First of all, what is worth noting: learn to make knives from available materials - iron, ceramics and, first of all, stones, of course. Survival conditions are conditions for which you find yourself, for some reason, unprepared, and you may not only have a knife with you, but nothing at all. Therefore, I advise you not only to train to make a fire during ordinary hikes. with bare hands, but also learn to find hard flint stones, distinguish them from piles of other stones, and make primitive fishing tools from them: knives, scrapers, arrowheads. In general, everything is the same primitive people. Such skills will be useful even if you have a knife with you.

Personal characteristics

The knife should be comfortable for you - carefully select the size, balance, shape of the handle and blade. The easier it is for you to handle a knife, the greater your chances of survival. The handle should fit comfortably in both your dominant hand and your auxiliary hand, using different grips. It follows from this that the handle should be symmetrical, without one-sided bevels. The sharpening should also be symmetrical. You should be able to wield your knife easily and fluently. I also recommend developing ambidexterity in case one of your hands loses functionality due to injury. Another very important psychological point is that good control of your own knife will give you confidence in yourself and in the future.

Functionality

There's a lot to argue about here, there's a lot right now various materials, grades of steel, you can buy, order a knife to your liking from a craftsman, I’m just thinking based on my own experience. The example below falls into the category of edged weapons, but that is not what the article is about.

1) Fultang and only Fultang

The handle can burn, melt, crack in the cold, split when dropped, or, in short, lose its shape. It should be possible to dial the handle yourself in hiking conditions. Fultang increases the weight of the knife, but gives strength to the handle, allows you to use the knife as a chisel, pierce various pieces of wood, striking the head.

2) Massive head with corrugation and through hole

The head should allow you to stun animals, break off pieces of stones, straighten tin, break locks, bolts, break car glass, in general, be a hammer. Hole for lanyard, cord, paracord. I think there is no need to explain that if there is a hole, it is more convenient to make a spear or harpoon.

3) Handle

As written earlier, you need a handle made of fire-resistant material that is comfortable for both hands and different grips. A slight emphasis on both the blade and head sides.

The material should prevent the knife from slipping out of the hand under a wide variety of climatic conditions, be it rain, heat, frost.

There should be no hollow separate welded handles with repair kits and NAZ. The hollow handle breaks more easily under stress or falling from rocks. As a child, I broke the handle just by throwing a knife at a tree. Therefore, the handle material should not be brittle. If the handle is hollow, then it should be forged from the continuation of the blade and form a single whole with it, not be too thick and round.

The color of the handle is poisonous yellow or orange, so that the knife can be easily found under water, on sand, on snow, in rocks, in the dark, etc. The color should differ from the natural background, unmasking the knife. You can wind fishing line around the black indentations that you see in the picture.

4) Garda

Garda is necessary. I have come across the opinion that the guard interferes in everyday life (although this is complete nonsense in my opinion, you just need to train more in everyday life...), but its protective function is simply necessary, especially if there is no lanyard, and the hand is cold or weak from hunger.

The upper part of the guard, by the way, can be made in the form of a ring - with a wide hole (like a bayonet-knife) so that a spear shaft can be inserted into it.

5) Blade

Steel the blade and the strip as a whole, since we have a fultang, should not be too hard. Hardness is fragility and brittleness. Naturally, the steel must be stainless. The width of the butt is 4-5 mm. Yes, the blade must be thick, it must withstand loads, the knife must withstand blows to the butt from stones and sticks.

Blade length- 18 centimeters (shorter in the picture). The blade is quite long, but with such a knife it is more convenient to split wood for a fire with both hands, chop bones, tendons of large game, and it is easier to reach the predator that attacked you or the noose in which you are entangled. With a long blade it is easier to go through thickets of some kind of nettle.

A little about shine. A shiny, polished blade can give a signal, for example, to helicopter pilots. One day, my friends and I were crawling along the rocks and local kites, fairly large birds of prey, began to dive at us. Taking out our shiny knives, we waved them away. A simple example, but even simple crows can actively attack you, defending their nesting territory. And if you show them that you have something big and shiny in your hands, they will moderate their ardor.

Another big shiny knife can be a powerful argument when meeting the most dangerous animal even at the negotiation stage...

Serreiter- makes sharpening more difficult field conditions. Its functionality when cutting game tendons can be replaced by a protruding sharpened heel.

middle part blades- straight. It is easier to separate the wood chips from the logs.

Climb the blade begins with a protrusion. Helps cut stretched ropes and slings. The rise itself is rounded, this makes it easier to remove the skin from the animal carcass.

Sharpening only double-sided with straight slopes.

Saw on the butt - useful so as not to dull the blade again, but at the same time keep the butt unsharpened.

Bevel- not sharpened, for your own safety, it makes the knife lighter and increases its “sharpness.”

Tip It is better to harden the knife; the soft tip can bend under load, but when unbent it will still break off, so it is better to break off under stronger loads.

Hole near the guard helps to fix the knife on the shaft. However, its presence can weaken the knife to break; it is better to do without it.

6) Sheath

Make it from leather. Why? Well, they can be chopped, boiled and eaten.

