In the duct system plastic pipes for ventilation - this base element designs. They are made with thermal insulation and come in various profiles. Most best option- PVC ventilation pipes, which have round or rectangular sections. They are widely used not only in production, but also in residential premises or public buildings.

This is an alternative metal systems ventilation and are sales leaders in the building materials market.

Characteristics of quality and general use

Plastic ventilation pipes have many positive characteristics and are therefore in high demand. From positive qualities can be distinguished:

- Strength;

- Durability (resource more than 50 years);

- Corrosion resistance - 100%;

- Increased tightness of connections;

- Environmental friendliness;

- Ease of transportation and installation (important for high-altitude work) ;

- Low noise;

- Relatively low cost.

They can also be characterized as follows:

- Meet all standards of sanitary and hygienic requirements;

- Resistant to chemical reagents;

- Easily mounted in hard-to-reach places;

- Do not resist air flow;

- Do not require labor-intensive maintenance;

- Easy to process;

- Unprecedented form factor in production and color palette;

- They are visually aesthetic and easily integrated into the design.

Application capabilities and features

When developing a ventilation project, you can make it of any shape to suit the characteristics of the building. The tightness of the joints prevents air from leaking, and the use of appropriate sealants strengthens the tightness of the joints. The smoothness of the inner surface eliminates turbulence and resistance to the air flow. The interior has a high class of cleanliness. A roughness of 10 hundredths of a millimeter is already critical. This can be seen in ventilation made from other materials, as they have to be cleaned more often. You can use antistatic agents, this eliminates the attraction of dust. By treating the entire system with such a preparation, you get rid of cleaning work in the future. Thanks to these qualities of plastic, it is possible to install ventilation equipment of lower power. This will significantly reduce the cost of the design and make the ventilation system as silent as possible.

In domestic and residential premises, plastic pipes for ventilation usually provide an outlet carbon dioxide, kitchen steam and supply of fresh atmospheric air. In public spaces you can install an effective channel system conditioning. Using pipes, the cooled air from the air conditioner is evenly distributed throughout the entire building. This allows you to reduce the number of cooling units.

Thanks to various sections, plastic ventilation pipes can be installed indoors without fear of spoiling the external aesthetic appearance. For example, use flat-oval, rectangular or other desired sections in small space between the ceiling and the suspended ceiling. Thus increasing the volume of low rooms.

Beautiful appearance surface and profile allows you to make a ventilation structure without subsequent cladding to hide it. When designing, you can also count on a structure with non-standard curly bends, recesses and thickenings. Rectangular, square, oval design elements can be made to order. It's not difficult to do production conditions and using special equipment.

Material for making plastic pipes

For the manufacture of ventilation pipes, three types of plastic are used: polyurethane, polypropylene, polyvinyl chloride. Various small additives are also possible for coloring and product resistance to temperatures and chemicals. For example, PVC pipe UV resistant. Polyurethane is an extremely durable and elastic material. Its abrasive resistance is superior to other plastics and even metal. Resistance to deformation allows the use of polyurethane pipe in places with elevated temperature. And the use of additives saves the material from destruction after several dozen frosts.

Installation. Things to consider

To ensure the most optimal functioning of ventilation, you first need to determine the purpose of all parts of the system. Pipes, fittings, fasteners, material for each specific hood or duct, round, rectangular or combined sections, must be selected individually. The purchase of materials and installation should always begin only with the project. All features of the location, installation, operation of the system (room area, temperature conditions, humidity, element performance, acoustic discomfort). Everything must be taken into account to ensure normal life.

Round and rectangular pipes small diameters can make more noise than wide-profile ones.

The optimal cross-sectional area of the air duct at a flow speed of 3 m/s is determined by the formula a=25s. The cross-sectional area in square centimeters (a) and the air flow velocity (s) are related to a constant (25). Thus, optimal area cross section is equal to 75 sq. cm. And knowing school geometry (a=π*r²), now you can easily determine required sizes. The diameter of the plastic pipe will be 2.8 cm. And according to the diameter, a certain length is made. Rectangular pipes are calculated using a similar method.

