changes well.

All these requirements are met by modern adhesives based on polyurethane, which usually connects metal with other materials. At the same time, one-component and two-component compositions are used specifically for roofing sandwich panels.

Just the service life of sandwich panels is limited by the service life of the adhesive layer itself, namely its destruction. By the way, sandwich panels with polyurethane insulation are sometimes made without glue at all, connecting the components to each other using a special molding. It is impossible to say whether it is better or worse - time will tell.

See what the finished sandwich panels look like when produced in production:

Important subtleties of fastening

The next moment: fasteners on roofing sandwich panels are made visible or hidden, and the lock is ordinary or with increased energy efficiency, which is provided by a special seal.

Roofing sandwich panels are connected to each other in such basic ways: a single fold with additional insulation, a double fold, a lock (for example, Roof-lock), and with the help of a special head of trapezoidal shape made of galvanized steel. The installation technology itself is dictated, of course, by the manufacturer.

To close a single and double fold, you need a special tool called a "frame". For modern panel locks, tools are not needed at all.

The most convenient, of course, is the castle. But there is a minus here: the sandwich panels, which were originally designed for such locks, have an easily deformed element along the entire length, which is not difficult to touch during installation or storage. So to speak, his weak point.

Here is what the fastening looks like for panels made of polyisocyanurate foam:

This is how mineral wool panels are attached:

What is good about the "roof of the future", or pleasant virtues

First of all, for the construction of the roof, it is of great value that, roof sandwich panels allow laying at large steps between runs. This in total greatly reduces the overall cost of building the roof itself.

That is why the use of sandwich panels is primarily based on economic feasibility, which today makes it possible to erect such roofs on almost all types of buildings. So far, at the moment, only apartment buildings are the exception, but this, according to experts, will not last long.

You will also be surprised that despite the seeming fragility of roofing sandwich panels, they are a fairly durable material that perfectly withstands wind and snow loads. At the same time, roofing sandwich panels do not create any special additional load on the foundation:

We also note that such panels are quickly and easily mounted, and just as easily dismantled. They do not need any finishing and special fasteners.

Disadvantages, shortcomings and other annoying facts

With all the advantages, the sandwich panel has a number of disadvantages. For example, their use of three-layer panels is predicted to decline over time, giving way to other types of sandwich panels.

Here is an entertaining video tutorial on the advantages and disadvantages of sandwich roof panels:

Features of the northern climate

The Russian climate is quite aggressive, especially in the north. And therefore, while many roofers are afraid to use roofing sandwich panels due to seasonal temperature fluctuations, which cause significant stress during operation.

The second moment, being on the roof under direct sunlight, sandwiches change their size. This is a natural process for metal surfaces, but it is extremely necessary to take into account when adjusting the angles of joints and seams so that the whole system does not eventually lead. That's just the element-by-element assembly sandwich panels are devoid of these disadvantages.

After all, it is not mineral wool that takes the load on them, but the box-shaped frame itself, thanks to which thermal insulation can be used lighter and cheaper. Yes, such elements provide more reliable sealing of the roof and the ability to remove condensate through an organized ventilation gap.

In addition, in the process of cyclic temperature transitions through the so-called “freezing point of water”, the block of mineral wool insulation is gradually destroyed, and the fibers are blown out. As a result, there is a loss of the bearing capacity of the structure itself.

Also, mineral wool itself is subject to physical aging, and in fact it accounts for the entire operational load. At the same time, there is a small actual fire resistance of such a roof, unfortunately.

Firstly, the maintainability of such panels still raises questions. If there is a problem, you will have to disassemble the entire roof, so repair costs will be significant.

Installation errors and their consequences

Further, while the locks of such panels leave much to be desired, and with not very accurate operation it can be unreliable. As we have already said, the accuracy of fastening and the tightness of the future roof are provided by special grooves in the folds. And the main problem with the installation of sandwich panels is that it turned out to be a successful or unsuccessful joint.