It is better if the knife sits in its sheath without additional fixation handles, i.e. without fasteners, because the knife should be pulled out in one movement and not two. But we have a large, heavy knife, so the clasp is useful, the main thing is to keep it unfastened during normal upright movement and fastened during complex movement. I had such a case, I was climbing the slope ahead of the group, when wolves quickly appeared blocked my path and stood, as they say, “point-blank.” The knife was in its sheath, and the handle was fastened, and I understood that I would not have time to get the knife if they jumped. I was lucky that the wolf closest to me, who was standing two meters from me, had a stone jump out from under his feet, on which he was leaning. He looked down. these seconds were enough, in a second I took the slingshot from my neck, pulled out a large pine cone that was accidentally lying around from my pocket and shot at the wolves. No matter how funny it is, they got scared and ran away. But, suppose I didn’t have a slingshot, and the wolves wouldn’t be scared and attack first. Seconds matter in general...

Where should the knife hang?

When hiking - on your belt on the side that is convenient for you. He's the least likely to interfere there. Can also be worn on outside thighs, but when crossing rocky obstacles it will need to be fastened and it will be inconvenient to reach with the opposite hand. When kayaking - on the chest, but so that in case of an accidental snag, when raising your arms or oar, the handle does not reach your face and neck (the knife itself should be shorter in this case, in short, it is already a rescue knife). Once, a knife hit me in the tooth like this, well, not in the eye.

Conclusion

A knife should be a knife: prick, pierce, cut, split, separate, nothing more. There have been historical solutions for a long time - these are hunting and fishing knives, as well as modern bayonet knives. These solutions are the result of centuries of practice. So invent now special knives for armchair survivalists, this is simply ridiculous. Flexible brains survive, trained healthy body and good experience. Better practice more. Learn to make cutting and piercing objects auxiliary to the main knife from improvised means. Learn to make and use bows, slings and spears. Practice setting traps. It is always easier to get a wood grouse, sparrow, gopher, squirrel, hare, pika, chipmunk, mouse, rat, fish, and for this a knife is not an essential item.

I repeat: hunting, fishing, army - these are real survival knives. What is now being sold under the guise of survival knives, against the backdrop of the popularity of the survival subculture, are versions of real knives cut down to those permitted by law. Manufacturing companies are well aware that they cannot sell knives en masse, which require licenses to own. And for mass sales they sell different acceptable models, thus undermining the long noble history of survival.

It’s good that in Russia we have a lot of recreational places where you can get involved in survival in the most different conditions. God grant you good luck in this difficult task, good health, quit smoking, don’t drink too much, take care of yourself and nature.

Addition

How to make a Finnish puuko knife with your own hands

Puukko is one of the main types of universal non-folding knives with a thousand-year history. This is a small (short blade, often shorter than the length of the handle), relatively easy to manufacture Finnish knife, the functionality of which is suitable for performing many tasks related to hunting and farming. Personally, I fell in love with this knife for its simplicity and asceticism: in its various variations you can find an excellent working tool, in which there will be nothing superfluous.

Search for information

This was my first experience making knives in principle, so the whole process began with collecting information. Thanks to the site guns.ru, I learned the terminology and main points in making knives from blade to handle, read an article about puukko on Wikipedia and studied links to third-party resources, from which sources for inspiration were subsequently taken, watched many videos on YouTube about production and features different kinds of Finns. A rough drawing was made. I was ready to get to work and it began to boil.

Main Ingredients

We will need: a workbench with a vice, a large file according to GOST 2 pcs., a wooden block (wood to taste), copper plates, a stove, emery, sandpaper, a hacksaw for metal, a screwdriver, machine oil, pinotex, epoxy glue, marker, etc. small things.

Manufacturing

It all started with annealing in a furnace. A similar procedure was performed with one of the files at a temperature of 800 degrees, followed by slow cooling.

Then, the blade and tang were brought into adequate condition using a file and emery. A small joint came out, I had to shorten the length of the blade. Cuts were made on the shank so that when inserted into the handle, the epoxy glue would fill them.

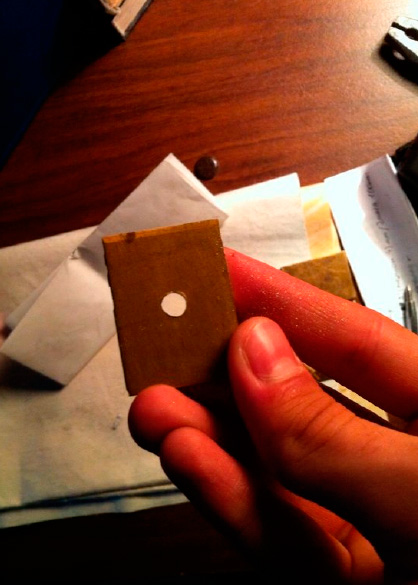

Since the bolster is threaded onto the shank first and only then the handle (suddenly), a hole was first drilled in a thick copper plate. It became difficult to put on the shank, which suited the role of a partition perfectly.

A hole was drilled in a wooden block slightly larger than the length of the shank and in the wooden block, then an inclined cut was made on its end part, which was a decision more for an aesthetic than a practical purpose.

And the blade, and the bolster, and the handle were connected and adjusted to each other in order to make sure that so far everything was going right.

The blade was hardened in an oven at a temperature of 900 degrees and then lowered into machine oil.