For those who do not want to deal with such nuances and have other concerns, they can entrust this work to several installers. And in order not to redo it or something worse, it is better, of course, to leave the matter to specialists with knowledge of all such nuances and experience. After all, ignoring all the features can lead to premature breakdowns and failure of almost the entire structure. And also entail additional unforeseen expenses.

Installation features and disadvantages

Polymers have practically no fire resistance. In this case apply combined installation and additional blower fans for forced acceleration of air flow. Installation specialists ventilation systems Usually they combine plastic and galvanized metal, round, rectangular or other sections. Such combinations are used when installing extended systems from technical rooms through crowded places (fitness centers, clubs, restaurants, etc.).

The most popular plastic pipes have a cross-sectional size of 55-110 millimeters and a length of 0.5 to 1.5 meters. When installing connections and fastening, many special fittings are used:

- Adapter reducers;

- Couplings for connection;

- Check valves in connectors;

- Adapters for change round section to rectangular;

- Tees and splitters;

- Elbows for bends;

- Lattices.

Ventilation is always more effective if it is as close to a straight line as possible. And the cost of all the turns and the necessary fittings for this will significantly increase the final cost of the repair. Ventilation of a certain size has its interchangeable established forms, diameters and all components. When choosing the shape of plastic pipes, you should also take into account the fact that rectangular pipes resist air flow more than round ones. A technological process fastening and docking requires more hassle.

Before you start designing, you need to know all the disadvantages of plastic pipes:

- Low fire resistance (the main disadvantage) limits the scope of use. The ventilation system may not be accepted according to the inspection report by the fire service. This is the main reason for unpopularity at production sites;

- Not used to transport very hot air or steam;

- Labor-intensive installation. Installation technology requires necessary knowledge and skills, as well as a huge number of varieties of accessories and special fittings.

Ventilation made from plastic pipes has excellent characteristics and fully complies budget option the entire ventilation system. This will significantly reduce the overall construction cost and beautify the exterior and internal view building.

Lightweight, strong and durable plastic materials for ventilation helps consumers move away from metal analogues.

But, with all this, skeptical people raise doubts: is it true that plastic is as durable as metal?

Plastic pipes for ventilation, the dimensions and features of which must be studied before installation, will delight you with a wide range of excellent characteristics. Due to these properties, these products are very popular.

Ventilation network from of this material can last more than 50 years. For fast air circulation, this is the best option.

The costs of purchasing and installing plastic pipes will be much lower than metal ones. It is also worth highlighting their aesthetic appearance and ease of maintenance.

Pipes in such systems:

- not prone to color change;

- do not corrode;

- easy to install;

- durable;

- acceptable price;

- flexible.

The ventilation system is difficult process indoor air exchange. It works this way: the air in the room (whether living room, office or production workshop), is displaced clean air- from outside (outside).

Only now the ventilation system can include not only the air exchange process itself, but also thanks to modern systems air conditioning, ionization, cooling and heating, humidification and dehumidification and other useful functions are also added.

The ventilation system also means the entire so-called “material part”: ventilation devices, hoods, fans, as well as pipes (which, in turn, are divided into round or square/rectangular sections), which are also an element of this system.