That is why manufacturers are constantly working on improving such locks. After all, the strength of the connection of such panels on the roof, and the absence of gaps, and tightness depend on this.

For a roof, these are critical indicators. And any unsuccessful joint can become a conductor for rain moisture and a bridge of cold, while for the same walls all this is not so important:

In bad weather conditions and often changing humidity and air temperature, cold bridges and leaks appear at a poorly laid roof made of sandwich panels. The lining from the insulation also peels off if a foam sandwich is used and the flammability of the middle layer increases, and if the insulation is made of mineral wool, the destruction of the bond between vertically oriented fibers due to moisture is noted.

They can lead to sealing of the longitudinal joint and further damage to the entire coating. Moreover, such damage is not so easy to detect by eye, and even more difficult to fix.

Although in fact, when working with sandwich panels, it is quite possible to avoid all the listed points and disadvantages if you strictly follow all the installation rules.

Difficulties of transportation and storage

And, finally, roofing sandwich panels have such a serious disadvantage as easy damage during transportation and installation, so they must be handled carefully, especially carefully. That is why manufacturing companies often provide services for a complete set of roofing, from its design to installation.

And we advise you to resort to such services, since the professional team already knows all the intricacies of working with this new roofing material, there is even a whole lot of recommendations even regarding the storage of the panels themselves.

By the way, most manufacturers worry about the fact that in our country installation rules are often neglected and roof panels sometimes get wet even before they are on the roof. In this case, the fibrous insulation quickly loses its properties and is destroyed during subsequent seasonal freezing and thawing processes.

Thanks to such doubts, the owners of their houses still everywhere prefer the more classic and proven “correct” pie, where the heater has its own specific place and always has access to it. At least, if cotton wool gets wet here, the bearing capacity of the roof will not decrease from this - just the problems will be different.

Installation steps: unusual technology

Let's look at the principles of installing roofing sandwich panels on the roof. So, three-layer roofing sandwich panels are used for buildings with a roof slope of no more than 12 meters, and a slope of at least 12%. They are laid on runs with a step of one and a half meters.

Compared to classic sandwich panels, monopanels are suitable for creating any area and any angle of inclination, and a step of 3-4 meters is allowed.

Here is how the installation of such a roof looks like in practice:

It is most convenient, of course, to use one panel per roof slope so that it does not have any transverse joints. Although today it is not uncommon for such sandwich panels to be assembled on the roof as a designer, with an overlap. In this case, the laying of the panel is led up, as it were, along the pillars.

This roofing is fixed with hat profiles across the rafters. The panels are laid along the rafters along the runs. And so that cold bridges do not form at the junction, here a thermal separation strip of isolon is fixed over the membrane along the shelves themselves.

Between themselves, the roofing sheets of monopanels are fastened with clamps, and the clamps themselves are connected with self-tapping screws. Install such a panel along runs up to 4 mm and fasten it with self-tapping screws:

Further, on top of it it is allowed to make a soft roof from ordinary traditional materials, for example, from piece shingles. By themselves, monopanels are convenient in that their installation can be performed by any builder without special qualifications, and almost at any time of the year.

The roof panels themselves are installed along the runs or fixed with bolts, as an option - with self-tapping screws with a special washer. The most practical is considered to be a spike type connection, a heat-insulating bundle and special ties.

The hat profile itself is determined by the very design of the roofing, and for a metal tile it is equal to its pitch.

Sandwich panels are fixed to the walls of the house using the same additional elements as in the case of a conventional roof:

But the main nodes of such a roof:

This is how the roof overhang is made of sandwich panels:

Here are the main options for organizing the drainage of such a roof:

The highest quality sandwich panels, according to manufacturers, last 25-30 years. At the same time, it is extremely important that during the installation and transportation of the panels they are not damaged, and the joint is sufficiently tight.

It is on the domestic market that so far the options with trapezoidal ledges on sandwich panels, which are also called roofing profiles, prevail.

