Believe me a private house can be arranged with so much high level comfort that living in it will be much more convenient than in a city apartment. In any case, the water supply can be used with no less convenience. In the same way, to get water you will only need to open the tap, which is not yet very compatible with suburban infrastructure, do you agree?

But this is not a “rosy” dream at all. To implement the idea, it is enough to include a pumping station in the water supply scheme. She will do a colossal amount of difficult work for her owners. physical work. True, to properly connect and operate it, you need to know the equipment design well.

We offer you valuable information about the specifics of using this technology. Our article will help you understand the operating principle of the pumping station and introduce you to the installation rules. The information we have provided has been expanded to the fullest extent possible. clear diagrams, photo collections and video tutorials.

Pumping station allows you to increase the efficiency of the water supply system, the safety of equipment and pipelines. The operating principle of the pumping station and its comprehensive equipment provide protection from external factors and the possibility of uninterrupted water supply even during a power outage. With constant use, permanent or long-term residence in a private home, such a station significantly increases the level of comfort.

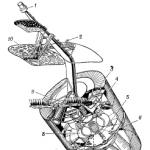

In order to understand how a pumping station for a summer house or private home works, you should take a closer look at its structure and main functional elements. Let's consider their sequence in the direction of water movement.

- The water intake, located in, is equipped with a filter mesh that prevents relatively large particles of impurities from entering the system. Located here check valve to prevent reverse flow of water when the pressure decreases or the pump stops working.

- The suction line is the section of pipeline from the water intake to the pump.

- Job centrifugal pump creates a vacuum in the pipeline supplying liquid from the source, which contributes to its intensive rise, and excess pressure in the line leading to the points of water consumption, to ensure the flow of water through communications. To optimize system performance the pump is equipped with a pressure gauge and pressure switch, the settings of which ensure that the pumping unit is turned on and off when critical values are reached.

- The principle of operation of a pumping station for a dacha would be incomprehensible without clarification - they are set taking into account the characteristics of the pump, volume and required pressure in the hydraulic accumulator and other parameters.

- The systems are equipped with reservoirs from which water is supplied to the pipeline.

Thus, the principle of operation of a pumping station for a home in stages is as follows:

- When the pump is turned on, water rises from the source, fills the system and the hydraulic accumulator until a certain pressure value or level is reached. After this, the pump is turned off.

- When water is consumed (opening a tap, using a shower or water-consuming equipment), the pressure or level in the system decreases, which facilitates the supply of liquid from the accumulator/storage tank chamber. In this way, water flow from the storage tank is carried out until a critical pressure/level value is reached. After this, the pump is turned on again and the cycle repeats.

Advantages of pumping stations

The installation of a pumping station for the home allows you to provide a number of advantages when used:

- possibility of supplying water in the absence of electricity supply,

- stability of pressure in the system,

- compactness and low weight of complex equipment,

- possibility to choose the installation location,

- economical operation by extending the service life of water supply system elements and reducing energy costs due to timely switching on and off of the pumping unit,

- equipment durability.

Selecting a drive

Pressure water storage tanks(conventional containers located at a height, which makes it possible to supply water to the system by gravity) are increasingly being replaced with more modern and efficient ones hydraulic accumulators.

The operating principle of the water supply pumping station remains the same in both cases. At the same time, the undoubted advantages of hydraulic accumulators are the ability to be placed next to the pump (without lifting to a height) and the presence of a chamber with compressed air, which makes it possible to adjust the value overpressure and, accordingly, the mode of water supply to the pipeline. Besides, The hydraulic accumulator better ensures the presence and stability of pressure.

Typical hydraulic accumulators for pumping stations in the budget and mid-price categories may have a small volume. If the tank capacity minus the volume compressed air will be 25-40 liters, the hydraulic accumulator will be able to work for the system, but it can no longer be regarded as an opportunity to provide a large supply of water in case of an emergency shutdown of the system. In most cases, the design of the pumping station allows the connection of an additional hydraulic accumulator without disruption. If the power in your home is frequently cut off, you should find out in advance whether such a possibility exists.

Nevertheless, pressure tank also has a certain advantage. Its presence allows you to choose a less powerful (and therefore cheaper) pump. Downside This advantage is the low productivity of low-power pumping units, which means that it will fill the tank slowly, that is, the tank must have a large volume.

Pump equipment

Modern manufacturers offer separately submersible pumps or pumping stations With surface pumps . It is believed that the first option is optimal for wells of almost all types, and the second is suitable for wells and Abyssinian springs (due to the minimum width of their casing pipes and the shallow location of the water surface).

- Indeed, submersible models have the ability to lift water even from very great depths (for example, the height of the casing pipe of artesian wells reaches 100 meters or more).

- At the same time, surface pumping units are easy to maintain, easy to inspect and periodically inspect. However, in the classical modification, such models are capable of lifting liquid from a maximum depth of 8-9 meters.