The blade, bolster and handle were reattached and sealed with epoxy glue. A rough marking was applied to the handle, which was then changed anyway, moving even further away from the original drawing.

All the most unnecessary things were again mercilessly sawed off.

Another small jamb was discovered in the handle, so I proceeded to fix it with the same epoxy and file. After post-processing sandpaper, the knife acquired the following, almost final appearance.

In the end, the handle was impregnated with Pinotex.

Bottom line

The product, although it turned out to be quite rough, still became a knife. The experience gained in the process of making this puukko is truly invaluable to me. I hope that from the information I have collected here, someone more careful and handy will be able to do something much better.

IN Everyday life knife - indispensable tool. No household can manage without it. Models presented for sale do not always meet the requirements for reliable and functional samples. To get a blade that combines best characteristics, you will have to make it yourself. Recently, information on how to make a knife with your own hands has become very popular.

Advantages of homemade models

There is a huge range of knives on sale now. You can get lost in it, but with some effort you can always find a ready-made model suitable for specific purposes. However, there is always a chance of encountering a poorly made blade or a finished model that does not fully meet expectations.

If the desired model is not available for sale, you can seek help from a blacksmith who will make a custom-made blade.

But such work, carried out in accordance with the wishes of the customer, is quite expensive. Usually in such a situation the idea comes to making a knife with your own hands from start to finish.

If you make a blade yourself, you can achieve a number of advantages:

Assortment in stores

Any quality product is always expensive. In addition, the choice of truly reliable and functional models not as wide as I would like. More often, models are offered for sale that do not require increased requirements for mechanical characteristics and functionality. These fairly common products are often:

- do not have sufficient strength, so they break easily;

- made of the cheapest steel, therefore they do not have the necessary hardness for cutting hard materials, do not hold an edge well and quickly become dull, which makes it impossible to perform the necessary functions;

- do not have high durability due to low-quality assembly, which cannot cost more than the materials used.

Commonly found knives like these are usually inexpensive. When they become unusable, they are simply thrown away and replaced with new ones. But this approach cannot be called rational, because it is not always possible to go to the store for a new purchase. The knife is often used by tourists and hunters far from civilization. It must not only cope brilliantly with the responsibilities assigned to it, but also be reliable enough not to let its owner down at a crucial moment.

To buy a high-quality blade at an affordable price, you need to carefully study the market and all the offers presented on it. It is imperative to have minimal technical knowledge about knife steels, their characteristics and mechanical properties finished blade. However, you can go the other way by applying this knowledge in practice yourself. This is what many people do when they decide to make a knife themselves.

Purpose and characteristics

The making of any knife is always preceded by a choice required type. Not only the characteristics of the future product, but also the conditions of its manufacture depend on the purpose and operating conditions.

The following types of knives are most often made independently:

There is often a misconception that confuses the purposes of hiking and hunting knife. Among newcomers to the field of tourism and hunting, there is an opinion that it is possible to make one universal blade that will cope with all the necessary tasks with equal success. However, this is not the case.

There is often a misconception that confuses the purposes of hiking and hunting knife. Among newcomers to the field of tourism and hunting, there is an opinion that it is possible to make one universal blade that will cope with all the necessary tasks with equal success. However, this is not the case.

Touring models are designed primarily for rough work. High hardness is also important for them, but fragility when working at fracture is strictly unacceptable. For hunting models, hardness always comes first, because their most important characteristic is the sharpness of the blade. Cutting prey with a camping knife is quite problematic due to the relatively soft blade, and a hunting blade can simply be broken if you try to use it instead of a camping one.

It is impossible to create a universal blade for all conditions. You always have to improve some qualities by reducing other characteristics. If you plan to solve a wide range of tasks, it makes sense to make several knives, each of which will perform its own function.

When the first stage is completed and the type of future knife is selected, preparatory work not finished yet. Before you start manufacturing, you still need to select the necessary materials. Most main element any knife - blade. The next stage begins with the selection of the steel necessary for its manufacture.

Steel selection

The type of knife dictates the operating conditions. According to these conditions, you need to choose the steel that will best meet the tasks assigned to the blade.

The most important characteristics of the blade that should be taken into account when choosing a steel grade are:

- hardness obtained as a result of heat treatment according to the required regime;

- impact strength, which is responsible for resistance to chipping and brittle fracture;

- corrosion resistance required for work in special conditions and in contact with liquids;

- wear resistance required under conditions of increased loads on the blade.

Bulat and Damascus have earned great popularity as materials for blades. But to obtain such blanks you need the knowledge and experience of a professional blacksmith. Even if you know how to use forging equipment They are quite difficult to produce. Not every experienced blacksmith is capable of this. You can buy a ready-made product, but it will be quite expensive.

More often, more affordable alloy steels are used, which are much easier to work with. In our country, the following grades of steel are most often used for the production of knives:

Other brands are used less frequently because they are less common or do not have the necessary characteristics.

The process of making a knife yourself contains a large number of stages. Each of them deserves detailed description, including all the nuances and advice of experienced craftsmen. Simplified, all actions can be divided into the following operations:

If you have experience working with metal, it is not so difficult to make knives with your own hands at home. Videos on this topic filmed experienced craftsmen, will always help you understand the intricacies of all stages of production. With each new blade you make yourself, the level of skill will increase, which will allow you to create beautiful samples with high technological properties and decorative characteristics.