Compared to the rest of the world, roofing sandwich panels are still produced in Russia in the following ratio of insulation: 85% mineral wool and 15% polyurethane foam. But in the world, everything is the other way around: 80% of such panels are made of polyurethane foam or polyisocyanate foam, and only a fifth of them are made of mineral wool. Although at the same time foam insulation is lighter.

Thus, the most high-quality products are supplied to the Russian market by companies such as Promkpanel, Petropanel, Kuznetsk Metal Structures, Techno-Izol and Azna-am. We will also consider products from such well-known manufacturers as Ruukki, Isobud and Kraft SPAN.

The well-known company Isobud has been manufacturing sandwich panels for prefabricated buildings since 1998 and today is included in the list of the most famous manufacturers of this roofing material in the Russian Federation.

And she produces sandwich panels from mineral wool and polyisocyanurate foam:

Here are the panels from Isobud made of mineral wool:

Kraft SPAN: new equipment

Kraft SPAN is a company from St. Petersburg that produces wall and roof sandwich panels made of mineral wool. They have high bearing properties, which are especially appreciated by designers.

It uses profiled steel sheets, mineral basalt wool and fire-resistant adhesive with a safety class Co. It is the production of Kraft SPAN that produces a single series of such panels - FF.

This construction technology has more and more supporters every day. Which is not surprising, because they are attracted by the beautiful appearance of the roof made of sandwich panels and the relatively low load on the supporting structures and the foundation of the building.

In addition, the modern market today is oversaturated with such panels, thanks to which there is high competition in this area, and manufacturers pay more attention to the quality of products. As well as additional related services, such as roof design and repair.

Would you like to have such an unusual roof?

The presence of stiffening ribs located in the protective metal layer makes the roofing sandwich panels a sufficiently durable material, which allows it to withstand a snow load of up to 150 kg per m 2 and ensure effective water runoff from the roof of the house. Due to reliable thermal insulation, such material can be used in any climatic zone of Russia. It is for these reasons that roofing made of sandwich panels is in high demand among developers. In order for the coating to serve for a long time and reliably, it is necessary to strictly follow the installation technology and the norms of SNiP.

roof pitch

According to the SNiP standards, the minimum slope of roofing sandwich panels is 5°, but on condition that the coating is made of continuous panels without joints along the length and that windows or other structures that violate the integrity of the finish layer are not provided in the roof. Otherwise, the minimum slope angle must be at least 7°.

When choosing the type of roof construction and the angle of its slope, you should pay attention to the climate in the construction area. If precipitation is frequent, it is recommended to make a roof slope under a sandwich panel with a slope of at least 40 ° - in this case, rainwater will not linger at the joints. In regions with a dry hot climate, the best option is a roof with a slope of 7-25 °.

It must be immediately taken into account that a steeper roof requires more roofing material.

If the slope is insufficient, moisture will stagnate on the roof, which negatively affects the waterproofing of the panel joints. During thaws and frosts, the accumulated water, turning into ice, can damage the outer protective layer of the panel and begin to destroy the metal of the shell.

The minimum roof slope of sandwich panels does not require the use of additional fasteners when installing the material on load-bearing structures made of wood, reinforced concrete or metal. If sandwich panels are laid on a structure with an inclination of more than 7°, it is required to install additional connecting fasteners.

Tools and materials for installation

Installation of a roof made of sandwich panels requires trimming the material, fixing it, and sealing the joints. Material cutting can be done:

- electric scissors;

- fine-toothed saw for cold cutting;

- stationary machine with a circular saw.

A grinder with an abrasive wheel or hot cutting tools should absolutely not be used.. Heating the cut will cause deformation of the panel, damage to its decorative and protective layer, which will eventually lead to corrosion of the material.

To move the sandwich panels from place to place without the risk of damaging their surface, it is recommended to use a mechanical or vacuum gripper. In places where the gripper is installed on the panel, the protective film should be removed from it.

