In the production of kitchen countertops or other surfaces, laminated chipboard has recently been most often used.

Chipboard countertops have a wide range of advantages:

- Low cost. The characteristics of a laminated chipboard tabletop are only slightly inferior to artificial stone, but it is much cheaper.

- Color palette. A wide variety of colors, textures and textures allows us to produce a unique laminated chipboard countertop.

- Wear resistance. Laminated chipboard countertops are not afraid of water and cleaning agents, and are resistant to mechanical damage.

- High quality. Thanks to the use of proven and reliable materials, the countertops will not swell or lose shape over time.

- Design possibilities. Laminated chipboard is easy to saw, which allows you to design a tabletop of any shape.

- Safety . The laminated chipboard tabletop does not emit or absorb odors and liquids, is heat-resistant and environmentally friendly.

- Durability. The service life of countertops is unlimited.

Chipboard countertops for the kitchen

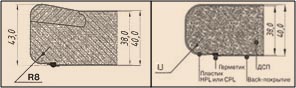

Chipboard countertops are very popular in the kitchen. The work surface is constantly exposed to various influences, so the kitchen laminated chipboard table top must be durable, moisture-resistant and beautiful. In the production of tabletops, 38 mm thick laminated chipboard is used, which guarantees the reliability and durability of the surface. The laminated chipboard tabletop is attached to the bottom row of kitchen cabinets, and can also smoothly flow into a bar counter or window sill.

In any house or apartment the most important and cozy place- it's a kitchen. Men can confirm this fact, because, as you know, the way to their heart is through the stomach. They won't be able to get past the kitchen. Women are also confident in this fact - they often spend a lot of time in the kitchens.

Each housewife has her own idea of functionality, as well as beauty. kitchen furniture. When it comes to choosing a countertop for the kitchen, the choice itself, for the most part, depends not only on wishes, but also on the budget. Today there are the most different types countertops for the kitchen. Let's try to find out which of them you can buy and how they differ.

What are the requirements for countertops?

Among the advantages, price comes first. It is about 80 dollars per linear meter.  This surface can withstand scratches and non-aggressive substances. These models are very easy to care for. The surface can imitate the most different materials. These are the most popular types of kitchen countertops made of MDF and chipboard. Organic and inorganic acids will instantly make the decorative coating cloudy. This is the only drawback.

This surface can withstand scratches and non-aggressive substances. These models are very easy to care for. The surface can imitate the most different materials. These are the most popular types of kitchen countertops made of MDF and chipboard. Organic and inorganic acids will instantly make the decorative coating cloudy. This is the only drawback.

Laminated chipboard: large selection of colors and textures

These workers kitchen surfaces are produced by pressing wood chips using high temperatures. Melamine film is used as a protective layer. This material as popular as laminated products. The advantage will be the low price - from $60, high resistance to various cleaning compounds, a huge number of various textures and colors, durability.

Well, there are downsides - you can’t live without them. The panel is not resistant to moisture and mechanical stress.  It is very easy to scratch. Manufacturers do not produce these models in non-standard sizes. Well, another significant drawback is its complete unsuitability for repair or restoration.

It is very easy to scratch. Manufacturers do not produce these models in non-standard sizes. Well, another significant drawback is its complete unsuitability for repair or restoration.

Types of kitchen countertops made of MDF: time-tested reliability

The base is a wood-fiber board, where wood fibers are connected using lignin or paraffin. These materials are safe and have been used in the production of furniture products for a long time. These countertops can be made in absolutely any colors, and the price of these solutions is more than affordable.

Light-colored surfaces may develop unsightly stains and scratches over time and under harsh conditions.  If the slab is glossy, then even the smallest damage will be clearly visible. These models, as well as all other types of countertops for which are listed above, do not like strong humidity.

If the slab is glossy, then even the smallest damage will be clearly visible. These models, as well as all other types of countertops for which are listed above, do not like strong humidity.

The price is based on thickness. So, countertops with a thickness of up to 10 mm will cost from 30 to 40 dollars, a panel with a thickness of 16-18 mm will cost 16-45 dollars. Thick 25mm panels start at $45.

All of these are inexpensive and affordable tabletop models for every family.  Of course, they do not look as expensive and elegant as some types of kitchen countertops from artificial stone, marble or granite, but they have a different niche. This is a completely budget solution.

Of course, they do not look as expensive and elegant as some types of kitchen countertops from artificial stone, marble or granite, but they have a different niche. This is a completely budget solution.

If you carefully weigh the advantages and disadvantages of each option for products made from chipboard or MDF, as well as financial possibilities, you can purchase a good inexpensive work surface.

