It is quite obvious that the main task of a heating radiator is to maximize efficient heating premises. And the main parameter that determines how well a heating device copes with this task is the heat transfer of the heating radiator.

This indicator is individual for each radiator model; in addition, the heat transfer is influenced by the type of device connection, features of its placement and other factors. How to choose the optimal radiator from the point of view of heat transfer, how to connect it as efficiently as possible, how to increase heat transfer? We will tell you about all this in this article!

Heat dissipation is a key performance indicator

Determination of heat transfer

Heat transfer is an indicator indicating the amount of heat transferred by a radiator to a room over a certain time. Synonyms for heat transfer are terms such as radiator power, thermal power, heat flow, etc. The heat output of heating devices is measured in Watts (W).

Note! In some sources, the thermal power of a radiator is given in calories per hour. This value can be converted to Watts (1 W=859.8 cal/h).

Heat transfer from the heating radiator occurs as a result of three processes:

- Heat transfer;

- Convection;

- Radiation (radiation).

Each heating radiator uses all three types of heat transfer, but their ratio differs for different types of heating devices. By by and large, radiators can only be called those devices in which at least 25% of the thermal energy is transferred as a result of direct radiation, but today the meaning of this term has expanded significantly. Therefore, very often under the name “radiator” you can find convector-type devices.

Calculation of the required heat transfer

The choice of heating radiators for installation in a house or apartment should be based on the most accurate calculations of the required power. On the one hand, everyone wants to save money, so they shouldn’t buy extra batteries, but on the other hand, if there aren’t enough radiators, then it won’t be possible to maintain a comfortable temperature in the apartment.

There are several ways to calculate the required thermal power of heating devices.

The simplest method is based on the number of external walls and windows in them. The calculation is made as follows:

- If the room has one external wall and one window, then for every 10 m 2 of room area, 1 kW of thermal power of the heating radiators is required.

- If the room has two external walls, then for every 10 m 2 of room area a minimum of 1.3 kW of thermal power of heating radiators is required.

The second method is more complicated, but it makes it possible to obtain the most accurate value of the required power. The calculation is made using the formula:

S x h x41, Where:

- S– area of the room for which the calculation is being made.

- h– height of the room.

- 41 – standard indicator of minimum power per 1 cubic meter room volume.

The resulting value will be the required power of the heating devices. Next, this power should be divided by the rated heat transfer of one section of the radiator (as a rule, this information is contained in the instructions for the heating device). As a result, we get what we need for efficient heating number of sections.

Advice! If as a result of division you get a fractional number– round it up, since a lack of heating power reduces the level of comfort in the room much more than its excess.

Heat transfer of radiators made of different materials

Heating devices from different materials differ in heat transfer. Therefore, when choosing radiators for an apartment or house, you need to carefully study the characteristics of each model - very often, even radiators that are similar in shape and dimensions have different power.

- Cast iron radiators– have a relatively small heat transfer surface and are characterized by low thermal conductivity of the material. Heat transfer occurs mainly due to radiation, only about 20% is due to convection.

Rated power of one section cast iron radiator MS-140 at a coolant temperature of 90 0 C is about 180 W, however, these figures are valid only for laboratory conditions.

In fact, in centralized heating systems, the coolant temperature rarely rises above 80 degrees, while some of the heat is lost along the way to the battery itself. As a result, the surface temperature of such a radiator is about 60 0 C, and the heat transfer of one section does not exceed 50-60 W.

- Steel radiators combine positive traits sectional and convection radiators. As a rule, a steel radiator includes one or more panels within which coolant circulates. To increase the thermal power of the radiator, steel fins are additionally welded to the panels, which act as a convector.

The heat transfer of steel radiators is not much greater than that of cast iron ones - therefore, the advantages of such heating devices include only a relatively small weight and a more attractive design.

Note! When the coolant temperature decreases, the heat transfer of a steel radiator decreases very much. Therefore, if water with a temperature of 60-75 0 circulates in your heating system, the heat transfer rates of a steel radiator may differ significantly from those declared by the manufacturer.

- Heat dissipation aluminum radiators significantly higher than that of the two previous varieties (one section - up to 200 W), but there is a factor that limits the use of aluminum heating devices.

This factor is water quality: when using contaminated coolant inner surface The aluminum radiator is subject to corrosion. That is why, despite good performance indicators, aluminum radiators should be installed only in private houses with an autonomous heating system.

- Bimetallic radiators are in no way inferior to aluminum radiators in terms of heat transfer. For example, the Rifar Base 500 model has a section heat output of 204 W. And they are not so demanding of water. But you always have to pay for efficiency, and therefore the price of bimetallic radiators is slightly higher than batteries made of other materials.

Radiator heat dissipation control

Dependence of heat transfer on connection

The heat transfer of a radiator depends not only on the temperature of the coolant and the material from which the radiator is made, but also on the method of connecting the radiator to the heating system:

- Direct one-sided connection is considered the most advantageous in terms of heat transfer. That is why the rated power of the radiator is calculated precisely with a direct connection (the diagram is shown in the photo).

- A diagonal connection is used if a radiator with more than 12 sections is connected. This connection minimizes heat loss.

- The lower radiator connection is used to connect the radiator to the heating system hidden in the floor screed. Heat transfer losses with such a connection are up to 10%.

- A single-pipe connection is the least profitable in terms of power. Heat transfer losses with such a connection can range from 25 to 45%.

Advice! You can learn methods for implementing different types of connections from the video materials posted on this resource.

Ways to increase heat transfer

No matter how powerful your radiator is, you often want to increase its heat output. This desire becomes especially relevant in winter period when the radiator, even operating at full power, cannot cope with maintaining the temperature in the room.

There are several ways to increase the heat transfer of radiators:

- The first way is regular wet cleaning and cleaning the radiator surface. The cleaner the radiator, the higher the level of heat transfer.

