The most functional piece of any kitchen is the countertop. High demands are placed on its quality: resistance to water, mechanical and thermal stress, ease of maintenance, aesthetics. Mainly used following materials(not counting exotic ones):

- Slab made of granite chips;

- Marble;

- Fake diamond;

- Stainless steel;

- Natural wood;

- Chipboard.

Of the above types, the most popular solution for the kitchen is chipboard countertops.

Characteristics of chipboard used for countertops

The kitchen is very demanding when it comes to furniture, dishes and interior items. Therefore, particle board in pure form furniture workshops never use. Its only variety is chipboard.

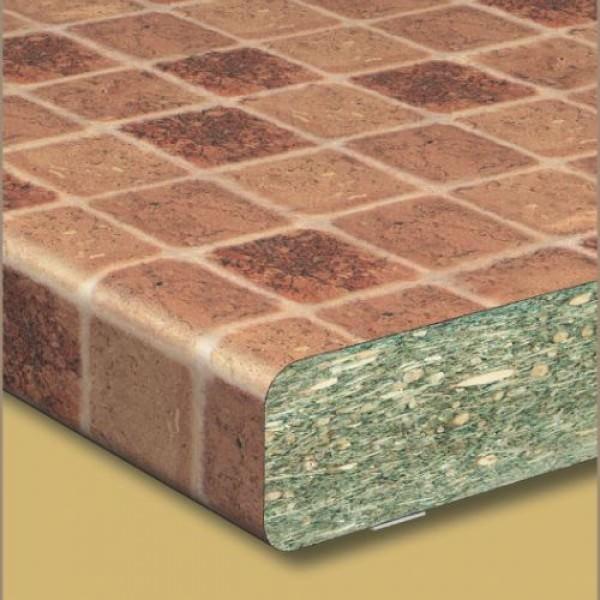

Laminated chipboard is a sheet lined with plastic, polyethylene or melamine film. The coating is glued to the surface of the slab and fixed by cold pressing.

Such processing ensures proper impact resistance, resistance to scratches, hot (up to +80°C) objects, water, solvents and acids.

Kitchen work surfaces made of laminated chipboard have the following advantages:

- Strength;

- Impact resistance;

- Hygiene;

