Every day the relevance of using alternative energy is increasing. One of the popular devices of this type is a wind generator, which you can make yourself.

A wind turbine or wind generator is a device that is used to convert the kinetic energy of the wind into electrical energy. The windmill has been known since the 7th century AD, but then it was a windmill in which energy from the wind was transferred to grain processing mechanisms.

Photo - windmill

The main resource for the operation of such a generator is wind. A quantitative measure of this energy is wind density. The data is compiled based on studies of how strong the wind blew in certain areas, how the force changed depending on the height of the air flow, and also what the air density was. Depending on these readings, it is calculated at what height it is most practical to place wind turbines, how many cavities are needed and in what zone of the site they should be installed.

Now there are improved homemade wind generators. In addition to converting energy, they can store it using Betz's law and standard batteries. Despite the fact that this device is an excellent option for an autonomous power plant, it has its drawbacks:

- Rapid wear of moving parts;

- Loss of power from the gearbox;

- Relatively low nutritional indicator.

Types of wind turbines and operating principle

Modern windmills come with a vertical and horizontal axis. At the same time, at home, as well as to provide uninterrupted energy for small industries, a model with a horizontal axis is used.

Photo - vertical windmill

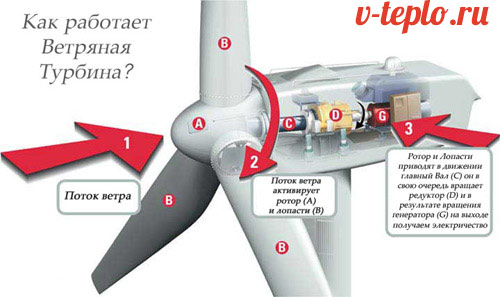

Horizontal wind turbine comprises:

- Gearboxes;

- Rotor shaft;

- Electric generator;

- Brake system.

The main structural components in horizontal wind generators are the rotor shaft and the electric generator. In some cases, the system is also equipped with an additional motor to receive energy from the blades in extreme situations. Powerful windmill must be complemented by a gearbox, which helps regulate the rotation of the mill depending on the wind strength and needs. The blades of this model are made of durable metal alloy, which is not subject to deformation under the influence of atmospheric precipitation or a strong gust of wind.

Photo - windmill with horizontal axis

Vertical wind generator has a rotor shaft that is installed in a vertical position. The most important advantage of this design is that the generator does not necessarily need the wind to blow with a certain force. Please note that this model is the only wind generator that does not need to be placed in open space. The gearbox and the unit for converting kinetic energy into electrical energy can be located close to the ground, which greatly facilitates their maintenance. The main disadvantage of such a mill is the relative speed of the shaft rotation, which means a low power factor. To increase this indicator, a motor is often installed that accelerates the turbine windmill to generate more current.

Principle of operation wind generator extremely simple. The wind turns the blades, which rotate the shaft, which in turn is connected to the generator. The generator converts kinetic energy into electrical energy and, with the help of additional mechanisms, directs it to the house or to certain equipment.

Video: how wind turbines work

How to make a homemade windmill

Making a wind generator for your home with your own hands is quite simple task. Unlike solar panels, which are very difficult to both install and develop at home, most of the components for the mill can simply be lying in your garage.

The first thing you need is to develop drawings, depending on the type of station. We recommend constructing a wind power generator with a horizontal axis to produce electricity for a summer house or home, it has simpler scheme and installation. Next, you need to choose a place where you can install the windmill. Be careful here, depending on the region, the permissible height of the windmill varies. Also consider the location of communications in the yard, the output of electricity from the house and other factors.

In order to make a homemade household wind generator, you will need:

- Electric generator;

- Suitable size turbines;

- A pillar for installing a large wind turbine;

- Solar panels;

- Control unit and speed switching.

It is permissible to use a car engine as a generator. On asynchronous motor much easier to work with, because generators direct current not designed to produce large amounts of energy. We recommend choosing small -30-volt units.

The blades can be chosen from metal, PVC or even wood. Please note that metal turbines will be quite heavy; to install them, you will need to mount a powerful support. The tree is not suitable for year-round work. fresh air, That's why the best option The blade is made of PVC. To make turbines out of them, you need to cut the pipes in half, then make the following holds in quarters and on the bases, as in the photo:

Photo - finished PVC blades

Many craftsmen make blades using neodymium magnets. This approach does not affect the fundamental parameters of the generator, but helps you reduce power losses. Advice: Using these additional parts, you can make a portable wind generator, for example, to charge a phone or laptop. Just remake the rotary Chinese fan– attach magnets to its blades. Such a homemade product will be an excellent example of a perpetual motion machine.

Photos - whole PVC pipes

Photo - PVC pipes cut in half

Photo - finished PVC blades

Now you need to create a stand for the blades yourself. Any plate or even an old gear will do. We drill several holes in it, two per blade, and attach them with bolts.

Photo - gear stand

On top of the blades we attach hubs, which can also be made from gears. This area should be covered with a lid on top to protect it from water. Now you need to make a tail for the windmill by attaching the engine to it. To create this design, you will need a small wooden block, to one side of which a previously purchased engine is mounted, and to the other - a shank. This plate can be made of aluminum or stainless steel. When the system is ready, the propeller is attached to it. This concludes the production of the upper part wind generator completed.

Photo - installation of a wind generator

Next, all that remains is to build the base for the generator. We install the pole in the chosen location, fill it with mortar for strength, and mount a propeller on top. So, using improvised means, you can make a compact and household wind generator with your own hands.