Fastening of roofing sandwich panels is carried out using long self-tapping screws made of stainless or carbon steel, equipped with washers and sealing elements. Synthetic rubber seals (ethylene propylene diene monomer, EPDM) are required to seal the attachment point. The length of the screws depends on the thickness of the panel and the material of the structure to which it is attached. To tighten the screws, an electric drill with speed control or a screwdriver is used.

Do not over-tighten the fasteners - this will reduce their service life. In addition, a “tightened” self-tapping screw can damage the panel.

It is important to correctly determine the required number of fasteners, taking into account:

- wind load on the object (depending on the height and location of its location);

- object type (closed/open);

- in which area of the roof the attached panel is located (the outermost panels are most exposed to wind load);

- bearing capacity of one fastener.

For accurate calculations, it is advisable to contact a specialist.

Joints between panels must be properly sealed. Gaps must not be allowed in the longitudinal joints.

How to do the work correctly, you can learn from the video instructions:

Regardless of the angle of the roof, the longitudinal joints are sealed with a special tape (for example, Abris Lb 10x2) or silicone sealant. Sealing tape is also necessary when arranging junctions to vertical structures.

Features of roofing material

Sandwich panels are an easy-to-install material suitable for roofing. Manufacturers offer a wide range of plates that differ in purpose, size, strength, filler. Can be used as a heat insulator:

- polyurethane foam;

- expanded polystyrene;

- polyisocyanurate;

- mineral wool.

The panels have a relatively small weight and at the same time perform the function of a finishing coating and insulation. The highest thermal insulation performance of sandwich panels with basalt wool.

A decorative and protective polymer coating is applied to the thin sheet metal from which the panel body is made. This allows you to paint the panels in different colors and protect the metal from corrosion.

In order not to damage the protective layer, the installation instructions for roofing sandwich panels require certain rules to be followed:

- do not use hot and abrasive cutting;

- the protective film from the bottom of the plate should be removed immediately before the installation of the element, and from the top - after the installation of the entire coating;

- carefully remove the metal chips formed during the cutting of the material and make sure that it does not scratch the polymer layer;

- in the process of roofing work on the roof, walk only in shoes with soft soles.

Sandwich panels when stored outdoors should be protected from precipitation, dirt and wind. The material is laid on a flat, solid base to avoid its deformation.

Conditions for installation work

Installation of roofing sandwich panels is carried out under certain conditions:

- wind speed should not exceed 9 m / s, since the panels have a relatively low weight with a large surface area;

- work is not carried out during rain, snow or thick fog;

- if artificial lighting is not provided, installation stops at dusk;

- sealing of longitudinal joints between sandwich panels is carried out at an air temperature above +4 °C.

Before starting roofing work,:

- verify the design, its compliance with the project and the quality of installation, eliminate the identified differences and shortcomings;

- check the compliance of girders, crossbars and other structural elements with the project;

- check for flatness the runs on which the panels will be attached;

- prepare tools.

Mounting technology

Sandwich panels are laid across the girders parallel to the eaves. The smaller the installation step of the purlins, the higher the bearing capacity of the mounted roofing will be. This is especially true for roofs with a slight slope in regions with high snow loads. But in any case, the distance between the runs should not exceed 2 meters.

If the slope of the roof from sandwich panels exceeds 15°, additional stops are installed on the overhangs so that the panels do not slide down.

It is most convenient to mount the roofing from slabs, the length of which does not exceed 10 meters. Firstly, it is easier to lift them onto the roof, and secondly, in this case, the likelihood of thermal deformations during the operation of the roof is lower.

Sandwich panels are mounted on top of the heat-insulating and waterproofing layer. As a heat insulator, it is easiest to use mineral wool. Before installing the panels, the horizontal installation of the girders and the condition of the supports made of wood, metal or reinforced concrete are checked. It is necessary to remove rust, mold, and other layers. Cracks are sealed in the tree, cavities are leveled in concrete with mortar. The joints of the elements from which the frame is made must be airtight. Wooden structures are treated with a fire-retardant composition, and metal structures with an anti-corrosion one.