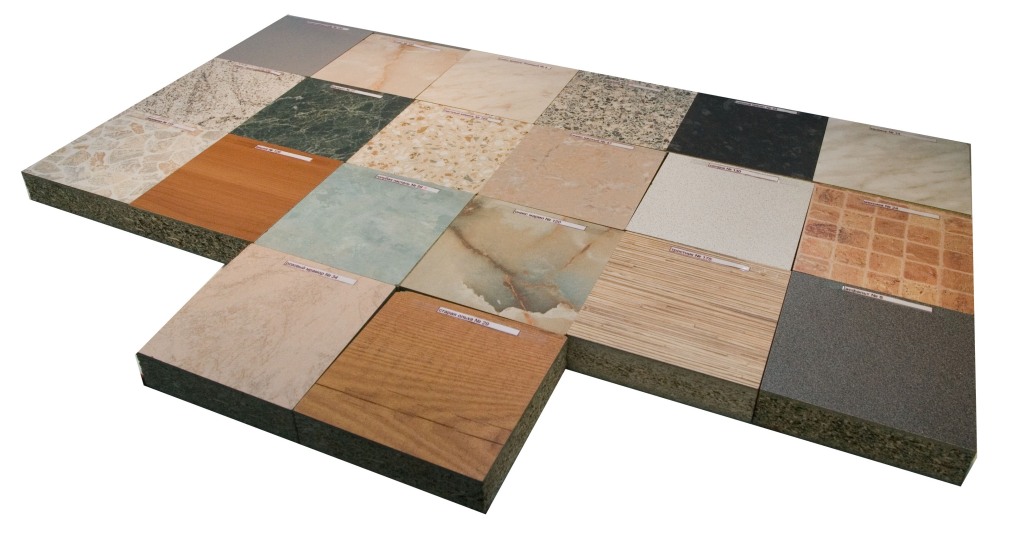

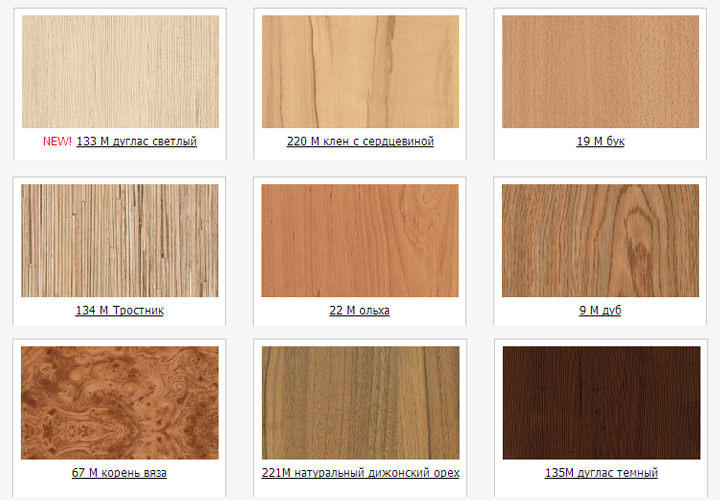

- A huge selection of shades, textures and patterns that imitate natural wood, stone, tiles, fabrics, plant and other patterns;

- Low price - compared to other materials, the slab is 3-12 times cheaper, which is why it is so widespread.

There are also disadvantages, but they can be completely mitigated:

- Low level of moisture resistance. All ends must be treated with acrylic waterproof sealants and covered either with edges or with special profiles, furniture baseboards and other accessories. At the same time, hydrophobic impregnation (with the addition of green or yellow pigments) is expensive moisture resistant chipboard will only delay, but not prevent, swelling and damage to the countertop. In addition to this, watch the video below for an experiment with an Egger countertop:

- Fears high temperatures . You cannot place hot pans and pots without special heat-resistant stands made of wood and glass.

- Laminated surface easy to scratch sharp knife , so you should definitely use cutting boards.

- In the “economy” series, the melamine coating fades over time when exposed to direct sunlight.

It is incorrect to talk about the environmental friendliness or, conversely, non-ecological friendliness of a material. Serious manufacturers conduct a full series of tests, including the emission of harmful substances, so it is enough to ask the seller for a test report and a sanitary and hygienic certificate. Their presence indicates that this countertop fully complies with safety standards and is approved for use in residential premises. And, of course, the price is much lower than the market average should immediately alert the buyer - most likely, a low-quality product is being offered.

For the kitchen, laminated chipboard is used, which has the following dimensions:

- width – 60-120 cm;

- thickness – 28 and 38 mm;

- length – 2.44, 3.05 and 3.66 m.

The variety of textures offered allows you to give unusual look even the most trivial kitchen:

The cost of countertops varies depending on the country of origin, thickness and decorative covering. Most expensive products German manufacturers, covered with layered PVC - its price starts from 1500 rubles/linear. m. Similar Russian products are much cheaper - from 400 rubles/linear. m. Belarusian chipboard is also in fairly steady demand - its cost starts from 700 rubles/linear. m.

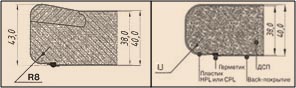

Technical features: profile shapes and end protection

A high-quality kitchen worktop is protected from all sides. The front part is made of decorative film with a pattern, the bottom part is made of thin plastic “backing”, the joint between them is usually blocked by a special rubber protrusion – a drip tray: it prevents moisture from flowing onto the weaker lower protective layer.  As for protecting the ends, there are 2 methods of moisture insulation: edging (plastic or acrylic (3D) tapes, metal profiles) or postforming/softforming.

As for protecting the ends, there are 2 methods of moisture insulation: edging (plastic or acrylic (3D) tapes, metal profiles) or postforming/softforming.

Postforming– rounding the end and then wrapping it with a PVC sheet or melamine paper. Softforming– the process is similar to the previous one, but is used for designer kitchen countertops with complex shapes. These processing methods provide complete protection against the destructive effects of moisture on chipboard.

Before starting work on attaching the edges, the ends should be treated with a waterproof adhesive-sealant (Bison, Moment, Kimtek) to ensure 100% protection from moisture. In extreme cases, you can soak it in paraffin or wax.

The working surface should be comfortable, preferably without sharp edges. Therefore, several forms of profiles are produced, which differ in ridges and hems. The most common type of profile is one that has one hem and one hem.

Based on this, manufacturers have developed the following labeling:

Docking methods

If it is expected complex shape countertops for the kitchen, then the connection of two parts at an angle of 90° or 135° is carried out by gluing.