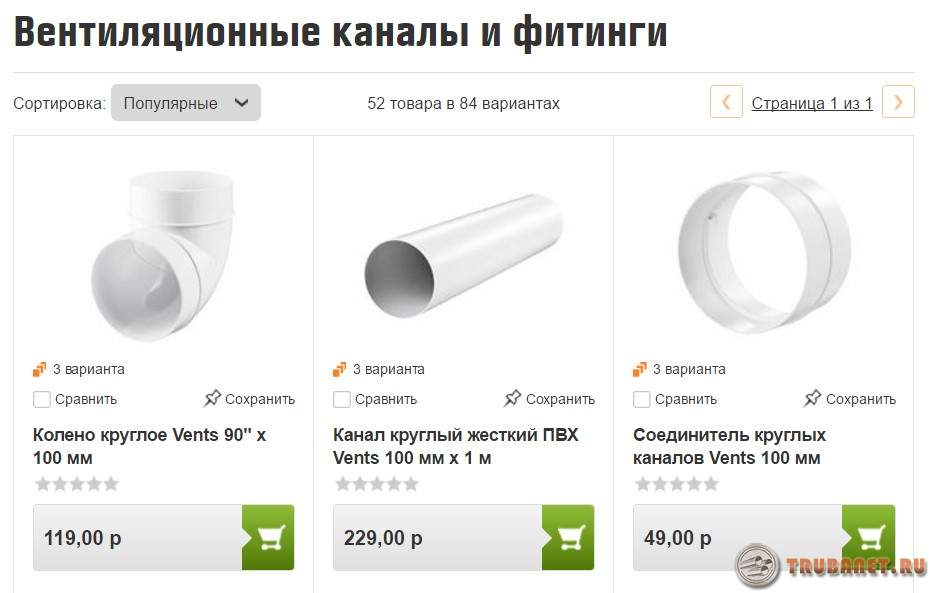

Let's take a look at the common sizes and their prices. Rectangular duct dimensions: 11 x 5.5 cm; 12 x 6 cm; 20.4 x 6 cm. Round diameter: 10 cm; 12.5 cm; 15 cm.

According to GOST, the air duct is produced with a size internal section from 10 to 200 cm. Traditional ventilation size for kitchen hood similar to the dimensions of a rectangular one.

Price of rectangular and round ducts on average will cost from 400 rubles and below, and you can purchase them at any construction supermarket.

At construction companies you can place an order for a round and flexible air duct. A flat PVC channel system will cost from 100 rubles.

Price for flexible and plastic version– this is approximately 320 rubles.

Ventilation system with a diameter of 12.5 cm

The main task of ventilation is to provide outflow or influx air. High strength of these products is not required, but their low weight is ideal for such a task.

This is very important when you have to install it not on a permanent wall, but on a decorative partition, or above a suspended ceiling.

Pipes with a diameter of 125 mm are used in a standard length of 5 meters. Longer workpieces are difficult to stack and transport. 125 pipes are most often used for the ventilation network in residential premises.

Pipe-rolling materials are joined very easily - they are simply inserted into the socket of another workpiece.

The throughput capacity in this case is 400 m/h. These are the most optimal indicators for domestic needs, which create the necessary air circulation and do not create unnecessary noise during operation.

How to calculate dimensions and cross-section

Various fittings are produced for laying, which makes it possible to connect several sections into a single whole.

Sealants help seal joints by preventing air from escaping at the joints.

Fastening of such a structure is carried out with fasteners. They are on sale in a large assortment.

It is recommended to choose plastic pipes for ventilation and their sizes depending on the type, purpose and length of the structure itself. The type, cross-sectional index, length and placement are determined at the design stage.

At the design stage, the performance of all system components is calculated. If this is not done, problems may arise in the form of insufficient air circulation or loud noise during operation.

The cross-sectional area of the channel for an air speed of three meters per second is calculated by the formula: S = 0.9 x L. In it, the designation S is the cross-sectional area, and L is an indicator of air speed.

An incorrectly selected diameter will cause components to quickly fail. And repairing those connected to the system will cost a decent amount.

Section

When installing plastic air ducts for ventilation, the cross-sectional dimensions must be selected accurately. They are an important characteristic in in this case. This selection is made depending on the location of the network.

For example, if the main floor and the ceiling are separated by a short distance, then a flat-oval type of air duct is recommended. Its design is not much different from the round system.

Air purification takes place with the same intensity. But, it should be noted that plastic structures with an oval cross-section do not create adequate resistance to air flow, as a result of which it passes easily and the engine does not operate under high load.