Price overview

Not all masters have enough time for independent work. Therefore, it is easier to buy a ready-made wind generator, the price of which depends directly on your needs. The devices are sold in all cities of the CIS.

The cost of mini-devices is much less, it varies between 100-400 USD. Let's consider how much a windmill with 6 blades and voltage up to 30 V costs:

Many manufacturing plants offer additional services when purchasing equipment: delivery, installation, configuration. Write in the comments your reviews about the operation of wind generators, as well as tips on their construction.

Until recently, wind generators were considered a rarity, but today this area It is developing rapidly, and many people have gained experience in creating wind turbines to generate electricity. Such devices can be used in the most different areas– for water supply, electrification of private houses, operation of agricultural units (for example, crushers) or heating water for home heating.

Industrial models have many advantages, except for cost. Therefore, today we will find out how to make a wind generator with our own hands and what materials/tools will be needed for this.

Design features and mechanics of a wind generator

The principle of operation of a wind generator is to convert kinetic energy into electricity. The device consists of a number of system elements, each of which has its own function. Let's try to figure this out.

Note! Wind generators can be rotary (vertical) or classic (horizontal). The latter have a higher efficiency, which is why they are made more often than others.

It is worth noting that vertical windmills must be turned towards the wind, because they are simply unable to function with a side flow. Horizontal generators have other advantages. Let's get to know them.

- Turbines of rotary devices will “catch” the wind regardless of which direction it blows from. Which is extremely convenient in case of unstable/variable wind in the region.

- It is much easier to build a horizontal windmill than a horizontal one.

- The structure can be located directly on the ground, but provided that there is enough wind there.

As for the disadvantages, a horizontal wind generator has only one - a rather low efficiency.

Calculating the power of the future wind generator

First, you should find out what power a wind generator should have with your own hands, what are the functions and loads that it will face. Usually, alternative sources electricity are used as auxiliary, that is, intended to assist the main power supply. Therefore, if the system power is even 500 watts or more, this is already quite good.

Note! To heat a private house, which is of medium size, you will need about two to three kilowatts.

At the same time, the final power of a wind generator depends on other factors, including:

- wind speed;

- number of blades.

To find out the appropriate ratio for fixtures horizontal type, we recommend that you familiarize yourself with the table below. The numbers in it at the intersection are the required power (indicated in watts).

Table. Calculation of the required power for horizontal wind generators.

| 1m | 3 | 8 | 15 | 27 | 42 | 63 | 90 | 122 | 143 |

| 2m | 13 | 31 | 63 | 107 | 168 | 250 | 357 | 490 | 650 |

| 3m | 30 | 71 | 137 | 236 | 376 | 564 | 804 | 1102 | 1467 |

| 4m | 53 | 128 | 245 | 423 | 672 | 1000 | 1423 | 1960 | 2600 |

| 5m | 83 | 166 | 383 | 662 | 1050 | 1570 | 2233 | 3063 | 4076 |

| 6m | 120 | 283 | 551 | 953 | 1513 | 2258 | 3215 | 4410 | 5866 |

| 7m | 162 | 384 | 750 | 1300 | 2060 | 3070 | 4310 | 6000 | 8000 |

| 8m | 212 | 502 | 980 | 1693 | 2689 | 4014 | 5715 | 7840 | 10435 |

| 9m | 268 | 653 | 1240 | 2140 | 3403 | 5080 | 7230 | 9923 | 13207 |

For example, if in your region the wind speed is predominantly from 5 to 8 meters per second, and the required wind generator power is 1.5-2 kilowatts, then the diameter of the structure should be approximately 6 meters or more.

What should the blades be like?

The shape of the blades can be:

- sailing;

- winged

As for sail-type blades, they are flat and therefore less efficient. They do not take into account aerodynamics, but spin exclusively under the pressure of the wind flow. As a result, no more than 10 percent of all energy is converted into electrical energy. But for wing blades, the area of the internal and external surfaces is different. It is also worth noting that such blades should be located at an angle of 7-10 degrees relative to the wind.

Now a few words about the material from which the blades should be. For vintage windmills Tonic frames made of wood were used, consisting of poles and lintels. Special “wings” made of fabric were stretched onto such frames. If the fabric wore out, it was simply replaced with a new one. Although there is Alternative option– take dense materials (for example, tarpaulin) for these purposes.

Although you can make blades with your own hands from more modern materials.

- If the propeller is small, then cut polyvinyl chloride pipes can serve as blades for it.

- You can also use light metals (for example, duralumin).

- If you plan to use “sails,” they can be cut from plywood.

- Finally, for a large unit, the blades can be made from boards (even if they are heavy, it doesn’t matter, they just need to balance each other).

Note! If gusty winds prevail in the region, it is better to give preference to heavy blades - this will ensure more stable operation of the entire system.

As for the diameter of the pipes, it should correspond to 1/5 of their total length. Each of these pipes is cut lengthwise into four pieces, and at the base it is necessary to cut a rectangle measuring 5x5 (the fastenings will be located here), and after that, make an oblique cut, thanks to which each blade will taper from the base. For processing torn edge emery is used.

Making a vertical wind generator at home

Now let’s find out how to actually make a wind generator with your own hands. The procedure consists of several stages; let’s get acquainted with the features of each of them.

Stage one. We prepare tools and materials

There are no requirements regarding the size of the turbine - the larger it is, the better for the system itself. And in the example given in this article, the diameter of the turbine is 60 centimeters.