At the ends of the blades, recesses for tie fastenings (tongue and groove) are cut out using a milling machine and processed sandpaper, are cleared of dust. Next, PVA or acrylic glue for chipboard is applied, the elements are connected and tightly fixed. The exposed glue and the seam itself are sanded and, if necessary, rubbed with special tinted mastics. As a rule, the joint is almost invisible to the eye and the tabletop looks like a single whole. This method of joining is called Euro-sawing, and it increases the cost quite noticeably work surface for the kitchen - from 3000 rubles. and higher.

You can increase the length of a typical tabletop using T-shaped profiles, which come in 2 types:

- aluminum with anodized or laminated coating. Dimensions: width – 1-3 cm, length – 0.9-1.8 m;

- Plastic with tinting. Dimensions are identical to metal profiles;

Due to their special shape, such connectors attract the blades to each other and, due to their tight fit to the surfaces, protect the ends from moisture. Product price Russian production quite acceptable - from 70 rubles/linear. m.

Debris can accumulate between the countertop and the wall and water can leak in. This type of joint can be sealed using a decorative kitchen plinth made of PVC or aluminum. Their convenience lies in the fact that in addition to soft sealing edges, they have a full set of components: corners, plugs and connectors - thanks to this, the design kitchen furniture turns out whole. The price of PVC skirting boards together with components starts from 180 rubles/linear. m., metal costs much more - from 300 rubles/linear. m.

Defects and methods for their elimination

Since the laminating film does not have the safety margin of the chipboard itself, the appearance of minor defects, which spoil the overall appearance. In addition, their danger lies in the fact that water, fruit juice, coffee or any other liquid can get under the coating, which will cause swelling and stains.

Point defects after contact with a hot object, abrasions or scratches from a knife can be rubbed with colored wax mastic (hard type), intended for furniture made of wood and chipboard (Tekhplast, Rico, TMB), then fixed with a spray varnish.

Chips and dents on the edges must be sealed with acrylic adhesive-sealant, and a self-adhesive patch should be placed on top. decorative film or completely cover the end with a U-shaped plastic edge.

The prevalence of kitchen countertops made of chipboard is explained by good combination"price quality". Special condition good performance properties - compliance with a few simple rules. In particular, do not cut food without a cutting board, use trivets when hot, immediately clean up spilled water, and so on. Careful treatment of the material will allow it to serve for a long time without losing its functional and aesthetic qualities.

The owner of the home spends a lot of time in the kitchen. It is necessary to prepare food for all family members, wash the dishes, make preparations for the winter months, etc. Therefore, a chipboard countertop for the kitchen is best option, combining high quality and affordable cost of material.

Getting to know the material

The following requirements apply to the kitchen countertop:

- high degree of wear resistance;

- hygiene;

- combination with other finishing materials and kitchen facade.

The technology of laminating chipboards itself originated in Germany in the 50s of the last century. The purpose of coating chipboard was the only one - extending their service life and increasing heat resistance. Gradually processing technique wooden surfaces caught on and is now used by everyone furniture factories peace.

Kitchen worktops made of chipboard with a laminated coating have a standard width of 60 cm. Many manufacturers take this value as a standard when making kitchen sets. But some craftsmen prefer exclusive furniture and order different sizes of tabletops; such a “custom-made” product costs much more than a standard one.

Classification of kitchen countertops

Modern kitchen countertops made of chipboard slabs can have different thicknesses: 38 or 28 mm. The surface of the product can also be different:

- embossed;

- glossy;

- matte.

Thanks to the use of plastic coating, kitchen countertops made of chipboard can have any color. The imitation of natural materials: stone, wood, sand looks very organic in the kitchen interior. But some clients want something exotic and they place an order for the production of a kitchen countertop made of chipboard, covered with an exotic ornament or images of animals, birds, and people.

Important: if you want to install a “marble” countertop in your kitchen, preference should be given to thicker slabs (at least 38 mm). This will emphasize massiveness and impressiveness natural material, under which the imitation is done.

Combination of countertops with the overall style of the room

A chipboard countertop for a kitchen should fit organically into the interior of the room, match the furniture and color finishing materials(walls, ceiling and floor). A calm atmosphere involves the use of countertops with elements of photo printing, tiles, neutral panels, etc. And if the style kitchen area approaches expressionism, then any combination of colors, textures and shapes will be appropriate.