A knife is an ancient tool with which a person protected himself from dangers and performed household work. Even in our age of high technology, this tool is not forgotten, but is used both in everyday chores and in professional activity. But there are situations when, in order to defeat the elements and enemies, you simply need to have a universal, improved weapon with you - a survival knife.

Lots of functions under the handle

With the release of Sylvester Stallone's film about the adventures of the Vietnam War hero named Rimbaud, Russian viewers learned not only about the tactical techniques of the American army, but also about the features of their weapons. Rimbaud manages to defeat the enemy in the jungle not only thanks to his ingenuity, but also to his universal survival knife - the multitool.

Device and intended use

This name comes from the English “multitool” - a multifunctional tool with a wide range of applications. At first, it was part of the basic set of weapons for US pilots and was a combination of an impressive blade with a massive handle with an insert saw. Later it was equipped with additional devices, and after the release of “Rambo” on the screens, all adventure lovers wanted to have such a weapon.

Now it is produced not only for the American army, but also for the military of most countries, because the unique ability to hold important diverse objects and supplies inside the cavity of the handle makes it indispensable for those caught in harsh and hazardous conditions soldier, traveler, scientist, meteorologist, polar explorer.

It will also be useful for those who like to go into the forest to pick mushrooms and berries, as there is a possibility of getting lost or stumbling upon a wild animal. Thus, a weapon for survival in extreme conditions will be useful not only during combat operations, but also on hiking trips and trips to the edges wildlife, because with its help you can:

- hunt and fish;

- light a fire and cook food;

- build a shelter from bad weather and predators;

- build a strong home;

- make additional equipment for hunting and fishing, sewing and repairs;

- protect yourself from attacks by animals and intruders;

- sew and patch clothes and shoes;

- cut branches and chop wood for the fire;

- control your location using compass directions;

- provide first medical care when injured.

All components of such a device must be of exceptional quality in order to withstand the most difficult weather. Leading engineers around the world have worked for decades to develop and analyze the strength of structural elements.

Unique content

High-strength steel and a comfortable blade shape are always combined with a wide, hollow handle, inside of which there is a whole arsenal necessary funds. This is the so-called emergency emergency reserve (EAS).

Survival knives are usually large, although some models adjust the size with a folding design. Blades smaller than 9 cm and larger than 15 cm are inconvenient to use, so it is better to choose a length in this range. The contents also vary depending on the model and type of production, but if you take the classic NAZ set, it includes the following components:

The presence of a compass in the kit greatly simplifies the survivalist’s task of determining the location, however, there is one difficulty - the blade and handle in this case must be made of non-magnetic metal, otherwise the arrow will not show the correct direction. But such materials are no different great strength, so it is better to carry the compass as a separate item in your backpack.

Purpose Determines Shape

According to experts, the best knife for survival in extreme conditions has a fixed, sharpened blade, the spine of which is wide and massive enough both to replace a hammer when hammering nails and chopping nuts, and to deliver blunt blows to an enemy for the purpose of neutralization.

The folding counterpart is more compact, but it is convenient for storage in a backpack and is suitable for a tourist, not a warrior. This does not make it useless, since the handle is quite roomy for many useful things, and the design itself is suitable for performing 20-30 basic actions. There are also disadvantages:

- high probability of breakdown of the folding mechanism due to a fall, accident, or prolonged contact with water;

- inconvenience of use in situations requiring a quick reaction - during an attack or accident, when you need to instantly strike or cut bonds;

- relatively small sizes, narrow and thin blade;

- small butt width.

Thus, a folding instrument is more suitable for a military doctor, traveler and tourist than for a trained special forces soldier. The suitable blade length for this model is from 10 to 15 mm, and the width is 5 mm. Special attention You need to pay attention to the blade material - chromium and vanadium are preferable to the more common carbon steel version, which is susceptible to corrosion in high humidity.

Thus, a folding instrument is more suitable for a military doctor, traveler and tourist than for a trained special forces soldier. The suitable blade length for this model is from 10 to 15 mm, and the width is 5 mm. Special attention You need to pay attention to the blade material - chromium and vanadium are preferable to the more common carbon steel version, which is susceptible to corrosion in high humidity.

The type of blade edge is also important, which is presented in two variations:

- Straight and sharpened;

- Serrated like a saw (serrated).

The second type seems more useful, because with the help of such a handy saw you can cut down a tree, cut thick bone and dense material, even a metal chain, if you try. But a serrated blade will become dull faster than a smooth one, and it is unlikely to be sharpened to the required sharpness far from civilization.

Therefore, they choose it for short-term trips or accept the fact that with frequent use such a knife will simply become a NAZ storage unit and a baton, in best case scenario. The smooth blade can be easily sharpened with a piece of sandpaper available in the NAZ.

Weapons, domestic and foreign

It is difficult to choose the ideal product that meets all the needs and wishes of users. Each model has advantages and disadvantages, so you need to carefully study the design visually and documented, because the quality certificate indicates many parameters that cannot be determined by eye.

Multitools and survival knives Russian production are in no way inferior to their American counterparts, although foreign models are still attractive to fans of adventure films. The main difference between a multitool and an army knife is the multitool additional tools, in addition to the compact blade. It's more of a portable craft workshop than a weapon.