- It is also important to paint the radiator correctly, especially if you are using cast iron sectional radiators. A thick layer of paint prevents effective heat transfer, therefore, before painting the batteries, it is necessary to remove a layer of old paint from them. It will also be effective to use special paints for pipes and radiators that have low heat transfer resistance.

- So that the radiator provides maximum power, it must be installed correctly. Among the most common mistakes in installing radiators, experts point out tilting the radiator, installing it too close to the floor or wall, and covering radiators with inappropriate screens or interior items.

- To increase efficiency, you can also inspect the internal cavity of the radiator. Often, when connecting the battery to the system, burrs remain, on which, over time, a blockage forms, preventing the movement of the coolant.

- Another way to ensure maximum efficiency is to install a heat-reflecting screen made of foil material on the wall behind the radiator. Particularly effective this method when improving radiators installed on the external walls of a building.

There are several more ways to increase the heat transfer of a radiator with your own hands. However, you may not need them if you initially choose a model that has enough power to keep your home warm!

Winter is ahead, so the question of “which heating radiator is better” is very important; the comfort in the house and the safety of property largely depend on it. Finding a heating device that will heat well, will not flood your neighbors and will harmoniously fit into the interior is an art.

Before you start choosing a radiator design, you need to decide initial conditions operation, namely: in which heating system will it be used (autonomous or centralized) and at what pressure - this indicator depends on the number of storeys of the object.

Any type of radiator is suitable for autonomous heat supply to private houses, since the owner can independently control the key parameters of the system, and the pressure in it usually does not exceed 3 atm.

Whereas residents of high-rise buildings do not have as much choice due to high and unstable operating pressure, poor quality coolant and its periodic drainage.

Before installing new radiators in a city apartment from specialists management company it is necessary to find out the parameters of the working and test pressure, the temperature and quality of the coolant (purity, acidity), the diameter of the supply pipes, as well as the type of system used in the house - one- or two-pipe.

You will also have to calculate the required power and compare different types radiators according to the following characteristics: inertia (low - the radiator quickly heats up and cools down quickly, high - vice versa), durability, ease of installation, operation and temperature control, design, price.

Steel panel radiators

Steel panel radiators are welded plates 1.25-1.5 mm thick with stamped recesses that form connecting channels.

The main advantages of devices of this type are a large range of sizes (one, two or three panels 0.4-3 m long, 0.3-0.9 m high), high heat transfer per unit volume due to fins, low inertia and good adjustability. At a low cost, they are considered fairly effective devices. However, steel radiators also have a number of serious disadvantages, for example, quite low operating pressure(6-8.5 atm).

With a water hammer of more than 13 atm, they can simply burst. Do not like steel radiators and dirty water, due to which siltation occurs in their lower parts. But the main problem is the formation of corrosion when draining the coolant, which significantly reduces the service life of the product. Thus, panel radiators are not the most the best option for use in city apartments with central heating, while for autonomous systems country houses they fit perfectly. A single-panel radiator with a size of 300×400 mm and a power of 300 W will cost 1500-1650 rubles.

Cast iron radiators

For many decades, cast iron radiators have been the only kind heating devices for most consumers - there was simply no other choice.

To be fair, it should be said that they have performed well, especially considering the low price. Cast iron has good thermal conductivity and is completely undemanding to the quality of the coolant (contamination, chemical aggressiveness, heat), holds pressure well, is strong and durable (its service life can be up to 50 years). Large mass causes high inertia - cast iron batteries They warm up slowly, but keep warm for a long time when turned off. Their main disadvantages are the fragility of the material, due to which it does not withstand water hammer, as well as the peculiarities of the shape of the batteries: they require regular painting and collect a lot of dust.

The conclusion is obvious - heavy cast iron batteries with a large volume of coolant are not suitable for a cottage, but are still in demand in multi-storey buildings, especially old building. One section of a cast iron battery has a heat output of approximately 160 W and costs about 300-360 rubles. (for example, widely famous model M140).

More modern products, for example “Breeze”, with factory-painted flat sections that look like bimetallic ones, will cost 400-470 rubles per section. The price of designer works in retro style is from powder painting and patterned relief casting (for example, GuRaTec) reaches 100,000 rubles. for one radiator.

Steel tubular radiators

Steel tubular radiators are made of thin welded columns with a wall thickness of 1.2-1.5 mm. No sharp corners and smooth surface make them easy to clean from dust, and high-quality multi-layer painting preserves the color for long years. Tubular steel radiators have the same advantages and disadvantages as panel radiators, however, in addition to good heat transfer properties, they provide unsurpassed design opportunities. Such heating devices are as varied as possible in size, for example, their height can be either 19 cm or 3 m, and in color (any shade of the RAL palette).

Of course, tubular radiators are not a cheap pleasure, but if you want the heating system in your country house has become an exclusive design element, then steel tubular radiators will allow you to go around corners, surround columns, and even disguise the battery as a bench or shelf.

For example: A Zehnder or Arbonia radiator of standard dimensions and a power of approximately 1.5 kW costs 10,000-13,000 rubles, Stealth - 2500-7100 rubles, Dia Norm Delta Standard - 546-4700 rubles.

Aluminum radiators

Aluminum radiators have a relatively low price and the highest heat transfer, that is, they quickly remove heat from the coolant and release it into the room. Sectional design And wide range standard sizes (depth, height) make it easy to obtain a battery of the desired configuration. The low weight of the material makes it possible to mount such radiators even on drywall, and big square fins create additional convection currents that increase heat transfer. Reinforced models of aluminum radiators can cope with a pressure of 12-16 atm, however, the main operational problem lies in the high requirements for the quality of the coolant - the pH of the water should not be less than 7.5.