To do vertical turbine yourself, prepare in advance:

- a pipe with a diameter of 60 centimeters, made of of stainless steel;

- screws, nuts and other fasteners;

- a pair of plastic disks with a diameter of 60 centimeters (it is important that the plastic is durable);

- a hub from a car for the base;

- corners with which the blades will be attached (six pieces for each element; that is, 36 copies in total).

In addition, take care of the following tools in advance:

- keys;

- jigsaw;

- mask;

- protective gloves;

- Bulgarian;

- screwdriver;

- electric drill.

To balance the blades, magnets or small metal plates. If the imbalance is minor, you can simply drill holes in the appropriate places.

Stage two. Makes a drawing

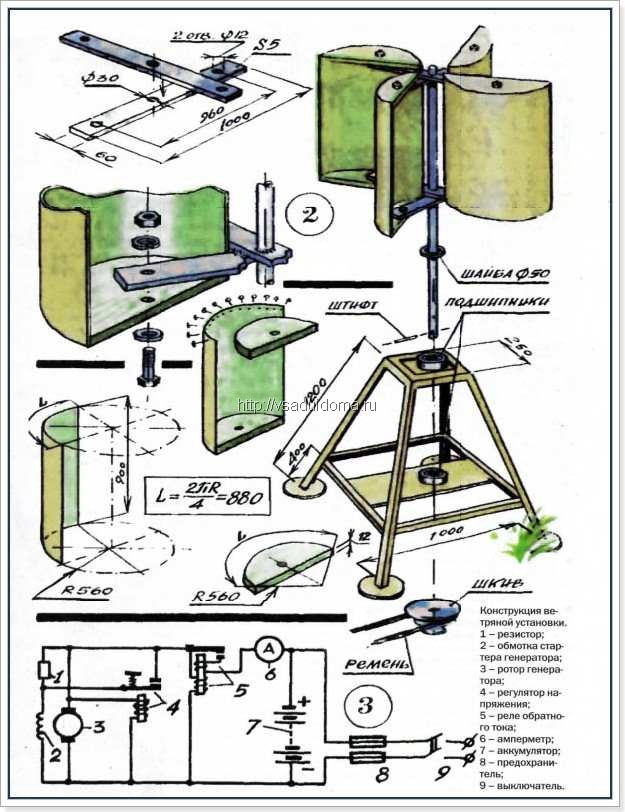

You definitely can’t do without a drawing here. You can use the one below or create your own.

Stage three. Making a vertical windmill

Step 1. First take metal pipe and cut it lengthwise so that you end up with six blades of the same size.

Step 2. Cut a pair of identical circles with a diameter of 60 centimeters from plastic. They will serve as supports for the lower and upper parts of the turbine.

Step 3. You can cut a small hole in the upper support (about 30 centimeters in diameter), which will make the structure somewhat lighter.

Step 4. Mark along the holes on the car hub similar holes in the lower plastic support required for fastenings. Use a drill to make holes.

Step 5. Mark the location of the blades in accordance with the template (you should get a pair of triangles that seem to form a star). Mark the mounting locations for the corners. Everything should be the same on both supports.

Step 6. Trim the blades. You can cut them several at a time using a grinder.

Step 7 Mark the mounting locations on the blades and corners. Make all these holes.

![]()

Step 8 Connect the blades to the bases using angles, bolts and nuts.

Note! The power of the device largely depends on the length of the blades, but if the latter are large, it will be much more difficult to balance them. Moreover, the structure can become loose under the influence of strong winds.