Multitools and survival knives Russian production are in no way inferior to their American counterparts, although foreign models are still attractive to fans of adventure films. The main difference between a multitool and an army knife is the multitool additional tools, in addition to the compact blade. It's more of a portable craft workshop than a weapon.

The leader is the Spanish utility knife “Jungle’s king”, the blade of which is presented in three different versions and the buyer can choose the model that suits his needs. The weapon became legendary, becoming famous in the hands of war heroes and famous travelers Worldwide. It is also the most functional, containing both a compass, and an impressive set of NAZ:

The handle of all models is wound with high-strength twine that can withstand a weight of 50 kg. The blade has a length of 12 to 15 cm and is made of an alloy of steel with chromium, molybdenum and vanadium, which makes it invulnerable to corrosion and mechanical damage.

Second place can be safely awarded to a Russian product - the NV-101 universal knife, codenamed “Basurmanin”. It is slightly smaller in size than the winner of the rating, but no less functional, his set includes:

The handle is made of steel and is divided into two compartments: one contains string and a compass, and the other contains a saw and stiletto. The blade is 16 cm long and 3.5 cm thick, made of high strength blued steel.

Among tourist models, the first place was unanimously given to Ganzo g8012. This knife is not only convenient, but also beautiful (and, with practical point vision) - it is made in black with fluorescent colored edging, which makes it easy to find it in a backpack even at night. The handle is wrapped in polymer material, which prevents it from slipping out of your hands, and inside are:

- sling cutter and flint;

- fishing gear;

- medicines;

- threads and needles;

- saw and tweezers.

The “heel” for ignition is located on the butt, which is wide enough to be used as a hammer. All this makes the knife of this model an ideal choice for lovers of mountain hiking and forest camping.

A variant called “Alligator” is also very popular among survivalists. In terms of its components, it differs little from the knives listed above; it has everything you need. The only thing you need to pay attention to is the quality of the saw. There have been many complaints from customers about difficulties in sawing large objects.

A variant called “Alligator” is also very popular among survivalists. In terms of its components, it differs little from the knives listed above; it has everything you need. The only thing you need to pay attention to is the quality of the saw. There have been many complaints from customers about difficulties in sawing large objects.

Even a thick tree branch had to be cut down for a long time. The scabbard also rattled noticeably while moving. If for a tourist this is not a very significant drawback, then for a military man who needs to move silently, this is an important nuance. The manufacturer has improved the equipment of this model, but, nevertheless, it is better to check these two factors when purchasing.

One of the universal items that a person may need in extreme conditions is a survival knife. Typically, it performs several important functions. Often such a knife comes in a set of emergency emergency supplies or NAZ. It is difficult to use it in everyday life, since it is not designed to perform such tasks. But such a tool becomes a good helper if a person finds himself in a forest or other place far from civilization.

Originally, survival knives were called army knives. They were created back in the 60s specifically for military pilots who served in Vietnam. These tools were distinguished by a rather weighty handle and saw. The last element was located on the end part. The saw allowed pilots to do without other weapons while in the impassable jungle.

Survival knives became most popular in America after the release of the legendary film “Rambo”. Has been developed for a long time modern design cold steel that meets all stated requirements. These models are still in great demand today.

Advantages and features of such knives

Survival knives are very convenient for extreme tourists

Survival knives are very convenient for extreme tourists Knives of this type have certain advantages over other bladed weapons that may be at a person’s disposal. This is a universal tool that can make the life of its owner much easier if he finds himself in difficult conditions.

The main feature of survival knives is that they can perform several important tasks at once.

Survival knives can be used during the following activities:

- Repair or full construction of a temporary shelter. The knife is used when cutting branches, digging holes and processing the turf required for a hut.

- Extraction and preparation of food. The tool allows you to increase the chances of a successful hunt and helps to properly cut up the animal carcass.

- Self-defense. In this case, it is used as a military weapon.

- Making weapons or tools using wood, metal, or bones.

- Making a fire.

- Creation and repair of clothing. In this case, the knife is used when cutting skins or any fabric. Additionally, a needle is used, which is in the NAZ set.

A survival knife can also help you navigate the terrain, as it often has a built-in compass.

What is included in the NAZ (emergency reserve)

A compass is indispensable for finding your way around unfamiliar terrain.

A compass is indispensable for finding your way around unfamiliar terrain. Standard knives that are used for survival and have NAZ are quite large in size. They can be recognized by their wide blade and massive handle. The handle is usually hollow. It is in it that the traditional set of emergency reserves is located. It consists of the following items:

- Several matches that are pre-lubricated with wax. The complex includes a grater for ignition. These components must be packaged in moisture-proof packaging.

- Lens designed for use in sunny weather.

- Compass. This is not the most convenient item that comes with the NAZ. But it always makes sense when a person is in a forest area.

- A fishing line measuring about 3-5 m, several hooks, and a sinker.

- Sewing needle with regular thread and surgical needle with nylon thread.

- Scalpel.

- Safety pin.

- Small tweezers and adhesive tape. These items will help provide first aid to a person in case of injury.