If the walls of the room are decorated with skin panels, then the kitchen countertops made of chipboard must be chosen noble dark shades. In the broadest sense of the word, the product personifies the earth with rising vegetation, after which the eye moves to the light background of the wall cabinets.

When decorating walls with materials with urban motifs, a chipboard countertop for a kitchen can imitate a road surface (“like paving stones,” “stone pavement,” etc.). The contrasting color of the cutting surface of the set against the background of photo wallpaper looks original. With any design, you need to strive to coordinate the countertop and the rest of the kitchen furniture.

Modern designers assure that kitchen countertops made of chipboard do not necessarily have to match the color of the apron. It can be combined with the facade, floor coverings, etc. The sets look no less interesting: an apron and a tabletop from the same manufacturer, when specialists: engineers, designers and other professionals work on the creation of this tandem.

The presence of small children in the family leaves its mark on the condition kitchen countertop: something caustic liquid will constantly be spilled on it, the knife will be used without a board, etc. The result is scratches, stains and dents on the work surface. Therefore, when choosing a coating for floor cabinets, you need to choose dark products with variegated colors and a matte structure. If these rules are neglected, all the experiments of young alchemists will be presented to everyone.

Important: the life of the countertop can be extended by several years if everyone in the household uses cutting boards for cutting food.

Liquids containing solvents and alkalis also require quick cleaning. If you miss the moment, these compounds can get into microcracks and cause subsequent deformation of the even base.

How can you protect your countertop?

The gap between the tabletop and the apron can be closed with a special plinth. This will prevent moisture and small pieces of food from entering. In order for furniture to serve for a long time, its edges and ends must be processed with high quality. To finish the edges, you can use the same laminate that is used to finish the countertop. In addition to laminate, steel is used for edges, natural wood and other materials.

Important: it is impossible to make an edge from polypropylene or acrylic at home. It must be ordered from specialized companies.

The more tightly the seams on the kitchen set are closed, the less risk of swelling from moisture. When purchasing ready-made edges, you must pay attention to the manufacturer's warranty. For more effective protection Chipboard boards, places of their contact with aggressive factors external environment treated with glue - silicone-based sealant.

Joining the table top with other interior items

Some kitchens have a sufficient area and require joining of two countertops. In this case, there is a need for a profile to mask the convergence point of the structures. The profile used is plastic and aluminum. The second option is stronger and more durable, although PVC offers the consumer a wider color scheme materials.

To increase the length of a kitchen countertop made of chipboard or to create corners (from 90 to 135º), it is better to order the tabletop panels from professionals. This is a guarantee of smooth and reliable seams, almost invisible from the outside.

The joining of 2 tabletops to each other is carried out using a T-shaped profile or a “euro saw”. It is unrealistic to make such a connection of canvases on your own; for work you need professional tool. IN general view The “euro-sawing” procedure looks like this:

- the slabs are cut according to patterns;

- locking mechanisms are machined using a milling tool;

- installation of tabletops involves securing the canvases using special ties; the fastening points are well impregnated with silicone;

- Excess sealant is cleaned off with a rag, the resulting seams are invisible and reliable.

Important: when gluing dark tabletops, the seams are less noticeable compared to light-colored products.

The profile used for kitchen countertops made of chipboards can have several shapes; the finished countertop can be with ridges, with folds, or without ridges. The most common profile for such work is a material that has 1 hem and 1 roll.

List of pros and cons of chipboard countertops

Chipboard as a material in the manufacture of kitchen countertops has many advantages:

- wide color palette products;

- affordable price;

- increased resistance to mechanical damage;

- high temperature resistance;

- the material is not susceptible to UV rays;

- hygiene;

- natural origin;

- long service life.

Chipboard countertops also have some disadvantages:

- afraid of water;

- release formaldehyde into the surrounding air;

- acid and alkali destroy the structure of the material.

There was a lot of talk about formaldehyde and the harmfulness of chipboard, tests and measurements were carried out. Modern production uses advanced adhesive composition, the safety of plastic coating has long been proven.

The safety of countertops made from chipboard panels has been confirmed by permission from environmental services to install such products in pharmacy chains and childcare centers.

Dedicated to choosing a kitchen countertop, we talked about the advantages, disadvantages and features of countertops made of artificial stone (composites). Artificial stone kitchen countertops are most popular when we're talking about about expensive kitchen furniture. Among economical options The greatest demand continues to be for countertops made of chipboard, finished with plastic (laminate). Tabletops made of laminated chipboard are attractive because they combine two advantages: low price and good performance.