The step of the arrangement of the supporting elements of the frame must correspond to the dimensions of the panels.

The width of the frame span should be selected so that the panels can be fastened five centimeters from the edge, and there is also a support for fastening the joined panels.

It is required to work in a respirator if the insulation in the panel is mineral wool. When lifting the slabs onto the roof, you can not put them on the lock so as not to deform it.

The installation technology of roofing sandwich panels prescribes to start laying the material from the lower corner of the roof (any). Next, the plates are mounted in a vertical direction. It should be taken into account in which case it is easier to perform work and more economically consumed material.

2

Last revision: 26.10.2016

A modern roof structure cannot be perfectly flat, since precipitation in the form of snow or rain must be removed from its surface in any case. That is why, when installing flat roofs, it is imperative to follow the rule of the so-called ramping, which provides for a slight slope of the flooring to one side. The presence of such a slope allows you to drain rainwater from the surface of the coating and collect it at the roof fence, where special drain holes are prepared in advance for these purposes. The minimum slope of the roof, as a rule, is selected taking into account the following parameters of the roofing to be installed (at the same time, its performance is also taken into account):

- used roofing material;

- type of roof (classical or inversion);

- number of waterproofing layers;

- average annual precipitation (snow load);

- wind loads on the structure.

SNiP requirements

The dependence of the angle of inclination on various factors is regulated by special building codes and regulations (SNiP). Among the requirements for the slope of a flat roof SNiP II-26-2010 “Roofs”, the following provisions regarding its dependence on the coating material are especially important:

- depending on the type of waterproofing used, the angle of inclination of the roof can vary from 1.5 to 10º;

- angles of inclination of a larger value (up to 2º) are chosen very rarely, which is explained by the difficulty of selecting a soft coating that would not slip to the base of the roof at high air temperatures;

- the minimum slope of the so-called flat roof should be at least 1–1.5º.

Note! There is a certain relationship between the slope of the roof structure and the number of layers of waterproofing coating laid on it. The more significant this value, the faster precipitation will be removed from it, and, therefore, the number of waterproofing layers may be less.

The roofing materials used for covering the roof differ in their structure, according to which they have a more or less smooth surface. With an insufficiently smooth (rough) structure of the coating, the probability of retaining both water and snow on it increases markedly.

This is what determines the dependence of the minimum slope angle on the roofing material used. Next, we will consider the specific values of this indicator for various types of coatings.

The smallest angle of inclination of the slope when arranging a tile roof is usually chosen at least 15º (for some material models, this value may be 14º). If it is necessary to reduce this figure, some manufacturers advise treating the joints of metal tile sheets with a special waterproof sealant that retains its properties at low temperatures.

Note! If the slope is too gentle, precipitation will linger in certain places on the roof and seep into the joints during heavy rains. And this will lead to an additional load on the roof in those areas where they are delayed.

It is possible to partially get rid of this disadvantage by using tile samples with a higher wave height.

When using this type of roofing, the indicator we are considering should have a slightly lower value (as a rule, it is 12º).

In the case of making roofs from profiled sheets with a smaller slope, when laying them, it is necessary to observe the so-called two-wave overlap, and at angles of the order of 15º and above, an overlap of 20 cm will be sufficient.

At the minimum angle of the roof (i.e. when it is almost flat), a continuous batten should be used to increase the load capacity of the supporting structure.

There are several types of soft roofs, differing in the material from which they are made:

- Flexible tiles. In the case of using the so-called soft roof as a coating (flexible tiles - in particular), the crate under it should be made in the form of a solid base made of plywood sheets (OSB). The minimum slope slope for this type of roofing is at least 11º.

- bituminous coatings. For soft coatings of this category, the minimum roof slope has the lowest value (its value, as a rule, does not exceed 2º). But at the same time, as noted earlier, you will need to increase the number of layers to be laid. In the event that for technical reasons it is not possible to lay more than 1-2 layers of bituminous material, you will have to increase this figure to 15º. The minimum angle of inclination of a coating made on the basis of ondulin, as a rule, does not exceed 6º. This roofing material is the most preferred for low pitched roofs, but you will need a continuous batten to install it.