The kit should also contain a small mirror, a water purification tablet, a small whistle and potassium permanganate. It is supplemented with a piece of sandpaper, which helps to sharpen the knife in the field.

How to choose a knife

Every person who periodically goes hiking knows that you definitely need to take a knife with you. This is the most important item in your travel gear. That is why its choice must be approached with special care.

When choosing a good survival knife, you must pay attention to its convenience, functionality, reliability and other factors of suitability for use in the field.

First of all, it is advisable to decide on the tool system. Folding knives are considered more convenient to carry as they are small and take up minimal space. However, most often preference is given to non-folding weapons for survival, since they allow you to perform many times more tasks.

Blade shape

The blade shape of such knives can have different modifications.

The blade shape of such knives can have different modifications. Squeezing knives differ from each other in the shape of the blade. An entire classification of weapons is distinguished by this feature. The most popular instruments are the following:

- spear-shaped;

- straight shape with a butt;

- with a concave blade;

- butt with a descending or rising line;

- American tanto.

More convenient are knives that have a spear-shaped shape. They are usually called universal. Most often, such weapons are chosen by people who are keen on hunting.

Shank

The best survival knives always have a strong tang. It happens different sizes and forms.

The tang is an integral part of the blade that remains hidden in the handle of the weapon.

Highlight different types shanks of knives. They are presented in the table.

| Type | general characteristics |

| "Mouse Tail" | This type of shank is made of a metal rod. It runs in a thin layer along the entire handle. In this case, the rod is a continuation of the blade. This shank has one significant drawback. Since it is too thin, it can easily break due to high load. Therefore, knives with it are not intended for use in the field. |

| Not completely hidden shank | The shank does not go through the entire handle, as in the previous version. It is located only in a separate part of it. The void zone is used for completely different purposes. This is where survival kits are hidden. Since the shank does not go through the entire part of the handle, it can also easily break under the pressure of increased load. This point must be taken into account by the person who is collecting the basic equipment for a hike. |

| Full shank | This shank goes through the entire handle. It is considered the largest in size. This feature ensures high strength and resistance of the tool to increased loads. Knives with such shanks are considered the most practical and useful in the field. |

It is imperative to pay attention to the type of shank of a survival knife, since its strength and effectiveness in performing the assigned tasks depends on this.

Material

The handle of a survival knife can be: wooden, plastic, rubber or other material and composition

The handle of a survival knife can be: wooden, plastic, rubber or other material and composition The best knives are made of steel. It should not be too hard, but not soft either. In this regard, you need to maintain a golden mean. This material is considered the most practical to use.

The most advantageous option is considered to be a knife made of steel of medium hardness 58-50 HCR. It meets the basic requirements for the selection of material from which survival tools should be made.

Blades of medium hardness can be easily correct sharpening. And it is often necessary if the owner has to regularly use his knife for its intended purpose.

It is also worth considering the materials that are used in the manufacturing process of the knife handle. It can be made of plastic, horn, bone, wood or high-tech raw materials. The latter are considered more durable and practical, as they are produced according to modern standards. When choosing a handle, you need to pay attention not only to the type of material, but also to its comfortable location in the hand.

Additional options

Most of the models included in the rating best knives for survival, have additional options. For user convenience, they are equipped with a flint and a sharpener. Maybe the set comes with a lighter. Typically, these and other items are part of the NAZ set. The Russian version of these tools also provides a number of similar additions that preppers need.

Rating of the best knives

A man might be interested in the top survival knives. It presents interesting models, which have already earned the trust of hunters and lovers of extreme hikes.

Jungle King

For those who like to travel, the knife will be indispensable, as it has a built-in compass.

For those who like to travel, the knife will be indispensable, as it has a built-in compass. This model is produced by the Aitor brand. The blade of the tool is made of a practical alloy based on chromium and molybdenum. Its hardness is 59 units. The length of the blade is limited to 13.5 cm. There is a NAZ in the handle of the knife. It also contains a compass, which will help the traveler not to get lost on the way.

There is a twine on the sheath. The owner of the knife can use it at his own discretion.

NV-1-01

A variant of a domestic knife, which has certain similarities with the Jungle King II model. The length of the tool blade is 16 cm. 8HF grade steel is used in production. The knife handle is also steel. Inside it are placed the items that are included in the NAZ kit.

The knife is equipped with a built-in compass. Its sheath is divided into equal cavities. The first contains a saw and a skinner knife, and the second has a cord wound around it.

Ganzo g8012

The Ganzo knife is very sharp and has proven itself well on tourist trips

The Ganzo knife is very sharp and has proven itself well on tourist trips This model completes the top of the best survival knives. She was recognized as the best in 2017. The tool fits well in the hand and does not cause any inconvenience. The handle of the product is painted bright color, making it quite difficult to lose it in snow, grass or foliage.

This knife comes complete with a flint, which is located in the heel area of the butt. The sheath contains a sling cutter designed for quickly cutting leather, fabrics and branches.

Is it possible to make a survival knife with your own hands?

If a person is familiar with sharpening blades and working with metal, he can try making a survival knife with his own hands. If desired, it can be equipped with a flint and sharpener.

- Blank for the handle and blade of the product.

- Metal for rivets.

- Sandpaper.

- A hacksaw that works on metal.

- Grinder or file.