This requirement is practically impossible for systems central heating, where the water is highly acidic, and this in turn inevitably causes corrosion of aluminum. In addition, the electrochemical reaction of aluminum oxide with an acidic environment causes the release of hydrogen, which can lead to the formation air jams, if the design does not provide exhaust valves.

One more nuance - there should be no antagonistic metals in the heating system. When paired with copper or brass components, the corrosion process starts (the more copper, the faster). To prevent aluminum from coming into contact with water, manufacturers produce radiator models with internal coating made of polymers, ceramics or resins, but reliable statistics on such devices have not yet been developed. Thus, aluminum radiators are not recommended for use in city apartments, but they are well suited for autonomous heating systems with careful control of coolant parameters.

Bimetallic radiators

Absolutely externally no different from aluminum bimetallic radiators, however, the channels through which water circulates are made of steel. This combines the advantages of both metals and minimizes their disadvantages.

Steel reliably resists corrosion and holds pressure, while aluminum quickly gains heat and releases it into the room. Attractive appearance, high heat transfer, exceptional performance characteristics (working pressure 35 atm, and pressure testing - up to 52.5 atm), neutrality chemical composition coolant, long service life (up to 20 years) make bimetal a market leader. In addition, the small internal volume of the radiator and, accordingly, the small volume of coolant circulating in autonomous system heating - this is a significant energy saving.

Among the disadvantages of bimetallic radiators it is worth noting small area cross-sections of intercollector tubes. In high-rise buildings built more than 30 years ago, dirty coolant from worn-out pipes can clog the collectors, and the radiator will not warm up completely.

The consumer must clearly understand that all of the listed advantages are available only to radiators in which both vertical and horizontal straits (collectors) are made of steel - only in this case corrosion will not destroy the battery and only such models have every right to be called bimetallic.

One section bimetallic radiator(Rifar. Faral, Global, Sira, Royal Thermo) with a heat output of 180-195 W costs 450-700 rubles.

One of the varieties of bimetallic radiators are copper-aluminum. The thermal conductivity of copper is several times higher. than steel, which means that at lower coolant temperatures such a battery will warm the room better. Copper-aluminum radiator allows the use of a boiler with copper heat exchanger, since electrochemical reaction and corrosion are excluded.

A section of such a radiator with a power of 180 W will cost on average from 600 to 2000 rubles.

HOW MUCH HEAT DOES YOU NEED?

The “weather in the house” will be negatively affected by both a lack of power - you will freeze and turn on electric heaters, and an excess - why heat the street? The most general calculation is 1 kW/10 sq. m. However, it is necessary to take into account such parameters as wall material, number of windows, type of glazing.

If the room is corner, then a coefficient of 1.2 is used. if it is a corner one with two windows - 1.3 If the window openings face north, you can safely add another 10% of power, and if the ceilings are higher than 3 m or the windows are larger than standard - then another 15%. In addition, experts unanimously recommend installing one extra section “in reserve”.

The design power should be reduced by 10-20% if you have high-quality plastic windows or heated floors, it is worth reducing it in the kitchen, where the stove provides a significant part of the heat.

The most accurate method will be to calculate power by room volume. If there are double glazed windows in panel houses requires about 40 W/cu. m, in brick houses - 35 W, in houses built using heat-saving materials - 20 W (for all - 10% power reserve).

REPLACING THE HEATING RADIATOR

Of course, it is more convenient to change radiators outside the heating season, because there is no need to turn off the heat throughout the entire riser. However, in this case, possible connection defects will only be visible in the fall.

So winter work has its advantage: the installer is present when filling the system with water, the result is visible immediately, and problems are corrected on the spot. You and your neighbors will not have time to freeze, since the outage usually does not exceed a couple of hours.

The easiest way is to invite specialists from a local management company. When hiring a third-party contractor to DEZ, you will need to provide a company certificate of state registration, certificates of conformity for materials, a connection project and thermal engineering calculations (officially operating companies independently prepare all required package documents and even agree on disconnecting the riser).

Note when installing a heating radiator with your own hands:

- It is necessary to provide sufficient space around the radiator for the free movement of warm air: 7-10cm to the floor, 3-5cm to the wall, 10-15cm to the window sill. If these requirements are not met, heat loss will be 10-15%.

- Usage decorative screens reduces the heat transfer of radiators by about a third.

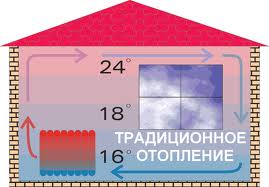

- Correct installation of the battery - under the window on external wall. The heated air will rise upward from the radiator, blocking the cold from the window, allowing for optimal heat distribution. If there are two windows in the room, radiators must be installed under each of them.

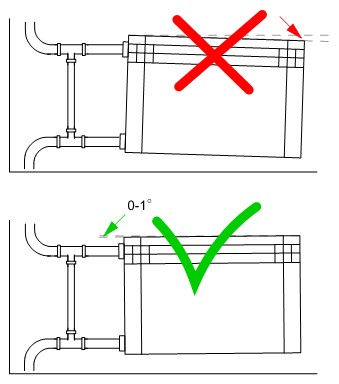

- The radiator must be installed strictly vertically/horizontally, then its heating will be uniform, and air will not begin to accumulate at the extreme points.

- On each battery it is necessary to install a thermostat (automatic or manual), as well as an air release valve (Mayevsky valve).

- It is more convenient to connect radiators through ball valves. If necessary, this makes it possible to completely disconnect them from the riser.