The main dilemma is the combination of a high lifting height with low productivity and rather modest pressure characteristics for submersible models, and good productivity and pressure combined with the possibility of use only for shallow sources for surface units.

A compromise could be ejector models. The ejector ensures the formation of a rarefied zone in the pipeline due to the pressure difference. The latter arises as follows: in a simplified form, the ejector is a cone-shaped device, moving through which the liquid increases speed as the lumen narrows. In the zone high speed flow, a vacuum is formed, which through an additional hole or pipe captures liquid from the external environment.

Important: When choosing a model, it should be taken into account that the ejector of the pumping station can be remote or built-in.

Equipped external ejector, which is directly lowered into the water source, the pump is capable of lifting water from a greater depth (depending on the power of the pumping unit and the design of the ejector - up to 25-40 meters). Remote ejectors are more efficient and usually differ in design, representing two parallel pipes (one of them can be replaced with a flexible hose) - a vacuum-discharge and a main one. But they are also sensitive to sand in the water and other contaminants.

To the disadvantages ejector stations with built-in device often referred to increased level noise during operation, but it can only become a noticeable nuisance if the pumping station is located in an open space and close to the windows of the house. When installed in a special building (which is often necessary to protect equipment from freezing in winter), thermal insulation also serves as a sound absorber. Soundproofing a room when installing equipment in the basement is also not difficult and will not require excessive costs. It should be noted that the lifting height does not increase when using equipment with a built-in ejector, but productivity increases.

We talked about this in more detail in a separate article.

If during its operation the need for repairs arises, then you will find it useful, which examines standard faults and gives recommendations on how to fix them yourself.

Information about self-cleaning well you will find on this page. Technologies and necessary equipment for works.

Automatic control systems

Availability automatic systems control significantly increases the cost of the pumping station, so the feasibility of such equipment is determined individually. Experts recommend installing control sensors and automatic regulators when constantly using the water supply system.

Automation can provide protection against various factors, for example, from the so-called “dry running”, when when the liquid level decreases, the pump takes in air, the pumping station operates jerkily, and the pumping unit overheats. In addition, protection from:

- increase in temperature (overheating) of the pump,

- voltage drops in the supply network, etc.

In the video you can see how the pumping station is constructed and a description of its operation.

An automatic pumping station for a summer residence is especially relevant. It allows you to provide water for irrigation and household needs, as well as deletion Wastewater even if there is large number people and a rather large area of the site.

The intensive pace of development of new sites is accompanied by the construction of not only residential multi-storey buildings, but also cottage villages, individual houses For permanent residence, the creation of holiday villages with houses.

In many areas of such construction, especially in cottage and dacha settlements, there are no centralized heat and water supply lines. In this regard, an automatic pumping station becomes the main equipment without which it is impossible to do in such conditions.

Helpful information:

Types of stations

Station automatic water supply performs key function, thanks to her it is created optimal pressure water, which can be used for various purposes.

Exist different kinds water supply stations. Devices can be classified according to their installation location into underground, buried and above-ground. In addition, pumping equipment can be used in the CAB various types, which allows us to divide them into:

- Vertical;

- Horizontal;

- Centrifugal;

- Axial.

Main features of automatic water supply stations

The device includes a hydraulic accumulator, a pump and a control system. Automatic water supply stations are compact, so their installation requires a minimum of space. With their help, you can create and maintain in the system required pressure water.

Their body can be made of cast iron or of stainless steel, which makes the device suitable for use in the most unfavorable conditions. It works almost silently.

Pumping equipment design

The presence of a centralized water supply system does not mean the possibility of regular provision of water at any time and in sufficient volume. This is especially typical for large holiday villages during the dry season or during the hours of maximum water consumption for irrigation.

This station is a type hydraulic device, which is designed to increase and maintain pressure in the existing water supply network or transport it in the absence of a centralized system.

There are quite a lot of models, they differ in some design features and configuration. However, the main components of the equipment and their design are not fundamentally different.

Thus, an automatic water supply pumping station consists of the following main components:

- Electric motor.

- A pump for collecting and pumping water, or a water pump.

- Automated control systems.

- Membrane tank.

- Mounting fittings.

In order to manufacture components and parts, high-strength materials that are resistant to aggressive environmental influences are used. They are made of stainless steel, diffusers are made of reinforced polymers, O-rings and gaskets are made of ceramic materials and graphite.

The use of high-quality materials helps to significantly increase the operating life of the equipment. The use of automatic control systems makes it possible to ensure the pump operating cycle in accordance with the required volume of water flow. This allows for significant savings in electrical energy.

Many models of automatic pumping stations are equipped with an operation indication screen. It displays the necessary information about any malfunctions that have occurred or the reasons for stopping the pump. They may be a lack of water at the source of intake, a valve closed by mistake, air leaks, and others.