Chipboard countertops are durable - they remain intact even when dropped from a height. Only the finishing of the countertop may suffer, and even then not much. Of course, chipboard cannot be called a moisture-resistant material, but modern production, thanks to the use of special impregnations, makes it possible to chipboard kitchen worktops much more resistant to moisture. However, how long the countertop will last depends on the quality of the coating.

Kitchen countertops made of chipboard are covered with laminate, or HPL plastic - these are the same thing, only the names are different. For this purpose, the postforming method is used. The coating makes the chipboard kitchen countertop heat-resistant and resistant to scratches from dishes, abrasives, etc.

Tabletops made of plastic-coated chipboard cannot be seamless, but when individual order the tabletop is glued together, and thanks to subsequent finishing, the seams become completely invisible.

Finishing of all end surfaces and edges is mandatory, and this finishing must be carried out maximum quality. Otherwise, moisture will get inside and the material will swell. To finish the edges, the same plastic (laminate) is used as for finishing the countertop, but this is not the best option. It is preferable that the end surfaces and edges be finished polypropylene, acrylic . Sometimes edges made of steel or natural wood are used.

When installing the sink and hob sealants are used to protect chipboard from moisture.

Kitchen countertops made of chipboard and MDF: what to choose?

Kitchen countertops are made from MDF less often than from chipboard. Chipboard and MDF - what's the difference? MDF is a fibreboard, and chipboard, respectively, is a particle board. In the production of chipboard, formaldehyde resins are used to hold wood particles together. Products made from chipboard emit a certain amount of formaldehyde into the air, which is not very useful for humans. For this reason, chipboard is considered not the most environmentally friendly material.

In MDF, wood fibers are bonded with paraffin and lingin, so MDF is considered safer for humans. This, in general, is the main difference between MDF and chipboard : the first is completely harmless, and the use of the second is not very desirable in areas where children live.

The difference, of course, is in price - any furniture made from MDF (including kitchen countertops ) usually costs more than similar chipboard products. Well, in operation it is impossible to feel the difference in materials, so you need to focus on the cost of the countertop and your financial capabilities.

Laminated chipboard and MDF countertops: what to consider when choosing and purchasing?

Laminate countertops from wood-like materials can be made in any way.

In the design of the tabletop, wood, stone, metal, leather, including exotic leather, can be imitated very realistically. Moreover: the tabletop can be decorated with a print. However, laminated countertops are still much less similar to natural stone than acrylic countertops . It’s not for nothing that acrylic stone is called stone. But HPL plastic can perfectly replicate the pattern of wood.

Much is possible with a laminate coating, but you need to keep in mind that lighter-colored countertops may develop permanent stains over time. More precisely, stains will remain on any tabletop over time, but on a light-colored one they will be more noticeable, especially if it is plain.

Therefore, if you want to purchase a kitchen countertop once and for many years, choose a darker option, preferably not a solid color.

Over time, scratches from sharp objects may appear on a laminated countertop. The coating will withstand moving dishes without consequences. Hot objects won't affect her either. appearance(but, of course, not hot ones - it is not advisable to place them on the countertop). However, scratches cannot be avoided if there is a lot of cooking in the kitchen.

It is worth remembering that scratches are less noticeable on a matte kitchen countertop, while any damage is visible on a glossy finish.

When choosing a laminated countertop from chipboard or MDF, you should pay attention to its thickness. Our manufacturers often offer countertops with a thickness of 28 mm. However, the European standard is 38 mm. It is precisely this thickness of the countertop that imported hobs are ideal for.

For a laminated chipboard and MDF countertop to serve for a long time, the most important thing is qualitatively process the ends and edges. Buy countertops from those kitchen furniture manufacturers who provide a guarantee on their products.

Many manufacturers offer chipboard as a set for laminated countertops. Wall panels for apron. The apron, by the way, does not have to be similar to the tabletop and match it in color and decor: in fact, the apron can be combined with the floor, with the facades, or even with floor covering. However, if you doubt your design abilities, purchase a tabletop along with an apron. This is a win-win and very convenient option.

And remember: kitchen countertops made of laminated chipboard and MDF do not like excessive moisture, do not tolerate cleaning with abrasives and become cloudy from exposure to many chemical substances(acids). Stains from the same vinegar can remain forever.