Table 1:

COMPARATIVE CHARACTERISTICS OF THE MAIN TYPES OF RADIATORS |

|||

Radiators | Heat dissipation. W | Working pressure, atm | Crimping pressure, atm |

Steel panel | 180-735 (depending on the number of panels) | ||

Steel tubular | 20-700 (depending on dimensions) | ||

Cast iron | 80-160 (one section) | ||

Aluminum | 125-280 (depending on the center distance) | ||

Bimetallic radiators (aluminium/steel) | 130-200 (depending on the center distance) | ||

Warmer climes

Every year, manufacturers of climate control equipment show us new modifications of water heating radiators. Sometimes only the design changes, and sometimes significant changes are made to the design

Following the proverb “You meet people by their clothes...”, let’s start the review with designer models of radiators and heated towel rails for bathrooms. This segment traditionally features a large number of Arbonia, Kermi, Cordivari, Zehnder products of a wide variety of shapes and colors, also made from various materials. Models with a body shaped like a ladder are popular. - a pair of vertical profiles on the sides, and between them a row of horizontally located pipes, such as, for example, in the Basic-50 (Kermi) or Toga (Zehnder) series models. On such a radiator you can hang wet towels or clothes. A similar design option - load-bearing vertical profiles are located in the center, and extend from them to the side horizontal pipes, like branches from a tree trunk (Yucca line (Zehnder).

Babula (Cordivari). Zeta (Kimry plant thermal equipment). The pipes can be round in cross-section or flat, as in the Giuly (Cordivari) series, located strictly symmetrically relative to the vertical profiles or placed to one side - there are many types of design radiators.

Much more interesting, however, are technical innovations in “ordinary”, non-designer devices. The largest number of new products in this segment relate to improvements in the geometry of the body so that it flows better around air flow. Thus, in the Revolution (Royal Thermo) models, the ribs have a wave-like shape, due to which the air does not stagnate, its circulation improves, and heat transfer increases by 5%. Indigo (Royal Thermo) models feature reverse convection.

The design of the upper part of the radiator creates a reverse flow of hot air, effectively cutting off the cold from the windows. Internal details are also being improved.

So, in steel Kermi radiators Therm-x2 technology is used, which allows coolant to flow consistently through the radiator panels. Thanks to this technology, an efficiency is achieved, which in the steel segment panel radiators until now was considered unattainable. New types of radiators are also appearing, for example Kermi panel models with an installation height of 200 mm, which are suitable for panoramic structures, as well as verandas, winter gardens and other rooms with large windows or low window sills.

Another improvement was proposed by the Rifar manufacturers. Their sectional radiators are BASE 200/350/500, ALUM 350/500. FORZA 350/500. ALP 500 can be equipped with a towel holder. The result is a convenient and neat design.

POINTS IN THE WORLD OF RADIATORS

How to determine which models are suitable for your home or apartment? First of all, they must meet a number of requirements that depend on the design of the heating system: the type and pressure of the coolant, the connection diagram of the radiators to the pipeline.

The operating pressure in the system can range from 1-3 atm in private cottages and up to 8-10 atm in apartment buildings. In the latter case, you need to be especially careful when choosing radiators; it is better to purchase models with a safety margin. For example, steel design radiators from the Kimry Thermal Equipment Plant are designed for an operating pressure of 15 atm and a test pressure of 22.5 atm. Arbonia tubular manifolds in high-pressure design - for a working pressure of 16 atm. and models of the Monolit (Rifar) series - for a working pressure of 100 atm. The coolant can be not only water, but also a mixture of various liquids with a low freezing point (ethylene picol, propylene glycol, etc.). Some of them are capable of entering into chemical reaction with aluminum and cause corrosion. For low-freezing coolants, it is better to choose radiators in which contact of the liquid with aluminum is excluded.

In this case, models with both a steel body and a bimetallic one are suitable, if the manufacturer indicates that the products can be used with any chemically aggressive coolants (such bimetallic radiators have a manifold entirely made of steel, so they are not inferior in durability to all-steel models). The radiator connection diagram determines how the pipelines supplying and discharging coolant are connected to the device. Three schemes are usually used: side, diagonal (hot coolant in both cases is supplied through the top pipe) and bottom (both pipes are connected at the bottom of the radiator). The lower connection option is less efficient from a heating engineering point of view (by about 15-20%). At the same time bottom connection more aesthetically pleasing. Both universal radiator models and those designed for only one connection scheme (side or bottom) are available.

Is the design and material of the radiator important?

Until recently, it was believed that for urban apartment buildings Steel or cast iron tubular appliances are optimal, but, say, panel or sectional aluminum ones are not suitable. But with the advent of radiators made using modern technologies(for example, flash butt welding is used instead of the classic intersectional assembly using a nipple and gasket), this opinion is outdated. If the model is designed for high operating pressure, then it can be used in urban environments, regardless of the type of structure. The same can be said about the material.

GO TO THE FLOOR?

In most rooms, heating radiators are traditionally installed in the window sill. This placement ensures good heat exchange, especially with the window open, when the cold street air is cut off by the rising warm flow. However, today mostly glass windows with good thermal insulation are used, without the flow of cold air from the window, so the need to install radiators under the windows is no longer so obvious. Heating appliances are increasingly being placed on walls, in the floor and even inside the walls of rooms. Moreover, if the last option (for example, system INSIDE (REGULUS) products is still considered exotic, then in-floor convectors have become quite widespread.

Like conventional convectors, in-floor models are tubes with plate fins placed in a long and narrow metal casing with a height of 9 to 20 cm (depending on the model). The top of the casing is closed with a grille. The device is installed during the laying of the subfloor so that the grating is subsequently flush with the floor covering.

There are models of floor convectors with both natural convection and forced convection, which uses a built-in fan. Systems of the first type are less widespread, since the design of in-floor convectors is not very convenient for natural air exchange and they are less efficient in terms of heat transfer.

The main advantage of in-floor appliances is that radiators take up absolutely no usable space in the room. As the saying goes, more space and less dust. The device can be installed in any part of the room where there are no carpets, furniture or other interior items.