Dedicated to choosing a kitchen countertop, we talked about the advantages, disadvantages and features of countertops made of artificial stone (composites). Artificial stone kitchen countertops are most popular when we're talking about about expensive kitchen furniture. Among economical options The greatest demand continues to be for countertops made of chipboard, finished with plastic (laminate). Tabletops made of laminated chipboard are attractive because they combine two advantages: low price and good performance.

Chipboard countertops are durable - they remain intact even when dropped from a height. Only the finishing of the countertop may suffer, and even then not much. Of course, chipboard cannot be called a moisture-resistant material, however modern production thanks to the use of special impregnations, it allows you to make chipboard kitchen worktops much more resistant to moisture. However, how long the countertop will last depends on the quality of the coating.

Kitchen countertops made of chipboard are covered with laminate, or HPL plastic - these are the same thing, only the names are different. For this purpose, the postforming method is used. The coating makes the chipboard kitchen countertop heat-resistant and resistant to scratches from dishes, abrasives, etc.

Tabletops made of plastic-coated chipboard cannot be seamless, but when individual order the tabletop is glued together, and thanks to subsequent finishing, the seams become completely invisible.

Finishing of all end surfaces and edges is mandatory, and this finishing must be carried out maximum quality. Otherwise, moisture will get inside and the material will swell. To finish the edges, the same plastic (laminate) is used as for finishing the countertop, but this is not the best option. It is preferable that the end surfaces and edges be finished polypropylene, acrylic . Sometimes edges made of steel or natural wood are used.

When installing the sink and hob sealants are used to protect chipboard from moisture.

Kitchen countertops made of chipboard and MDF: what to choose?

Kitchen countertops are made from MDF less often than from chipboard. Chipboard and MDF - what's the difference? MDF is a fibreboard, and chipboard, respectively, is a particle board. In the production of chipboard, formaldehyde resins are used to hold wood particles together. Products made from chipboard release a certain amount of formaldehyde into the air, which is not very useful for humans. For this reason, chipboard is considered not the most environmentally friendly material.

In MDF, wood fibers are bonded with paraffin and lingin, so MDF is considered safer for humans. This, in general, is the main difference between MDF and chipboard : the first is completely harmless, and the use of the second is not very desirable in areas where children live.

The difference, of course, is in price - any furniture made from MDF (including kitchen countertops ) usually costs more than similar chipboard products. Well, in operation it is impossible to feel the difference in materials, so you need to focus on the cost of the countertop and your financial capabilities.

Laminated chipboard and MDF countertops: what to consider when choosing and purchasing?

Laminate countertops from wood-like materials can be made in any way.

In the design of the tabletop, wood, stone, metal, leather, including exotic leather, can be imitated very realistically. Moreover: the tabletop can be decorated with a print. However, laminated countertops are still much less similar to natural stone than acrylic countertops . It's not in vain acrylic stone called a stone. But HPL plastic can perfectly replicate the pattern of wood.

Much is possible with laminated coating, but you need to take into account that on lighter countertops over time, permanent stains may remain. More precisely, stains will remain on any tabletop over time, but on a light-colored one they will be more noticeable, especially if it is plain.

Therefore, if you want to purchase a kitchen countertop once and for many years, choose a darker option, preferably not a solid color.

Over time, scratches from sharp objects may appear on a laminated countertop. The coating will withstand moving dishes without consequences. Hot objects will also not affect its appearance (but, of course, not red-hot objects - it is not advisable to place such objects on the countertop). However, scratches cannot be avoided if there is a lot of cooking in the kitchen.

It is worth remembering that scratches are less noticeable on a matte kitchen countertop, while any damage is visible on a glossy finish.

When choosing a laminated countertop from chipboard or MDF, you should pay attention to its thickness. Our manufacturers often offer countertops with a thickness of 28 mm. However, the European standard is 38 mm. It is precisely this thickness of the countertop that imported hobs are ideal for.

For a laminated chipboard and MDF countertop to serve for a long time, the most important thing is qualitatively process the ends and edges. Buy countertops from those kitchen furniture manufacturers who provide a guarantee on their products.

Many manufacturers offer laminated chipboard table top Wall panels for apron. The apron, by the way, does not have to be similar to the tabletop and match it in color and decor: in fact, the apron can be combined with the floor, with the facades, or even with floor covering. However, if you doubt your design abilities, purchase a tabletop along with an apron. This is a win-win and very convenient option.

And remember: kitchen countertops made of laminated chipboard and MDF do not like excessive moisture, do not tolerate cleaning with abrasives and become cloudy from exposure to many chemical substances(acids). Stains from the same vinegar can remain forever.

The most functional piece of any kitchen is the countertop. High demands are placed on its quality: resistance to water, mechanical and thermal stress, ease of maintenance, aesthetics. Mainly used following materials(not counting exotic ones):

- Slab made of granite chips;

- Marble;

- Fake diamond;

- Stainless steel;

- Natural wood;

- Chipboard.