Covered with laminated plastic, durable and shock-resistant, easy to care for and unpretentious in choice detergents. All these flattering reviews have been earned by a chipboard countertop for the kitchen, which, among other things, can reflect almost any color from the RAL table and imitate natural and artificial materials.

Thanks to affordable price and all of the above qualities have earned it considerable popularity in the kitchen furniture market.

Wide choose

Options

Kitchen countertops made of 28mm chipboard: different colors and shapes

Most often, kitchen countertops made of chipboard have the following dimensions:

- 3660x600x26 mm;

- 2440X600x26 mm;

- 3050x600x28 mm, 3050x900x28 mm, 3050x1200x28 mm;

- 3050x600x38 mm, 3050x900x38 mm, 3050 x 1200 x 38 mm.

Also, kitchen countertops made of chipboard have different profiles:

R8 - profile

R3 - profile

Operating characteristics of kitchen countertops

- The color of the countertops is preserved under the influence of ultraviolet rays (sun from the window) and over time.

- Neutrality to acids of food origin: wine, vinegar, tea, coffee.

- Kitchen countertops based on chipboard They have sufficient heat resistance, which is enough to withstand the temperature of a hot saucepan, kettle or frying pan.

- Laminated coating The kitchen countertop serves as an excellent sealing layer, so the surface is neutral to the spillage of water of any temperature, as well as the length of time that various sources of moisture, such as wet rags, remain on it.

- The hard plastic coating is quite resistant to mechanical damage such as impacts, scratches and chips.

- There is another important positive aspect: a kitchen countertop made of chipboard can be easily purchased in offline and online stores, and often even with installation at home.

Tabletop accessories

- Debris in the form of small crumbs or residue from spilled liquid may accumulate between the countertop and the work wall. To do this, a decorative plinth is installed at the junction point, which simultaneously performs a sealing function, preventing the accumulation of the above waste.. Such a profile can always be selected according to color and material - they are made from both polyvinyl chloride (PVC) and aluminum.

- When assembling the headset length Chipboard table tops for the kitchen is usually not enough, so various connecting strips are used for jointing without gaps. Also, strips are necessary when joining panels of corner sets. In the case when the end of the table does not rest against the wall, but moves away towards the room, then an end strip is used for this case.

Tabletop manufacturing technology

- The manufacture of kitchen countertops from chipboard 28 mm or larger is carried out using the sandwich gluing method. Before gluing, the board is cleaned with isopropyl alcohol, and then glue is evenly applied to the panel using a spatula or roller. All polyacetate adhesives D-3 and D-4 are suitable for gluing, the consumption of which is from 150 to 200 g/m2, but in any case, the manufacturer's instructions are required for orientation.

- The plates are subjected to cold pressing at a pressure of 50 to 80 N/cm 2 and a temperature not exceeding 30⁰C. The panel is under the press for 8 minutes, and then stored in stacks, where it is dried under a pressure of 1500 N/m2 for 24 hours.

- The dimensions of kitchen countertops made of chipboard are not always standard and they can be connected with an invisible seam. The panel is first milled according to a certain template, and then recesses for tie elements and slots for lamellas are cut into it (see photo above). A groove for the insert tenon is selected from above, 12 mm deep, and the end is cleaned with sandpaper.

- The treated end is wiped with isopropyl alcohol and dried, and then the sample is coated with two-component acrylic glue and a tenon is inserted into it. The surface of the end is treated with polyvinyl acetate glue and inserted into the slots of the lamellas. The same operation is performed with the slab that will be docked.

- Both tabletops are combined and moved so that glue comes out of the seam, and a clamp is used to secure it firmly (a video about the tabletops is located on the page). Air bubbles will form in the released glue - they should be pierced with some sharp object (a sliver, a match, a wire).

Advice. At the time of buying kitchen set the countertops may be long, and the kitchen will be a bit cramped, especially if there is still a corner with a table. In this case, you can simply trim them yourself.

To do this, it is best to use a stationary or manual electric circular saw, after which the cut is smooth and precise. The most important thing in this situation is to accurately measure each of the panels so that their length matches each other.

In order for the kitchen to be as comfortable and functional as possible, it is important not only the number of necessary appliances and fixtures, but also the quality of the furniture. Surface kitchen table is the most vulnerable part of the headset and can often fail before the modules themselves become unusable.