WE COUNT THE NUMBER OF SECTIONS

With simplified thermotechnical calculation heat consumption is 100 W per each square meter area of the room. To find out required amount sections of the radiator, you should multiply the footage of the room by 100 and divide the result by the amount of heat transfer of one section depending on the temperature of the coolant (it is indicated in the characteristics of the radiator).

So, if the area of the room is 16 m2, and the heat transfer of the section is 160 W, then the number of sections is 16 x X 100/160 = 10 pcs.

This method of calculation is not accurate, since it does not take into account a number of parameters: for example, ceiling heights or the method of connecting the radiator. Therefore, it is necessary for a specialist to perform the final calculation.

CONVECTOR PROVIDES HEAT

Convectors are used for in-floor installation. In these devices, related to radiators, the main heat transfer occurs due to heat transfer by hot air flows (convection), while in the former, convection is added thermal radiation. By design, convectors are pipes with fins. Coolant flows through the pipes and heats the fins. A heated air stream passes through them. Devices are usually equipped protective casing. The main advantage of convectors is more efficient heat transfer (therefore the devices are compact), but the disadvantage is that during operation, unwanted air flows (drafts) can form.

IN-FLOOR CONVECTORS

PROS

and pipelines are removed from the premises. + Easy to maintain - the convector can be easily vacuumed by removing the decorative grille. + Can be placed in any convenient place on the floor. + Models with forced convection are highly efficient.

MINUSES

Insufficient heat transfer efficiency of a convector with natural ventilation.

Convector with forced ventilation Requires connection to an electrical outlet.

The built-in convector will be difficult to replace if, for example, you want to redesign the room.

Expert opinion

There are several signs by which you can determine the quality of heating radiators. These include weight, which affects the heat transfer of devices, metal alloy, painting material, and the thickness of the section being manufactured. Of course, a non-specialist is unlikely to be able to assess the quality of the alloy. All reliable information about the characteristics of radiators and certificates of compliance with standards international standard indicated in the technical data sheet of the product.

But, unfortunately, today there is no mandatory state certification of radiators. Some manufacturers obtain certificates from dubious organizations that do not guarantee the accuracy of the declared data. It is risky to purchase their products.

Those certified according to GOST seem to be more reliable. domestic radiators, for example, products that are manufactured under the Royal Thermo brand, or under the ISO 9001 certificate, if we are talking about products manufactured in Europe.

Below are other entries on the topic “How to do it yourself - for a homeowner!”

The main task of batteries is to efficiently heat the room. A key characteristic of the high-quality operation of a heating system is heat transfer, which expresses the volume of heat transferred over a certain amount of time. The heat transfer of heating radiators depends on many nuances, the details of which will be discussed below.

Heat transfer is a key characteristic of high-quality operation of a heating system

What you need to know about heat transfer

Radiator power, thermal ceiling, thermal power - all these concepts are identical to thermal output, the unit of measurement of which is Watt. Sometimes the thermal ceiling is also measured in calories. This value can be converted into Watts: 1 W is equal to approximately 860 calories per hour.

Heat transfer occurs through several processes:

- heat exchange;

- convection;

- radiation.

All three methods of heat transfer are carried out in the battery, but their specific proportions vary depending on the type of heating equipment. Radiators may include devices in which at least a quarter of the heat is released in the form of direct radiation. However, it must be noted that today the boundaries of this requirement have become somewhat blurred, since convector devices have also come to be called radiators.

Calculation of the required thermal output

The choice of batteries should be based on the most accurate calculations of the required power. On the one hand, there is no need for extra sections, but on the other, a lack of power will lead to the inability to achieve the desired temperature.

Heating efficiency is influenced by the characteristics of the room. Among them:

- room area;

- ceiling height;

- location of the premises (on a corner or not);

- floor;

- quantity external walls and windows;

- characteristics of installed windows;

- presence of insulation on external walls;

- presence in the room additional sources heat;

- Availability attic space and the quality of its insulation.

There are several methods for calculating the required power of a heating system. The simplest method is based on the number of windows and walls bordering the street. The calculation is done as follows:

The easiest way to calculate the power of a heating system is to count the number of windows and walls bordering the street

- in a standard situation (one window, one external wall) you will need 1 kW of thermal power for every 10 square meters of room;

- if the room has two windows or two external walls, a correction factor of 1.3 is applied (in other words, for every 10 square meters 1.3 kW of thermal power is required).

The next method is a little more complicated, but it allows you to get more accurate indicators of the required power, since one of the parameters used is the height of the room.

The formula is used for calculation:

Power = room area x room height x 41 (according to standards - minimum power per cubic meter of room).

The result obtained is the required thermal power. To determine the number of sections needed, we divide this result by the thermal output of one section (indicated in the battery data sheet).

Advice! The calculation may result in a fractional number. In this case, the number must be rounded up.

Heat dissipation and battery material

From the point of view of structural materials, there are four main types of radiators: cast iron, steel, aluminum and bimetallic. In each case, the heat transfer is different.

Cast iron batteries

Such radiators are characterized by a small heat transfer surface, as well as low thermal conductivity. Heat transfer from cast iron radiators is carried out primarily by radiation and only a fifth of it occurs by convection.

Each section of the cast iron battery has a rated power of 180 watts. Although such indicators are achieved only in laboratory testing conditions. If we are talking about central heating systems, the coolant only occasionally warms up above 80 degrees, and some of the thermal energy is lost on the way to the radiator. As a result, the actual heat transfer is fixed at 50-60 W.

Steel batteries

Steel radiators consist of one or more panels, between which there are so-called fins that act as a convector. The thermal output of steel devices is only slightly higher than that of cast iron. Therefore, their main advantage is low weight and more aesthetic design.

If the coolant temperature decreases, heat transfer steel battery falls sharply. In this regard, the actual characteristics of the radiator may differ greatly from those indicated by the manufacturer.