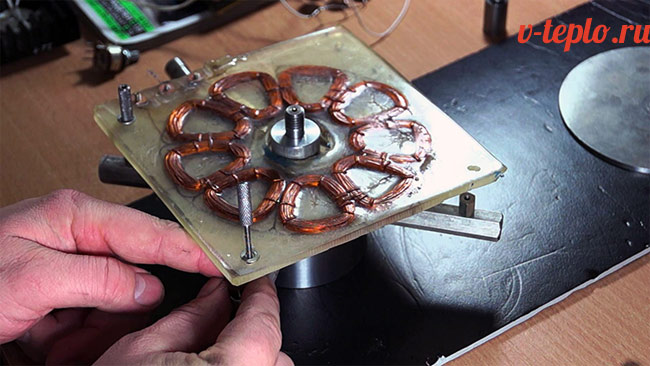

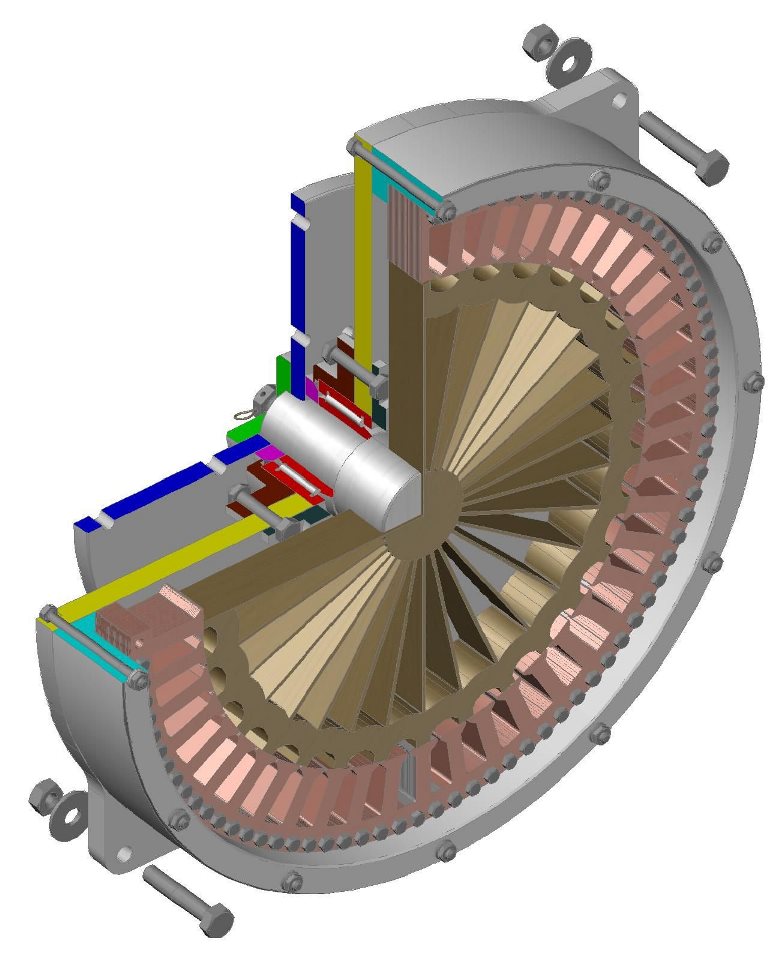

Stage four. We make a generator

Generator in in this case must be self-exciting, and necessarily on permanent magnets. If you take a regular generator from a car, then the voltage winding here operates from the battery, in other words, in the absence of voltage there will be no excitation. Consequently, if you use a simple generator in tandem with a battery, and the wind is relatively weak for a long time, the battery will soon simply discharge, and later, when the wind returns, the wind generator will not start again with your own hands.

It is also possible to make a system using neodymium magnets. This kind of device will produce from 1.5 kilowatts (if the wind is weak) to 3.5 kilowatts (if the wind is strong). Step-by-step instruction to create such a generator is as follows.

Step 1. Make a couple of metal pancakes, each about 50 centimeters long.

Step 2. Using superglue, glue neodymium magnets measuring 2.5x5.0.12 centimeters (twelve pieces for each) to the pancakes around the entire perimeter.

Step 3. Place the pancakes opposite each other, remembering the polarity.

Step 4. Place a home-made stator between them (make 9 coils from wire with a cross-section of 0.3 centimeters, each with 70 turns). Connect the coils with an asterisk (as shown in the image), and then fill them with polymer resin. In this case, it is important that the coils are wound in one direction; you can mark the end/beginning of the winding using a colored isolette - this will be more convenient.

Step 5. The stator should be about 2 centimeters thick. The winding should come out through bolts and nuts. The distance between the rotor and stator should be 2 millimeters.

The magnets will be attracted quite strongly, and for a smooth connection it is necessary to make holes in them and cut threads for the studs. Immediately align the rotors, then use the keys to lower the upper one onto the lower one. Then you can remove the temporary pins.

Note! The generator described above can be used not only for vertical, but also for horizontal windmills.

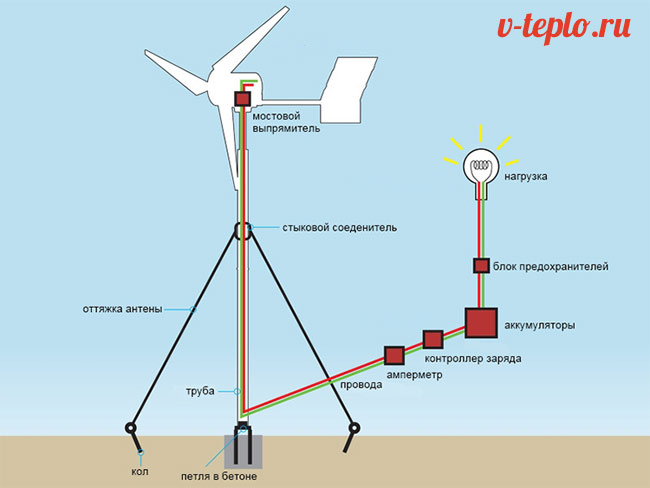

Stage five. We assemble the entire structure

First, install a special bracket on the mast, through which the stator will be attached (which, in turn, can have either three or six blades). Fix the hub above the bracket using the same nuts. Screw the finished generator onto the four studs located at the hub. After this, connect the stator to the bracket, which is fixedly fixed on the mast. Attach the turbine to the second rotor plate. Connect the stator wires to the voltage regulator using terminals.

Stage six. We install a unit that can turn wind into electricity

To install the entire wind generator with your own hands, you need to follow the steps below in the form of step-by-step instructions.

Step 1. Concrete a reliable and durable foundation in the ground.

Step 2. Pouring there concrete mortar, add the studs necessary to attach the massive hinge (all this can be easily done by hand).

Step 3. When the concrete has completely hardened, place the hinge on the studs and secure with nuts.

Step 4. Install the mast into the moving part of the hinge.

Step 5. Attach 3 or 4 guys to the top of the mast (you can use a flange or welding). You will also need a steel cable.

Step 6. Raise the mast on a hinge using one of the prepared cables (you can pull it using a car).

Step 7 The verticality of the entire mast is strictly fixed by guy wires.

Where can such a wind generator be installed?