If the protection mechanism is triggered, the pump also automatically restarts at certain repeated time intervals. The devices have stop and soft start modes, which significantly reduces the reactive power of the motor.

Thanks to this, there is no possibility of a water hammer effect occurring in the pipeline with damage to the system. Some models of pumping stations are equipped with devices to protect the pump from possible overheating.

Using an electronic relay, which is equipped with a timer for turning on and off over periods of time, you can independently set the required operating mode. In other words, it is possible to limit the number of starts, thereby significantly increasing the life of the device.

The tank is divided into two sections by an elastic membrane. Air is pumped into one of them using a pump. As a result, a pressure is created in it that exceeds the planned water pressure in the system.

When the pump operates, water enters the second section under pressure and compresses the air in the first section. When the required pressure in the system is reached, the pump turns off, the membrane deforms in the opposite direction, as a result of which it decreases gradually. When the pressure drops to a critical level, the pump turns on again.

Water can be collected from a well, and for irrigation - from a nearby river, lake or pond. Sometimes it makes more sense to draw water from different sources for different needs.

For example, to water a plot, you can use water from a reservoir, and for drinking water, use water from a well. There is no need to additionally purchase devices for complex filtration, purification and disinfection. Therefore, you can install several automatic pumping stations of low power.

Main selection criteria

If you are planning to buy a water supply station, try to find out the most important selection criteria in advance. So, an important role is played by the pressure or the height to which the device can raise water. When determining the desired indicator, make a small reserve of power.

It is also important to consider the depth of suction. This is the distance from the pump axis to the water surface. You should also be interested in the performance of the device - the volume of water that it can supply per unit of time. Remember that system manufacturers indicate maximum capacity, which is calculated at zero suction depth.

If you are planning to live in a private house or in a comfortable country house, then you should undoubtedly be interested in the question autonomous system water supply Not in every way cottage village or the private sector, and even more so in the dacha society there is centralized system water supply Public utilities, presented by third-party companies, “bite” strongly.

Complete water supply system personal plot must include a pumping station, which can be assembled with your own hands, without the involvement of third-party craftsmen. Self-installation Such equipment will significantly save your family budget.

Why is a pumping station needed in a water supply system?

The autonomous source of water supply in the vast majority of household plots is a well. P , we will look at in our article. It can be of varying depths, depending on the level of the aquifer, but usually a shaft is drilled to a depth of at least 20 meters to avoid contaminated surface groundwater entering the water supply system.

Water is lifted from a well of this depth using a pump. But for a complete system autonomous water supply One pump and the pipelines connected to it are not enough. The pump cannot and should not work constantly, as its components and mechanisms will become unusable in a fairly short time. To ensure an uninterrupted supply of water to all water points in your home, it must have a pumping station - a set of equipment that allows you to use water around the clock and at any time of the year.

Composition of pumping station equipment

In order to raise water from a well you need pumping device. It may be different devices and placement, for example, surface (taking up water through an inlet pipe lowered into the well) or submersible (located directly in the well, at the level of water occurrence and pushing it to the surface), working using the centrifugal or vibration method. Almost all pumping devices for autonomous water supply are powered from the electrical network.

The next element of the pumping station is pressure accumulator or hydraulic accumulator. It ensures constant water pressure in water supply pipelines. Classic option The pressure accumulator is a steel tank divided into two parts by an elastic rubber partition. When working pumping device water fills part of the tank, stretching the membrane. When the pumping device is turned off, the membrane, trying to return to its original position, pushes water into the water supply. In addition to ensuring constant water pressure in the system, the pressure accumulator protects it from water hammer - a sudden change in pressure parameters in pipelines.

The moments of turning on or off the pumping device are determined automation unit - control relay, which is triggered depending on the pressure in the pipelines. When the pressure in the water supply pipeline system drops below a certain value, the unit turns on and water fills the pressure accumulator, tensioning the membrane. When the set pressure parameters are reached, the relay is activated and the pump is turned off.

All components of the pumping station are interconnected pipelines, with which the equipment is connected to input circuit home plumbing.

The most common configuration of a pumping station in a private home is a combination of a surface pumping device with a pressure accumulator and control equipment.

The price of ready-made pumping stations can vary within quite a wide range. By purchasing all the components separately and installing them yourself, you can save a lot of money.

How to install a pumping station yourself?

On initial stage it is necessary to correctly calculate all the parameters of the future water supply system. The starting point for this calculation will be three values.

- Well debit- the amount of water that a pumping device is capable of pumping out of it in a certain period of time.

- Water consumption parameters– the number of people permanently residing in the house, the number of appliances and equipment that consume water (for example, an automatic washing machine or dishwasher). Naturally, this parameter cannot in any way be greater than the first one, but there are situations when a well has an excess flow rate that is simply not needed for use in a particular house. When calculating water consumption parameters, do not forget to seasonal work, for example, summer watering of crops or engineering works, for example, washing your car regularly.