Actually the only downside would be it's a high cost. But this is justified by the need to use exactly this form based on design features premises.

Ventilation ducts

Plastic ventilation ducts fit harmoniously into interior design premises.

And the presence of a visor adds elegance and sophistication. This element allows you to hide not only flat, but also round channels.

They are used not only in everyday life. This type of duct is often used to construct an exhaust duct in offices and small commercial premises.

TO merits can be attributed.

- Smooth surface outside and inside.

- High strength index.

- High connection rate.

- Simplicity and ease of cleaning the surface.

- Presentable appearance.

TO shortcomings This design is due to its high cost when compared with galvanized and flexible options. This also includes the limitation of manufactured PVC diameters channels.

Flat ducts

Rectangular plastic pipes are used for laying flat plastic systems.

Their purpose is as follows.

- Creation of networks of supply and exhaust facilities for small and medium-sized premises.

- For constructing a flat outlet channel.

- For supplying exhaust and ventilation equipment.

Design features.

- Made from environmentally friendly material High Quality, which is not subject to combustion.

- Wide temperature range of use (from -30 to +70 degrees).

- Low resistance to air flow.

- Long service life.

- Slight noise during operation.

- Economical use of space between the ceiling.

- Wide range of choices when searching for standard size and rating of flat pipe materials.

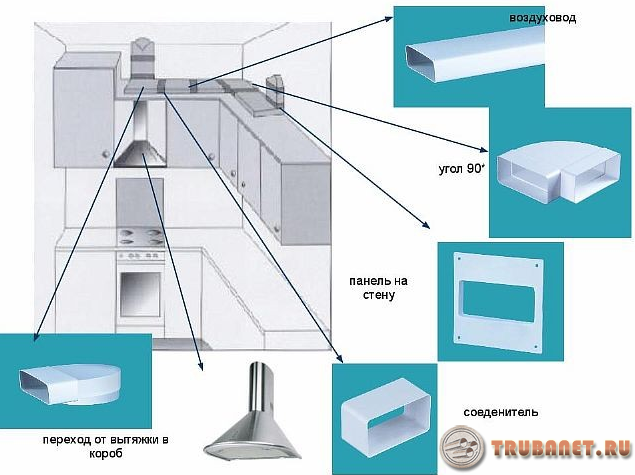

Connecting elements and fittings

Plastic ventilation is easy to assemble; this is facilitated by fittings that greatly simplify this process.

The air duct network is constructed into a single modular structure using connecting parts according to the scheme for working with a children's construction set.

These modules are divided into the following types:

- Connectors. They are intended for direct fastening of parts of the same type and size. For example - this rectangular duct made of plastic 6x12 cm with a similar 6x12 cm (SKP 612). Also elbows for fastening networks of the same type and dimensions at an angle (KKP 12.5 or KRP 612).

- Gearbox. They are installed for the same type of network, but of different sizes.

- Adapter. This part serves to fasten various sections of different sizes.

- Splitter (tee). Installed to divide the system into separate branches.

- Flange and cover. Such elements are installed when attaching the system to the ventilation hole.

- Holder. Mounted for fastening to walls and other surfaces.

Modular network fittings fit perfectly one to another and do not cause difficulties during installation.

Fittings do not spoil the appearance of the structure in its visible areas. Connecting elements They help hide the air duct in niches or run it unnoticed, for example, above a kitchen unit.

Fittings in the ventilation network made of rectangular pipe materials allow it to be located inside a plasterboard partition or behind suspended ceilings without much difficulty.

Correctly selected pipes allow you to create a beautiful and reliable modern ventilation system. Thanks to the large number of positive characteristics of plastic, it will serve for a long time effectively and uninterruptedly.

Selecting the material from which the pipes will be made

So, let's imagine the situation. You moved to new house. Ventilation in the home is a very important issue.

There are several types of air ducts: plastic and metal (including metallized galvanized and others).

Owners of residential premises are giving less and less preference to metal pipes.