The efficiency of its operation largely depends on how correctly you choose the place to install the wind generator. The location should be such that the system blades get as much large quantity wind. The site should be open and elevated (for example, the roof of a house, but as far away from trees and other buildings as possible). Typically, the reason for this lies not only in interference, but also in the device making some noise during operation, which may not be liked by neighbors or the owners themselves.

For a more detailed understanding of the problem, we recommend that you watch the thematic video below.

Video - How to make a wind generator using a household fan

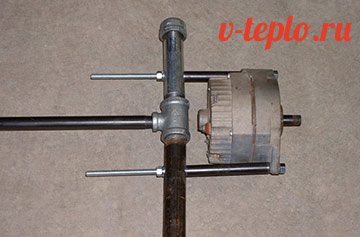

Rotary (horizontal) wind generator

Such a device will cope with the provision of electricity small house or several outbuildings. The maximum power of the wind generator will not exceed 1.5 kilowatts.

For work, prepare:

- 12 watt car generator;

- relay, battery indicator light;

- the battery itself is 12 watts;

- current converter;

- a large pan or bucket made of duralumin or stainless steel;

- a pair of clamps for attaching the generator to the mast;

- switch;

- wire, 0.4 and 0.25 centimeters;

- bolts, nuts, washers;

- voltmeter.

The tools you will need are the same as in the previous case. First, take a pan (or bucket) and, using a marker and tape measure, divide it into four equal parts. Cut out the blades, but do not cut all the way (as shown in the picture).

Make holes for the bolts in the bottom, then bend the blades, but not too much. Take into account the fact how the generator will rotate (clockwise or counterclockwise).

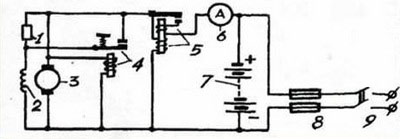

Next, attach the pan with the prepared blades to the pulley and secure it with bolts. Install the generator on the mast, fixed in advance (to do this, use the supplied clamps), then connect all the cables and assemble the circuit. Rewrite the entire circuit, fix the wires on the support.

To connect the battery, use a 4mm cable with a maximum length of 1 meter. To connect the load, use a cable with a smaller cross-section. Also install an inverter. Below is approximate diagram connections.

As you can see, it is quite possible to build a wind generator with your own hands. The design can be of two types, but if you have the skills and proper zeal, you can handle the work even alone. That's all, good luck!

Do-it-yourself vertical wind generator, drawings, photos, videos of a wind turbine with a vertical axis.

Wind generators are divided according to the type of placement of the rotating axis (rotor) into vertical and horizontal. We looked at the design of a wind generator with a horizontal rotor in the previous article, now let’s talk about a wind generator with a vertical rotor.

First of all, let's look at the advantages and disadvantages of a vertical windmill.

Advantages:

Low noise level - wind, the wheel makes virtually no noise and does not interfere, there is no characteristic whistling of the propeller.

Simplicity of design - making such a wind generator and installing it will not be particularly difficult.

Reliable design - all components are compact and easy to maintain.

Flaws:

The main disadvantage of the design of a wind generator with a vertical rotor is its low speed; such a wind turbine must be installed in an area with a prevailing wind speed of more than 4 m/s.

There is practically no protection from hurricane winds - if in a horizontal windmill during a hurricane, the folding tail is automatically activated and turns the wind wheel, then in such a design you need to manually jam the rotor, or, as an option, close the contacts at the output of the coils.

First of all, if you decide to make a windmill with a vertical axis, you need to decide on a generator.

Since the vertical wind generator is low-speed, you will therefore need a generator capable of charging the battery at sufficiently low speeds.

A car generator is not entirely suitable for this design, since it produces charging current at speeds of more than 1000 rpm. For a car generator, you need to use a pulley with a gear ratio of 4 - 5 and modify the generator itself.

It is more practical to use an axial generator as a generator; you can make it yourself; the manufacturing process is described in this.

Scheme of an axial generator for a wind generator.

Manufacturing a wind wheel for a vertical windmill.

A wind wheel (turbine) consists of two supports, upper and lower, as well as blades.

The wind wheel is made from sheets of aluminum or stainless steel; the wind wheel can also be cut from a thin-walled barrel. The height of the wind wheel must be at least 1 meter.

In this wind wheel, the bending angle of the blades sets the rotation speed of the rotor; the greater the bend, the greater the rotation speed.

The wind wheel is bolted directly to the generator pulley.

For installation vertical wind generator You can use any mast; the manufacture of the mast is described in detail in this article.