The heat transfer of aluminum radiators is higher than that of steel and cast iron devices (up to 200 W per section). However, there is a limit to the use of aluminum in heating system- susceptibility to corrosion. Aluminum is very sensitive to the quality of the coolant, so it is better to install such radiators in private homes.

Bimetallic batteries

In terms of thermal efficiency, this type of radiator is no worse than aluminum. In some cases it exceeds 200 W. At the same time, bimetallic devices are not so sensitive to the quality of the coolant. The disadvantage of these devices is their high cost.

Dependence of thermal output on connection type

The characteristics of the battery depend not only on the temperature conditions of the coolant and construction material, but also on the type of connection of the device to the heating system:

- direct one-way connection- the most effective, reference type of connection;

- diagonal connection - used to reduce heat loss if the battery has more than 12 sections;

- bottom connection, in which up to 10% of energy is lost - used to connect to the heating system in the floor screed;

- single-pipe connection is the most unprofitable, heat losses range from 30-45%.

Options for increasing heat transfer

There are several ways to increase thermal output:

- The radiator must be clean, so it needs systematic wet cleaning.

- Too thick a layer of paint on a cast iron battery interferes with heat transfer. Therefore, when painting, you need to use special paints with reduced heat transfer resistance.

- Before applying paint to a used battery, you must carefully remove old paint. For painting, it is better to use dark enamel, applied in two layers. Dark colors allow you to increase heating power by approximately 10%. Light-colored surfaces usually look more impressive, but are not as effective for heating purposes.

- The battery must be installed correctly: without tilting, on correct distance from the wall and floor.

- The radiator should not be covered with decorative grilles or curtains.

- There should be no blockages in the inside of the device that interfere with the circulation of the coolant.

- Screens with foil, which can be installed on the wall behind the battery, increase heat transfer.

- The reason for the decrease in temperature may be valves that are too tight. Moreover, attempts to turn them on may not be successful due to formations that have arisen on the thread. In this case, you need to call a plumber.

- If during the heating season it turns out that some segment of the radiator is cold, we're talking about about disruption of coolant flow due to the accumulation of foreign matter at the bottom of the device. Gently tapping the device can get rid of the problem. You can also turn it on next electric stove or electric heater. When the water in the battery is heated, a vortex movement is initiated, which can dislodge deposits of rust or debris.

- The temperature may also drop due to repair work neighbors if they made the riser narrower when installing “warm floors” or began heating additional rooms, which reduced the pressure in the system.

So, the factors for good heat transfer of radiators: model and material of the device, type of connection, correct calculation of the number of sections, taking into account the characteristics of the room, compliance with the rules of operation of the equipment. To achieve maximum heat transfer, it is necessary to take into account all the specified parameters. The reward for this will be warmth and comfort in the room.

When designing a home heating system, designers first of all try to determine how much heat will need to be used to create comfortable living conditions in the house. What does this depend on? First of all, from such an indicator as the heat transfer of heating radiators (the table will be indicated below).

So, what is the heat transfer of a heating battery? This is a criterion of thermal energy that is released over a certain period of time. It is measured in W/m*K; some manufacturers indicate another unit of measurement in their passports - cal/hour. Essentially, it's the same thing. To convert one to the other, you will have to use the ratio: 1.0 W/m*K= 859.8452279 cal/h.

What affects the heat transfer coefficient

- Coolant temperature.

- The material from which heating batteries are made.

- Proper installation.

- Installation dimensions of the device.

- Dimensions of the radiator itself.

- Connection type.

- Design. For example, the number of convection fins in panel steel radiators.

Everything is clear with the coolant temperature, the higher it is, the more heat the device gives out. The second criterion is also more or less clear. Here is a table where you can see what material gives off heat and how much it gives off.

Let's face it, this indicative comparison says a lot; from it we can conclude that, for example, aluminum has a heat transfer rate almost four times higher than cast iron. This makes it possible to reduce the temperature of the coolant if aluminum batteries are used. And this leads to fuel savings. But in practice, everything turns out differently, because the radiators themselves are made according to different forms and designs, in addition the lineup there are so many of them that it is not necessary to talk about exact numbers here.

Read also:

Classification of electric wall-mounted heating radiators

Heat transfer depending on coolant temperature

Heat transfer depending on coolant temperature

As an example, we can give the following variation in the degree of heat transfer between aluminum and cast iron radiators:

- Aluminum - 170-210.

- Cast iron - 100-130.

Firstly, comparative fell sharply. Secondly, the range of spread of the indicator itself is quite large. Why does this happen? Primarily due to the fact that manufacturers use various shapes and wall thickness heating device. And since the model range is quite wide, hence the heat transfer limits with a strong range of indicators.

Let's look at several positions (models), combined into one table, which will indicate the brands of radiators and their heat transfer rates. This table is not comparative, we just want to show how the thermal output of a device changes depending on its design differences.

As you can see, the heat transfer of heating radiators largely depends on model differences. And there are a huge number of such examples. It is necessary to draw your attention to one very important nuance– some manufacturers in the product passport indicate the heat transfer of not one section, but several. But all this is spelled out in the document. Here it is important to be careful and not make a mistake when making calculations.Connection type

I would like to dwell on this criterion in more detail. The thing is that the coolant, passing through the internal volume of the battery, fills it unevenly. And when it comes to heat transfer, this very unevenness greatly affects the degree of this indicator. Let's start with the fact that there are three main types of connection.

Read also:

Decoupage heating radiator - do it yourself

- Lateral. Most often used in city apartments.

- Diagonal.

- Lower.

If we consider all three types, we will highlight the second (diagonal) as the basis of our analysis. That is, all experts believe that it is this scheme can be taken as a coefficient such as 100%. And this is actually true, because the coolant according to this scheme passes from the upper pipe, going down to the lower pipe installed on the opposite side of the device. It turns out that hot water moves diagonally, evenly distributed throughout the entire internal volume.