This is understandable: the material is less wear-resistant than plastic, difficult to process, weighs a lot and, if fastened unreliably, even poses a danger to others.

So metal air ducts mainly used in non-residential premises and various industries. Plastic ventilation pipes are the most popular material for a “home” system.

Moreover, the plastic for air ducts also varies. The most common materials are PVC (polyvinyl chloride), polypropylene, polyethylene, polyurethane and some other materials of similar type and composition.

Advantages of plastic ventilation systems

Don't worry about internal state Your ventilation communications - many are afraid that plastic pipes retain a static charge, and as a result, dust, dirt, fluff, debris, insects, and light household waste become electrified and settle on the inner surface of the ventilation pipeline.

Only in reality there is no dense layer of dirt and dust there, because manufacturers take care of those who will use their products in advance. How, you ask?

Everything is extremely simple - one of the most important processes in the production processing of products is the so-called “antistatic” treatment.

Simply put, plastic pipes, both outside and inside, are treated with an antistatic agent so that no particles stick to inner surface. Safety for the client’s health – most important aspect for air duct manufacturers!

And one more “myth”: the owners of residential premises are afraid that the plastic may melt under the influence of high temperatures and will even “drip” into your kitchen, creating a health hazard for those living in the apartment.

Well, this option seems completely fantastic, and here’s why: first of all, the minimum temperature threshold that plastic pipes can withstand for ventilation is at least 80 degrees Celsius.

No matter how hard you try, you will not be able to create such high temperatures in the kitchen, unless, of course, you yourself create a threat to your health and the health of your loved ones, for example, by lighting a small fire in the kitchen.

And one more thing - all manufacturers also care about your safety, therefore, in addition to antistatic treatment, they use a layer of special fire-resistant compounds to treat the products.

Moreover, modern production plastic products It has already reached the point that special fire-resistant compounds are used not only in the processing of finished plastic, but also in its direct creation!

That is, the plastic product already contains a fire-resistant layer of substance, which will create safety for you and your ventilation!

Where ventilation and exhaust are needed

Now we will discuss directly where it is necessary to install ventilation systems and hoods in a residential area. Exhaust/ventilation must be installed in the kitchen (in the dining room) and in the bathroom (as well as in the toilet, if the bathroom is separate).

The logic is clear: it is necessary to remove hot air from the kitchen (which will always be there, because there is a stove working there, as well as many electrical appliances), food odors, burning, soot, unpleasant odors and others.

In the kitchen, you can use air purifiers with various filters (including carbon, etc.), as well as a hood, which you install directly above the stove (gas/electric) and duct it through a pipeline into the main ventilation.

There should be no humid air or outsiders in the bathroom and toilet. unpleasant odors, so it is also necessary here. Additional devices for ventilation in the bathroom are not required, but there must be an outlet for ventilation.

Combined ducts

Once every two weeks, it is recommended to carefully wash the air intake grille and clean it of accumulated dust.

By the way, when installing ventilation you can use not only plastic or only metal air ducts.

Firstly, these can be combined options - with metal components such as couplings, clamps or the air intake grilles themselves.

And secondly, there is another common type of pipes for ventilation - corrugations. The corrugation is not used as a solid pipeline, but rather as another element such as an adapter unit.

Simply put, if vent Due to the circumstances and the location of the appliances in your kitchen, it is not above the stove and hood, but away from them, then corrugation will help you here.

A distinctive feature of corrugation is its versatility and the “spring” principle, which allows you to smoothly connect pieces of pipe with corrugation, turning them as you like and without making angles of more than 90 degrees.

After all, if during installation you create too right an angle, this will be a serious loss in the air exchange process.

Each 90-degree angle not only “slows down” the air flow, but also significantly reduces the productivity of the ventilation process itself - by 10-15% or more!

Your task is to simplify the installation of your ventilation as much as possible and create ideal conditions for the air exchange process. So corrugation is an excellent “helper” for connecting plastic elements.