- In addition, when choosing equipment for a pumping station, such a characteristic as and house configuration. Purchased and installed equipment must have power and pressure sufficient to lift water from the lowest point of the well to the very high point water supply in the house.

Thus, having calculated all the parameters of water intake and water consumption, you purchase all the main components of the pumping station and begin their independent installation.

Prices for a pumping station

pumping station

Where should the pumping station be located?

In order for your pumping station to ensure constant delivery of water with specified pressure parameters to any point in the house, its location must meet the following requirements:

- be located sufficiently close to the source of water supply so that the pumping device can operate reliably at all times;

- have comfortable temperature conditions, so that work at negative temperatures did not damage equipment components;

- the place where the pumping station is located must be accessible for preventive maintenance and repair work.

The most suitable place for installing a pumping station in a private house, based on such requirements, is either a specially built caisson, or a special room or part of it in the basement of the house, or in outbuildings.

Let's consider all the pros and cons of installing pumping stations in various places.K , you can read in our article.

When the pumping station is located indoors inside a private house you get ideal access to the equipment, but if the noise insulation is poor, the operation of the equipment will cause you discomfort. But if the well is located directly under the house, then best option can not found. When choosing such a location, you should take into account that the room should be warm, or better yet, heated. Basically, separate room in the insulated basement of a private house is one of the ideal options.

An option for location in the house is to install a pumping station in a separately located outbuilding. In this case, you will not be able to quickly access the equipment, but you will be spared noise problems. When separating the production segment and the consumption segment, it is necessary to pay attention to Special attention for laying a water supply pipeline. It must be located below the freezing level of the soil, or sufficiently insulated to prevent freezing of water in the pipes in winter.

One of the traditional locations for a pumping station is a caisson - a special container located directly on a personal plot above the location of the well head. Caisson can be either a permanent structure made of monolithic concrete or brickwork, buried in the ground, and steel or plastic container, also buried in the ground with the lower part below the soil freezing level. However, this method of placement is fraught with difficult access to equipment. Also in this case, it is necessary to insulate or sufficiently deepen the water pipeline leading to the house or to other points of consumption.

How to install a pumping station yourself?

So, we have figured out the composition and location of the pumping station, now it’s time to start installing it.

Step 1

To ensure that the station does not experience unnecessary vibrations during operation, it must be secured to a solid base. One of the options for constructing such a base is a solid concrete slab. Can be picked up ready-made option, or you can fill the base for the pumping station yourself. The technology for pouring the foundation generally coincides with the algorithm for pouring slab foundations. A thickness of 10-15 centimeters will be quite enough for such a base.

A sand cushion is poured into the prepared shallow pit. Then a reinforcing frame is made of metal rods, which are tied together. On the sides, the area of the future base is limited by boards or chipboard scraps. After pouring, the concrete will mature for several weeks.

Also, the base for the pumping station can be laid out of bricks. Two layers placed on a compacted sand bed will be sufficient.

The pumping station can also be placed on a solid wooden shield, knocked together from beams, but in this case it is necessary to provide for the placement of shock-absorbing rubber pads. The thickness of the bars must be at least 10 centimeters. The base of the pumping station should extend approximately 10 centimeters beyond the perimeter of the equipment.

Step 2

We place the pumping station equipment on the prepared site. When installing a station from ready-made units, you should not have any special problems. It is worth paying attention to the cross-section of the pipelines connecting the elements of the pumping station and their correct fastening.

Simply place the pumping device, pressure accumulator and control unit on the prepared site and connect them with pipelines. If you are using concrete base, especially if the pumping station is located in a residential building, be sure to place and secure rubber gaskets under the equipment supports. In addition to reducing noise from devices, such gaskets will protect your equipment from excessive wear.

Step 3

We connect the pumping station to the well head and the input circuit of the home water supply. At the connection between the pumping station and the water intake well, it is necessary to provide for the placement of a check valve and a shut-off valve. In addition, a check valve is also installed at the outlet of the pumping station complex (on the inlet water supply pipeline).

Important! Do not forget that “water will find its way everywhere,” so insulate especially carefully the connecting sections of pipelines and equipment components.

Step 4

We are conducting a test run of the equipment. We fill all the equipment with water; to do this, using the filler neck, we run water into the pumping device, the pressure accumulator and into all the lines. We open all shut-off valves and start the electric motor of the pumping device.

The pumping station operates as follows:: the impeller of the pumping device pumps water into the system until the pressure parameters set by the automation are reached. Typically, the pressure in the water supply system is 1.5 - 3 atmospheres. The indicator at which the pump stops can be adjusted using an automation unit.

Video - DIY pumping station