Heat dissipation depending on the device model

Heat dissipation depending on the device model

Side connection in in this case has one drawback. The coolant fills the radiator, but the last sections are poorly covered. That is why heat loss in this case can be up to 7%.

And the lower connection diagram. Let's face it, it's not entirely efficient; heat loss can be up to 20%. But both options (side and bottom) will work effectively if used in systems with forced circulation coolant. Even a slight pressure will create a pressure that is enough to bring water to each section.

Correct installation

Not all ordinary people understand that heating radiator must be installed correctly. There are certain positions that can affect heat transfer. And these positions in some cases must be strictly implemented.

Eg, horizontal landing device. This is an important factor; it determines how the coolant will move inside and whether air pockets will form or not.

Therefore, advice to those who decide to install heating radiators with their own hands - no distortions or displacements, try to use the necessary measuring and monitoring tools (level, plumb line). Batteries must not be allowed to different rooms were not installed at the same level, this is very important.

Read also:

Flat type heating radiators

And that is not all. Much will depend on the distance at which the radiator will be installed from the restrictive surfaces. Here are just the standard positions:

- From the window sill: 10-15 cm (3 cm error is acceptable).

- From the floor: 10-15 cm (3 cm error is acceptable).

- From the wall: 3-5 cm (1 cm error).

How can an increase in error affect heat transfer? There is no point in considering all the options; let’s give an example of a few main ones.

- An increase in the error in the distance between the window sill and the device reduces the thermal efficiency by 7-10%.

- Reducing the error in the distance between the wall and the radiator reduces heat transfer by up to 5%.

- Between the floor and batteries – up to 7%.

It would seem like just a few centimeters, but they are the ones that can reduce temperature regime inside the house. It seems that the reduction is not that big (5-7%), but let's compare all this with fuel consumption. It will increase by the same percentage. It won’t be noticeable in one day, but in a month, but in the whole heating season? The amount immediately grows to astronomical heights. So it’s worth paying special attention to this.

Don't forget to rate the article.

One of the main parameters of a room heating device is its heat transfer. But no less important when installing a heating system are such indicators as heat capacity and thermal inertness of the material from which the radiators are made. Cast iron radiators, which are mainly used in central heating systems multi-storey buildings, have high thermal power, but at the same time they are quite compact and can withstand high pressure coolant and are not afraid of rust. The massiveness of cast iron and large volume coolant in each section (MC 140 section weighing 7.5 kg contains 4.2 liters of water) provides cast iron radiators with greater heat capacity than heating batteries from other materials, so the temperature in the room rises and falls gradually.

Thus, the heat transfer of a cast iron radiator MC 140 is much lower than that of a modern aluminum or bimetallic radiator, but it retains heat much longer.

Decorative cast iron radiator Bohemia in retro style

How to choose a cast iron radiator

- What radiator performance characteristics should you pay attention to when choosing radiators? First of all this:

- operating pressure;

- operating temperature in the heating system for which heat transfer is calculated;

- heat transfer;

heat-emitting surface area;

The shape of the purchased radiator deserves special attention. It is no secret that the prejudice against cast iron radiators is caused by the fact that when they are mentioned, many people remember the “cast iron accordion” under the window, which they have become accustomed to since childhood. Indeed, the usual “finned batteries” have a small and ineffective heating surface area (heat transfer) - for example, for a section of the familiar MS 140 radiator, this figure is 0.23 sq.m.

Part of the heat of the incoming coolant is lost “on the way” from the heating boiler to the water heating battery, because massive supply pipes are used for such systems. In addition, to heat water to a design temperature of 90 degrees. only suitable steam boilers high power. Therefore, in private homes the heating system sometimes operates at a lower temperature.

However, modern cast iron radiators and appearance, and, accordingly, in terms of parameters they can differ significantly from their “accordion” predecessors.

While retaining all the advantages of traditional cast iron batteries, it is devoid of many of their disadvantages. Thus, the Minsk-made 1K60P-500 radiator is assembled from flat plates, each of which has a small heating area (0.116 m2) and low power (70 W).

However, a radiator assembled from them is essentially a heating panel, which (unlike finned batteries) produces a wide directed heat flow. Other manufacturers also provide a wide selection of such radiators. The advantage of modern cast iron radiators is that many models allow you to assemble batteries required power

from separate sections.

Radiators sold assembled (for example, Conner, STI Breeze and some others) are formed from a number of sections designed for rooms of various sizes based on an engineering calculation of the required thermal power per square meter of room.

For example, you can purchase one radiator of 4-6-8-12 sections or two radiators of 4 (6, 8 sections).

Real heat transfer of the radiator section

As already indicated, the power (heat transfer) of radiators must be indicated in their technical data sheet. But why, a few weeks after installing the heating system (or even earlier), does it suddenly turn out that the boiler seems to be heating as it should, and the radiators are installed according to all the rules, but it’s cold in the house? There may be several reasons for a decrease in the actual heat transfer of radiators.

We present the indicators of the heating surface and the declared heat transfer for the most common models of cast iron radiators. We will need these figures in the future for examples of calculating the real power of the radiator section.

As already mentioned, when using such radiators for medium- and low-temperature heating systems (for example, 55/45 or 70/55), the heat transfer of a cast-iron heating radiator will be less than that stated in the passport. Therefore, in order not to make a mistake with the number of sections, its actual capacity must be recalculated using the formula:

Q = K x F x ∆ t

K is the heat transfer coefficient;

F is the heating surface area;

∆ t - temperature difference °C (0.5 x (t in. + t out.) - t in.);

tin – temperature of water entering the radiator,

tout – water temperature at the radiator outlet;

t int - average air temperature in the room.

When the temperature of the incoming coolant is 90 degrees, the outlet temperature is 70 degrees, and the temperature in the room is 20 degrees.