- Clay tile (slate). When laying hard clay tiles or classic slate sheets, which have an uneven surface that holds snow well, the slope of the slopes must be at least 22º. At the same time, it is necessary to pay very close attention to the calculation of the rafter system, which, due to the large weight of the material, will experience significant loads. In addition, one should not forget about the additional loads on the rafters, which are possible with the accumulation of large amounts of snow on the roof, as well as with powerful gusts of wind in bad weather.

Taking into account all these factors, the requirements for the load capacity of the roofing system increase significantly.

Note! When making a roof made of tile or slate with a slope of less than 22º, you will have to recalculate the entire rafter system, since the loads on it in this case increase many times over.

According to the requirements of SNiP, the minimum slope of sandwich panel decking should be approximately 5º (provided that the coating is made continuous and has no joints along the entire length). Let us make a reservation right away that this indicator is valid only for cases where the roof does not provide for built-in windows or other elements that violate the integrity of the continuous coating.

In the presence of all these violations of the integrity of the flooring, the minimum slope of such a roof must be at least 7º.

Even at the design stage of a future roofing system (and, in particular, when choosing a roof construction option with a certain angle of inclination), it is imperative to take into account the climatic features of your area. In the event that precipitation in your area falls quite often, the minimum slope of the slope for the sandwich panel should be at least 40º, since only with such a slope of the roof will rain moisture not linger in the joints. Well, in areas with a small indicator of average annual precipitation, a slope of about 7–22º is considered optimal.

Note! Before arranging roofs with large slopes, it is necessary to take into account the fact that in this case you need more building material.

On the other hand, with an underestimated value of this indicator, water will accumulate on the roof, which over time can destroy the waterproofing seals of the panel joints. And in the off-season (during the onset of thaws and frosts), ice growths form from the accumulated moisture, which can damage the protective layer of the sandwich panels, as well as their metal shell.

With a small roof slope (less than 7º), there is no need for additional fastening of panels on a frame base made of reinforced concrete, wood or metal. On roof structures with a large angle of inclination, additional fasteners are required.

You may also be interested in these materials of our site:

- What is an inverted operated roof

Video

From this video you will learn how to make a roof slope.

In the construction of residential and industrial buildings, sandwich panels are often used. It is an inexpensive and building material, from which walls and roofs are mainly erected.

Structure

The sandwich panel is a sheet consisting of the following layers:

- external coating on both sides (galvanized steel, polyester, oriented strand board or drywall);

- insulation (mineral wool, polyurethane foam, fiberglass or expanded polystyrene).

Advantages of sandwich panels

The widespread use of this building material for roofing is due to the following advantages:

- thermal insulation at a high level;

- low flammability;

- low cost;

- high level of sound insulation;

- no need for complex construction equipment for laying;

- reduced load on load-bearing structures due to low weight;

- a wide range of shades, so there is no need for additional finishing;

- high resistance to negative environmental influences (humidity, microorganisms, chemicals, temperature extremes).

Roofing

In order for a roof made of sandwich panels to be reliable and of high quality, the following rules must be taken into account:

- The minimum possible roof slope angle is 50. This is the lowest mark, an excess is permissible here.

- Only solid panels without joints, windows and other elements that violate their integrity are suitable for laying.

Since 50 is the minimum mark, other criteria are needed to determine the size of the angle suitable for this particular roof. An important one is the climate of the region in which the building is being built. If the region is characterized by frequent and heavy rainfall, then it is necessary to provide such a slope that would maximize the removal of moisture from the roof. The optimal indicator here is 400. So the water will not stagnate at the joints, and in winter this is especially true, since snowdrifts and ice destroy the roof, expand the cracks and lead to the risk of collapse if snow masses have accumulated in large quantities.

If the climate is dry enough, then the slope is allowed from 70 to 250.