Of the above types, the most popular solution for the kitchen is chipboard countertops.

Characteristics of chipboard used for countertops

The kitchen is very demanding when it comes to furniture, dishes and interior items. That's why particle board V pure form furniture workshops never use. Its only variety is chipboard.

Laminated chipboard is a sheet lined with plastic, polyethylene or melamine film. The coating is glued to the surface of the slab and fixed by cold pressing.

Such processing ensures proper impact resistance, resistance to scratches, hot (up to +80°C) objects, water, solvents and acids.

Kitchen work surfaces made of laminated chipboard have the following advantages:

- Strength;

- Impact resistance;

- Hygiene;

- A huge selection of shades, textures and patterns that imitate natural wood, stone, tiles, fabrics, plant and other patterns;

- Low price - compared to other materials, the slab is 3-12 times cheaper, which is why it is so widespread.

There are also disadvantages, but they can be completely mitigated:

- Low level of moisture resistance. All ends must be treated with acrylic waterproof sealants and covered either with edges or with special profiles, furniture baseboards and other accessories. At the same time, hydrophobic impregnation (with the addition of green or yellow pigments) is expensive moisture resistant chipboard will only delay, but not prevent, swelling and damage to the countertop. In addition to this, watch the video below for an experiment with an Egger countertop:

- Afraid of high temperatures. You cannot place hot pans and pots without special heat-resistant stands made of wood and glass.

- Laminated surface easy to scratch sharp knife , so be sure to use cutting boards.

- In the “economy” series, the melamine coating fades over time under the influence of direct sun rays.

It is incorrect to talk about the environmental friendliness or, conversely, non-ecological friendliness of a material. Serious manufacturers conduct a full series of tests, including the emission of harmful substances, so it is enough to ask the seller for a test report and a sanitary and hygienic certificate. Their presence indicates that this countertop fully complies with safety standards and is approved for use in residential premises. And, of course, the price is much lower than the market average should immediately alert the buyer - most likely, a low-quality product is being offered.

For the kitchen, laminated chipboard is used, which has the following dimensions:

- width – 60-120 cm;

- thickness – 28 and 38 mm;

- length – 2.44, 3.05 and 3.66 m.

The variety of textures offered allows you to give unusual look even the most trivial kitchen:

The cost of countertops varies depending on the country of origin, thickness and decorative covering. Most expensive products German manufacturers, covered with layered PVC - its price starts from 1500 rubles/linear. m. Similar Russian products are much cheaper - from 400 rubles/linear. m. Belarusian chipboard is also in fairly steady demand - its cost starts from 700 rubles/linear. m.

Technical features: profile shapes and end protection

High quality kitchen countertop protected from all sides. The front part is made of decorative film with a pattern, the bottom part is made of thin plastic “backing”, the joint between them is usually blocked by a special rubber protrusion – a drip tray: it prevents moisture from flowing onto the weaker lower protective layer.  As for protecting the ends, there are 2 methods of moisture insulation: edging (plastic or acrylic (3D) tapes, metal profiles) or postforming/softforming.

As for protecting the ends, there are 2 methods of moisture insulation: edging (plastic or acrylic (3D) tapes, metal profiles) or postforming/softforming.

Postforming– rounding the end and then wrapping it with a PVC sheet or melamine paper. Softforming– the process is similar to the previous one, but is used for designer kitchen countertops with complex shapes. These processing methods provide complete protection against the destructive effects of moisture on chipboard.

Before starting work on attaching the edges, the ends should be treated with a waterproof adhesive sealant (Bison, Moment, Kimtek) to ensure 100% protection from moisture. In extreme cases, you can soak it in paraffin or wax.

The working surface should be comfortable, preferably without sharp edges. Therefore, several forms of profiles are produced, which differ in ridges and hems. The most common type of profile is one that has one hem and one hem.

Based on this, manufacturers have developed the following labeling:

Docking methods

If it is expected complex shape countertops for the kitchen, then the connection of two parts at an angle of 90° or 135° is carried out by gluing.

At the ends of the blades, recesses for tie fastenings (tongue and groove) are cut out using a milling machine and processed sandpaper, are cleared of dust. Next, PVA or acrylic glue for chipboard is applied, the elements are connected and tightly fixed. The exposed glue and the seam itself are sanded and, if necessary, rubbed with special tinted mastics. As a rule, the joint is almost invisible to the eye and the tabletop looks like a single whole. This method of joining is called Euro-sawing, and it increases the cost quite noticeably work surface for the kitchen - from 3000 rubles. and higher.