∆ t = 0.5 x (90 + 70) – 20 = 60

The K coefficient for the most common cast iron radiators can be found here:

Even the actual heat transfer of one section of an average cast iron radiator with an area of 0.299 sq. m (M-140-AO) with an incoming water temperature of 90 degrees and an outlet water temperature of 70 degrees will differ from the declared one. This occurs due to heat loss in the supply pipes, and for other reasons (for example, reduced pressure), which cannot be foreseen in laboratory conditions.

So, the heat transfer of a section with an area of 0.299 sq. m. at a temperature of 90/70 will be:

- 7 x 0.299 x 60 = 125.58 W

Considering that heat transfer is always indicated with some margin, we multiply this figure by 1.3 (this coefficient is used for most cast iron radiators) and we get: 125.58 x 1.3 = 163.254 W - compared to the declared 175 W.

There will be an even greater difference in the numbers if the water entering the radiator does not heat above 70 degrees. (and the exiting coolant, accordingly, cools down to 60-50 degrees), so before buying new radiators, it is advisable to find out the real thermal parameters of your heating system.

How to save on heating?

The first rule of reasonable saving is to remember what you should never save on! Radiators should always be taken with a reserve, because you can reduce the temperature in the room by reducing the temperature of the water in the system or using shut-off valves. But if the actual heat transfer turns out to be lower than that declared by the manufacturer, the rooms will be cool at best. By the way, Conner cast iron radiators, which are quite good in most respects in terms of actual operation, have a heat transfer rate that is 20-25 percent lower than indicated in the data sheet.

Radiator 1K60P-500 (Minsk)

As already indicated, heat transfer may differ from the declared one due to the fact that the water temperature in the heating system is much lower than the “standard” one, that is, the one at which factory tests were carried out, since the declared radiation power is achievable only under laboratory conditions. Imagine that the MS-140 radiator section (160 W power indicated) at a water temperature of 60/50 degrees. (and the boiler can’t handle any more!) will produce a power of no more than 50 W. And if you believed the technical data sheet and decided to install 5 heating sections, then instead of 800 W (160 x 5) you will get only 250.

However, it is quite possible to foresee this situation and even take advantage of it! Based on the calculations given above, the lower ∆ t (that is, the temperature of the coolant water), the larger the radiating surface of the radiator should be. So, at ∆ t 60, for 1 kW radiation, a radiator with a height of 0.5 m x 0.520 m is sufficient, and at ∆ t 30 - 0.5 m x 1.32 m.

“Traditional” cast iron radiator MS-140M2

However, it is precisely due to the low temperature of the medium and increasing the radiating area of the radiator or the number of sections that heating costs can be reduced.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to consider technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different sizes windows, etc. Most important parameters

- which are taken into account when determining the required radiator power are:

- floor;

- the area of your premises;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

There is a fireplace and air conditioning in the room. Others need to be taken into account important features . How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Has it been done walls and which one (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of room. You can take into account not the volume, but the area of the room. For 10 square meters of a standard room with one door and one window, one door and outer wall The following thermal power of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- Indoors panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Formulas for calculating heater power for various rooms

The formula for calculating the heater power depends on the ceiling height. For rooms with ceiling height< 3 метров эта зависимость выглядит следующим образом:

S x 100 W / ∆T

- S – room area;

- ∆T – heat transfer of the heating device section.

For rooms with ceiling heights > 3 m, calculations are carried out according to the formula

S x h x 40 / ∆T

- S – total area of the room;

- ∆T – heat transfer of a separate section of the battery;

- h – ceiling height.

These simple formulas will help you accurately calculate the required number of sections of the heating device. Before entering data into the formula, determine the real heat transfer of the section using the formulas given earlier! This calculation is suitable for an average incoming coolant temperature of 70˚ C. For other indicators, it is necessary to take into account the correction factor.

Let us give examples of calculations. Let's imagine that the room or non-residential premises has dimensions of 3 x 4 m, ceiling height is 2.7 m ( standard height ceilings in Soviet-built city apartments). Let's determine the volume of the room:

- 3 x 4 x 2.7 = 32.4 cubic meters.

Now let’s calculate the thermal power required for heating: multiply the volume of the room by the indicator required to heat one cubic meter of air:

- 32.4 x 41 = 1,328.4 kW.

Knowing the actual power of an individual radiator section, select the required number of sections, rounding it up. So, 5.3 is rounded to 6, and 7.8 – to 8 sections. When calculating the heating of adjacent rooms that are not separated by a door (for example, a kitchen separated from the living room by an arch without a door), the areas of the rooms are summed up. For a room with double-glazed windows or insulated walls, you can round down (insulation and double-glazed windows reduce heat loss by 15-20%), and in a corner room and rooms by high floors add one or two sections “in reserve”.

Why doesn't the battery heat up?

But sometimes the power of the sections is recalculated based on the actual temperature of the coolant, and their number is calculated taking into account the characteristics of the room and installed with the necessary margin... and it’s cold in the house! Why is this happening? What are the reasons for this? Is it possible to correct this situation?

The reason for the decrease in temperature may be a decrease in water pressure from the boiler room or repairs from neighbors! If during repairs a neighbor narrowed the riser with hot water, installed a “warm floor” system, started heating the loggia or glass balcony, on which he arranged winter Garden– pressure hot water, entering your radiators, of course, will decrease.

But it is quite possible that the room is cold because you installed the cast iron radiator incorrectly. Typically, a cast iron battery is installed under a window so that rising from its surface warm air created before window opening kind thermal curtain. However, with its back side, the massive battery heats not the air, but the wall! To reduce heat loss, glue a special reflective screen to the wall behind the heating radiators. Or you can purchase decorative cast-iron batteries in a retro style, which do not have to be mounted on the wall: they can be mounted at a considerable distance from the walls.