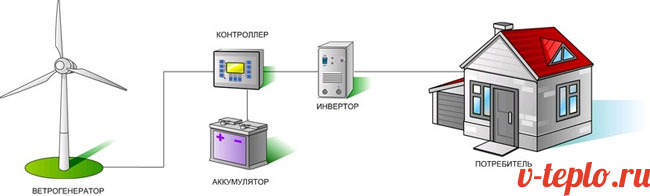

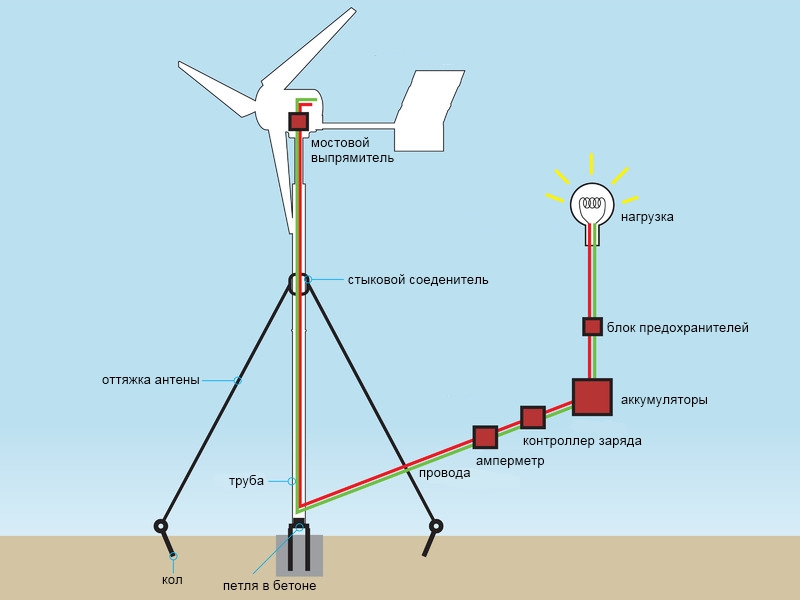

Wiring diagram for wind generator.

The generator is connected to the controller, which in turn is connected to the battery. It is more practical to use a car battery as an energy storage device. Since household appliances run on alternating current, we will need an inverter to convert 12 V DC to 220 V AC.

For connection, a copper wire with a cross-section of up to 2.5 square is used. The connection diagram is described in detail.

Vertical wind generator in operation video.

Popular articles from this section

Solar collectors for home

How to connect a solar panel

How to install solar panels

Wind, as an endless source of energy, is becoming increasingly widespread. This source of alternative energy is especially popular in remote regions (for example, Taiga) and at polar stations. In addition, household wind generators are increasingly being manufactured by suburban residents. What types of windmills exist and how to assemble a device for converting wind energy with your own hands - read below.

What is wind generation based on?

Wind generation is the ability to generate electricity from wind energy. A wind generator is, in fact, a solar generator: winds are formed due to uneven heating of the Earth's surface by the sun, the rotation of the planet and its topography. Generators use motion air masses and convert it into electricity through mechanical energy.

On average, one 20 kW wind turbine can provide electricity to one small village.

Based on the principle of wind generation, an entire power plant can be built, as well as standalone devices to provide electricity to certain areas and even houses. Today, 45% of all energy is generated using wind generators. The largest wind power plant is located in Germany, and each year produces up to 7 million kW of energy per hour. Therefore, increasingly, owners country houses in remote regions and villages they are thinking about using wind energy for domestic purposes. At the same time, wind turbines can be used as the only or additional source of energy.

Wind generator: principle of operation, types of devices

Most wind turbines consist of a steel tower - a mast, at the top of which three blades are attached. A modern household wind turbine of 5 kW of the second magnitude can easily generate up to 5000 W of electricity. This is quite enough to provide electricity to a residential building or cottage. Axial generator produces up to 500 W/h. The world's most powerful wind generator - 8 MW.

A modern wind turbine may have:

- Horizontal axis of rotation;

- Vertical axis of rotation.

A horizontal windmill has an axis that rotates parallel to the ground (like a regular windmill). Vertical wind turbines can have both blades and rotors that move parallel to the ground.

Rotors can vary in shape and size, and are divided into:

- Savonius devices (rotors are made in the form of semi-cylinders);

- Ugrinsky rotors (improved semi-cylindrical type rotors);

- Daria rotors (can be helical, curved or H-shaped);

- Multi-bladed wind generators (used in rotary-type wind turbines);

- Helicoid rotors (have a cone rotor).

Often vertical wind generators are spinning top-shaped (an example is the Genghis Khan rotary wind generator). Most effective device A multi-bladed top-type design is considered in its group.

Homemade wind generator: advantages and disadvantages

Installing a wind turbine may be necessary if there is no electricity supplied to your site, there are constant interruptions in the power transmission network, or you want to save on electricity bills. A windmill can be purchased, or you can make it yourself.

A homemade wind generator has the following advantages:

- It allows you to save money on the purchase of a factory device, because production is most often made from scrap parts;

- Ideally suited to your needs and operating conditions, because you calculate the power of the device yourself, taking into account the density and strength of the wind in your region;

- Blends better with home decor and landscape design, after all appearance windmill depends only on your imagination and skills.

To the disadvantages homemade devices This can be attributed to their unreliability and fragility: often homemade ones are made from old engines from household appliances and cars, so they quickly fail. At the same time, in order for a wind turbine to be effective, it is necessary to correctly calculate the power of the device.

How to make a windmill with your own hands

In order to make a wind generator with your own hands, you should know exactly what parts exist in its design and what they are responsible for. This way you can understand how to replace some parts that are difficult to find at home.

Any wind turbine has in its design:

- Blades that rotate;

- Electric generator producing alternating current;

- A controller is a device that transforms mechanical energy from the blades to the current;

- Inverter is a device that converts direct current into alternating current;

- Rechargeable batteries;

- Mast.

A simple small windmill can be made using household fan. Some craftsmen adapt an old one into a mini-windmill computer cooler. True, the power of such a wind blower will not exceed 100 W. When a wind generator with a power of 5 kW is needed to power small and medium-sized houses, and for commercial facilities – 10 kW.

Do-it-yourself electric generator: calculating the power of the device

The manufacture of any windmill for private use begins with preparatory stage– calculation of device power. So, for example, to operate water heating, you will need to install a windmill at least 5-6 meters high. At the same time, it is not possible to use only wind energy for heating: the wind speed is quite changeable. But as additional source, which will save money, you can use the wind.