Once all the tools and materials are prepared, you can begin to work directly on the knife. To prepare the blade, it is permissible to use a file or car springs. On the workpiece you need to draw the blade of the future product. You need to make a couple of holes around the perimeter. Before you start working on the handle, you should drill holes in a suitable area for the rivets. Now you can begin to give the blanks the correct shape.

After making a knife blade, it must be hardened

After making a knife blade, it must be hardened It is mandatory to mark on the workpiece cutting edge. Afterwards it should be ground down until the desired sharpness is achieved. For these purposes, it is advisable to use a file.

The workpiece must be secured with a vice when working with a file. This measure will help avoid injury. In addition, it is much easier to work with workpieces that are in a fixed position.

Upon completion of this work, the cutting part should be treated with sandpaper. Also, the metal itself must be hardened. This procedure ensures its strength and reliability. To harden the metal, you need to hold it on hot coals for 15 minutes.

After completing this stage, you need to cool the knife with oil. Next, the future knife is placed in the oven for 40 minutes. At the same time, it should maintain a temperature of about 300-400 degrees. You need to bake the metal in the oven twice.

After the blade has been fully baked and cooled, it must be thoroughly polished. Next is the bluing procedure. With its help, you can protect your survival tool from rust.

Now the craftsman can begin turning the handle for the knife. Next, the two main elements need to be securely fastened to each other.

If during all the work the master strictly adhered to the manufacturing technology, then at the end of his work he will receive quality knife. A homemade product will serve him for a long time and help him cope with problematic situations.

The Fortis team is scientists, writers, clairvoyants, ufologists, who have gathered together with one goal: to unravel the secrets of the Russian land.

Strong not only in spirit and physically, but also in knowledge, many areas of which today are only opening up to the thinking part of humanity.... Read more...

DIY survival knife

As already mentioned, now buying a survival knife does not cause big problems, if not for one “but”: good knife can hit your pocket hard, and a bad one can let you down at the most inopportune moment. As a rule, inexpensive knives are made in the Middle Kingdom, and we all know the quality of their metal well. If you still want to have a good survival knife for practically nothing, then the only way out is to make a knife with your own hands from available materials. And we will help you with this. It is worth noting that professional knife makers use special devices and tools for their masterpieces, but we will limit ourselves to the minimum set of tools that can be found in any garage. For work we will need:

Electric sharpener and/or angle grinder (grinder); |

|

Grinder and/or drill attachment; |

|

|

|

|

|

|

|

Set of needle files; |

|

Sandpaper of different grain sizes; |

|

|

|

|

|

|

|

|

The most important thing in a knife, as everyone knows, is the blade. The steel for a survival knife blade should be hard enough to hold an edge well, but not brittle, and can be sharpened in the field. The best option will be an alloy tool steel having a hardness after hardening of 57-60 Rockwell units (HRC). A suitable workpiece can be purchased from a tool store or construction market.

For this master class on making a survival knife, we purchased a tool of suitable size from steel, grade 95X18, 5 mm thick, from the construction market. Since the workpiece was partially hardened, it was released by heating it with a gas burner on a brick to about 500 degrees and leaving it to cool on it. After tempering, the metal becomes ductile and easier to process.

After purchasing the blank, you need to draw a sketch of the future knife. To do this, you can use a graphic editor, but you can simply outline the workpiece with a pencil or make markings directly on the blade. We will use a mounted mounting and a combined stacked handle, so, for reliability, we leave the shank about 3/4 of the handle long. The shape, thickness and size of the blade and bolster in our case are determined by the existing sheath, so for your survival knife you can choose the shape based on your imagination, limiting it only to the strength characteristics of the selected workpiece and its dimensions.

After the workpiece is marked, we shape the blade on sandpaper, form slopes and cut out the shank. After sharpening, the blade must be sanded with sandpaper. To do this, we secure it to the shank with a clamp on a wooden block and sand it with sandpaper, strictly in one direction, moving from coarse to fine, periodically wetting it with water. To grind this blade, 3M sandpaper was used with grains of 120, 240, 400, 800, 1200, 1500, 2000 and 2500 sequentially. In principle, at this stage it is not necessary to grind the blade with an abrasive finer than 1200.

Now you can move on to hardening. The necessary heat treatment modes for each specific grade of steel can be found in the table or in reference books. The steel, 9X18, used on our blade, according to the table, is hardened at a temperature of 1050 degrees, followed by cooling in oil. Accordingly, to independently harden a blade you need oil and a source high temperature. You can use any mineral oil that you don't mind. In this case, it was a TNK transmission. A kind of forge was used for heating.

It should be noted important nuances that must be taken into account when heating the blade:

- It is necessary to ensure uniform heating. To do this, it is best to place the blade on the butt and rake up the coals on both sides.

- Apply air from the side, and under no circumstances onto the blade.

- The heating temperature of the blade can be determined visually using this table, but for better hardening it is necessary to use a pyrometer.

After heating to the required temperature, remove the blade from the forge using any suitable tool and quickly lower it into the oil.