Today the use of solid " kitchen islands", covered with a marble or granite slab. But you can make a countertop that has no joints with your own hands, using chipboards and sheet plastic.

Chipboard table top

The kitchen countertop is central element, forming the interior of the kitchen. In addition, it performs important functions and takes on the main load when operating the kitchen.

A kitchen table must certainly be very durable, resistant to various types of impacts, easy to clean and durable.

Kitchen countertops can be made of solid wood, concrete, metal, natural and artificial stone, chipboard, MDF and even glass. A countertop made of chipboard is considered the most economical option, not much inferior to materials such as fake diamond or wood.

Size selection

The size of the kitchen countertop depends on factors such as:

- The ratio of the size of the kitchen room with the furniture;

- Location of the lower modules;

- Residents' preferences.

The standard width of the tabletop is, as a rule, no more than 60 cm, the length can vary depending on the design of the cabinets, the maximum thickness is 4 cm.

Table top made of chipboard. Advantages and disadvantages

Technology for making kitchen countertops with your own hands from particle board allows it to have the following advantages:

- Solid surface. Thanks to the sheet plastic coating, a surface is formed that does not have seams, which significantly improves the performance of the tabletop itself, in contrast to ready-made laminated models.

- Wide decorative range. The choice of colors and textures of sheet plastic is much wider than that of ready-made laminated chipboard countertops. In addition to monochromatic options and traditional textures, geometric patterns, textile motifs and even animal prints are offered.

- Availability. Anything you do yourself is certainly much cheaper than purchased models. In addition, plastic and chipboard sheets are not expensive.

- Easy to care for. A countertop made of chipboard does not require special care: unlike natural stone, it does not require regular sanding or polishing. In addition, the plastic coating is not afraid of alkaline-based detergents.

Unfortunately, nothing ideal exists in the world, and homemade chipboard countertops are no exception. Their disadvantages include:

- Primitiveness. Unlike more expensive materials, a tabletop made of chipboard covered with sheet plastic will in any case look more modest.

- Probability of deformation. In places where there are scratches and chips, the plastic may swell and peel off from the main surface.

- Weak stability. Plastic is susceptible to mechanical damage and high temperatures, so the service life of such a countertop can be significantly reduced.

With careful use of a hand-made countertop, most of its shortcomings can be easily avoided.

Tools and materials

First of all, you need to make an accurate measurement of the surface to be covered and purchase required quantity materials and fasteners. D To make a kitchen countertop with your own hands you will need:

First of all, you need to make an accurate measurement of the surface to be covered and purchase required quantity materials and fasteners. D To make a kitchen countertop with your own hands you will need:

- Chipboard sheets;

- Sheet plastic;

- Self-tapping screws;

- Staples for stapler 0.6 cm;

- Glue;

- Silicone sealant.

- Yardstick;

- Construction or simple pencil;

- Rubber hammer;

- Building level;

- Jigsaw;

- Manual frezer;

- Screwdriver;

- Scissors or construction knife;

- Furniture stapler;

- Silicone gun.

Making a tabletop with your own hands

When everything you need is at hand, you can start working:

- Preparation of parts. We cut out parts of the table top using a jigsaw from chipboard according to the given dimensions. If the tabletop consists of several parts (which is quite likely), its parts need to be fastened together with a stapler.

- Preparing the hole for the sink. We measure the dimensions of the sink, draw a contour on the workpiece in the required place. Carefully make a cut.

- Processing of joints.Even if the surfaces of the countertop parts are at different heights, the connection must be perfect. To do this, you need to apply a few strokes with a pencil at the joints and process them with sandpaper until traces of the pencil are no longer visible.

- Preparing the cladding. Sheet plastic for cladding is cut off construction knife or scissors. The strips for the ends should be made a little longer: it is better to cut off the excess during the cladding process. The cuts do not have to be perfect, as the edges will require further sanding.

All internal and external end sections of the tabletop must be treated with silicone sealant before cladding.

- Table top finishing. Carefully glue the plastic to the cladding and secure it in some places with a rubber hammer. The end strips are glued along the lower level of the edge, the excess is cut off with a router. In order for the surface to be perfectly flat, it must be smoothed. This can be done with a bar wrapped in a towel. The hole for the sink in the plastic is cut with a router.

- Assembly of the structure. The tabletop is attached to the base using a screwdriver. Rating