To do this, you can use numerous formulas that are presented on the Internet. Most simple solution will use a calculator that calculates the wind force yourself. In this case, you will only need to enter into the program required values. Most often these are: the area over which the wind blows, the density and speed of the wind.

You can find out the average speed of air masses in your region by contacting the weather service.

In addition, for work you will need electrical diagram windmill, detailed design drawings that can be drawn on a regular sheet of paper or visualized using computer program for 3D modeling.

Which generator to choose for a windmill

Domestic windmills should be low noise. Therefore, it is better to use a low-speed (low-speed) engine as a generator for wind turbines. Such an engine is capable of making from 350 to 700 revolutions per minute. In addition, a low-speed motor can be used even on a single-blade windmill. Also, a low-speed generator can be made from a stepper motor.

To increase the speed of the windmill, you can use a multiplier: it will speed up the rotation of the blades by 5-10 times.

Disc motors with neodymium magnets are especially popular. Magnets, in this case, can be different sizes and, accordingly, power. The manufacture of such a generator is quite simple, but its cost is quite high.

In order to start the propeller, you can use a pedal bicycle generator.

Many people make a low-power generator from a gas generator, a car or tractor generator, or a battery from a screwdriver. It should be taken into account that on a design with a generator from a tractor and a car generator, it will be necessary to install a gearbox that reduces the speed.

Do-it-yourself wind generators for 220 V

In order to assemble a wind catcher we will need: a 12 volt generator, batteries, a converter from 12 v to 220 v, a voltmeter, copper wires, fasteners (clamps, bolts, nuts).

The manufacture of any windmill involves the following steps:

- Manufacturing of blades. The blades of a vertical wind generator can be made from a barrel. You can cut parts using a grinder. A propeller for a small windmill can be made from a PVC pipe with a cross-section of 160 mm.

- Making a mast. The mast must be at least 6 meters high. At the same time, in order to prevent the twisting force from tearing off the mast, it must be secured with 4 guy wires. Each guy rope needs to be wound around a log, which should be buried deep in the ground.

- Installation of neodymium magnets. Magnets are glued to the rotor disk. It is better to choose rectangular magnets, in which the magnetic fields are concentrated over the entire surface.

- Winding generator coils. Winding is performed with a copper thread with a diameter of at least two mm. At the same time, there should be no more than 1200 skeins.

- Fixing the blades to the pipe using nuts.

In the presence of powerful batteries and an inverter, the resulting device will be able to generate an amount of electricity that will be sufficient for use household appliances(for example, refrigerator and TV). Such a generator is perfect for maintaining the operation of lighting, heating and ventilation systems of a small country house, greenhouses.

DIY wind turbines 5 kW (video)

A wind turbine is safe, modern device, which allows you to transform wind energy into electricity necessary for the operation of household appliances, heating systems, water supply, and ventilation. With a little calculation, you can build a wind generator without professional help. The above can help with this detailed instructions, pictures and recommendations for choosing components!

Wind power plants- This is the most alternative option for saving electrical energy today.

Very often, such installations can be found in summer cottages.

People use them in places where suburban areas removed from the main electrical networks. But this is not the only reason. Most people use wind power plants for reasons of economy and autonomy.

Wind power plants have their own characteristics that potential buyers need to know, and how productivity depends on their competence.

The main incentive to purchase a wind generator- this is undoubtedly its expediency. One of the main criteria for achieving this goal is wind requirements. It is known that the average annual wind speed is about 4.0-4.5 m/s, this figure is more than enough for a home wind power plant to be profitable to use, that is, it makes it possible to save electricity.

To estimate the wind speed in your area, you can use a wind map. If you want to measure wind speed with maximum accuracy, you should purchase a special device that will help you with this.

This invention includes a part called an anemometer. With its help, you receive a signal equivalent to the speed of the wind. Also, you will need a device that reads the signals that the anemometer gives. There are other devices of this type.

In order for the data to be as accurate as possible, such devices must be installed high so that external factors, such as trees, various buildings, etc., do not distort the results of the device.

Device components

When purchasing home wind power plants, it is very important to know its components; this will give you the opportunity to be more competent in this matter and select the best model for your home.

The wind power plant includes:

- Rotor with blades(depending on the model, wind generators are divided into two-blade, three-blade and multi-blade).

- A gearbox, in other words, a gearbox. Its job is to regulate the speed between the rotor and the generator.

- Protective cover- its name speaks for itself; it is designed to protect all components of a wind power plant from external influences.

- "Tail" of a wind turbine- needed to rotate the structure in the direction of the wind.

- Accumulator battery– its main purpose is to accumulate electricity. This is due to the fact that weather conditions are not always favorable for a wind power plant, and with the help of this component a certain amount of energy is saved.

- Inverter installation– designed to convert direct current into alternating current. This is necessary to ensure the operation of household electrical appliances.

Types and principle of operation

Wind power plants are divided into types according to the following four criteria:

- In the direction of the axis of rotation of the blades(divided into horizontal and vertical. Vertical ones are more resistant to external conditions, but they have less electricity generation).

- By number of blades(in this case, wind generators are two-, three- and multi-blade).

- According to the material used(they are distinguished with rigid and sailing blades. The main difference is that sailing blades are cheaper, but they are less durable);

- According to the method of controlling the blades(they exist with fixed and variable blade pitch. Experts recommend a fixed blade pitch, since variable pitch causes difficulties in use).