After the blade has cooled completely, take it out, wipe it and, after letting it rest for several hours, move on to the next important stage - tempering. After hardening, the blade acquires the necessary hardness, but becomes brittle, and if tempering is not carried out, the cutting edge may begin to chip. The tempering mode, as well as the hardening mode, is determined from tables and reference books for each steel grade. Our 9X18 requires a tempering at a temperature of 150 degrees: that is, it is enough to keep the blade in a preheated oven for the required time, and then let it cool slowly. The heating temperature can be determined by the color of the tarnish, in accordance with this table.

After heat treatment, we grind the blade clean and form the cutting edge. In addition, you can decorate the blade by etching, or apply a pattern galvanically. Read about how to do this at. Our blade was pickled in vinegar.

When the blade is completely ready, wrap it masking tape, so as not to cut your hands or scratch them, and move on to installing the handle.

Before making the handle of a survival knife, you need to decide on the shape and material. The knife we are assembling is intended for a girl, so we make the handle not thick and as beautiful as possible, based on the available materials. We used:

Copper plates of different thicknesses for making bolsters, back plates and spacers; |

|

Roe deer horn; |

|

Multi-colored fiber for gaskets (can be replaced with thick craft paper); |

|

Wood for the handle. For the handles of our survival knives, we choose birch burl or suvel. This material is very beautiful, durable, and has wonderful energy. |

In addition you will need:

So, the material has been selected, the blade is ready - let's start manufacturing.

The first thing you need is a bolster. For it we use a thick copper plate. At the request of the future owner of this survival knife, the bolster and butt plate are finished with mokume (how to do this is described in), here we will tell you how to make a bolster from a simple copper plate. It is not difficult. We draw the proposed bolster on cardboard, cut it out, try it on, trim it, repeat until we like it. Then we transfer the resulting shape onto a copper plate and cut it out with a grinder or cut it out with a chisel, and grind it using sandpaper. Now you need to make a mounting hole. To do this, mark it according to the template and drill several holes:

After this, we cut down the partitions with a chisel and level the shape and size with needle files. We polish. Polishing. Bolster is ready.

Now we will make a spacer from horn. Sawing off a piece of horn the right size, mark and form the mounting hole - drill and remove the excess with a file:

We collect everything on the blade:

And we give it an approximate shape using sandpaper or a grinder, leaving about 0.5 mm for final processing.

In the same way as a bolster, we make a copper spacer, only we don’t grind the surfaces, but roughen them with coarse sandpaper or some other tool so that the surface is rough and sticks together better. We cut all the necessary spacers from fiber or paper. We form a landing hole in the burl block. There are many ways to do this, but the simplest is to drill several parallel holes and remove the jumpers with the same drill. The main thing is to constantly check the fit so that eventually the shank fits completely into it, but tightly enough and without play. We cover all surfaces ready for finishing with masking tape so as not to smear the glue or scratch it.

We pour glue into the seating hole in the mouth guard, place it on the shank, removing any leaking glue, remove it, lubricate the shank with more glue, add a little into the hole, and push it on completely, without squeezing it too hard. Let the entire structure sit for 10 - 15 minutes so that the glue is absorbed into the wood and paper, and compress it with a clamp for a couple of days. Usually the glue completely hardens after 24 hours, but it is better to keep everything under pressure for some more time.

When the shape of the handle is drawn, we make the butt. We cut it out of a copper plate according to the template. We solder the pins from thick copper wire. It is best to solder with refractory PSR solder or copper-phosphorus solder. Drill holes in the handle.

Cut it out required quantity spacers and put everything together. Don't forget to wrap the handle with masking tape.

Now we glue everything together with epoxy and clamp it in a clamp for a day. When the resin has hardened, we grind the back plate, without overheating, using a grinder, or better the old fashioned way - without a machine - with a file, and obtain the final shape.

Let's start the final processing. Use sandpaper P180 - P240 to remove large scratches and irregularities. With a finer one, we smooth the surface and reach a grain size of P600. After processing it, we cover the wooden part of the handle with water-based “Mahogany” stain, using a brush or swab, and let it dry for several hours.

When dry, sand it with P1000 sandpaper and cover it with stain again. We repeat this with sandpaper R1500 - R 2000 - R2500. After treatment with P2500, we do not cover it with stain. The surface becomes even and smooth. We polish the metal parts of the handle with GOI paste, trying not to stain the wood and horn.

Now you need to soak the handle with linseed oil in order to reveal the texture of the wood and protect it from moisture. This can be done by immersing the handle in a container with oil for a fairly long time, or using a brush, periodically lubricating it, soaking it, and placing it on polyethylene. It is necessary to soak until the oil stops being absorbed. After soaking, leave the knife for several days until the oil dries.

After the oil has completely dried, rub the handle thickly with beeswax...

This way we get a high-quality and beautiful survival knife with minimal material costs. In addition, you can always be confident in a survival knife made by yourself, since you set all its properties yourself - during the manufacturing process and selection of materials.

|

The last step in the process of making a survival knife with your own hands is sharpening. Let’s make a reservation right away: sharpen a knife yourself without special devices It’s possible, but it’s better not to hope for special quality. If you don’t have tools for sharpening and a set of bars with different grain sizes at hand, you can do this using the same sandpaper. Tear off a strip of approximately 40x150 mm, place it on a wooden block and sharpen it. For relatively high-quality sharpening, it is advisable to use sandpaper P240 - P400 - P600 - P1200 - P200 - P2500.