The following ratio should be remembered: the steeper the roof is built, the greater the consumption of building materials will be needed. If the roof is quite flat (5-7 degrees) there is no need for additional fasteners to fix the sandwich panels to the supporting structure made of metal, reinforced concrete or wood. However, if this low mark is exceeded, additional connecting fasteners are indispensable.

Formulas for calculation

Slope is the angle of inclination of the roof surface relative to the horizon. The larger the angle, the steeper the roof. The slope is expressed either as a percentage or in degrees. For example, 40 is equivalent to 7%.

Required equipment

When constructing a roof from sandwich panels, it is necessary to constantly cut them with electric shears, a stationary machine or a fine-toothed saw. A grinder or hot cutting devices are not recommended here, because when heated, the cut lines deform and bend, the protective coating is broken and corrosion appears.

To transport the panels to the roof, vacuum or mechanical grippers are used, which do not damage the surface and do not violate the integrity of the panels. Before installing the grips, a protective film is glued in the right places. Secure the panels with long stainless steel self-tapping screws for sandwich panels, supplemented with sealing gaskets and washers. The length of the fasteners must correspond to the thickness of the plates and the frame.

To prepare for work, you need to first calculate how many fasteners you will need. Their number is influenced by the following factors:

- wind load. This factor depends on the height of the building, its location and the angle of the roof.

- Type of building (closed or open).

- Attachment area. The outer panels experience more wind load than the panels located in the center.

- Characteristics of fasteners (load-bearing capacity).

Based on all these factors, the required number of hardware is calculated, and it is important that the resulting figure corresponds to the proper SNiP.

Secrets of proper styling

When building a roof from sandwich panels, it is important to maintain their integrity, otherwise the result of the work will be unsatisfactory. The following guidelines will help you complete the entire process correctly:

- When cutting boards, abrasive or hot cutting is not allowed, as it damages the integrity of the protective layer.

- Both sides of the sandwich panels are covered with protective films. From the bottom, it must be removed immediately before the moment when the laying is carried out, not earlier. The top film must be removed at the end of all work, so as not to stain or deform the surface.

- If chips appear during the cutting of metal, they must be removed immediately so that they do not linger on the surface of the plate.

- When performing installation work, workers who are on the roof must wear shoes with soft soles only.

- If the slabs are stored outdoors while awaiting erection, care must be taken to protect them from aggressive weather conditions. It is recommended to stack the material on a level and dry area.

- The weather for installation must be dry, without precipitation and strong winds. The maximum allowable wind speed is 9 m/s. The minimum ambient temperature is +40C.

- Good lighting is essential for the installation process.

Preview

Before laying the sandwich panel on the roof, you need to carefully examine the roof structure so that it fully complies with the project, the correct laying of the plates depends on this. If defects and errors are found, they must be eliminated before the installation of sandwich panels.

Laying process

Sandwich panels are mounted in the transverse direction to the girders, located parallel to the cornices. To improve the bearing capacity of the roof, you can reduce the installation step of the runs. This is true when building a roof with a slight slope, if the region is characterized by heavy snowfalls.

Before the erection of the plates, a layer of waterproofing and insulation is laid (often mineral wool is used in this capacity). Runs and supports are checked. All deposits, including mold and rust, must be removed. Preliminary preparation of supports depends on what material they are made of.

- Wooden structures are cleaned of mold and fungus, and cracks on their surface are sealed. A protective layer is applied that prevents ignition and mold.

- Metal elements are coated with an anti-corrosion agent.

First, slabs are laid, the length of which does not reach 10 meters. Due to their low weight, they easily climb onto the roof. It is forbidden to put the panels on the lock, as this can lead to the distortion of the panels. Laying starts from the bottom corner of the roof and is carried out vertically: from the bottom up.

Conclusion

The slope of the roof is one of the factors that determines the laying process and further operation. To avoid corrosion, leaks and other troubles, it is important to correctly calculate what slope the roof should have.

This parameter is influenced by the climatic features of the region where the building is being built.