When choosing a power plant, it would be advisable to know what the operating principle of the wind generator is. The operating principle of the installation is extremely simple. The design consists of a shank with blades mounted on a metal mast, which rotate with the help of the wind and spin the generator rotor.

Before current is supplied to the battery compartment, it passes through a converter, where alternating current is converted into direct current to a voltage of 220 volts with a frequency of 50 hertz and supplies the house with electricity in calm weather.

A modern wind generator does not need strong wind. Its design is so well thought out that for a private house a wind speed of up to 4 - 5 m/s is sufficient.

Advantages and disadvantages

The main advantages of wind generators:

- Costs go towards installation and maintenance of the device. No more expenses are required since the design does not require fuel to operate.

- You do not need to control or interfere with the operation of the windmill, since energy generation occurs whenever there is wind.

- Depending on the type of generator, it will not produce unnecessary noise.

- The device is suitable for most climate conditions.

- Part wear is insignificant.

The main disadvantages of a wind power plant:

- In certain modes or when incorrect installation masts, a wind generator can produce infrasound.

- High mast necessarily requires grounding.

- The need for regular prevention.

- Possibility of damage to the device during hurricanes, etc.

Selecting the size and location

The size of a wind farm is a very important issue for potential buyers. In order to decide on the size, you need to carefully study - how much energy do you consume in one month? The resulting figure must be multiplied by 12 months.

The size of a wind farm is a very important issue for potential buyers. In order to decide on the size, you need to carefully study - how much energy do you consume in one month? The resulting figure must be multiplied by 12 months.

Then, you need to use the formula: AEO = 1.64 * D*D * V*V*V.

Notations you need to know when using the formula:

- AEO- the electricity you use per year.

- D— rotor diameter, which is indicated in meters.

- V— average annual wind speed, indicated in m/sec.

So these calculations will help you determine what size generator you need based on your power consumption.

When thinking about purchasing a wind power plant for your home, you need to study as accurately as possible all the details associated with the design, since the extent to which your goal will be satisfied depends on this.

When placing a wind generator, you should consider the following factors:

- There should be no trees near your installation, various buildings and other things that could interfere with the maximum productivity of your generator.

- It is best to install the wind generator on a specially constructed structure, which should be a couple of meters higher than obstacles located at a distance of at least 200 meters.

- It is recommended to place wind power plants at a distance of about 30-40 meters from residential buildings , since they create a certain noise that brings discomfort.

Also, you must take into account that you will not be able to get the same result from your wind farm all the time, since natural conditions change, they can be in the same place different impulses wind, accordingly, the amount of energy you receive will be dynamic.

Price overview

In most cases, the price of wind power plants depends on their power. In domestic conditions, generators with a power of 5 to 50 kW are quite sufficient.

More details about the price ratio and types of generators:

- Wind generators with a power of 3 kW /48V– approximate cost RUB 93,000.00 These can be used not only as an additional source of power supply, but also as the main one. Such models are able to provide electricity to a cottage.

- Wind generators with a power of 5 kW /120V– approximately 220,100.00 rub. This design can provide energy whole house. You can simultaneously turn on a fairly large number of household electrical appliances.

- Wind generators with a power of 10 kW/240V– prices within 414,000.00 rub. It is enough to provide energy farm or several houses. In addition to household appliances, you can use, for example, electric construction tools all day long without any problems. Such power generators are often used for supermarkets to provide permanent job departments and video surveillance.

- Wind generators with a power of 20 kW/240V— the price of such a device is 743,700.00 rubles. Power plants of this type are very powerful. They are able to provide electricity to an entire water system. In domestic conditions, it will be able to more than fully provide energy to a huge house.

- Wind generators with a power of 30 kW/240V— cost within 961,800.00 rubles. This model is so powerful that it can provide electrical energy to a five-story building.

- Wind generators with a power of 50 kW/380V— approximate price about 3,107,000.00 rub. This model is not rational for use in domestic conditions, since it is so powerful that it can more than provide energy to several multi-story buildings.

When purchasing a home power plant, it is worth knowing that in most cases prices are indicated for complete set, but you can add or exclude certain components yourself. This is subject to your personal discretion.

Efficiency and payback

Wind power plants for home are alternative solution while saving energy. They have become quite widespread.

Wind power plants for home are alternative solution while saving energy. They have become quite widespread.

In order to provide energy to an entire house, it is enough to use one wind generator and at the same time not limit yourself by saving on electricity.

It is also beneficial that to obtain such an effect it is enough minimum speed winds from 1.8 to 4.5 meters per second.

But weather conditions are not always suitable for a wind generator, so you need to purchase a backup generator that will provide a reserve of energy. This will provide the opportunity to increase the productivity of your home wind farm.

Among positive aspects The following settings are worth noting:

- Having spent a large amount to the electric generator, you won't need to spend any more cash, since fuel is not needed to operate the device. That is, your purchase will be able to pay for itself within a few years.

- Wind generator performance does not depend on the time of year or others weather conditions, its work does not stop even in winter, which is undoubtedly a plus, since in winter time year, energy consumption is higher than in others. This fact undoubtedly testifies to its effectiveness and payback.

- Minor wear on generator parts, taking into account regular maintenance of the wind generator, which is necessary. With the correct and proper installation, as well as operating a wind power plant for your home, it can serve you for more than thirty years, which is undoubtedly a significant advantage.

Full payback period wind power plants is approximately 5-7 years, and then you will be able to use electricity absolutely free.