You can increase the length of a typical tabletop using T-shaped profiles, which come in 2 types:

- aluminum with anodized or laminated coating. Dimensions: width – 1-3 cm, length – 0.9-1.8 m;

- Plastic with tinting. Dimensions are identical to metal profiles;

Due to their special shape, such connectors attract the blades to each other and, due to their tight fit to the surfaces, protect the ends from moisture. The price of Russian-made products is quite acceptable - from 70 rubles/linear. m.

Debris can accumulate between the countertop and the wall and water can leak in. This type of joint can be sealed using a decorative kitchen plinth made of PVC or aluminum. Their convenience lies in the fact that in addition to soft sealing edges, they have a full set of components: corners, plugs and connectors - thanks to this, the design of the kitchen furniture is seamless. The price of PVC skirting boards together with components starts from 180 rubles/linear. m., metal costs much more - from 300 rubles/linear. m.

Defects and methods for their elimination

Since the laminating film does not have the safety margin of the chipboard itself, the appearance of minor defects who spoil general form. In addition, their danger lies in the fact that water, fruit juice, coffee or any other liquid can get under the coating, which will cause swelling and stains.

Point defects after contact with a hot object, abrasions or scratches from a knife can be rubbed with colored wax mastic (hard type), intended for furniture made of wood and chipboard (Tekhplast, Rico, TMB), then fixed with a spray varnish.

Chips and dents on the edges must be sealed with acrylic adhesive-sealant, and a self-adhesive patch should be placed on top. decorative film or completely cover the end with a U-shaped plastic edge.

The prevalence of kitchen countertops made of chipboard is explained by good combination"price quality". Special condition good performance properties - compliance with a few simple rules. In particular, do not cut food without cutting board, use coasters for hot dishes, immediately clean up spilled water, and so on. Careful treatment of the material will allow it to serve for a long time without losing its functional and aesthetic qualities.

Modern technologies make it possible to create high-quality and unique furniture that exceeds operational indicators models of the last century. In this case, such products are characterized by:

- relatively low cost;

- excellent design indicators;

- increased protection from external influences;

- high level wear resistance;

- excellent environmental performance.

- appropriateness in almost any type of interior, etc.

In addition, furniture can be made from various materials, including universal ones, suitable for use in different zones house, apartment or public institution. Such materials include chipboard. For example, modern laminated chipboard countertops, sold by the Magic Furniture company, demonstrate an excellent balance of quality, wear resistance and cost.

Features of laminated chipboard countertops

This material consists of particle board and applied coating. The coating is upper layer plastic made from:

- kraft paper (for strength);

- decorative layer;

- overlay (layer to protect against damage and increase wear resistance).

Decor of laminated chipboard tabletops

Today you can order a countertop made of laminated chipboard to suit almost every taste. Manufacturers offer numerous options for different types style directions, including in the form of:

- natural stone;

- mosaic pattern;

- surfaces with ornaments.

- In a single color design, in more than 150 colors and shades.

In addition, a laminated chipboard countertop for a kitchen can have one of several types of texture, including:

- under the tree;

- gloss;

- shagreen.

But the most important thing is laminated chipboard tabletop to order can be made in individual, most outlandish decor options. To do this, it is enough to come up with an appropriate sketch, which will subsequently be transferred by our specialists to the surface of the tabletop using digital printing.

Why do you need an overlay?

The overlay is designed to save appearance countertops. This protective layer protects the decor from impacts, chips and scratches. Besides, decorative surface protected by overlay:

- withstands temperatures up to 240 degrees Celsius during the first 20 seconds of exposure (for example, a accidentally placed frying pan, not to mention pots of boiling water and kettles);

- not exposed to ultraviolet radiation. This means that the design will not fade even with prolonged exposure to direct sunlight;

- is not afraid of fading with the constant use of aggressive chemical cleaning agents.

The edges of the tabletop are under special control

The edges of any surface represent an increased risk zone and lose their decorative and operational functions faster than facades. To protect this critical zone, modern protective technologies are used, which not only prevent harmful external influences, but also to make the countertop more attractive.

In particular, in our work we use chrome plating and postforming. Thanks to them, the appearance of unprotected areas is practically eliminated. In this case, no seams will be visible externally on the tabletop.

Postforming involves bending the outer layer of plastic onto an edge. This technology It is effective only for flat areas, therefore, when designing a tabletop with curved edges, edging is appropriate - gluing the edges. Moreover, the edge can be made of any material - from inexpensive acrylic to stylish and durable aluminum. In any case, we guarantee high-quality performance.

Standard sizes of laminated chipboard

Like all building materials and their components, laminated chipboard has its own standard sizes. Basically, the thickness of the sheet is 28-38 mm, although it is possible to order a non-standard plate with a thickness of 12 to 100 mm.

The typical slab width is 600 mm. At the same time some modern manufacturers They offer products up to 1200 mm wide, which significantly expands the range of applications for laminated chipboard countertops.